engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1347 of 3000

2GR-FE CHARGING – CHARGING SYSTEMCH–7

CH

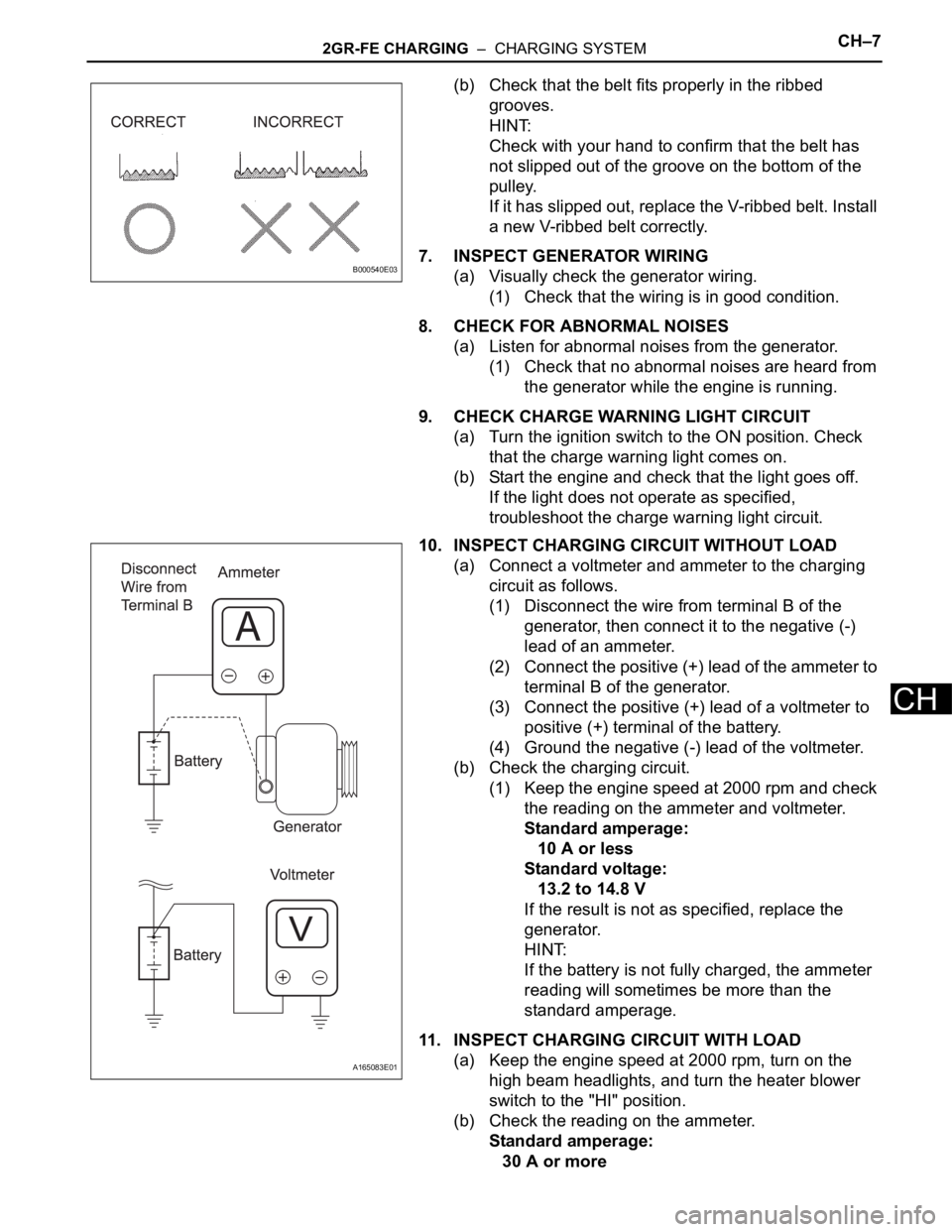

(b) Check that the belt fits properly in the ribbed

grooves.

HINT:

Check with your hand to confirm that the belt has

not slipped out of the groove on the bottom of the

pulley.

If it has slipped out, replace the V-ribbed belt. Install

a new V-ribbed belt correctly.

7. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

8. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from

the generator while the engine is running.

9. CHECK CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch to the ON position. Check

that the charge warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified,

troubleshoot the charge warning light circuit.

10. INSPECT CHARGING CIRCUIT WITHOUT LOAD

(a) Connect a voltmeter and ammeter to the charging

circuit as follows.

(1) Disconnect the wire from terminal B of the

generator, then connect it to the negative (-)

lead of an ammeter.

(2) Connect the positive (+) lead of the ammeter to

terminal B of the generator.

(3) Connect the positive (+) lead of a voltmeter to

positive (+) terminal of the battery.

(4) Ground the negative (-) lead of the voltmeter.

(b) Check the charging circuit.

(1) Keep the engine speed at 2000 rpm and check

the reading on the ammeter and voltmeter.

Standard amperage:

10 A or less

Standard voltage:

13.2 to 14.8 V

If the result is not as specified, replace the

generator.

HINT:

If the battery is not fully charged, the ammeter

reading will sometimes be more than the

standard amperage.

11. INSPECT CHARGING CIRCUIT WITH LOAD

(a) Keep the engine speed at 2000 rpm, turn on the

high beam headlights, and turn the heater blower

switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

B000540E03

A165083E01

Page 1349 of 3000

2GR-FE CHARGING – CHARGING SYSTEMCH–9

CH

INSPECTION PROCEDURE

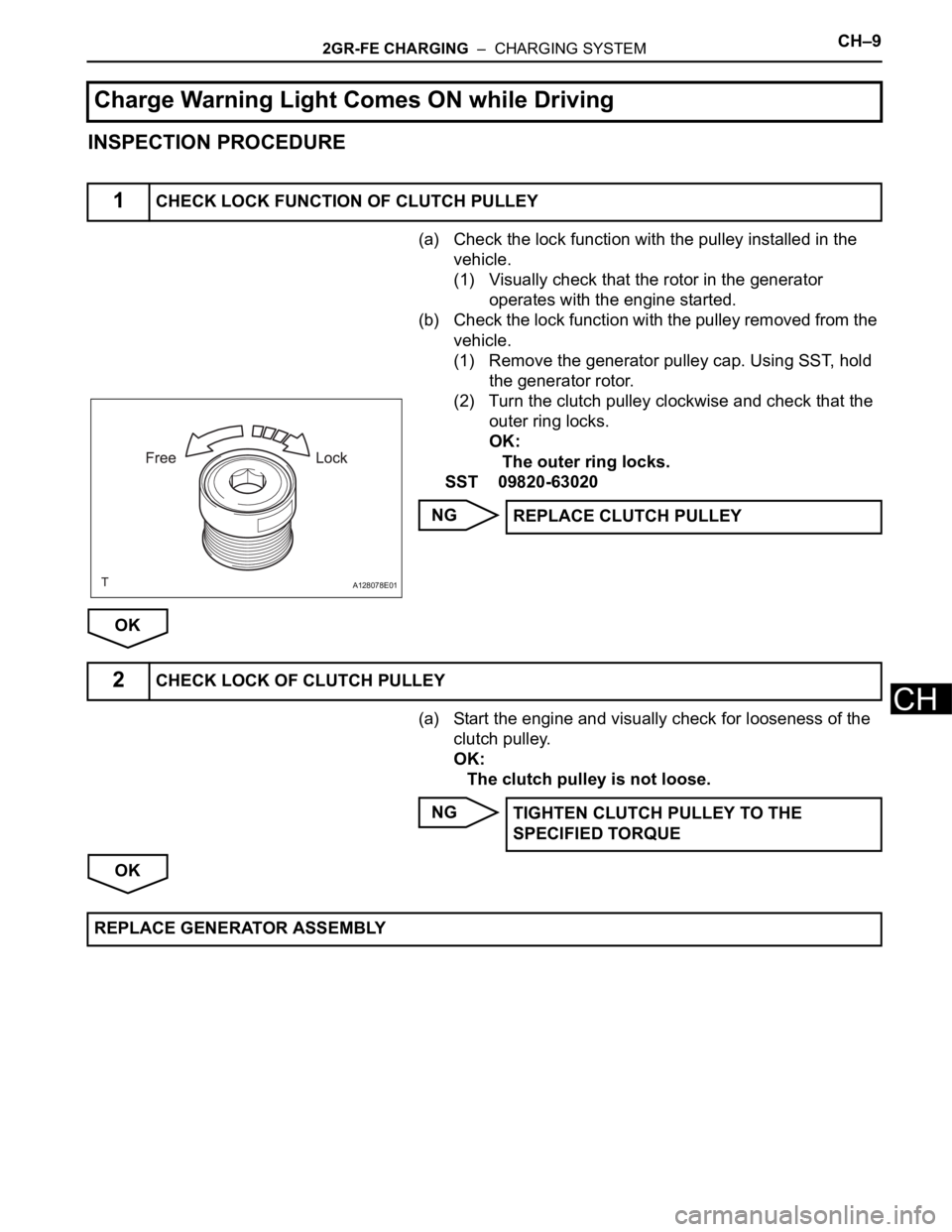

(a) Check the lock function with the pulley installed in the

vehicle.

(1) Visually check that the rotor in the generator

operates with the engine started.

(b) Check the lock function with the pulley removed from the

vehicle.

(1) Remove the generator pulley cap. Using SST, hold

the generator rotor.

(2) Turn the clutch pulley clockwise and check that the

outer ring locks.

OK:

The outer ring locks.

SST 09820-63020

NG

OK

(a) Start the engine and visually check for looseness of the

clutch pulley.

OK:

The clutch pulley is not loose.

NG

OK

Charge Warning Light Comes ON while Driving

1CHECK LOCK FUNCTION OF CLUTCH PULLEY

A128078E01

REPLACE CLUTCH PULLEY

2CHECK LOCK OF CLUTCH PULLEY

TIGHTEN CLUTCH PULLEY TO THE

SPECIFIED TORQUE

REPLACE GENERATOR ASSEMBLY

Page 1350 of 3000

CH–102GR-FE CHARGING – CHARGING SYSTEM

CH

INSPECTION PROCEDURE

(a) Check the tension of the belt by pushing it down with a

finger.

OK:

The tension of the belt is enough.

NG

OK

(a) Check the V-ribbed belt for wear.

OK:

The V-ribbed belt is not worn.

NG

OK

(a) Check the clutch pulley groove for wear or other defects.

OK:

The clutch pulley groove is not damaged.

NG

OK

(a) Perform a road test and check if noise occurs when

decelerating.

OK:

Noise does not occur.

NG

OK

Noise Occurs from Generator while Engine is Running

1CHECK LOOSENESS OF V-RIBBED BELT

REPLACE V-RIBBED BELT TENSIONER

ASSEMBLY

2CHECK V-RIBBED BELT FOR WEAR

REPLACE V-RIBBED BELT

3CHECK CLUTCH PULLEY FOR WEAR

REPLACE CLUTCH PULLEY

4CHECK FOR NOISE WHILE CLUTCH PULLEY IS OPERATING

REPLACE CLUTCH PULLEY

REPLACE GENERATOR ASSEMBLY

Page 1351 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)

Page 1356 of 3000

CH–162GR-FE CHARGING – GENERATOR

CH

REMOVAL

1. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER (See page

EM-26)

4. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

5. DRAIN ENGINE COOLANT (See page CO-6)

6. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

7. REMOVE BATTERY (See page EM-26)

8. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-3)

9. REMOVE FRONT BUMPER ENERGY ABSORBER

10. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

11. DISCONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-28)

12. DISCONNECT NO. 1 RADIATOR HOSE (See page CO-

28)

13. DISCONNECT NO. 2 RADIATOR HOSE (See page CO-

29)

14. REMOVE HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-29)

15. REMOVE HOOD LOCK ASSEMBLY (See page CO-29)

16. REMOVE HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-29)

17. DISCONNECT COOLING FAN ECU CONNECTOR

(See page CO-30)

18. REMOVE RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-30)

19. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY (See page CO-31)

20. REMOVE HEADLIGHT ASSEMBLY RH (See page LI-

69)

21. REMOVE RADIATOR SIDE DEFLECTOR RH (See

page CO-31)

22. REMOVE HEADLIGHT BRACKET RH (See page CO-

32)

23. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-32)

Page 1369 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1378 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1380 of 3000

AX–6U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The ECT (Electronic controlled automatic

transmission/transaxle) is an automatic

transmission/transaxle that electronically controls

shift timing using the ECM. The ECM detects

electrical signals that indicate engine and driving

conditions, and controls the shift point, based on

driver habits and road conditions. As a result, fuel

efficiency and power transmission performance are

improved.

Shift shock has been reduced by controlling the

engine and transmission simultaneously.

In addition, the ECT has features such as follows:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.

Page 1387 of 3000

AX–10U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the ATF temperature 50 to 80

C

(122 to 176

F) in the normal operation.

(a) D position test:

Shift into the D position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that 1

2, 2 3, 3 4 and 4 5th up-

shifts take place, and that the shift points

conform to the automatic shift schedule (See

page SS-24).

HINT:

5th Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 80 km/h (176

mph) or less.

• ATF temperature is -2

C (28F) or less.

4th Gear Up-shift Prohibition Control

• Coolant temperature is 47

C (117F) or less

and vehicle speed is at 55 km/h (34 mph) or

less.

5th and 4th Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Coolant temperature is 60

C (140F) or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3, 3

4 and 4 5th up-shifts.

(3) Check for abnormal noise and vibration.

Drive in the D position lock-up or 5th gear, and

check for abnormal noises and vibration.

HINT:

The check for the cause of abnormal noise and

vibration must be done very thoroughly as it

could also be due to loss of balance in the

differential, torque converter clutch, etc.

(4) Check kick-down operation.

Check that the possible kick-down vehicle speed

limits for 2nd to 1st, 3rd to 2nd, 4th to 3rd, 5th to

4th kick-downs conform to those indicated on

the automatic shift schedule while driving

through all gears with the shift lever in the D

position (See page SS-24).

(5) Check abnormal shock and slip at kick-down.

Page 1388 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–11

AX

(6) Check the lock-up mechanism.

• Drive in D position (5th gear), at a steady

speed (lock-up ON).

• Lightly depress the accelerator pedal and

check that the engine speed does not change

abruptly.

HINT:

• There is no lock-up in the 1st and 2nd gear.

• 4th lock-up operates while uphill-downhill

control is active in D position.

• 3rd lock-up operates while uphill-downhill

control is active in D position.

• ATF temperature is 120

C (248F) or more.

• If there is a big jump in engine speed, there is

no lock-up.

(b) 4 (O/D OFF) position test:

Shift into the 4 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2, 2 3 and 3 4 up-shift

take place and that the shift point conforms to

the automatic shift schedule (See page SS-24).

HINT:

There is no 5th up-shift in the 4 position.

(2) Check engine braking.

While driving in the 4 position and 4th gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(c) 3 position test:

Shift into the 3 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 and 2 3 up-shift take

place and that the shift point conforms to the

automatic shift schedule (See page SS-24).

HINT:

There is no 4th up-shift and lock-up in the 3

position.

(2) Check engine braking.

While running in the 3 position and 3rd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.