oil filter TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1024 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–77

EM

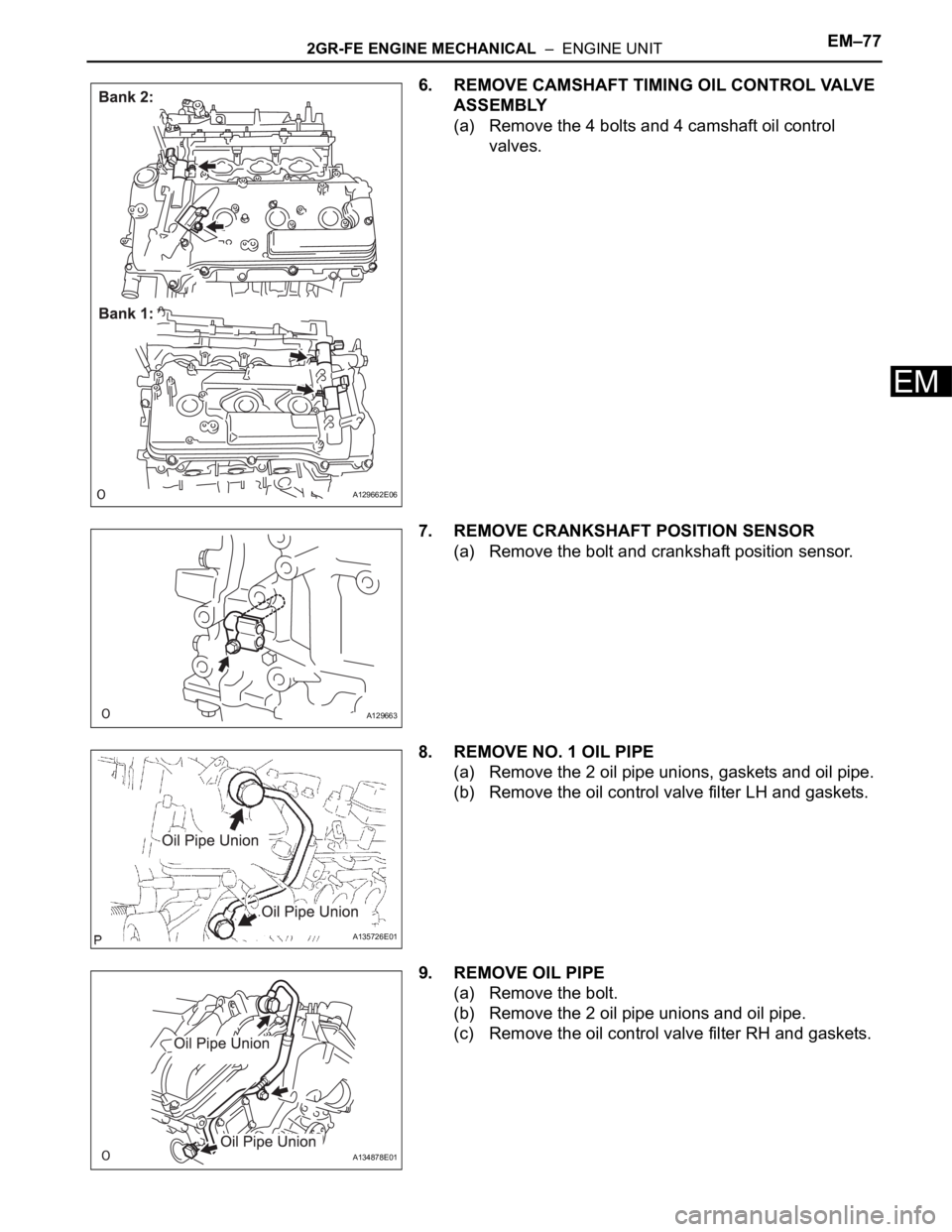

6. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Remove the 4 bolts and 4 camshaft oil control

valves.

7. REMOVE CRANKSHAFT POSITION SENSOR

(a) Remove the bolt and crankshaft position sensor.

8. REMOVE NO. 1 OIL PIPE

(a) Remove the 2 oil pipe unions, gaskets and oil pipe.

(b) Remove the oil control valve filter LH and gaskets.

9. REMOVE OIL PIPE

(a) Remove the bolt.

(b) Remove the 2 oil pipe unions and oil pipe.

(c) Remove the oil control valve filter RH and gaskets.

A129662E06

A129663

A135726E01

A134878E01

Page 1025 of 3000

EM–782GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

10. REMOVE CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Remove the cylinder block water drain cocks from

the cylinder block.

(b) Remove the cylinder block water drain cock plugs

from the water drain cocks.

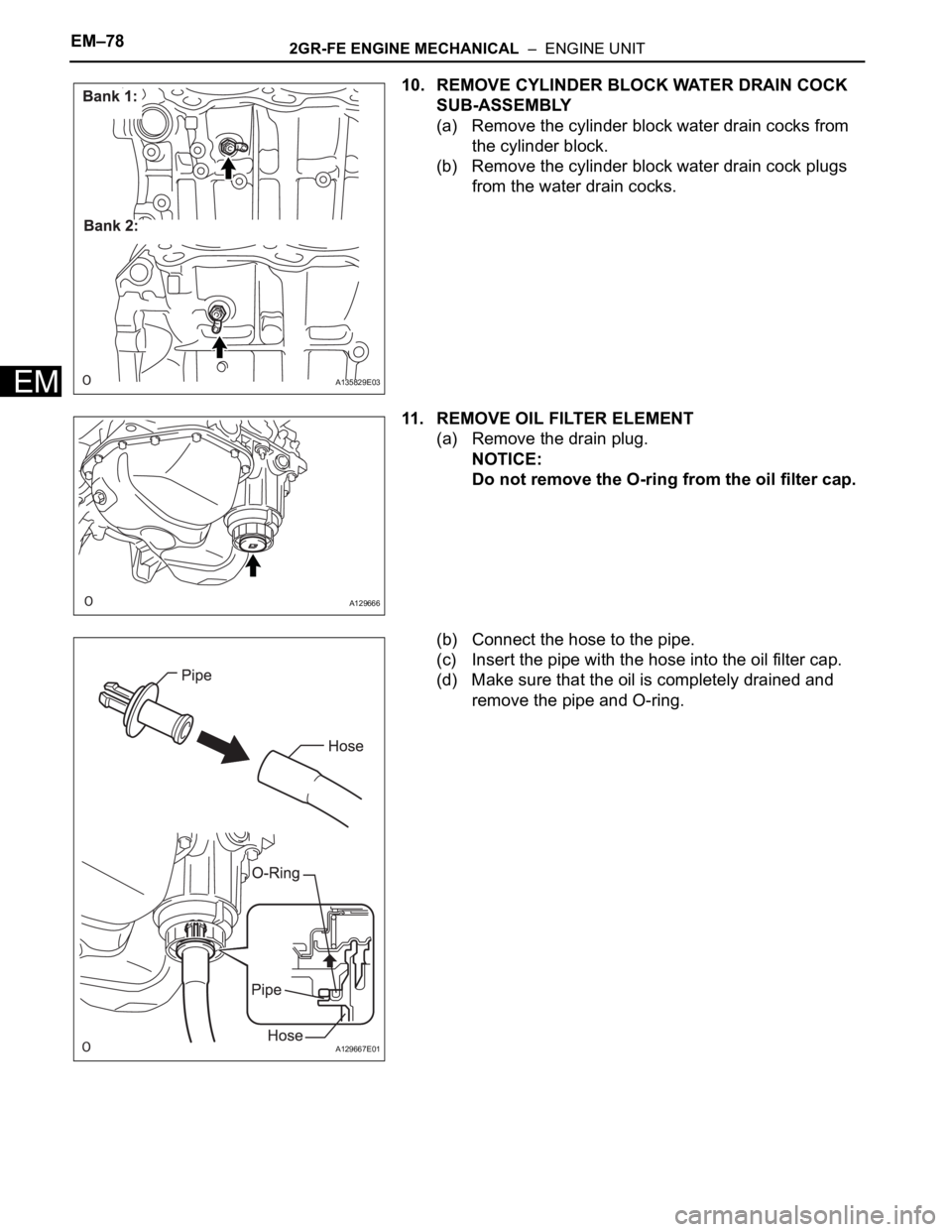

11. REMOVE OIL FILTER ELEMENT

(a) Remove the drain plug.

NOTICE:

Do not remove the O-ring from the oil filter cap.

(b) Connect the hose to the pipe.

(c) Insert the pipe with the hose into the oil filter cap.

(d) Make sure that the oil is completely drained and

remove the pipe and O-ring.

A135829E03

A129666

A129667E01

Page 1026 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–79

EM

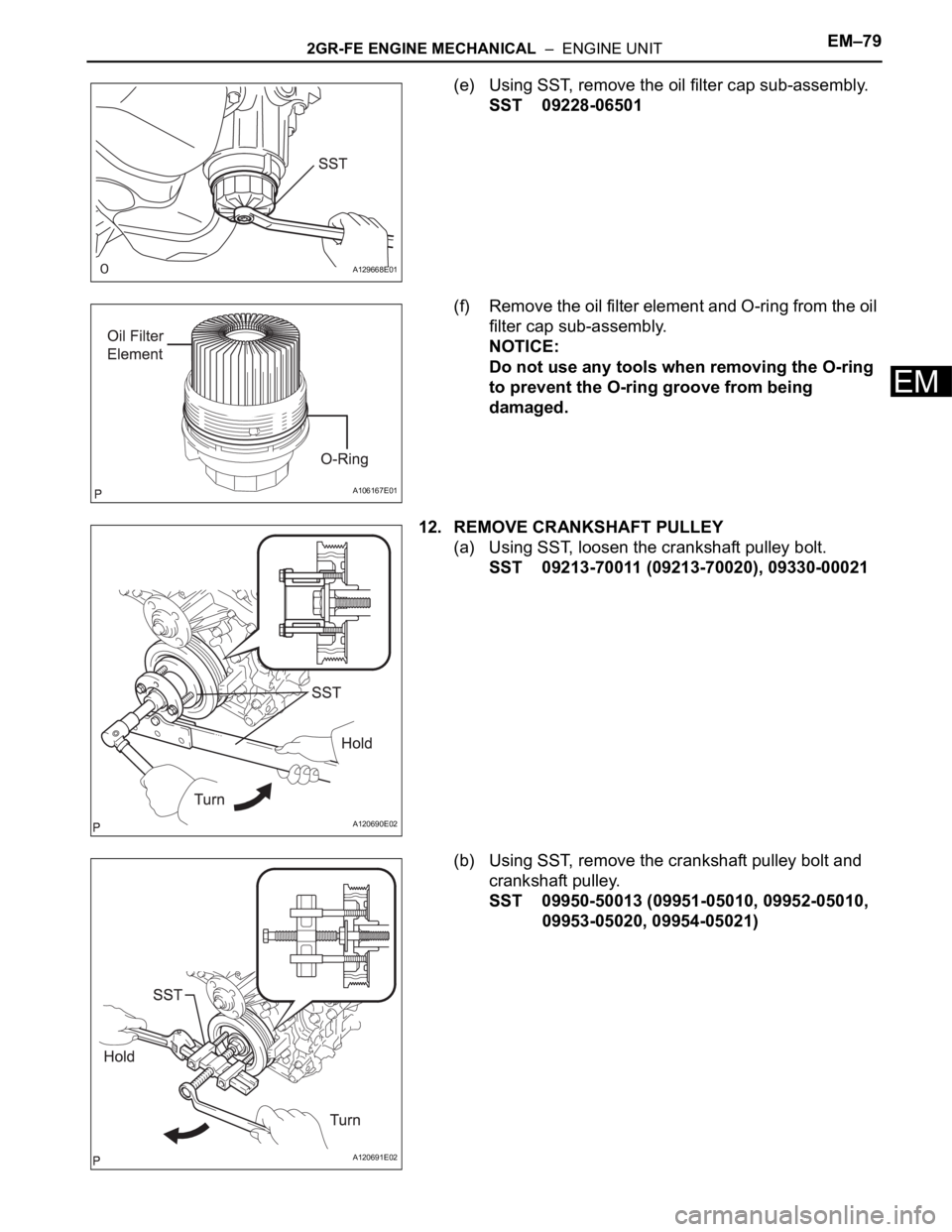

(e) Using SST, remove the oil filter cap sub-assembly.

SST 09228-06501

(f) Remove the oil filter element and O-ring from the oil

filter cap sub-assembly.

NOTICE:

Do not use any tools when removing the O-ring

to prevent the O-ring groove from being

damaged.

12. REMOVE CRANKSHAFT PULLEY

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

(b) Using SST, remove the crankshaft pulley bolt and

crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010,

09953-05020, 09954-05021)

A129668E01

A106167E01

A120690E02

A120691E02

Page 1113 of 3000

EM–1662GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(c) Install the 2 water by-pass hoses with the bolt, 2

clamps, and 4 clips.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

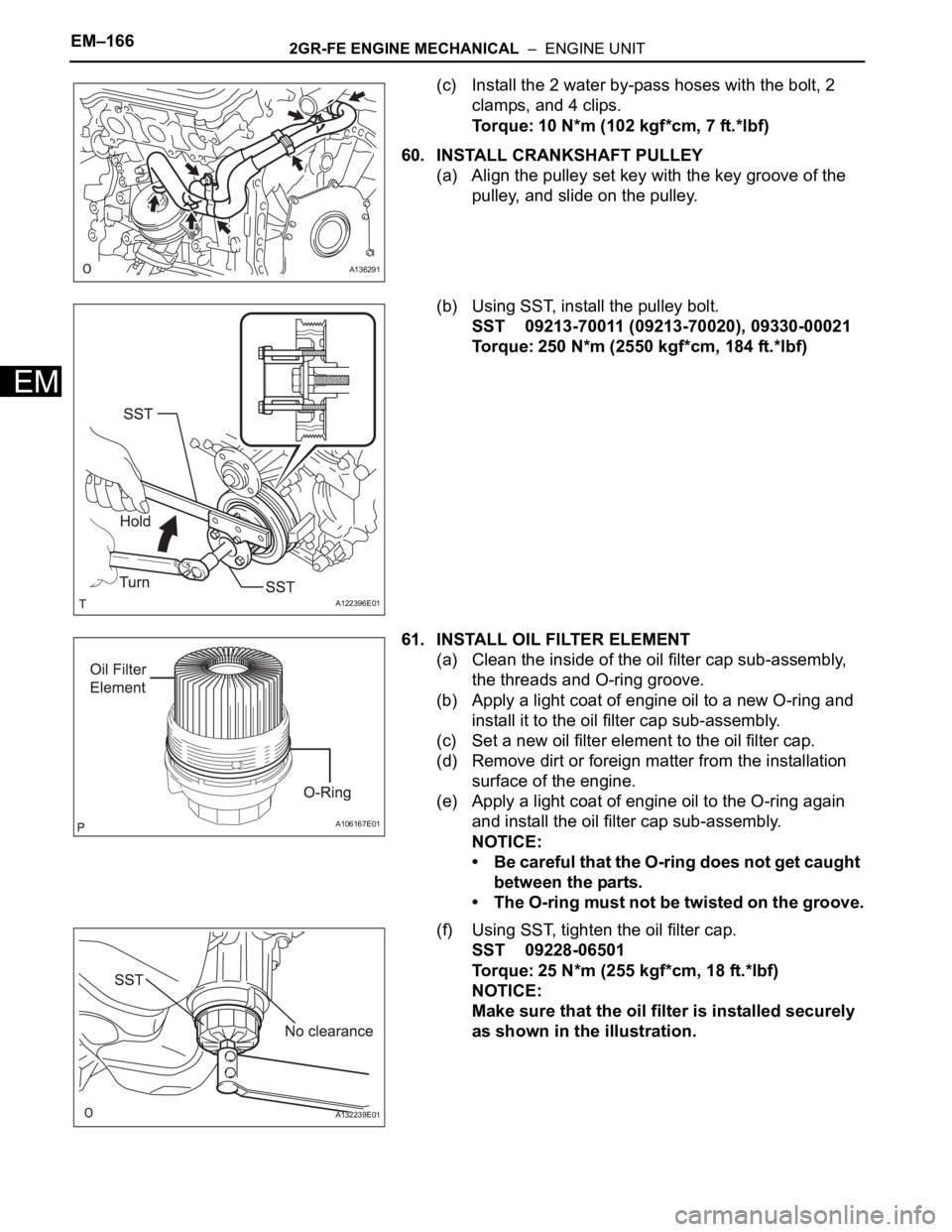

60. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the

pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

Torque: 250 N*m (2550 kgf*cm, 184 ft.*lbf)

61. INSTALL OIL FILTER ELEMENT

(a) Clean the inside of the oil filter cap sub-assembly,

the threads and O-ring groove.

(b) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap sub-assembly.

(c) Set a new oil filter element to the oil filter cap.

(d) Remove dirt or foreign matter from the installation

surface of the engine.

(e) Apply a light coat of engine oil to the O-ring again

and install the oil filter cap sub-assembly.

NOTICE:

• Be careful that the O-ring does not get caught

between the parts.

• The O-ring must not be twisted on the groove.

(f) Using SST, tighten the oil filter cap.

SST 09228-06501

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Make sure that the oil filter is installed securely

as shown in the illustration.

A136291

A122396E01

A106167E01

A132239E01

Page 1114 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–167

EM

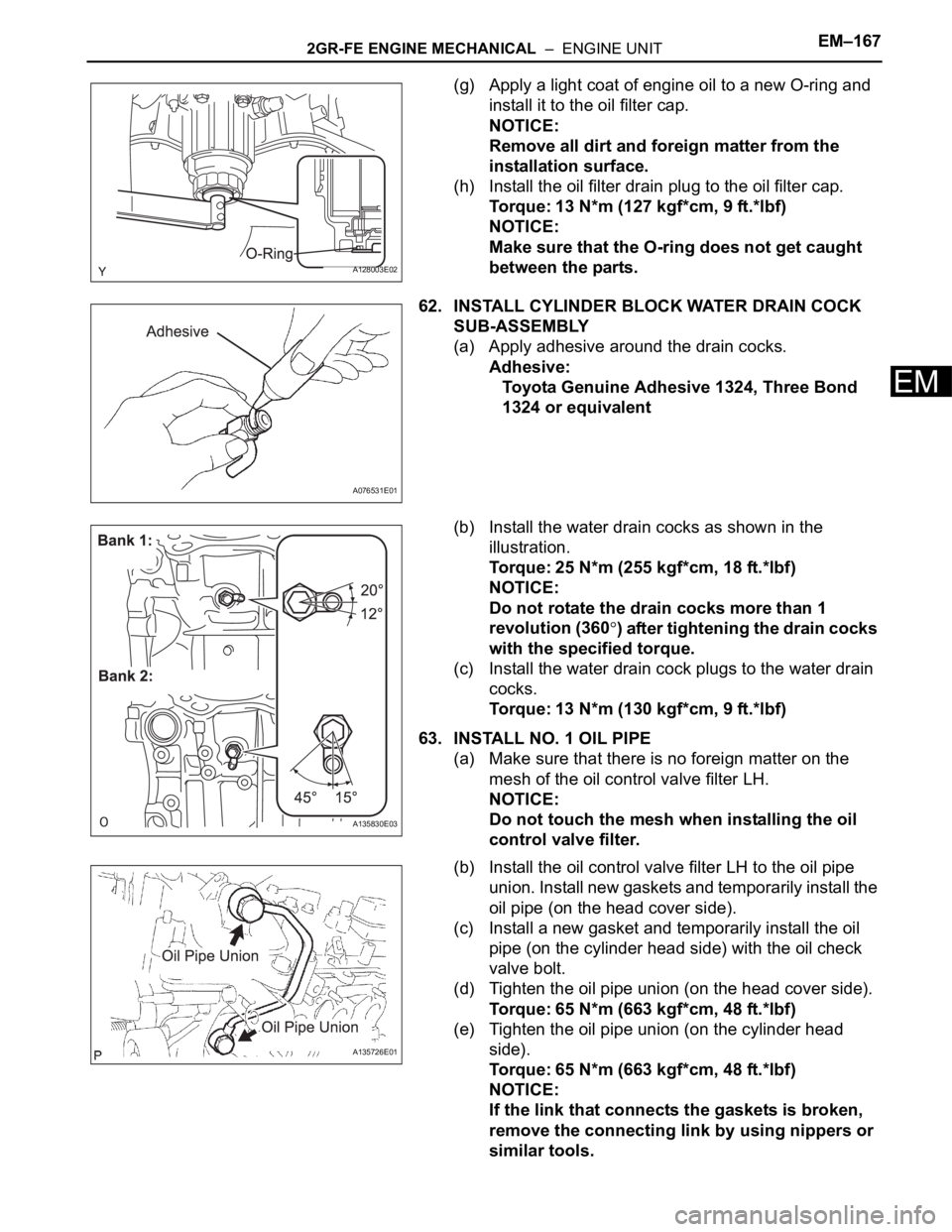

(g) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Remove all dirt and foreign matter from the

installation surface.

(h) Install the oil filter drain plug to the oil filter cap.

Torque: 13 N*m (127 kgf*cm, 9 ft.*lbf)

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

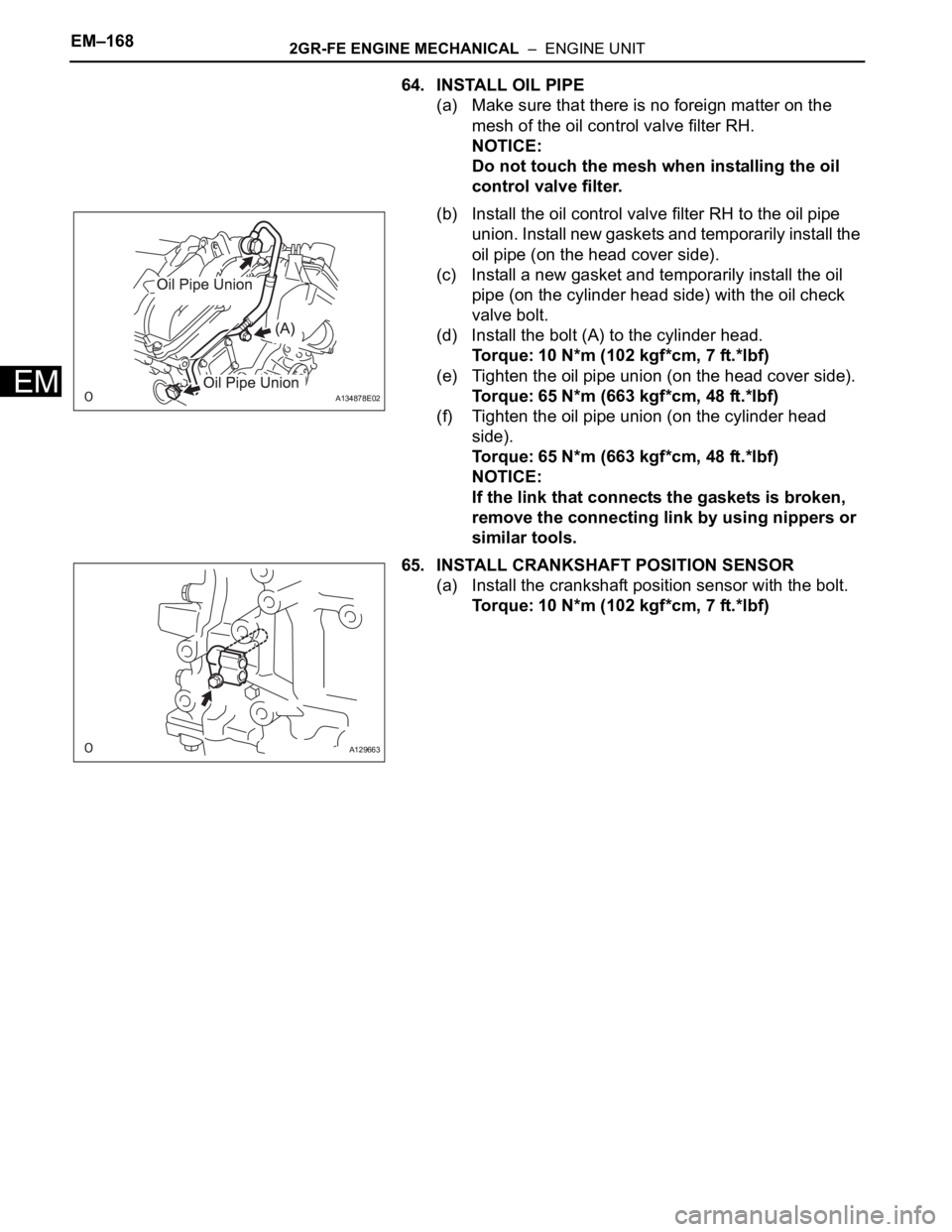

62. INSTALL CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Apply adhesive around the drain cocks.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(b) Install the water drain cocks as shown in the

illustration.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Do not rotate the drain cocks more than 1

revolution (360

) after tightening the drain cocks

with the specified torque.

(c) Install the water drain cock plugs to the water drain

cocks.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

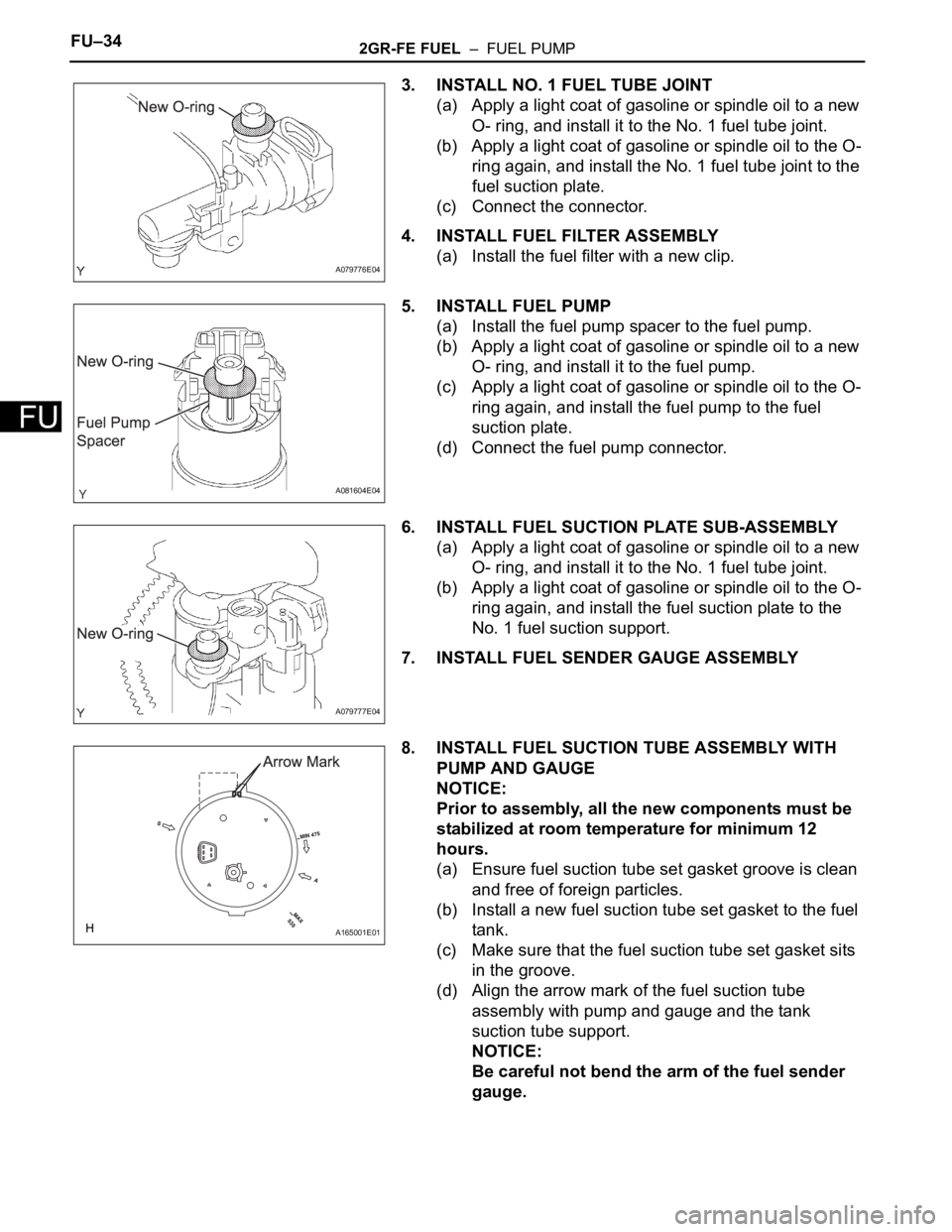

63. INSTALL NO. 1 OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter LH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter LH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(e) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

A128003E02

A076531E01

A135830E03

A135726E01

Page 1115 of 3000

EM–1682GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

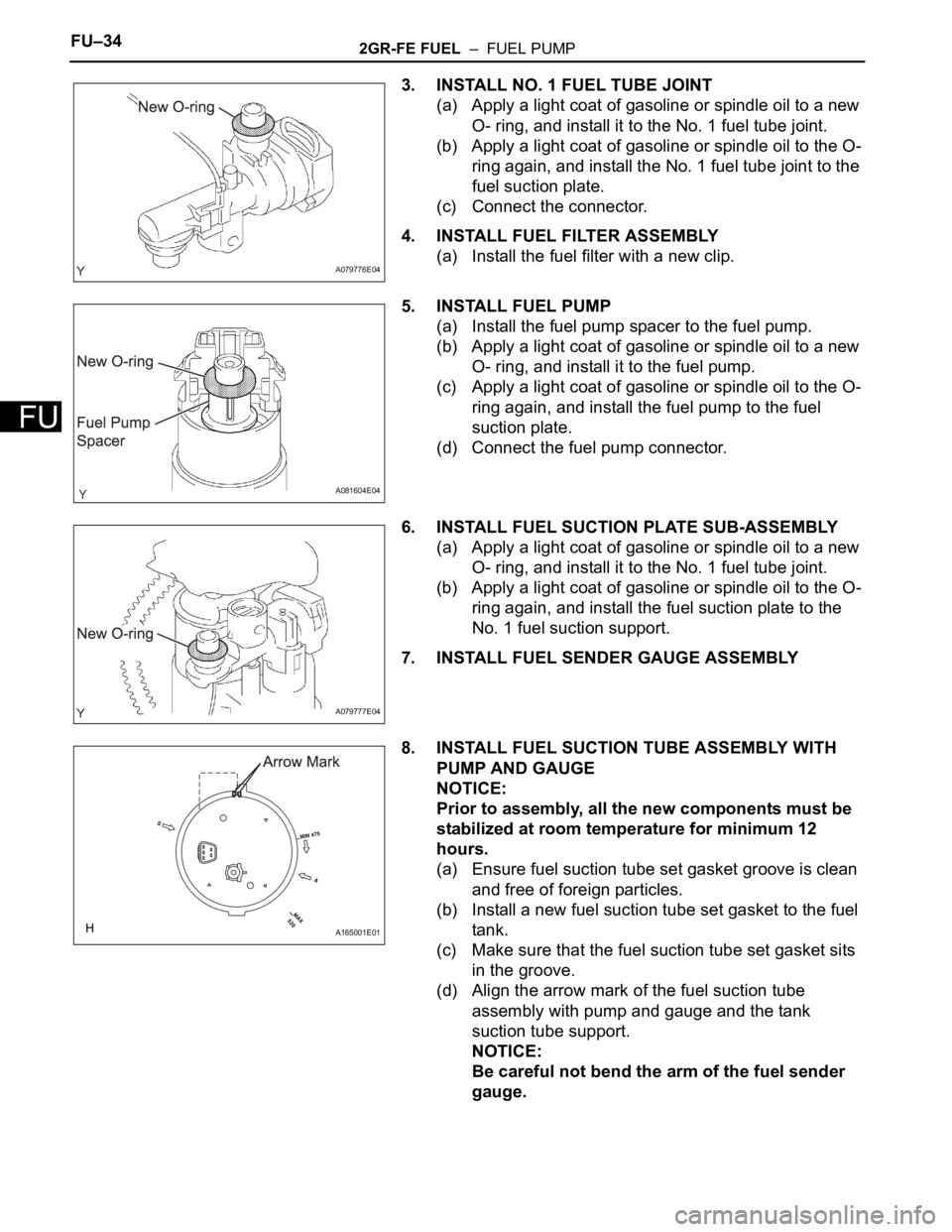

64. INSTALL OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter RH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter RH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Install the bolt (A) to the cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(e) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(f) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

65. INSTALL CRANKSHAFT POSITION SENSOR

(a) Install the crankshaft position sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A134878E02

A129663

Page 1152 of 3000

FU–342GR-FE FUEL – FUEL PUMP

FU

3. INSTALL NO. 1 FUEL TUBE JOINT

(a) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the No. 1 fuel tube joint.

(b) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the No. 1 fuel tube joint to the

fuel suction plate.

(c) Connect the connector.

4. INSTALL FUEL FILTER ASSEMBLY

(a) Install the fuel filter with a new clip.

5. INSTALL FUEL PUMP

(a) Install the fuel pump spacer to the fuel pump.

(b) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the fuel pump.

(c) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the fuel pump to the fuel

suction plate.

(d) Connect the fuel pump connector.

6. INSTALL FUEL SUCTION PLATE SUB-ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the No. 1 fuel tube joint.

(b) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the fuel suction plate to the

No. 1 fuel suction support.

7. INSTALL FUEL SENDER GAUGE ASSEMBLY

8. INSTALL FUEL SUCTION TUBE ASSEMBLY WITH

PUMP AND GAUGE

NOTICE:

Prior to assembly, all the new components must be

stabilized at room temperature for minimum 12

hours.

(a) Ensure fuel suction tube set gasket groove is clean

and free of foreign particles.

(b) Install a new fuel suction tube set gasket to the fuel

tank.

(c) Make sure that the fuel suction tube set gasket sits

in the groove.

(d) Align the arrow mark of the fuel suction tube

assembly with pump and gauge and the tank

suction tube support.

NOTICE:

Be careful not bend the arm of the fuel sender

gauge.

A079776E04

A081604E04

A079777E04

A165001E01

Page 1157 of 3000

FU–342GR-FE FUEL – FUEL PUMP

FU

3. INSTALL NO. 1 FUEL TUBE JOINT

(a) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the No. 1 fuel tube joint.

(b) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the No. 1 fuel tube joint to the

fuel suction plate.

(c) Connect the connector.

4. INSTALL FUEL FILTER ASSEMBLY

(a) Install the fuel filter with a new clip.

5. INSTALL FUEL PUMP

(a) Install the fuel pump spacer to the fuel pump.

(b) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the fuel pump.

(c) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the fuel pump to the fuel

suction plate.

(d) Connect the fuel pump connector.

6. INSTALL FUEL SUCTION PLATE SUB-ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to a new

O- ring, and install it to the No. 1 fuel tube joint.

(b) Apply a light coat of gasoline or spindle oil to the O-

ring again, and install the fuel suction plate to the

No. 1 fuel suction support.

7. INSTALL FUEL SENDER GAUGE ASSEMBLY

8. INSTALL FUEL SUCTION TUBE ASSEMBLY WITH

PUMP AND GAUGE

NOTICE:

Prior to assembly, all the new components must be

stabilized at room temperature for minimum 12

hours.

(a) Ensure fuel suction tube set gasket groove is clean

and free of foreign particles.

(b) Install a new fuel suction tube set gasket to the fuel

tank.

(c) Make sure that the fuel suction tube set gasket sits

in the groove.

(d) Align the arrow mark of the fuel suction tube

assembly with pump and gauge and the tank

suction tube support.

NOTICE:

Be careful not bend the arm of the fuel sender

gauge.

A079776E04

A081604E04

A079777E04

A165001E01

Page 1299 of 3000

2GR-FE LUBRICATION – LUBRICATION SYSTEMLU–1

LU

LUBRICATION SYSTEM

ON-VEHICLE INSPECTION

1. CHECK ENGINE OIL LEVEL

(a) Warm up the engine, stop it and wait 5 minutes. The

oil level should be between the dipstick's low level

mark and full level mark.

If the engine oil level is low, check for leakage and

add oil up to the full level mark.

NOTICE:

Do not add engine oil above the full level mark.

2. CHECK ENGINE OIL

(a) Check the engine oil for deterioration, water

contamination, discoloring or thinning.

If the oil is bad, replace the engine oil and engine oil

filter.

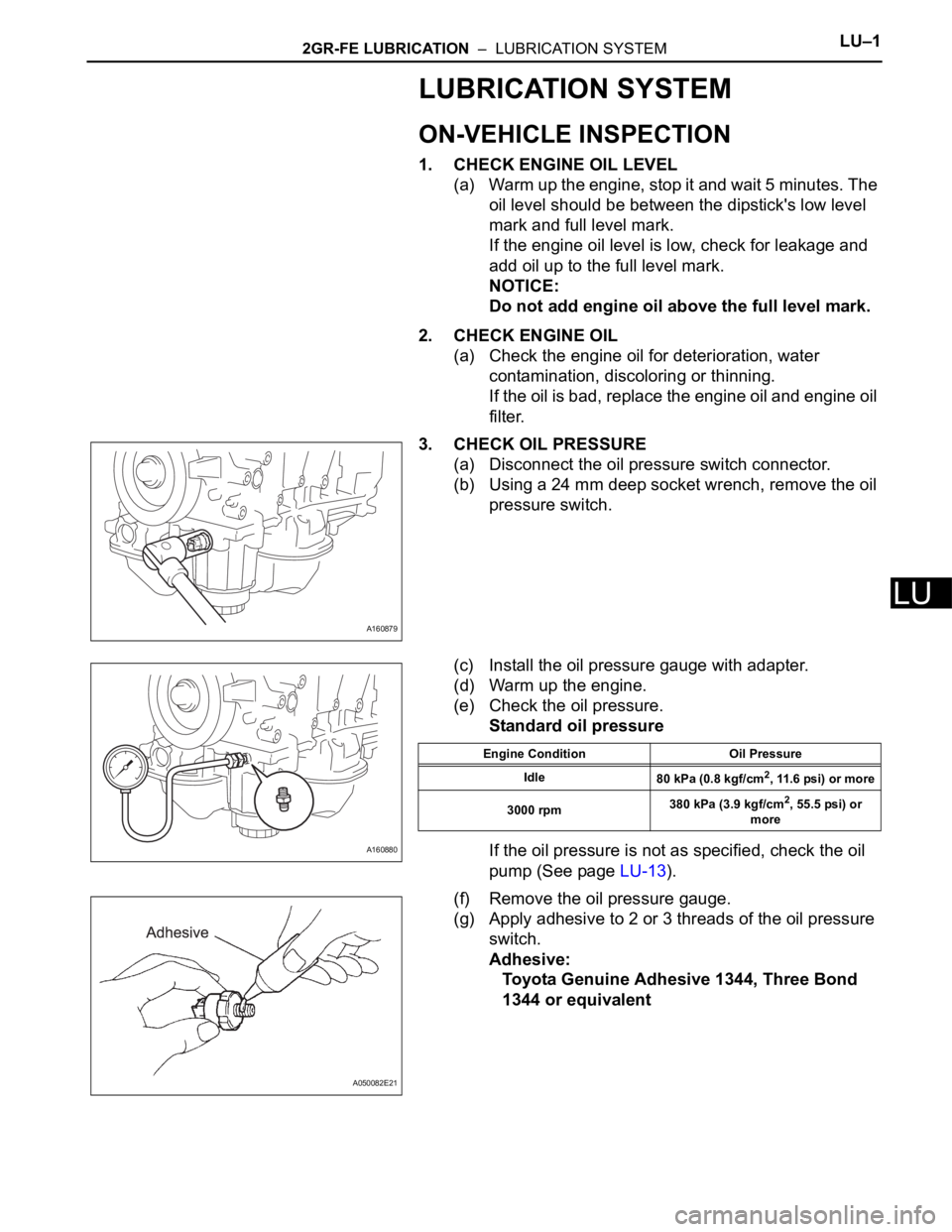

3. CHECK OIL PRESSURE

(a) Disconnect the oil pressure switch connector.

(b) Using a 24 mm deep socket wrench, remove the oil

pressure switch.

(c) Install the oil pressure gauge with adapter.

(d) Warm up the engine.

(e) Check the oil pressure.

Standard oil pressure

If the oil pressure is not as specified, check the oil

pump (See page LU-13).

(f) Remove the oil pressure gauge.

(g) Apply adhesive to 2 or 3 threads of the oil pressure

switch.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond

1344 or equivalent

A160879

A160880

Engine Condition Oil Pressure

Idle

80 kPa (0.8 kgf/cm

2, 11.6 psi) or more

3000 rpm380 kPa (3.9 kgf/cm

2, 55.5 psi) or

more

A050082E21

Page 1301 of 3000

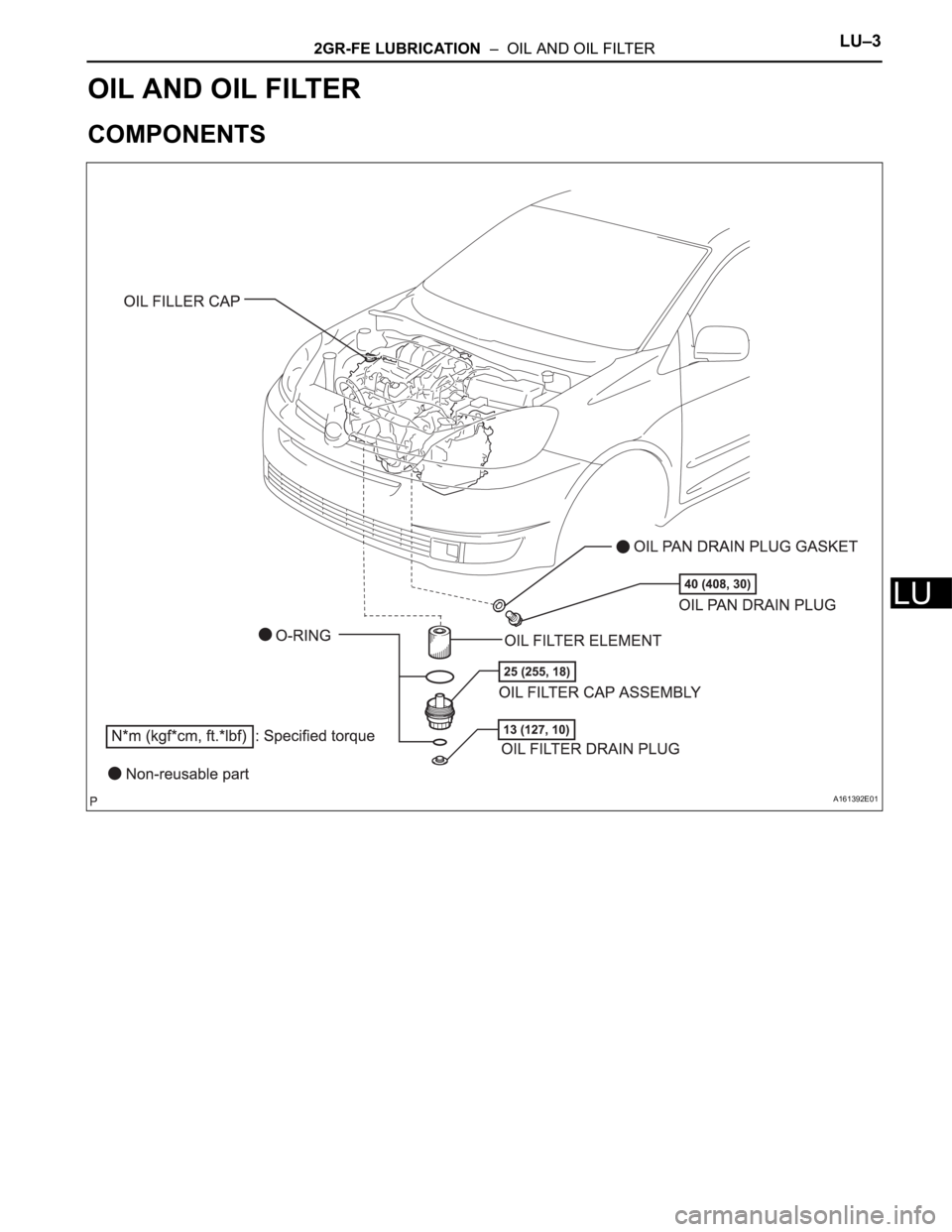

2GR-FE LUBRICATION – OIL AND OIL FILTERLU–3

LU

ENGINE

2GR-FE LUBRICATION

OIL AND OIL FILTER

COMPONENTS

A161392E01