air filter TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 27 of 3000

EM–282GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

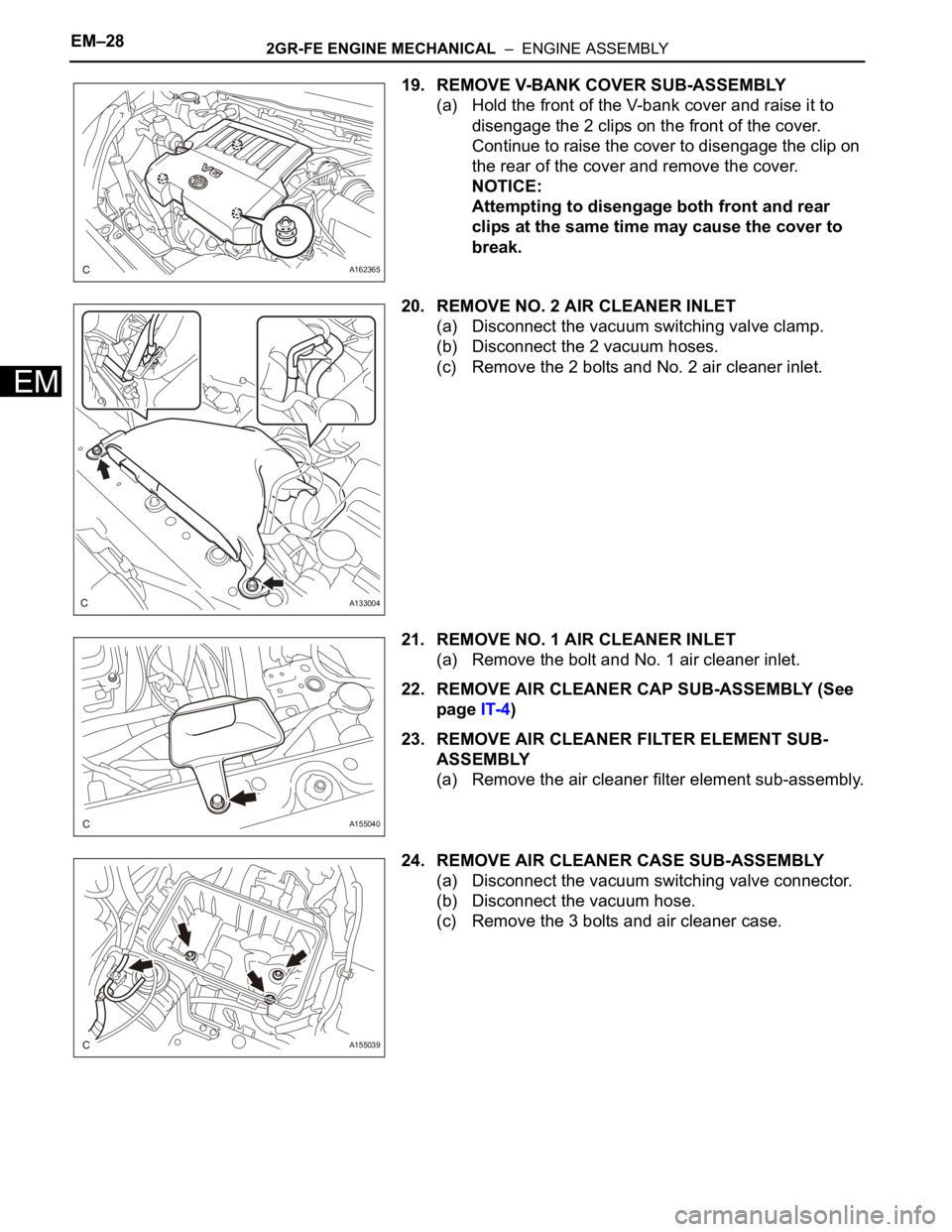

19. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Hold the front of the V-bank cover and raise it to

disengage the 2 clips on the front of the cover.

Continue to raise the cover to disengage the clip on

the rear of the cover and remove the cover.

NOTICE:

Attempting to disengage both front and rear

clips at the same time may cause the cover to

break.

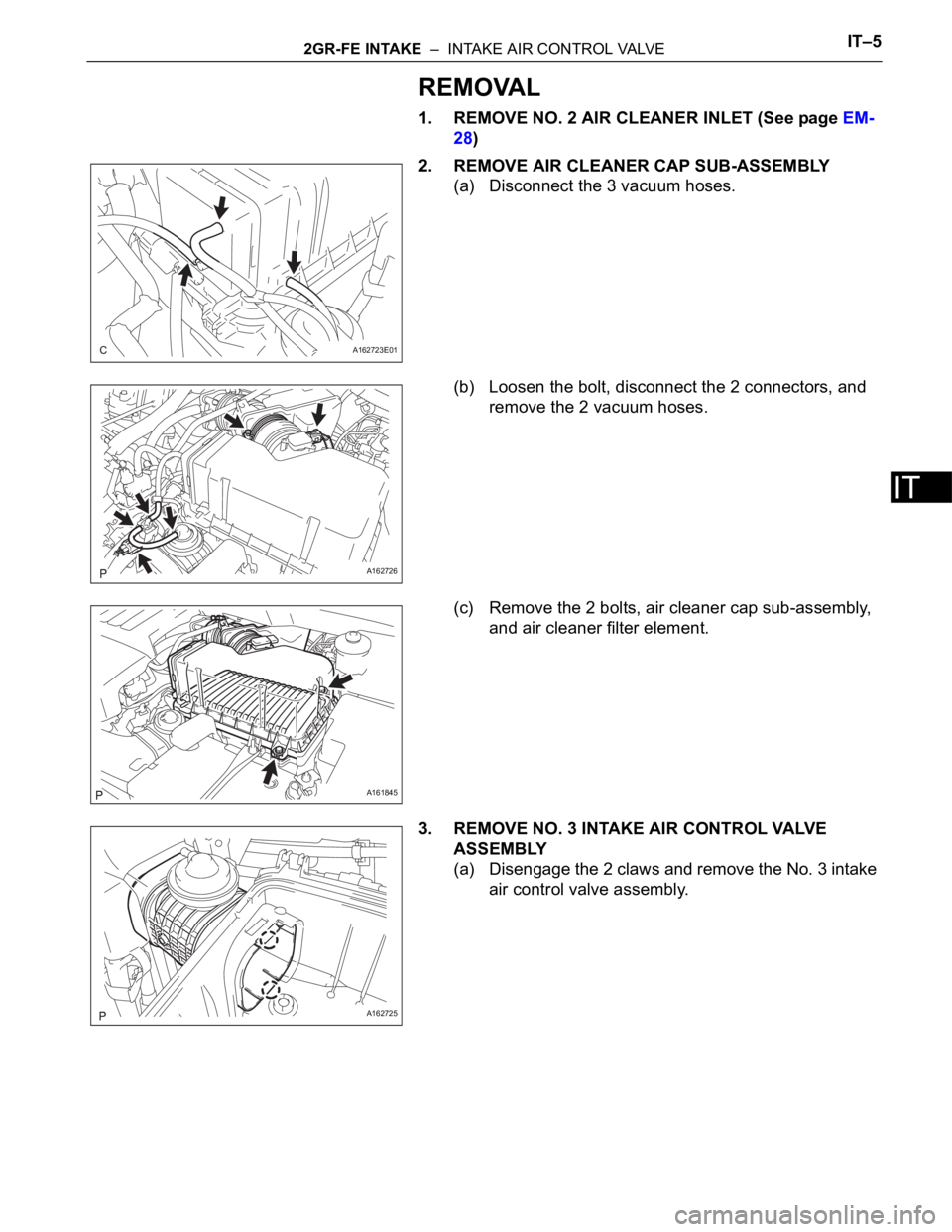

20. REMOVE NO. 2 AIR CLEANER INLET

(a) Disconnect the vacuum switching valve clamp.

(b) Disconnect the 2 vacuum hoses.

(c) Remove the 2 bolts and No. 2 air cleaner inlet.

21. REMOVE NO. 1 AIR CLEANER INLET

(a) Remove the bolt and No. 1 air cleaner inlet.

22. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page IT-4)

23. REMOVE AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

24. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

(a) Disconnect the vacuum switching valve connector.

(b) Disconnect the vacuum hose.

(c) Remove the 3 bolts and air cleaner case.

A162365

A133004

A155040

A155039

Page 46 of 3000

2GR-FE INTAKE – INTAKE AIR CONTROL VALVEIT–5

IT

REMOVAL

1. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

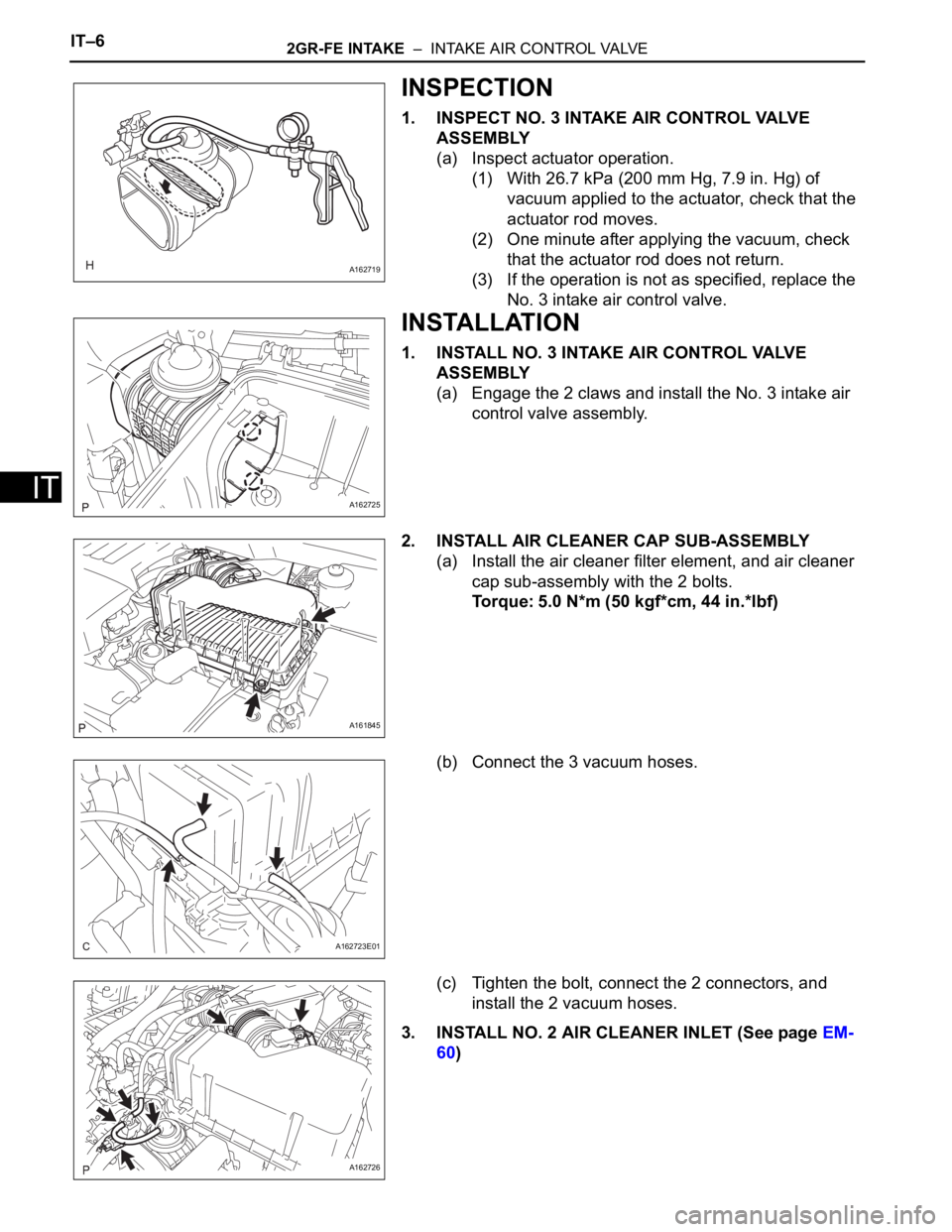

2. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

(b) Loosen the bolt, disconnect the 2 connectors, and

remove the 2 vacuum hoses.

(c) Remove the 2 bolts, air cleaner cap sub-assembly,

and air cleaner filter element.

3. REMOVE NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Disengage the 2 claws and remove the No. 3 intake

air control valve assembly.

A162723E01

A162726

A161845

A162725

Page 47 of 3000

IT–62GR-FE INTAKE – INTAKE AIR CONTROL VALVE

IT

INSPECTION

1. INSPECT NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Inspect actuator operation.

(1) With 26.7 kPa (200 mm Hg, 7.9 in. Hg) of

vacuum applied to the actuator, check that the

actuator rod moves.

(2) One minute after applying the vacuum, check

that the actuator rod does not return.

(3) If the operation is not as specified, replace the

No. 3 intake air control valve.

INSTALLATION

1. INSTALL NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Engage the 2 claws and install the No. 3 intake air

control valve assembly.

2. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the air cleaner filter element, and air cleaner

cap sub-assembly with the 2 bolts.

Torque: 5.0 N*m (50 kgf*cm, 44 in.*lbf)

(b) Connect the 3 vacuum hoses.

(c) Tighten the bolt, connect the 2 connectors, and

install the 2 vacuum hoses.

3. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

A162719

A162725

A161845

A162723E01

A162726

Page 58 of 3000

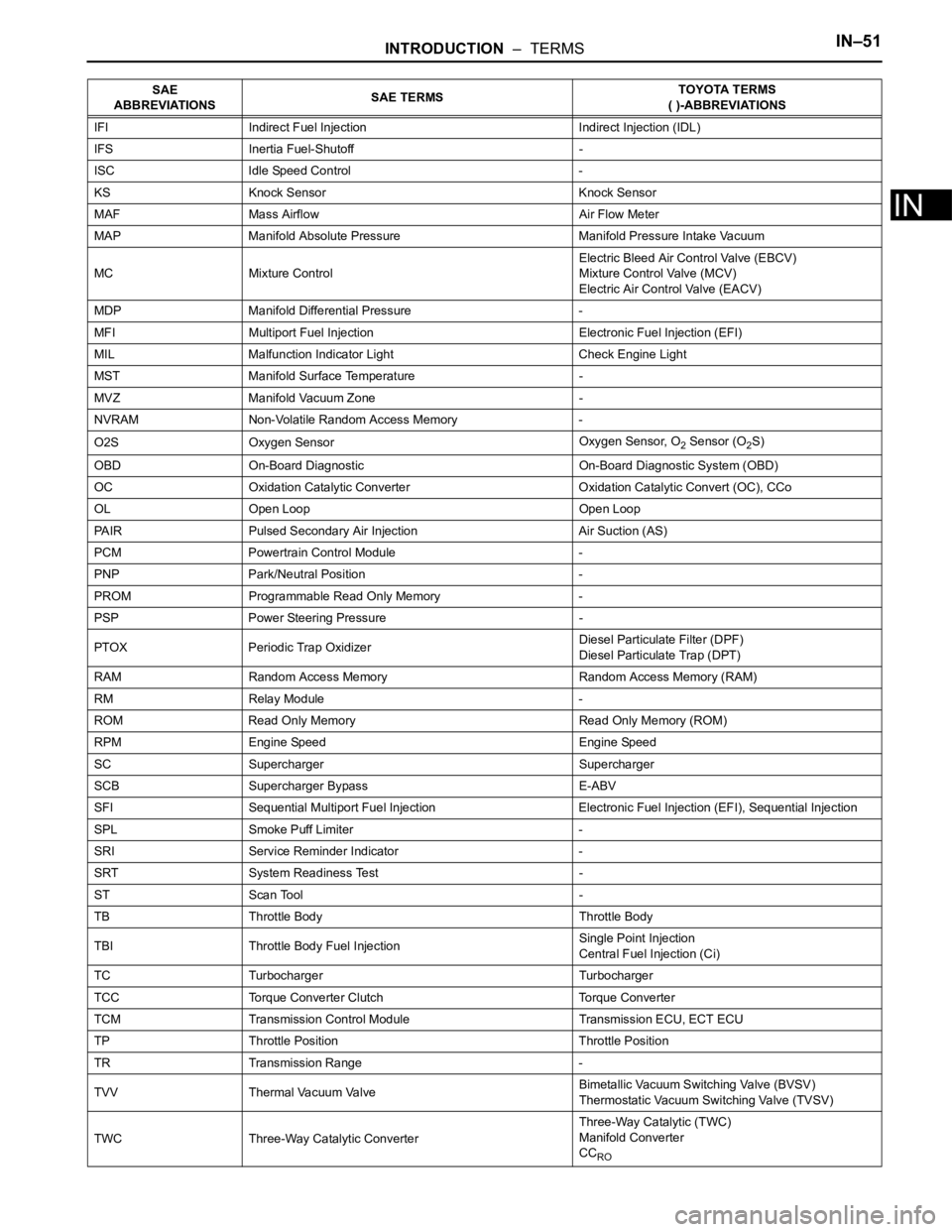

INTRODUCTION – TERMSIN–51

IN

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Light Check Engine Light

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen SensorOxygen Sensor, O

2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalytic Convert (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV)

TWC Three-Way Catalytic ConverterThree-Way Catalytic (TWC)

Manifold Converter

CC

RO

SAE

ABBREVIATIONSSAE TERMSTOYOTA TERMS

( )-ABBREVIATIONS

Page 83 of 3000

2GR-FE STARTING – STARTERST–5

ST

REMOVAL

1. REMOVE BATTERY (See page EM-26)

2. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

3. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page FU-13)

4. REMOVE AIR CLEANER FILTER ELEMENT (See page

EM-28)

5. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

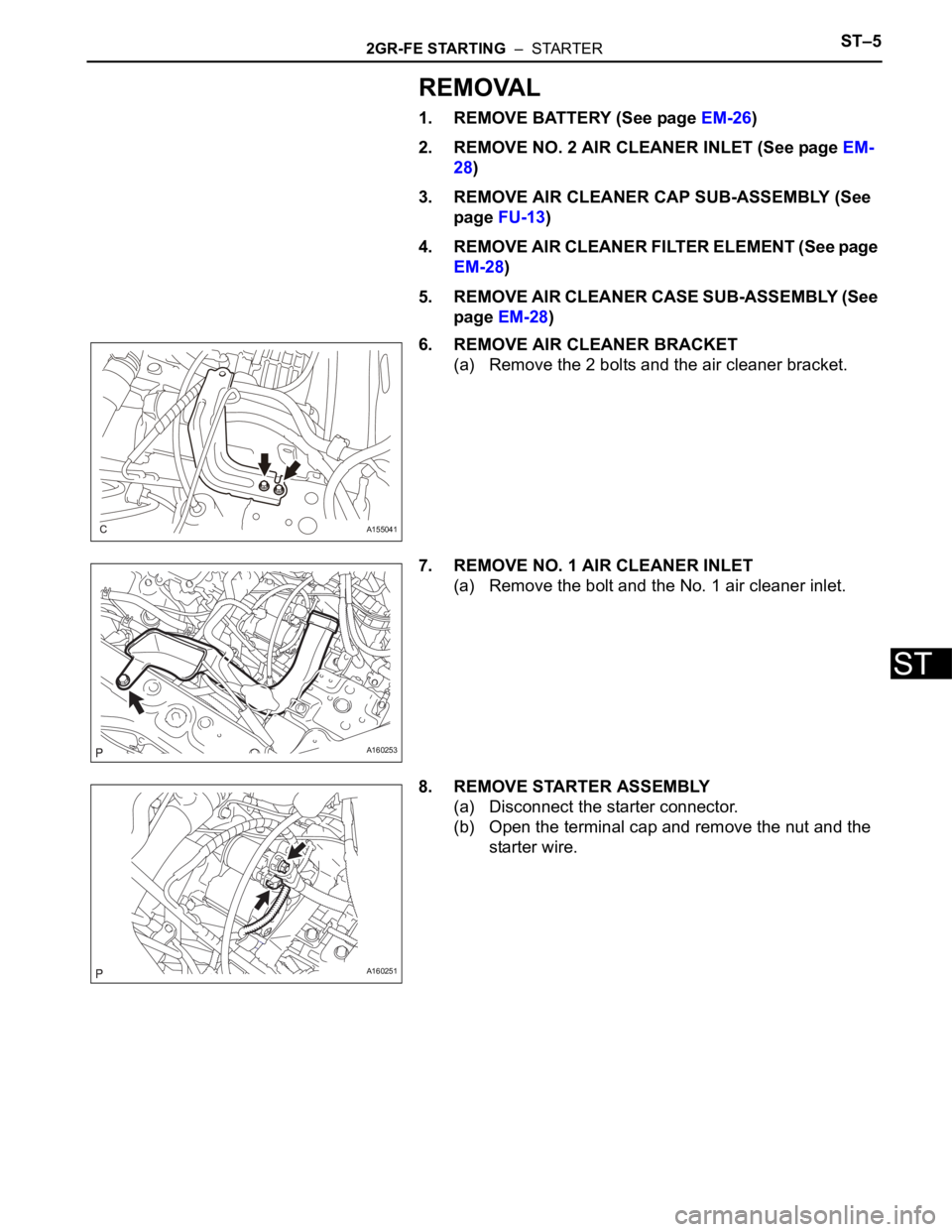

6. REMOVE AIR CLEANER BRACKET

(a) Remove the 2 bolts and the air cleaner bracket.

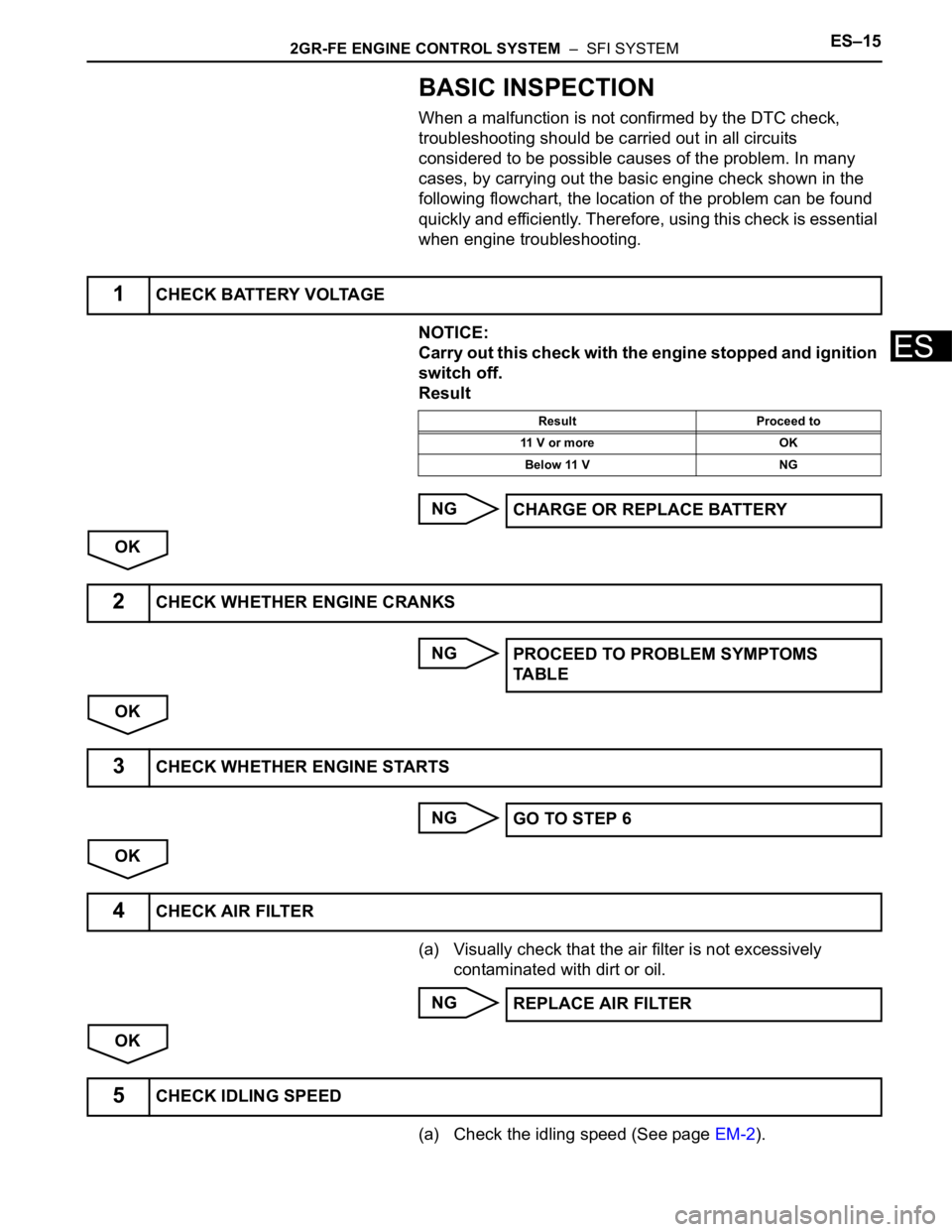

7. REMOVE NO. 1 AIR CLEANER INLET

(a) Remove the bolt and the No. 1 air cleaner inlet.

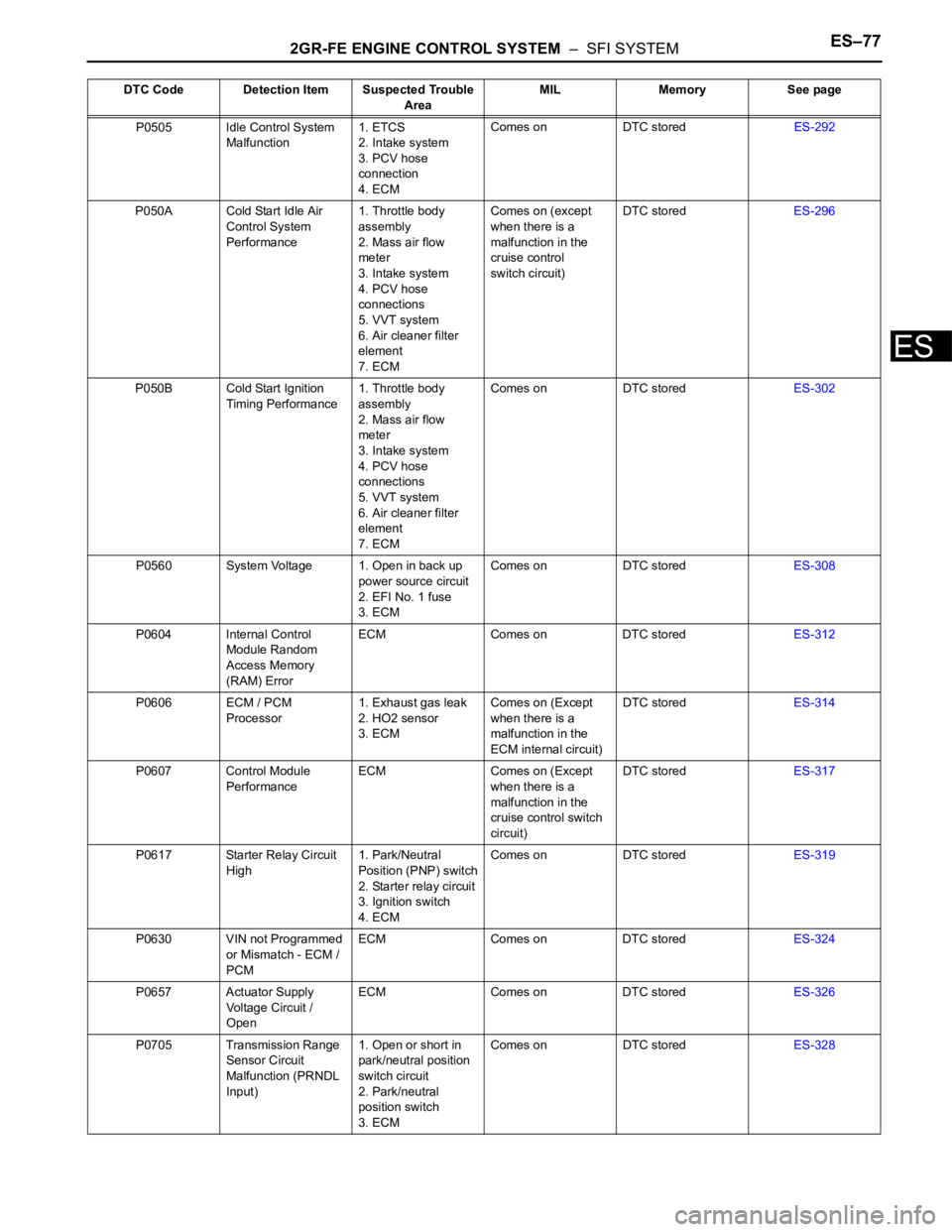

8. REMOVE STARTER ASSEMBLY

(a) Disconnect the starter connector.

(b) Open the terminal cap and remove the nut and the

starter wire.

A155041

A160253

A160251

Page 341 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–15

ES

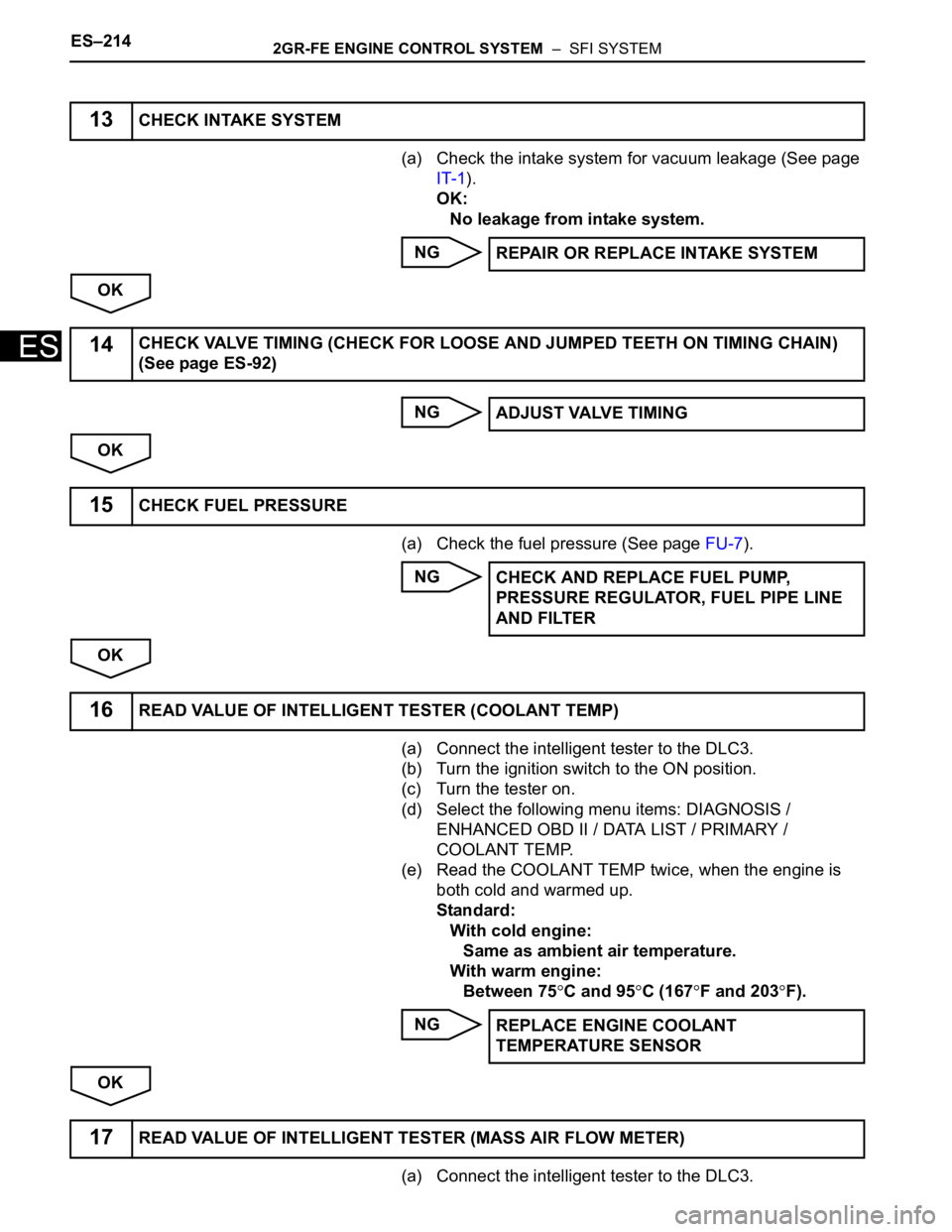

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when engine troubleshooting.

NOTICE:

Carry out this check with the engine stopped and ignition

switch off.

Result

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

(a) Check the idling speed (See page EM-2).

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE CRANKS

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

Page 383 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–77

ES

P0505 Idle Control System

Malfunction1. ETCS

2. Intake system

3. PCV hose

connection

4. ECMComes on DTC storedES-292

P050A Cold Start Idle Air

Control System

Performance1. Throttle body

assembly

2. Mass air flow

meter

3. Intake system

4. PCV hose

connections

5. VVT system

6. Air cleaner filter

element

7. ECMComes on (except

when there is a

malfunction in the

cruise control

switch circuit)DTC storedES-296

P050B Cold Start Ignition

Timing Performance1. Throttle body

assembly

2. Mass air flow

meter

3. Intake system

4. PCV hose

connections

5. VVT system

6. Air cleaner filter

element

7. ECMComes on DTC storedES-302

P0560 System Voltage 1. Open in back up

power source circuit

2. EFI No. 1 fuse

3. ECMComes on DTC storedES-308

P0604 Internal Control

Module Random

Access Memory

(RAM) ErrorECM Comes on DTC storedES-312

P0606 ECM / PCM

Processor1. Exhaust gas leak

2. HO2 sensor

3. ECMComes on (Except

when there is a

malfunction in the

ECM internal circuit)DTC storedES-314

P0607 Control Module

PerformanceECM Comes on (Except

when there is a

malfunction in the

cruise control switch

circuit)DTC storedES-317

P0617 Starter Relay Circuit

High1. Park/Neutral

Position (PNP) switch

2. Starter relay circuit

3. Ignition switch

4. ECMComes on DTC storedES-319

P0630 VIN not Programmed

or Mismatch - ECM /

PCMECM Comes on DTC storedES-324

P0657 Actuator Supply

Voltage Circuit /

OpenECM Comes on DTC storedES-326

P0705 Transmission Range

Sensor Circuit

Malfunction (PRNDL

Input)1. Open or short in

park/neutral position

switch circuit

2. Park/neutral

position switch

3. ECMComes on DTC storedES-328 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 520 of 3000

ES–2142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Check the intake system for vacuum leakage (See page

IT-1).

OK:

No leakage from intake system.

NG

OK

NG

OK

(a) Check the fuel pressure (See page FU-7).

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

COOLANT TEMP.

(e) Read the COOLANT TEMP twice, when the engine is

both cold and warmed up.

Standard:

With cold engine:

Same as ambient air temperature.

With warm engine:

Between 75

C and 95C (167F and 203F).

NG

OK

(a) Connect the intelligent tester to the DLC3.

13CHECK INTAKE SYSTEM

REPAIR OR REPLACE INTAKE SYSTEM

14CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN)

(See page ES-92)

ADJUST VALVE TIMING

15CHECK FUEL PRESSURE

CHECK AND REPLACE FUEL PUMP,

PRESSURE REGULATOR, FUEL PIPE LINE

AND FILTER

16READ VALUE OF INTELLIGENT TESTER (COOLANT TEMP)

REPLACE ENGINE COOLANT

TEMPERATURE SENSOR

17READ VALUE OF INTELLIGENT TESTER (MASS AIR FLOW METER)

Page 521 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–215

ES

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY / MAF and

COOLANT TEMP.

(e) Allow the engine to idle until the COOLANT TEMP

reaches 75

C (167F) or more.

(f) Read the MAF with the engine in an idling condition and

at an engine speed of 2500 rpm.

Standard:

MAF while engine is idling:

Between 1.8 g/s and 4.7 g/s (shift position: N, A/

C: OFF).

MAF at engine speed of 2500 rpm:

Between 7.4 g/s and 18.9 g/s (shift position: N, A/

C: OFF).

NG

OK

(a) Check the intake system for vacuum leakage (See page

IT-1).

OK:

No leakage from intake system.

NG

OK

NG

OK

(a) Check the fuel pressure (See page FU-7).

NG

OKREPLACE MASS AIR FLOW METER

REPLACE ECM

18CHECK INTAKE SYSTEM

REPAIR OR REPLACE INTAKE SYSTEM

19CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN)

(See page ES-92)

ADJUST VALVE TIMING

20CHECK FUEL PRESSURE

CHECK AND REPLACE FUEL PUMP,

PRESSURE REGULATOR, FUEL PIPE LINE

AND FILTER

Page 577 of 3000

ES–2842GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

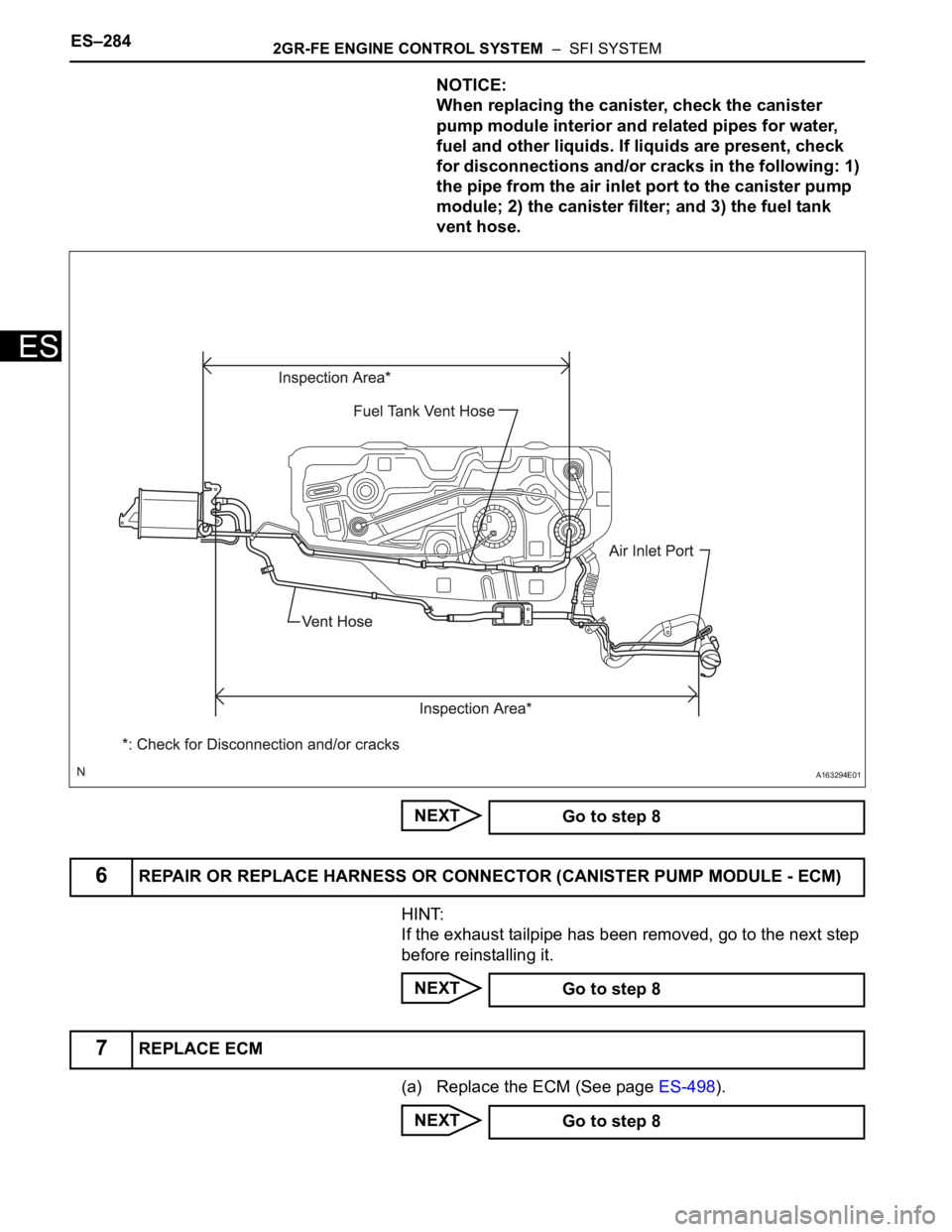

NOTICE:

When replacing the canister, check the canister

pump module interior and related pipes for water,

fuel and other liquids. If liquids are present, check

for disconnections and/or cracks in the following: 1)

the pipe from the air inlet port to the canister pump

module; 2) the canister filter; and 3) the fuel tank

vent hose.

NEXT

HINT:

If the exhaust tailpipe has been removed, go to the next step

before reinstalling it.

NEXT

(a) Replace the ECM (See page ES-498).

NEXT

A163294E01

Go to step 8

6REPAIR OR REPLACE HARNESS OR CONNECTOR (CANISTER PUMP MODULE - ECM)

Go to step 8

7REPLACE ECM

Go to step 8