service TOYOTA SIENNA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 773 of 3000

ED–214ENGINE HOOD / DOOR – BACK DOOR

ED

DISASSEMBLY

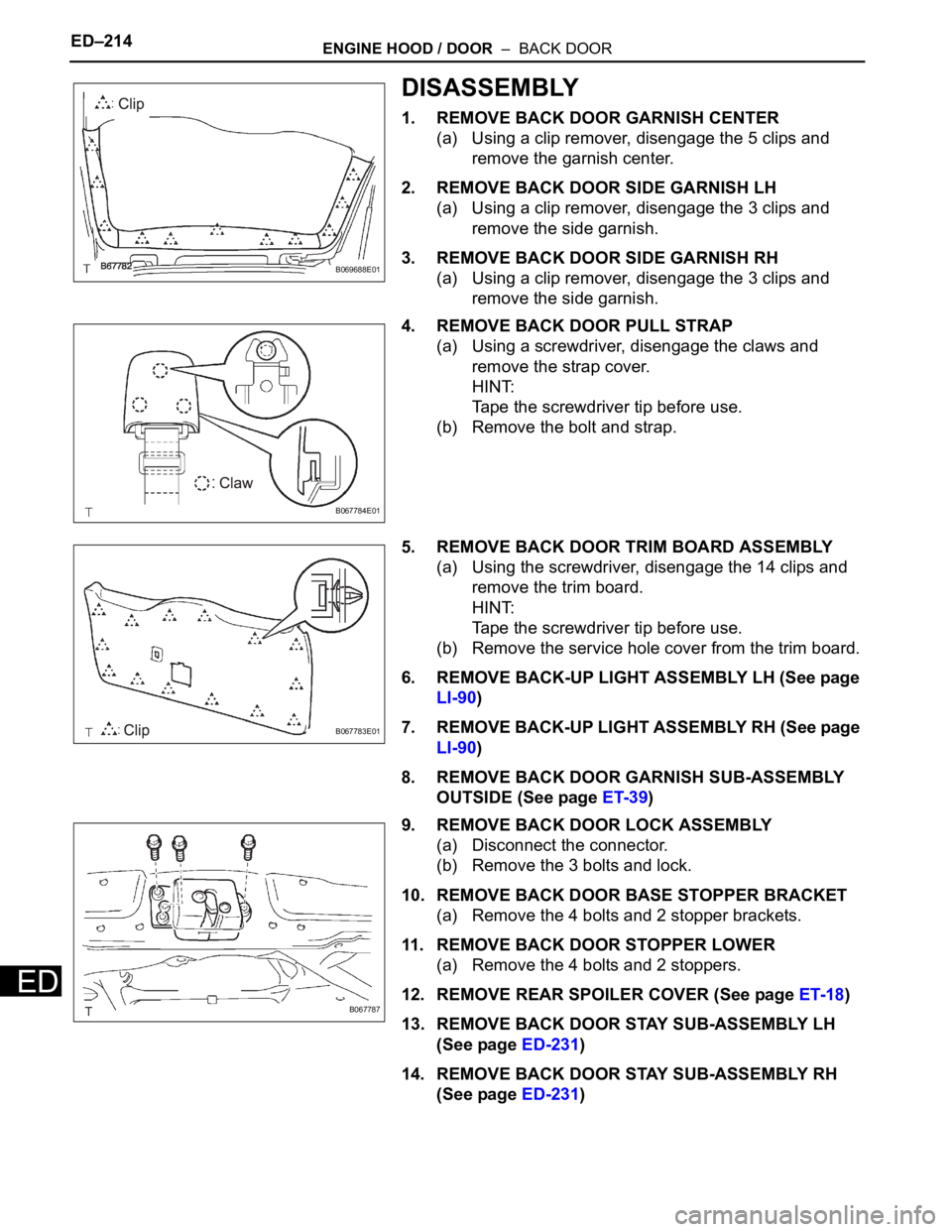

1. REMOVE BACK DOOR GARNISH CENTER

(a) Using a clip remover, disengage the 5 clips and

remove the garnish center.

2. REMOVE BACK DOOR SIDE GARNISH LH

(a) Using a clip remover, disengage the 3 clips and

remove the side garnish.

3. REMOVE BACK DOOR SIDE GARNISH RH

(a) Using a clip remover, disengage the 3 clips and

remove the side garnish.

4. REMOVE BACK DOOR PULL STRAP

(a) Using a screwdriver, disengage the claws and

remove the strap cover.

HINT:

Tape the screwdriver tip before use.

(b) Remove the bolt and strap.

5. REMOVE BACK DOOR TRIM BOARD ASSEMBLY

(a) Using the screwdriver, disengage the 14 clips and

remove the trim board.

HINT:

Tape the screwdriver tip before use.

(b) Remove the service hole cover from the trim board.

6. REMOVE BACK-UP LIGHT ASSEMBLY LH (See page

LI-90)

7. REMOVE BACK-UP LIGHT ASSEMBLY RH (See page

LI-90)

8. REMOVE BACK DOOR GARNISH SUB-ASSEMBLY

OUTSIDE (See page ET-39)

9. REMOVE BACK DOOR LOCK ASSEMBLY

(a) Disconnect the connector.

(b) Remove the 3 bolts and lock.

10. REMOVE BACK DOOR BASE STOPPER BRACKET

(a) Remove the 4 bolts and 2 stopper brackets.

11. REMOVE BACK DOOR STOPPER LOWER

(a) Remove the 4 bolts and 2 stoppers.

12. REMOVE REAR SPOILER COVER (See page ET-18)

13. REMOVE BACK DOOR STAY SUB-ASSEMBLY LH

(See page ED-231)

14. REMOVE BACK DOOR STAY SUB-ASSEMBLY RH

(See page ED-231)

B069688E01

B067784E01

B067783E01

B067787

Page 825 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–43

ES

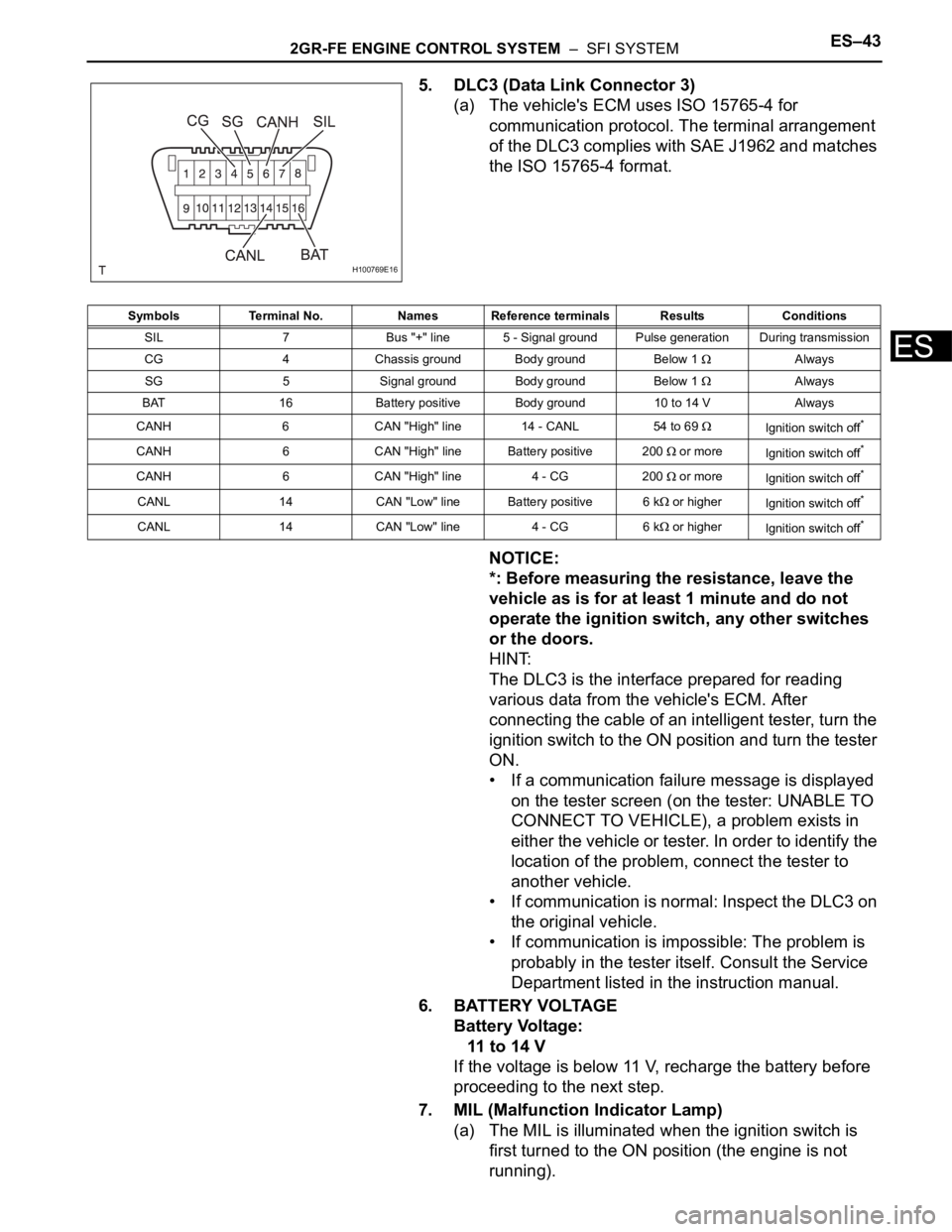

5. DLC3 (Data Link Connector 3)

(a) The vehicle's ECM uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the doors.

HINT:

The DLC3 is the interface prepared for reading

various data from the vehicle's ECM. After

connecting the cable of an intelligent tester, turn the

ignition switch to the ON position and turn the tester

ON.

• If a communication failure message is displayed

on the tester screen (on the tester: UNABLE TO

CONNECT TO VEHICLE), a problem exists in

either the vehicle or tester. In order to identify the

location of the problem, connect the tester to

another vehicle.

• If communication is normal: Inspect the DLC3 on

the original vehicle.

• If communication is impossible: The problem is

probably in the tester itself. Consult the Service

Department listed in the instruction manual.

6. BATTERY VOLTAGE

Battery Voltage:

11 to 14 V

If the voltage is below 11 V, recharge the battery before

proceeding to the next step.

7. MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the ignition switch is

first turned to the ON position (the engine is not

running).

H100769E16

Symbols Terminal No. Names Reference terminals Results Conditions

SIL 7 Bus "+" line 5 - Signal ground Pulse generation During transmission

CG 4 Chassis ground Body ground Below 1

Always

SG 5 Signal ground Body ground Below 1

Always

BAT 16 Battery positive Body ground 10 to 14 V Always

CANH 6 CAN "High" line 14 - CANL 54 to 69

Ignition switch off*

CANH 6 CAN "High" line Battery positive 200 or more

Ignition switch off*

CANH 6 CAN "High" line 4 - CG 200 or more

Ignition switch off*

CANL 14 CAN "Low" line Battery positive 6 k or higher

Ignition switch off*

CANL 14 CAN "Low" line 4 - CG 6 k or higher

Ignition switch off*

Page 1323 of 3000

2GR-FE STARTING – STARTERST–9

ST

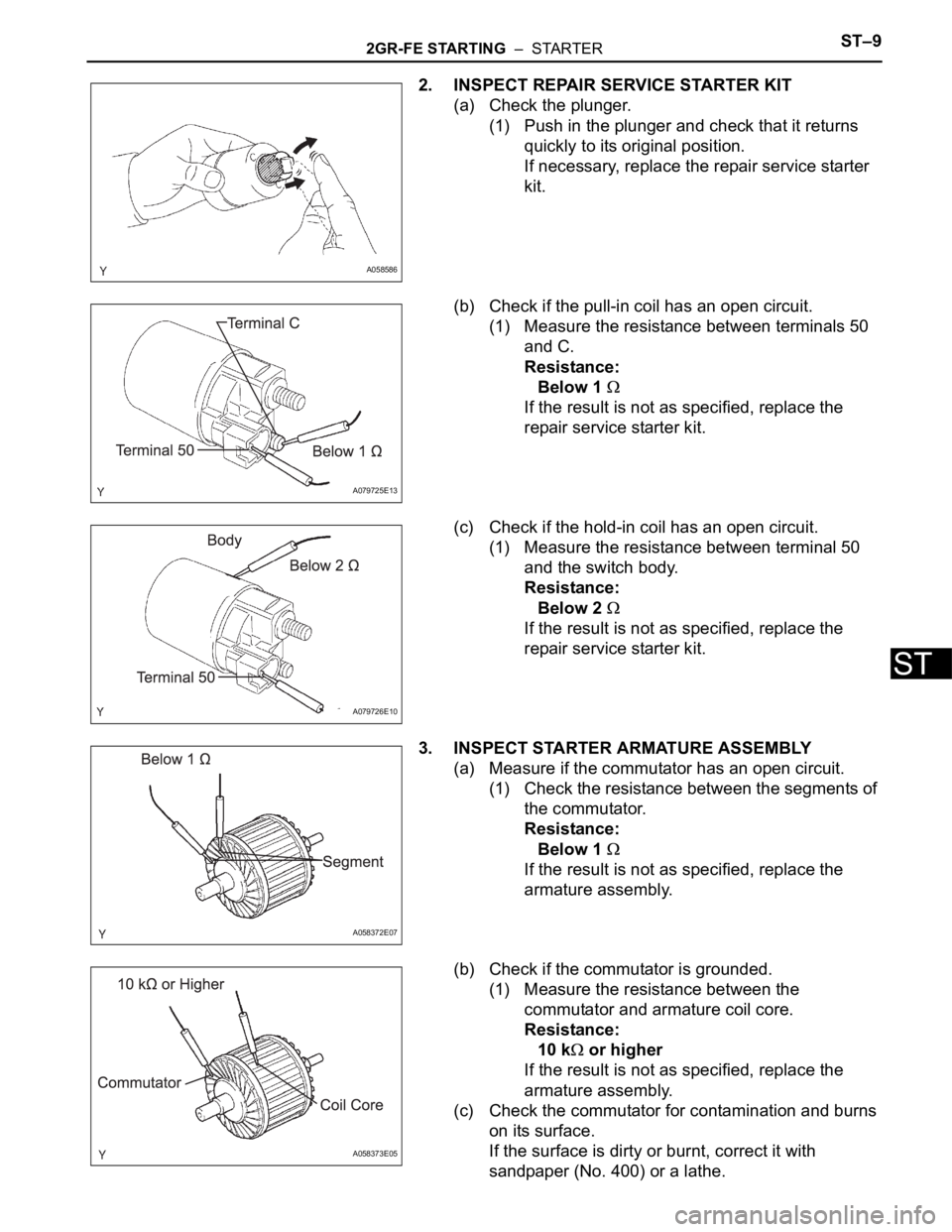

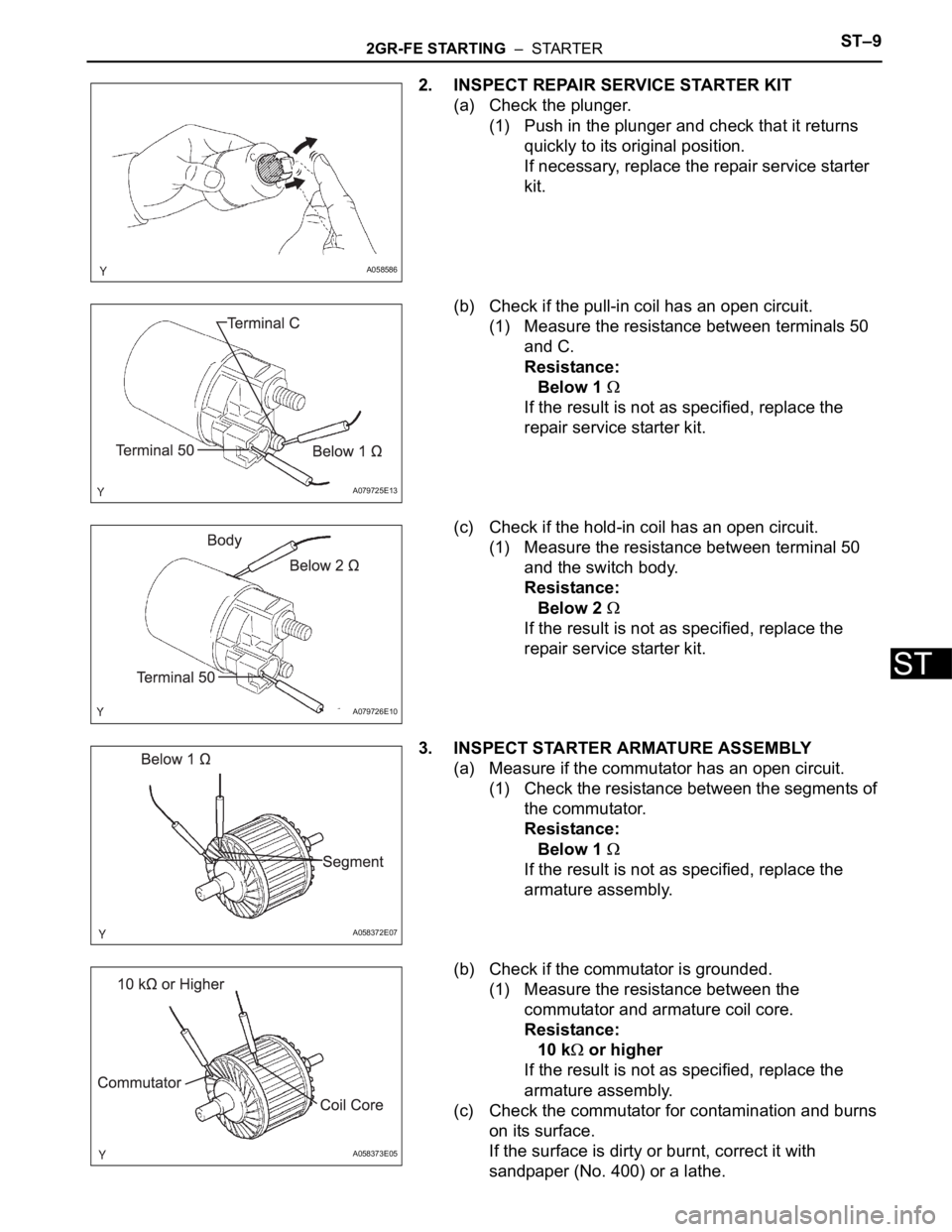

2. INSPECT REPAIR SERVICE STARTER KIT

(a) Check the plunger.

(1) Push in the plunger and check that it returns

quickly to its original position.

If necessary, replace the repair service starter

kit.

(b) Check if the pull-in coil has an open circuit.

(1) Measure the resistance between terminals 50

and C.

Resistance:

Below 1

If the result is not as specified, replace the

repair service starter kit.

(c) Check if the hold-in coil has an open circuit.

(1) Measure the resistance between terminal 50

and the switch body.

Resistance:

Below 2

If the result is not as specified, replace the

repair service starter kit.

3. INSPECT STARTER ARMATURE ASSEMBLY

(a) Measure if the commutator has an open circuit.

(1) Check the resistance between the segments of

the commutator.

Resistance:

Below 1

If the result is not as specified, replace the

armature assembly.

(b) Check if the commutator is grounded.

(1) Measure the resistance between the

commutator and armature coil core.

Resistance:

10 k

or higher

If the result is not as specified, replace the

armature assembly.

(c) Check the commutator for contamination and burns

on its surface.

If the surface is dirty or burnt, correct it with

sandpaper (No. 400) or a lathe.

A058586

A079725E13

A079726E10

A058372E07

A058373E05

Page 1324 of 3000

ST–102GR-FE STARTING – STARTER

ST

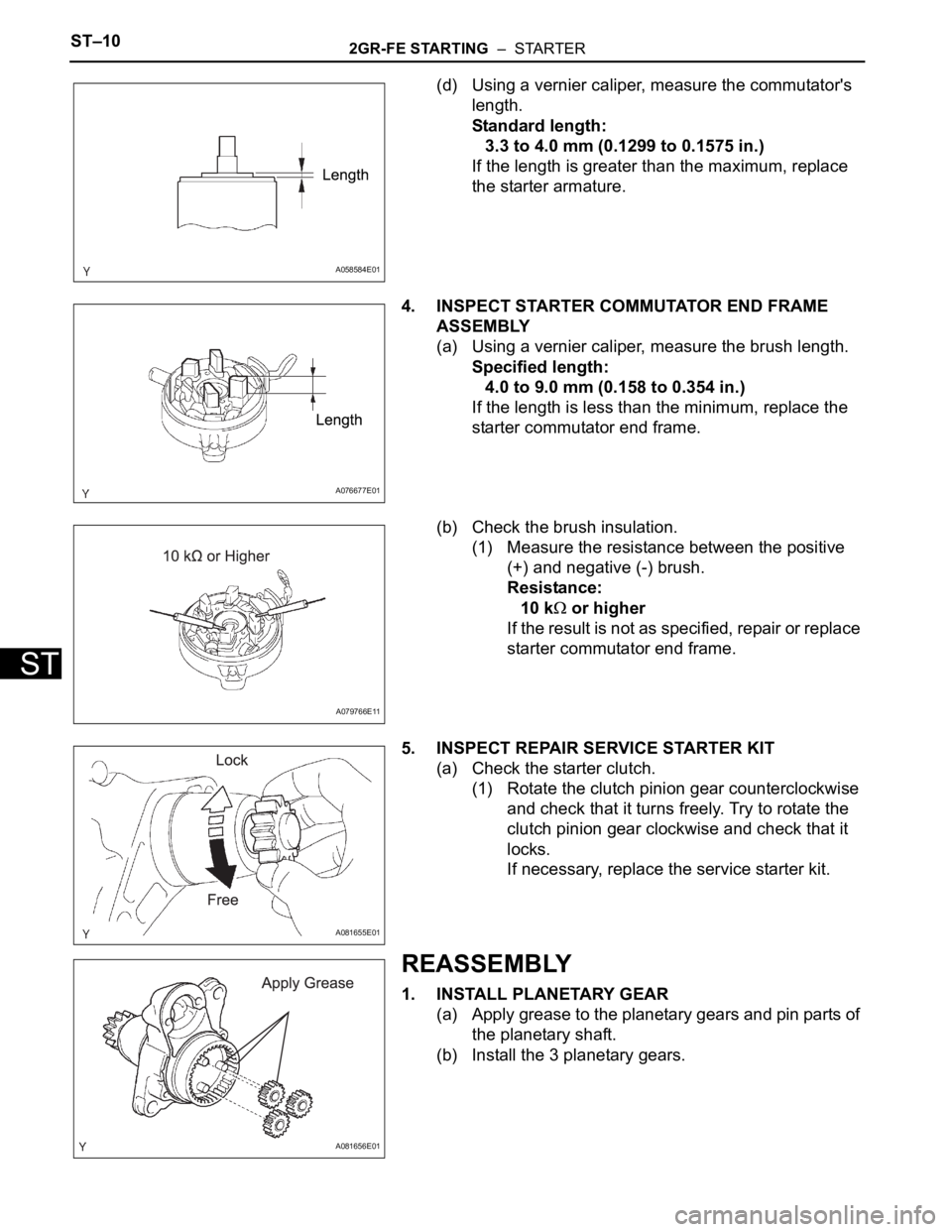

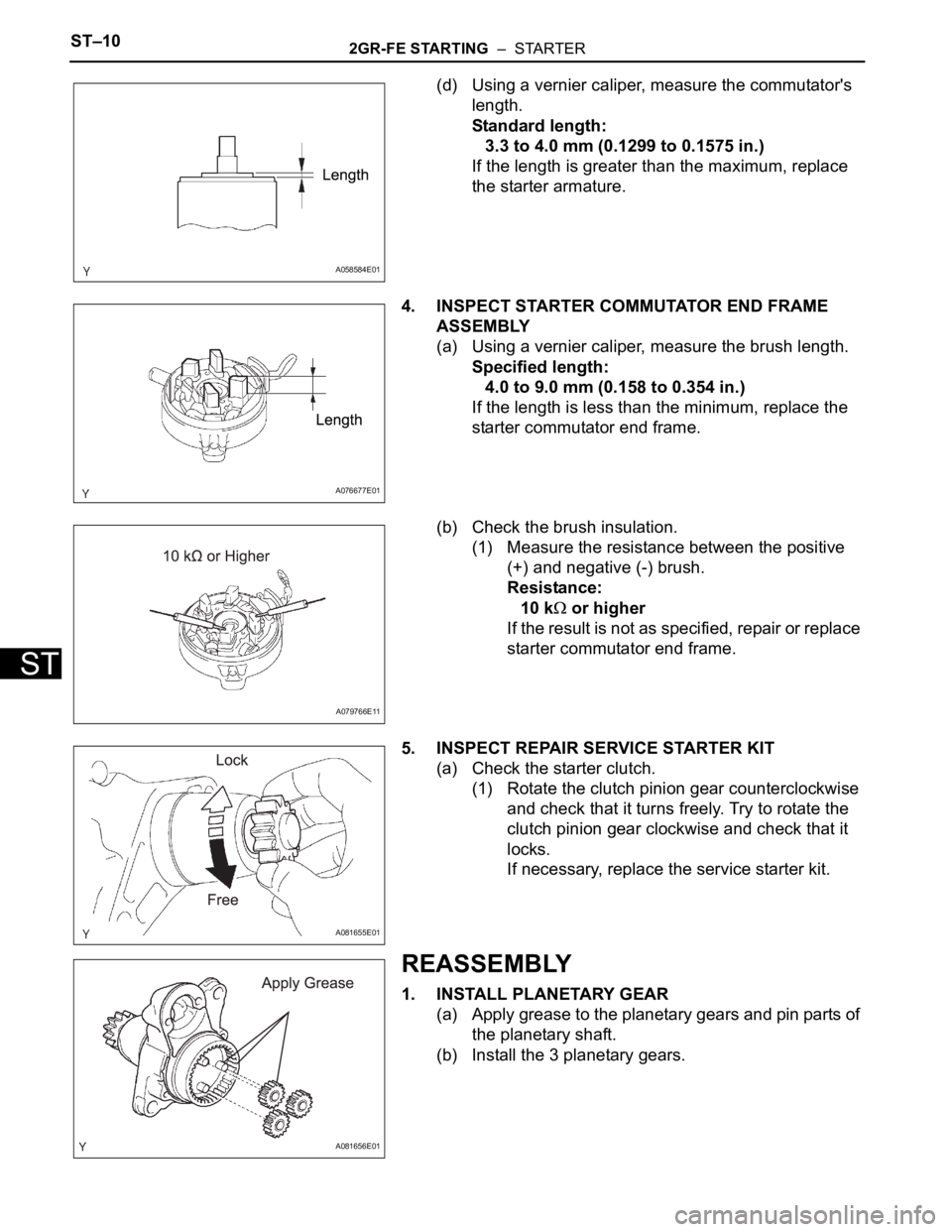

(d) Using a vernier caliper, measure the commutator's

length.

Standard length:

3.3 to 4.0 mm (0.1299 to 0.1575 in.)

If the length is greater than the maximum, replace

the starter armature.

4. INSPECT STARTER COMMUTATOR END FRAME

ASSEMBLY

(a) Using a vernier caliper, measure the brush length.

Specified length:

4.0 to 9.0 mm (0.158 to 0.354 in.)

If the length is less than the minimum, replace the

starter commutator end frame.

(b) Check the brush insulation.

(1) Measure the resistance between the positive

(+) and negative (-) brush.

Resistance:

10 k

or higher

If the result is not as specified, repair or replace

starter commutator end frame.

5. INSPECT REPAIR SERVICE STARTER KIT

(a) Check the starter clutch.

(1) Rotate the clutch pinion gear counterclockwise

and check that it turns freely. Try to rotate the

clutch pinion gear clockwise and check that it

locks.

If necessary, replace the service starter kit.

REASSEMBLY

1. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of

the planetary shaft.

(b) Install the 3 planetary gears.

A058584E01

A076677E01

A079766E11

A081655E01

A081656E01

Page 1326 of 3000

ST–122GR-FE STARTING – STARTER

ST

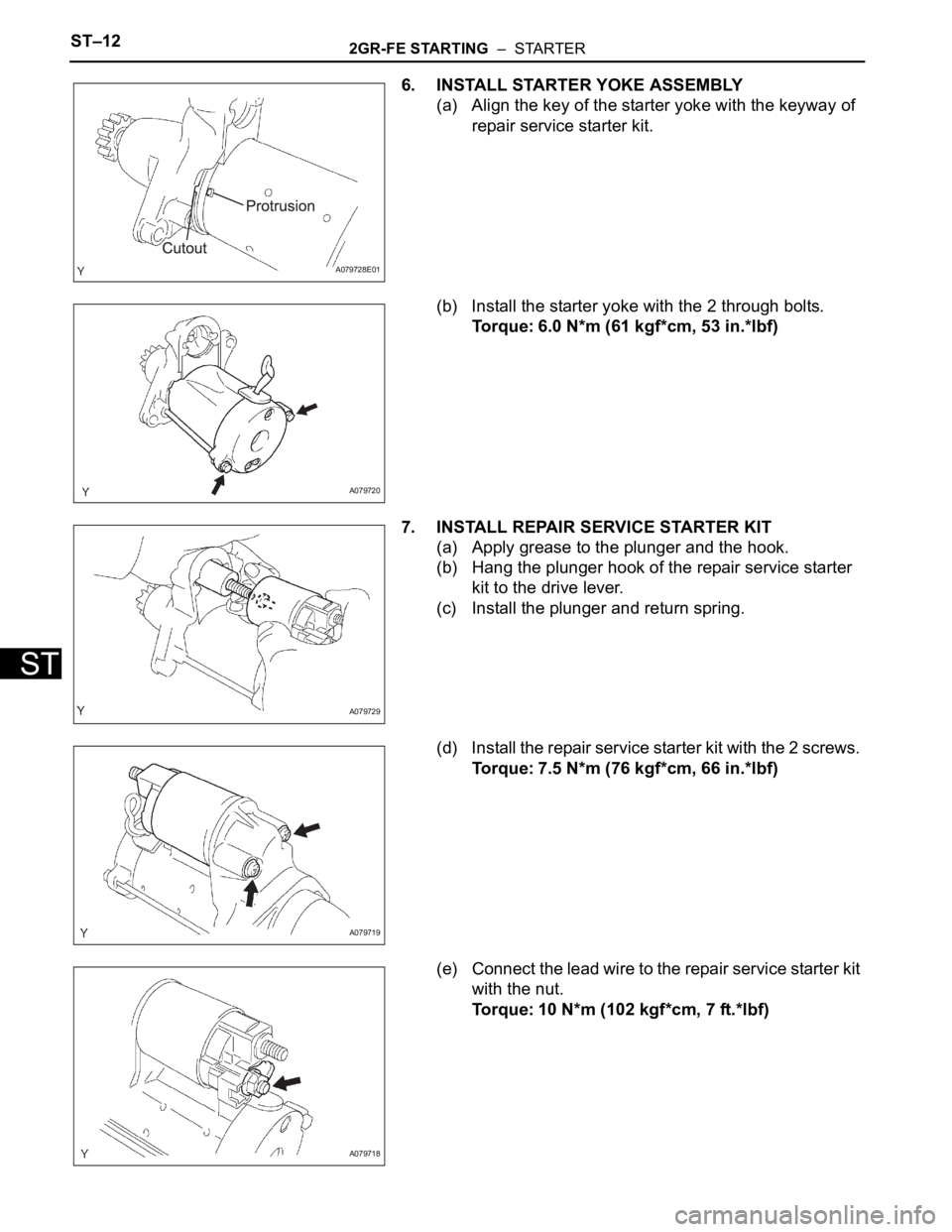

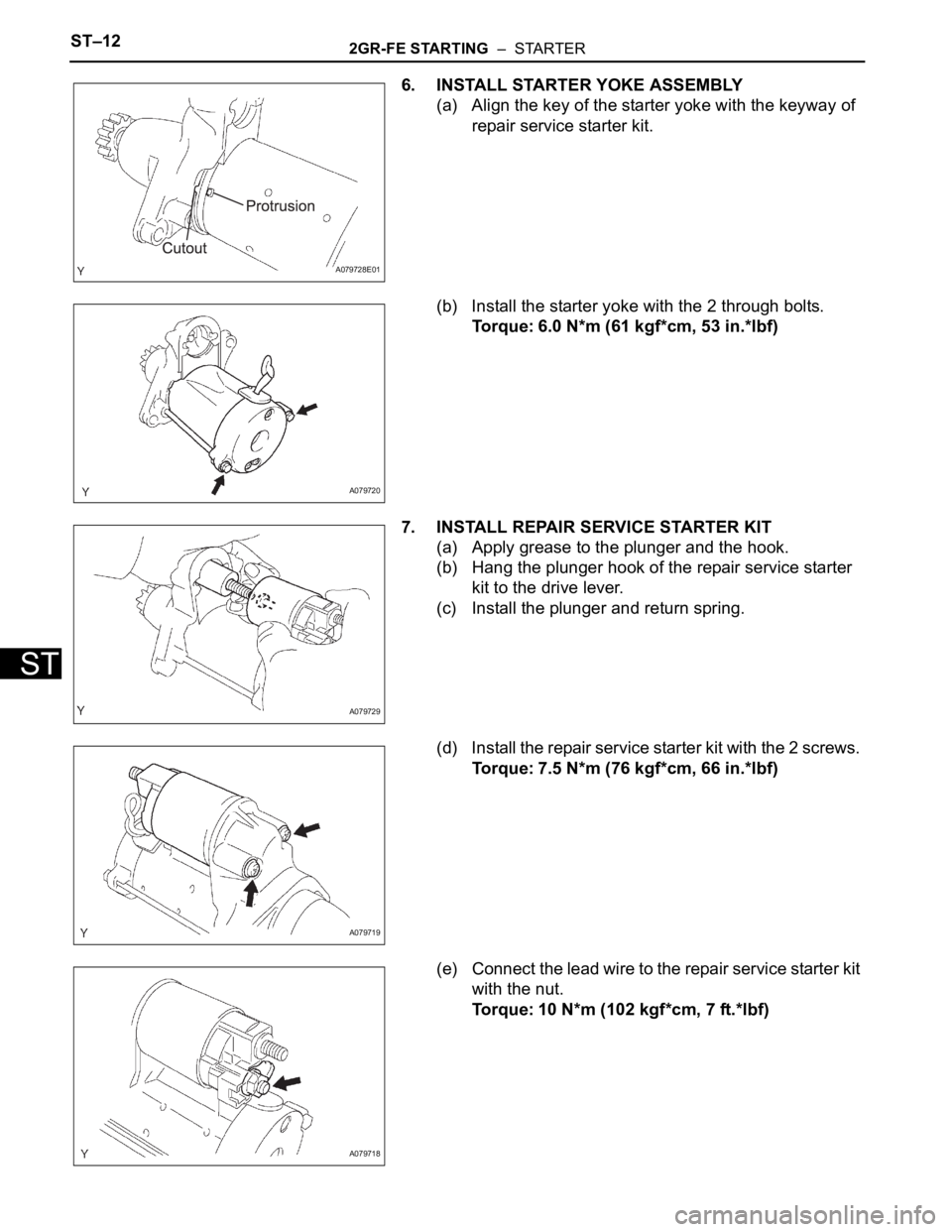

6. INSTALL STARTER YOKE ASSEMBLY

(a) Align the key of the starter yoke with the keyway of

repair service starter kit.

(b) Install the starter yoke with the 2 through bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

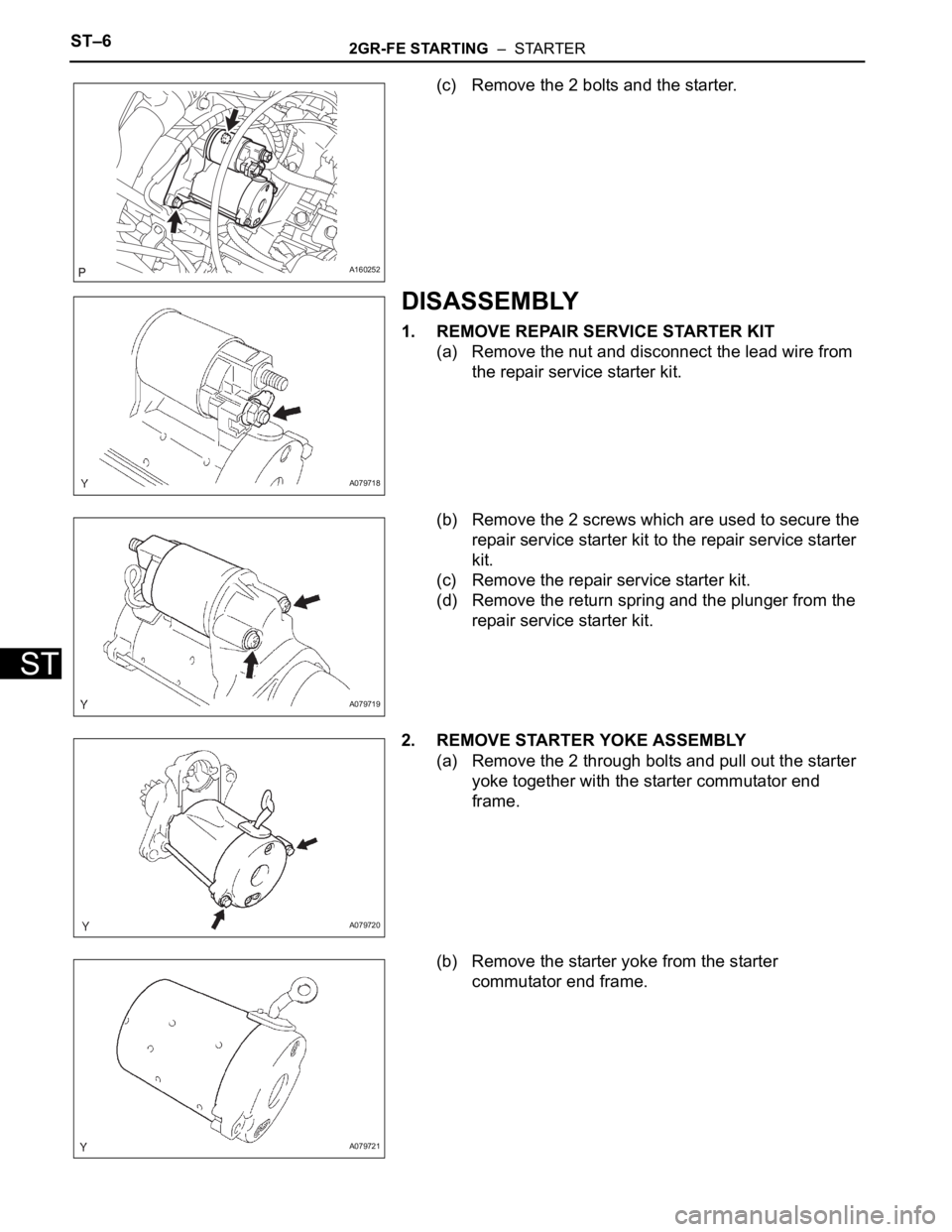

7. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and the hook.

(b) Hang the plunger hook of the repair service starter

kit to the drive lever.

(c) Install the plunger and return spring.

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(e) Connect the lead wire to the repair service starter kit

with the nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A079728E01

A079720

A079729

A079719

A079718

Page 1329 of 3000

ST–62GR-FE STARTING – STARTER

ST

(c) Remove the 2 bolts and the starter.

DISASSEMBLY

1. REMOVE REPAIR SERVICE STARTER KIT

(a) Remove the nut and disconnect the lead wire from

the repair service starter kit.

(b) Remove the 2 screws which are used to secure the

repair service starter kit to the repair service starter

kit.

(c) Remove the repair service starter kit.

(d) Remove the return spring and the plunger from the

repair service starter kit.

2. REMOVE STARTER YOKE ASSEMBLY

(a) Remove the 2 through bolts and pull out the starter

yoke together with the starter commutator end

frame.

(b) Remove the starter yoke from the starter

commutator end frame.

A160252

A079718

A079719

A079720

A079721

Page 1330 of 3000

2GR-FE STARTING – STARTERST–7

ST

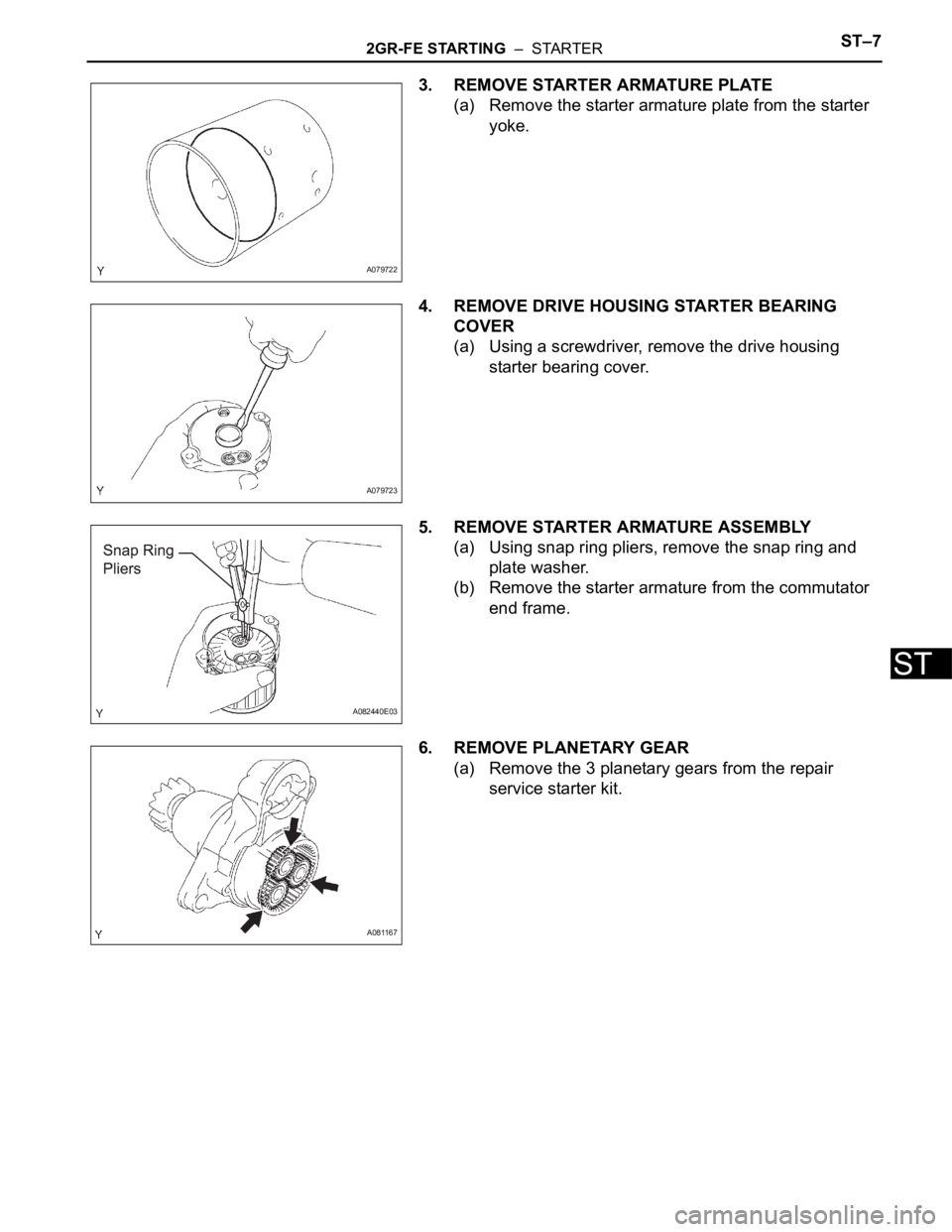

3. REMOVE STARTER ARMATURE PLATE

(a) Remove the starter armature plate from the starter

yoke.

4. REMOVE DRIVE HOUSING STARTER BEARING

COVER

(a) Using a screwdriver, remove the drive housing

starter bearing cover.

5. REMOVE STARTER ARMATURE ASSEMBLY

(a) Using snap ring pliers, remove the snap ring and

plate washer.

(b) Remove the starter armature from the commutator

end frame.

6. REMOVE PLANETARY GEAR

(a) Remove the 3 planetary gears from the repair

service starter kit.

A079722

A079723

A082440E03

A081167

Page 1332 of 3000

2GR-FE STARTING – STARTERST–9

ST

2. INSPECT REPAIR SERVICE STARTER KIT

(a) Check the plunger.

(1) Push in the plunger and check that it returns

quickly to its original position.

If necessary, replace the repair service starter

kit.

(b) Check if the pull-in coil has an open circuit.

(1) Measure the resistance between terminals 50

and C.

Resistance:

Below 1

If the result is not as specified, replace the

repair service starter kit.

(c) Check if the hold-in coil has an open circuit.

(1) Measure the resistance between terminal 50

and the switch body.

Resistance:

Below 2

If the result is not as specified, replace the

repair service starter kit.

3. INSPECT STARTER ARMATURE ASSEMBLY

(a) Measure if the commutator has an open circuit.

(1) Check the resistance between the segments of

the commutator.

Resistance:

Below 1

If the result is not as specified, replace the

armature assembly.

(b) Check if the commutator is grounded.

(1) Measure the resistance between the

commutator and armature coil core.

Resistance:

10 k

or higher

If the result is not as specified, replace the

armature assembly.

(c) Check the commutator for contamination and burns

on its surface.

If the surface is dirty or burnt, correct it with

sandpaper (No. 400) or a lathe.

A058586

A079725E13

A079726E10

A058372E07

A058373E05

Page 1333 of 3000

ST–102GR-FE STARTING – STARTER

ST

(d) Using a vernier caliper, measure the commutator's

length.

Standard length:

3.3 to 4.0 mm (0.1299 to 0.1575 in.)

If the length is greater than the maximum, replace

the starter armature.

4. INSPECT STARTER COMMUTATOR END FRAME

ASSEMBLY

(a) Using a vernier caliper, measure the brush length.

Specified length:

4.0 to 9.0 mm (0.158 to 0.354 in.)

If the length is less than the minimum, replace the

starter commutator end frame.

(b) Check the brush insulation.

(1) Measure the resistance between the positive

(+) and negative (-) brush.

Resistance:

10 k

or higher

If the result is not as specified, repair or replace

starter commutator end frame.

5. INSPECT REPAIR SERVICE STARTER KIT

(a) Check the starter clutch.

(1) Rotate the clutch pinion gear counterclockwise

and check that it turns freely. Try to rotate the

clutch pinion gear clockwise and check that it

locks.

If necessary, replace the service starter kit.

REASSEMBLY

1. INSTALL PLANETARY GEAR

(a) Apply grease to the planetary gears and pin parts of

the planetary shaft.

(b) Install the 3 planetary gears.

A058584E01

A076677E01

A079766E11

A081655E01

A081656E01

Page 1335 of 3000

ST–122GR-FE STARTING – STARTER

ST

6. INSTALL STARTER YOKE ASSEMBLY

(a) Align the key of the starter yoke with the keyway of

repair service starter kit.

(b) Install the starter yoke with the 2 through bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

7. INSTALL REPAIR SERVICE STARTER KIT

(a) Apply grease to the plunger and the hook.

(b) Hang the plunger hook of the repair service starter

kit to the drive lever.

(c) Install the plunger and return spring.

(d) Install the repair service starter kit with the 2 screws.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

(e) Connect the lead wire to the repair service starter kit

with the nut.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A079728E01

A079720

A079729

A079719

A079718