change time TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 259 of 3000

AUDIO / VISUAL – AUDIO AND VISUAL SYSTEMAV – 7

AV

(f) File names

(1) Only files with an extension of ".mp3" or ".wma"

can be recognized and played as MP3 or WMA

files.

(2) Save MP3 or WMA files with an extension of

".mp3" or ".wma".

NOTICE:

If saving non-MP3 or non-WMA files with an

extension of ".mp3" or ".wma", those files

are wrongly recognized as MP3 or WMA files

and played. A loud noise may occur and

damage to the speaker may result.

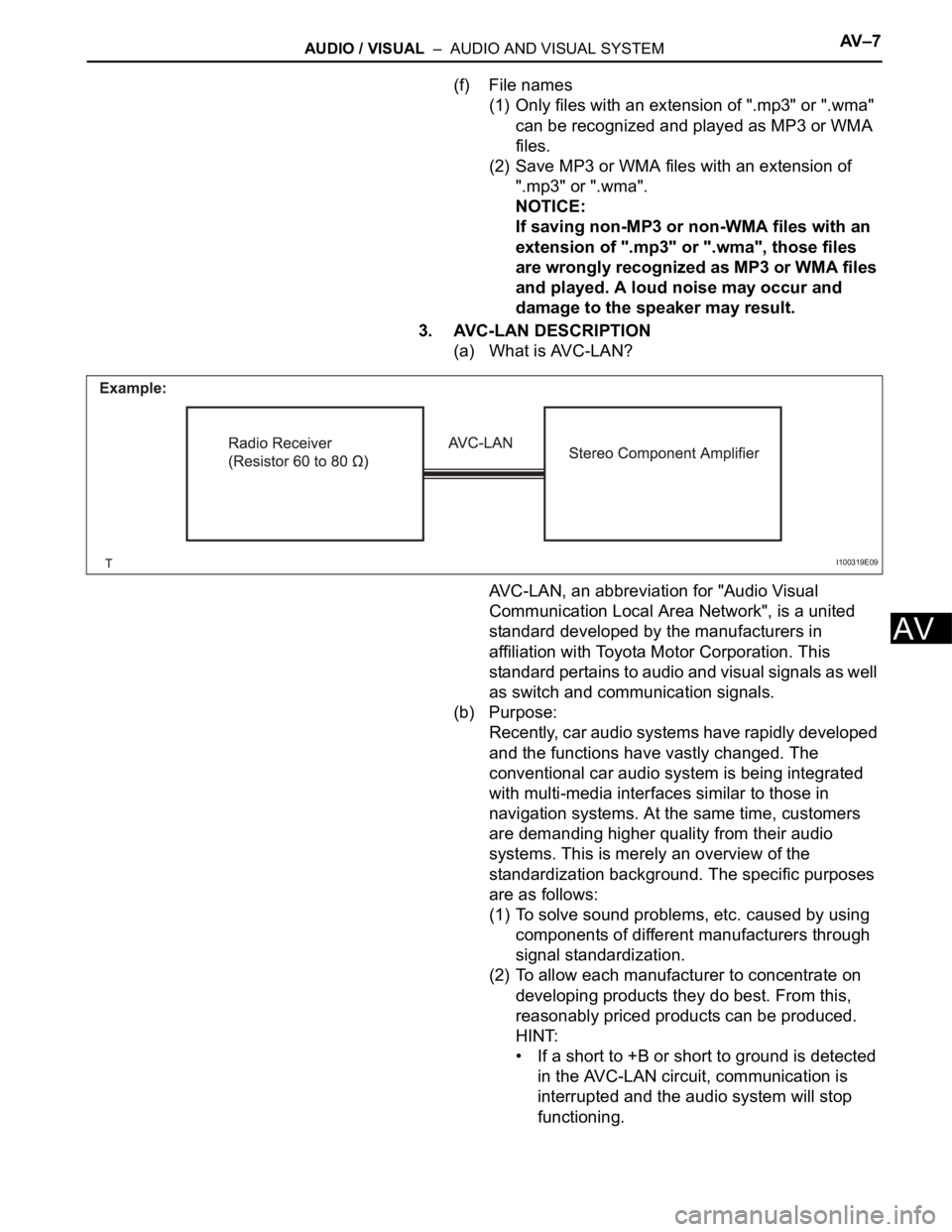

3. AVC-LAN DESCRIPTION

(a) What is AVC-LAN?

AVC-LAN, an abbreviation for "Audio Visual

Communication Local Area Network", is a united

standard developed by the manufacturers in

affiliation with Toyota Motor Corporation. This

standard pertains to audio and visual signals as well

as switch and communication signals.

(b) Purpose:

Recently, car audio systems have rapidly developed

and the functions have vastly changed. The

conventional car audio system is being integrated

with multi-media interfaces similar to those in

navigation systems. At the same time, customers

are demanding higher quality from their audio

systems. This is merely an overview of the

standardization background. The specific purposes

are as follows:

(1) To solve sound problems, etc. caused by using

components of different manufacturers through

signal standardization.

(2) To allow each manufacturer to concentrate on

developing products they do best. From this,

reasonably priced products can be produced.

HINT:

• If a short to +B or short to ground is detected

in the AVC-LAN circuit, communication is

interrupted and the audio system will stop

functioning.

I100319E09

Page 275 of 3000

NS–14NAVIGATION – NAVIGATION SYSTEM

NS

(b) Purpose:

Recently, car audio systems have rapidly developed

and the functions have vastly changed. The

conventional car audio system is being integrated

with multi-media interfaces similar to those in

navigation systems. At the same time, customers

are demanding higher quality from their audio

systems. This is merely an overview of the

standardization background. The specific purposes

are as follows:

(1) To solve sound problems, etc. caused by using

components of different manufacturers through

signal standardization.

(2) To allow each manufacturer to concentrate on

developing products they do best. From this,

reasonably priced products can be produced.

HINT:

• If a short to +B or short to ground is detected

in the AVC-LAN circuit, communication is

interrupted and the audio system will stop

functioning.

• If an audio system is equipped with a

navigation system, the multi-display unit acts

as the master unit.

If the navigation system is not equipped, the

audio head unit acts as the master unit

instead. If the radio and navigation assembly

is equipped, it is the master unit.

• The radio and navigation assembly contains

a resistor that is necessary to enable

communication on the different AVC-LAN

circuits.

• The car audio system with an AVC-LAN

circuit has a diagnostic function.

• Each component has a specified number (3-

digit) called a physical address. Each function

has a number (2-digit) called a logical

address.

7. Communication system outline

(a) Components of the navigation system communicate

with each other via the AVC-LAN.

(b) The radio and navigation assembly has enough

resistance (60 to 80

) necessary for

communication.

(c) If a short circuit or open circuit occurs in the AVC-

LAN circuit, communication is interrupted and the

navigation system will stop functioning.

8. Diagnostic function outline

(a) The audio system has a diagnostic function (the

result is indicated on the master unit).

(b) A 3-digit hexadecimal component code (physical

address) is allocated to each component on the

AVC-LAN. Using this code, the component in the

diagnostic function can be displayed.

Page 354 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 395 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–89

ES

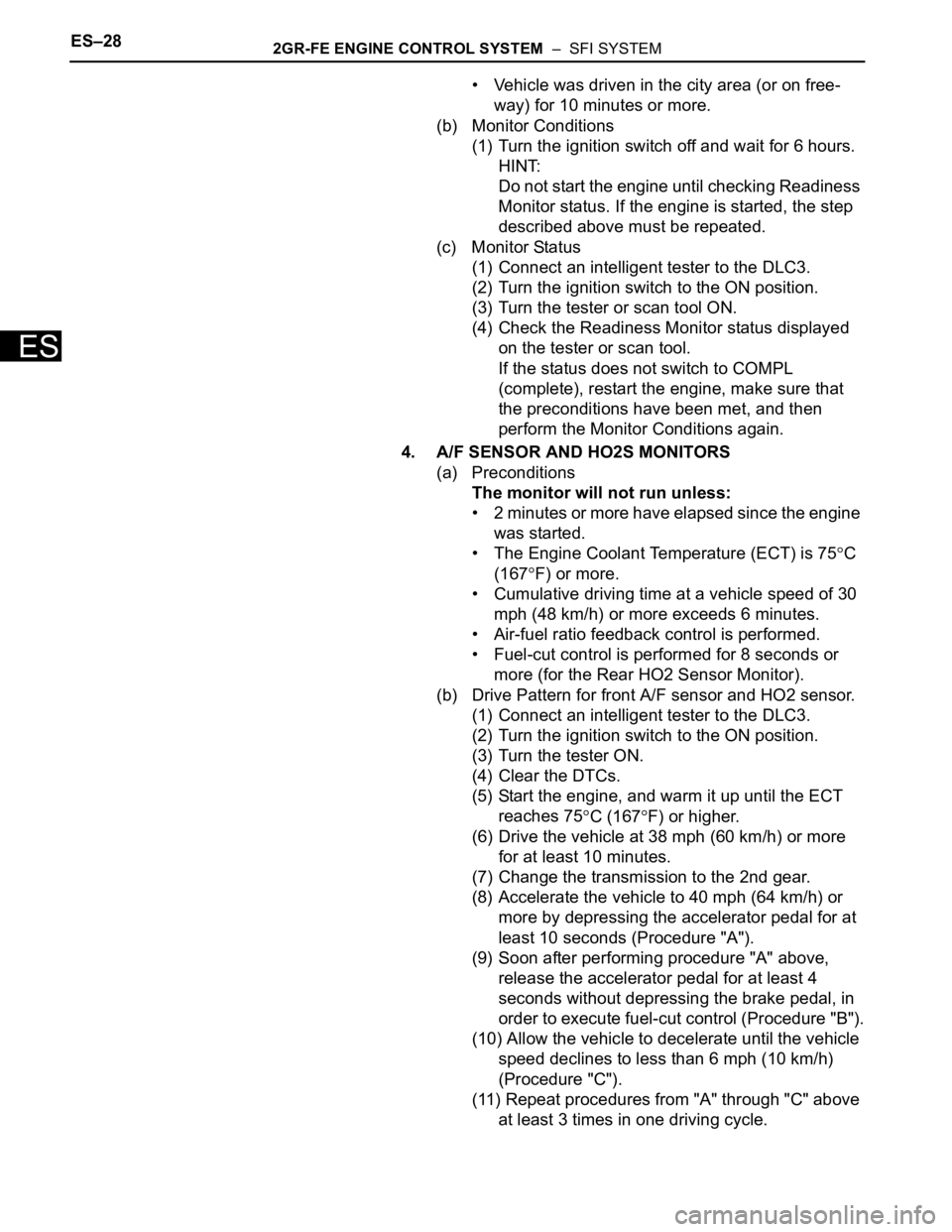

3) After above conditions 1) and 2) are met, the OCV is forcibly activated 63 times or more.

DTCs P0011 and P0021 (Advanced Cam Timing) are detected with 1 trip detection logic.

DTCs P0012 and P0022 (Retarded Cam Timing) are detected with 2 trip detection logic.

These DTCs indicate that the VVT controller cannot operate properly due to OCV malfunctions or the

presence of foreign objects in the OCV.

The monitor will not run unless the following conditions are met:

- The engine is warm (the engine coolant temperature is 75

C [167F] or more).

- The vehicle has been driven at more than 40 mph (64 km/h) for 3 minutes.

- The engine has idled for 3 minutes.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

P0011, P0021:

P0012, P0022:

If the difference between the target and actual camshaft timings is greater than the specified value, the

ECM operates the VVT actuator.

Then, the ECM monitors the camshaft timing change for 5 seconds.

WIRING DIAGRAM

Refer to DTC P0010 (See page ES-77).

INSPECTION PROCEDURE

Related DTCsP0011: Advanced intake camshaft timing (bank 1)

P0012: Retarded intake camshaft timing (bank 1)

P0021: Advanced intake camshaft timing (bank 2)

P0022: Retarded intake camshaft timing (bank 2)

Required sensors / components (Main) VVT OCV, VVT Actuator

Required sensors / components (Related) Crankshaft position sensor, Camshaft position sensor, ECT sensor

Frequency of operation Once per driving cycles

Duration Less than 10 seconds

MIL operationP0011 and P0021: Immediate

P0012 and P0022: 2 driving cycles

Sequence operation None

The monitor will run whenever these DTCs are not

presentP0100, P0101, P0102, P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT

Sensor), P0125 (Insufficient ECT for Closed Loop), P0335 (CKP Sensor), P0340

(CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356 (Ignitor)

Battery voltage 11 V or more

Engine RPM 500 to 4000 rpm

ECT 75 to 100

C (167 to 212F)

Duration of actual valve timing and target valve timing More than 5

CA (Crankshaft angle)

Valve timing No change in advanced valve timing

Duration of actual valve timing and target valve timing More than 5

CA (Crankshaft angle)

Valve timing No change in retarded valve timing

Abnormal bankAdvanced timing over

(Valve timing is out of specified range)Retarded timing over

(Valve timing is out of specified range)

Bank 1 P0011 P0012

Bank 2 P0021 P0022

Page 445 of 3000

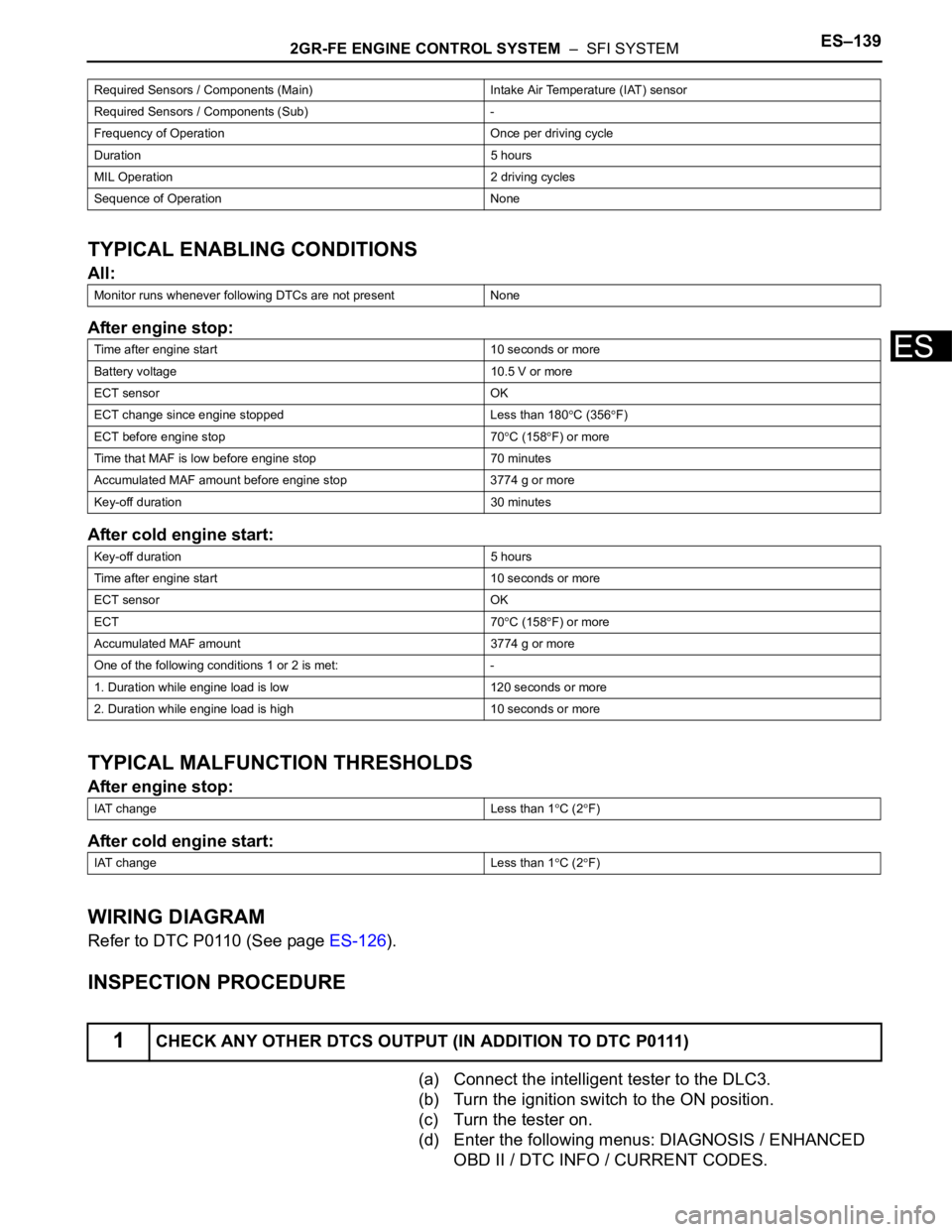

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–139

ES

TYPICAL ENABLING CONDITIONS

All:

After engine stop:

After cold engine start:

TYPICAL MALFUNCTION THRESHOLDS

After engine stop:

After cold engine start:

WIRING DIAGRAM

Refer to DTC P0110 (See page ES-126).

INSPECTION PROCEDURE

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Enter the following menus: DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CURRENT CODES.

Required Sensors / Components (Main) Intake Air Temperature (IAT) sensor

Required Sensors / Components (Sub) -

Frequency of Operation Once per driving cycle

Duration 5 hours

MIL Operation 2 driving cycles

Sequence of Operation None

Monitor runs whenever following DTCs are not present None

Time after engine start 10 seconds or more

Battery voltage 10.5 V or more

ECT sensor OK

ECT change since engine stopped Less than 180

C (356F)

ECT before engine stop 70

C (158F) or more

Time that MAF is low before engine stop 70 minutes

Accumulated MAF amount before engine stop 3774 g or more

Key-off duration 30 minutes

Key-off duration 5 hours

Time after engine start 10 seconds or more

ECT sensor OK

ECT 70

C (158F) or more

Accumulated MAF amount 3774 g or more

One of the following conditions 1 or 2 is met: -

1. Duration while engine load is low 120 seconds or more

2. Duration while engine load is high 10 seconds or more

IAT change Less than 1

C (2F)

IAT change Less than 1

C (2F)

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0111)

Page 454 of 3000

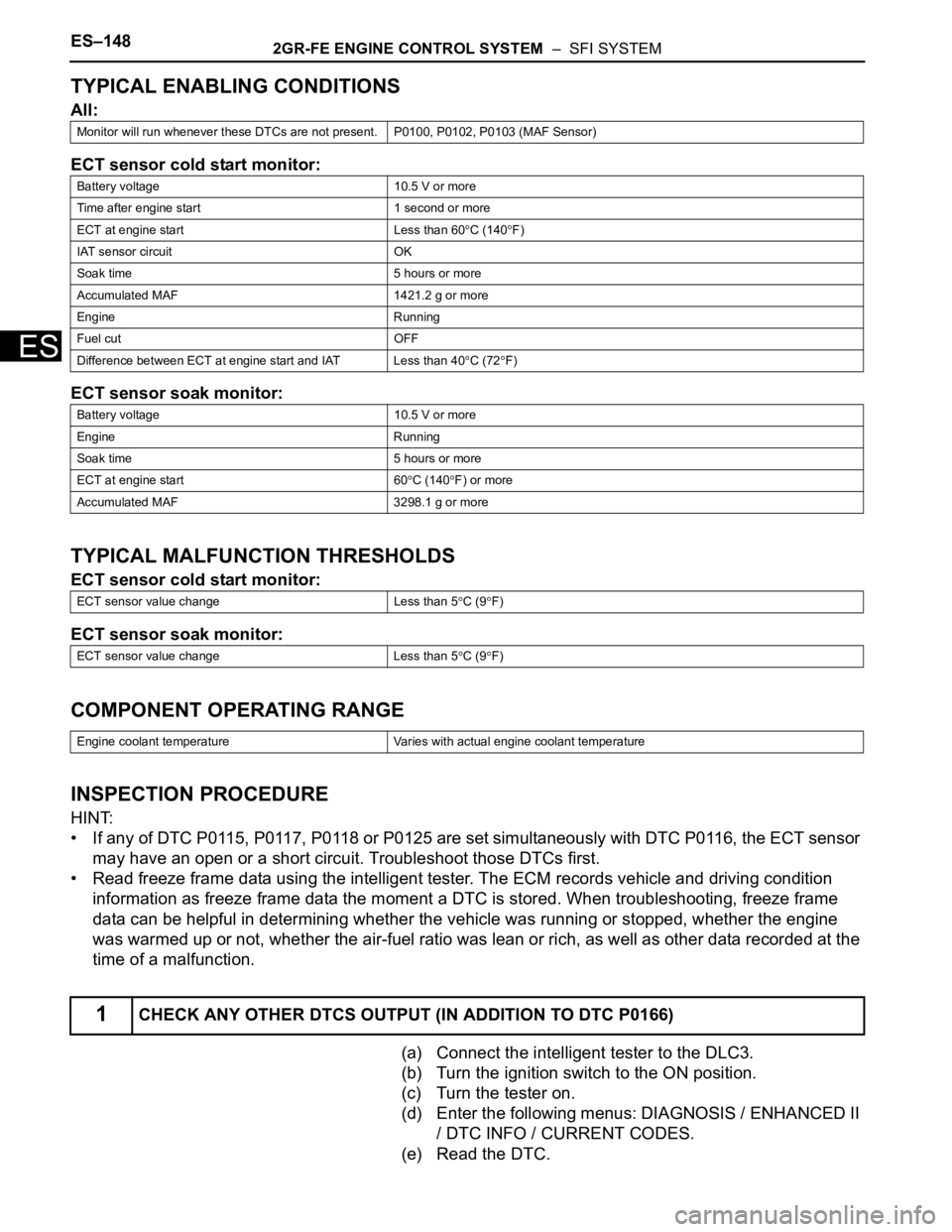

ES–1482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

TYPICAL ENABLING CONDITIONS

All:

ECT sensor cold start monitor:

ECT sensor soak monitor:

TYPICAL MALFUNCTION THRESHOLDS

ECT sensor cold start monitor:

ECT sensor soak monitor:

COMPONENT OPERATING RANGE

INSPECTION PROCEDURE

HINT:

• If any of DTC P0115, P0117, P0118 or P0125 are set simultaneously with DTC P0116, the ECT sensor

may have an open or a short circuit. Troubleshoot those DTCs first.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Enter the following menus: DIAGNOSIS / ENHANCED II

/ DTC INFO / CURRENT CODES.

(e) Read the DTC.

Monitor will run whenever these DTCs are not present. P0100, P0102, P0103 (MAF Sensor)

Battery voltage 10.5 V or more

Time after engine start 1 second or more

ECT at engine start Less than 60

C (140F)

IAT sensor circuit OK

Soak time 5 hours or more

Accumulated MAF 1421.2 g or more

Engine Running

Fuel cut OFF

Difference between ECT at engine start and IAT Less than 40

C (72F)

Battery voltage 10.5 V or more

Engine Running

Soak time 5 hours or more

ECT at engine start 60

C (140F) or more

Accumulated MAF 3298.1 g or more

ECT sensor value change Less than 5

C (9F)

ECT sensor value change Less than 5

C (9F)

Engine coolant temperature Varies with actual engine coolant temperature

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0166)

Page 482 of 3000

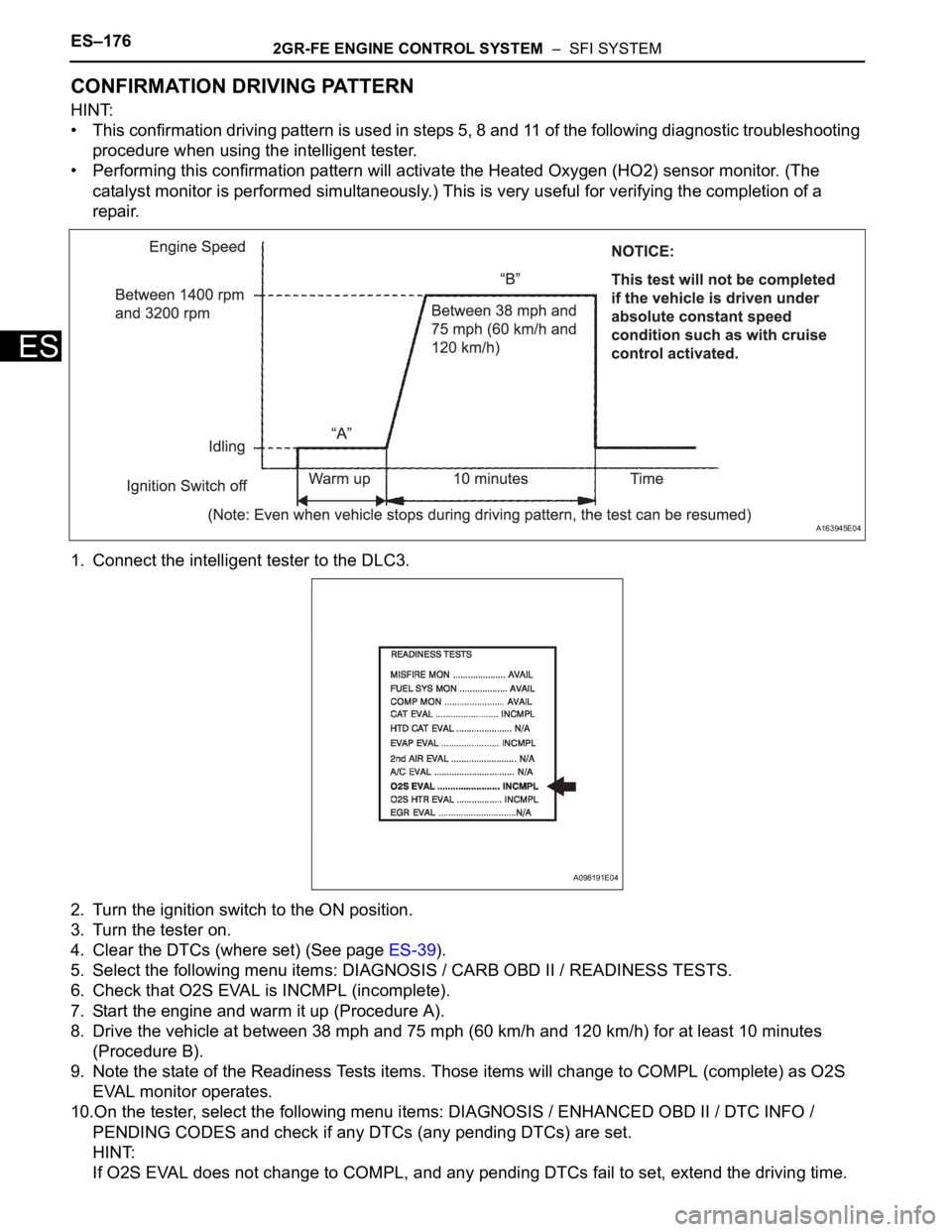

ES–1762GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

CONFIRMATION DRIVING PATTERN

HINT:

• This confirmation driving pattern is used in steps 5, 8 and 11 of the following diagnostic troubleshooting

procedure when using the intelligent tester.

• Performing this confirmation pattern will activate the Heated Oxygen (HO2) sensor monitor. (The

catalyst monitor is performed simultaneously.) This is very useful for verifying the completion of a

repair.

1. Connect the intelligent tester to the DLC3.

2. Turn the ignition switch to the ON position.

3. Turn the tester on.

4. Clear the DTCs (where set) (See page ES-39).

5. Select the following menu items: DIAGNOSIS / CARB OBD II / READINESS TESTS.

6. Check that O2S EVAL is INCMPL (incomplete).

7. Start the engine and warm it up (Procedure A).

8. Drive the vehicle at between 38 mph and 75 mph (60 km/h and 120 km/h) for at least 10 minutes

(Procedure B).

9. Note the state of the Readiness Tests items. Those items will change to COMPL (complete) as O2S

EVAL monitor operates.

10.On the tester, select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES and check if any DTCs (any pending DTCs) are set.

HINT:

If O2S EVAL does not change to COMPL, and any pending DTCs fail to set, extend the driving time.

A163945E04

A098191E04

Page 494 of 3000

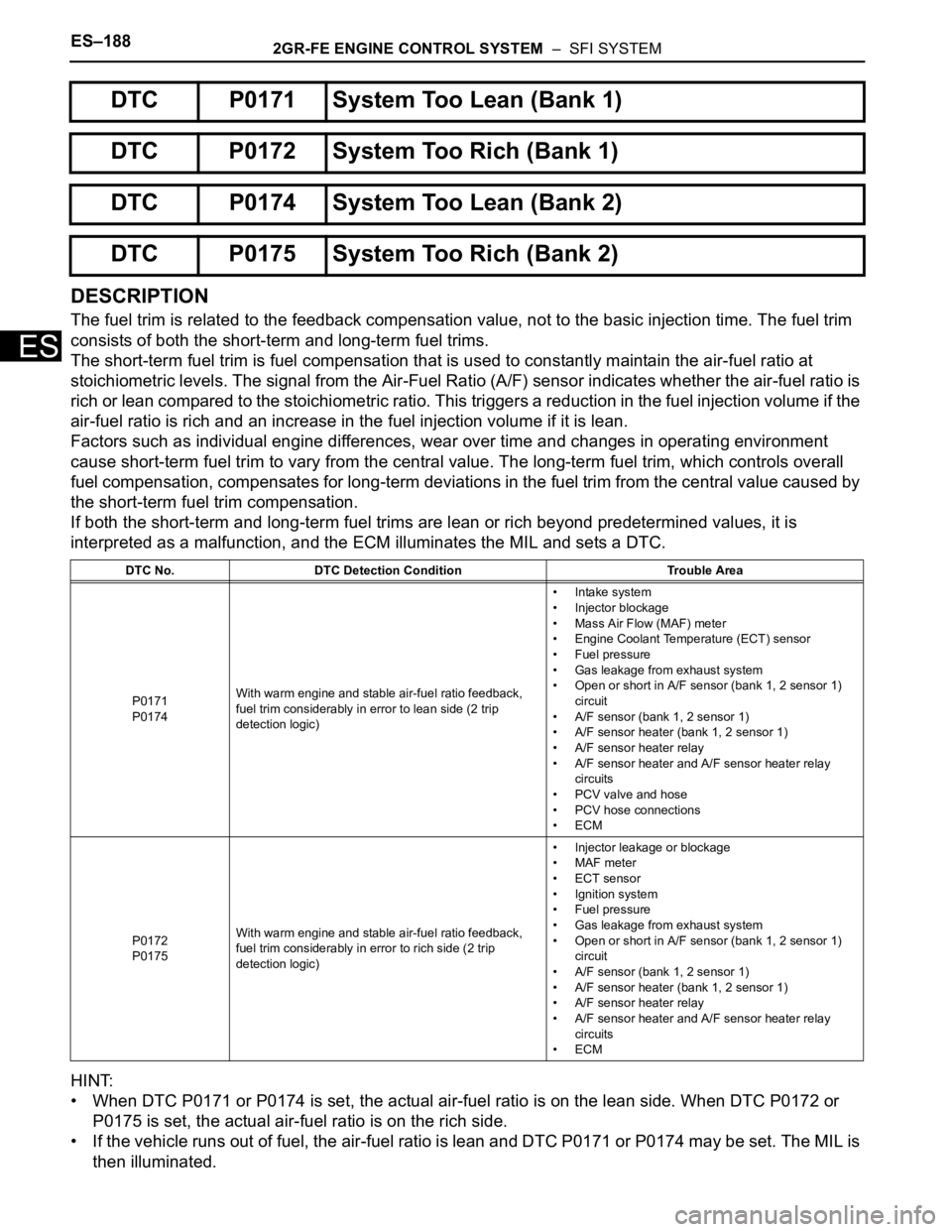

ES–1882GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

The fuel trim is related to the feedback compensation value, not to the basic injection time. The fuel trim

consists of both the short-term and long-term fuel trims.

The short-term fuel trim is fuel compensation that is used to constantly maintain the air-fuel ratio at

stoichiometric levels. The signal from the Air-Fuel Ratio (A/F) sensor indicates whether the air-fuel ratio is

rich or lean compared to the stoichiometric ratio. This triggers a reduction in the fuel injection volume if the

air-fuel ratio is rich and an increase in the fuel injection volume if it is lean.

Factors such as individual engine differences, wear over time and changes in operating environment

cause short-term fuel trim to vary from the central value. The long-term fuel trim, which controls overall

fuel compensation, compensates for long-term deviations in the fuel trim from the central value caused by

the short-term fuel trim compensation.

If both the short-term and long-term fuel trims are lean or rich beyond predetermined values, it is

interpreted as a malfunction, and the ECM illuminates the MIL and sets a DTC.

HINT:

• When DTC P0171 or P0174 is set, the actual air-fuel ratio is on the lean side. When DTC P0172 or

P0175 is set, the actual air-fuel ratio is on the rich side.

• If the vehicle runs out of fuel, the air-fuel ratio is lean and DTC P0171 or P0174 may be set. The MIL is

then illuminated.

DTC P0171 System Too Lean (Bank 1)

DTC P0172 System Too Rich (Bank 1)

DTC P0174 System Too Lean (Bank 2)

DTC P0175 System Too Rich (Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0171

P0174With warm engine and stable air-fuel ratio feedback,

fuel trim considerably in error to lean side (2 trip

detection logic)• Intake system

• Injector blockage

• Mass Air Flow (MAF) meter

• Engine Coolant Temperature (ECT) sensor

• Fuel pressure

• Gas leakage from exhaust system

• Open or short in A/F sensor (bank 1, 2 sensor 1)

circuit

• A/F sensor (bank 1, 2 sensor 1)

• A/F sensor heater (bank 1, 2 sensor 1)

• A/F sensor heater relay

• A/F sensor heater and A/F sensor heater relay

circuits

• PCV valve and hose

• PCV hose connections

•ECM

P0172

P0175With warm engine and stable air-fuel ratio feedback,

fuel trim considerably in error to rich side (2 trip

detection logic)• Injector leakage or blockage

• MAF meter

• ECT sensor

• Ignition system

• Fuel pressure

• Gas leakage from exhaust system

• Open or short in A/F sensor (bank 1, 2 sensor 1)

circuit

• A/F sensor (bank 1, 2 sensor 1)

• A/F sensor heater (bank 1, 2 sensor 1)

• A/F sensor heater relay

• A/F sensor heater and A/F sensor heater relay

circuits

•ECM

Page 540 of 3000

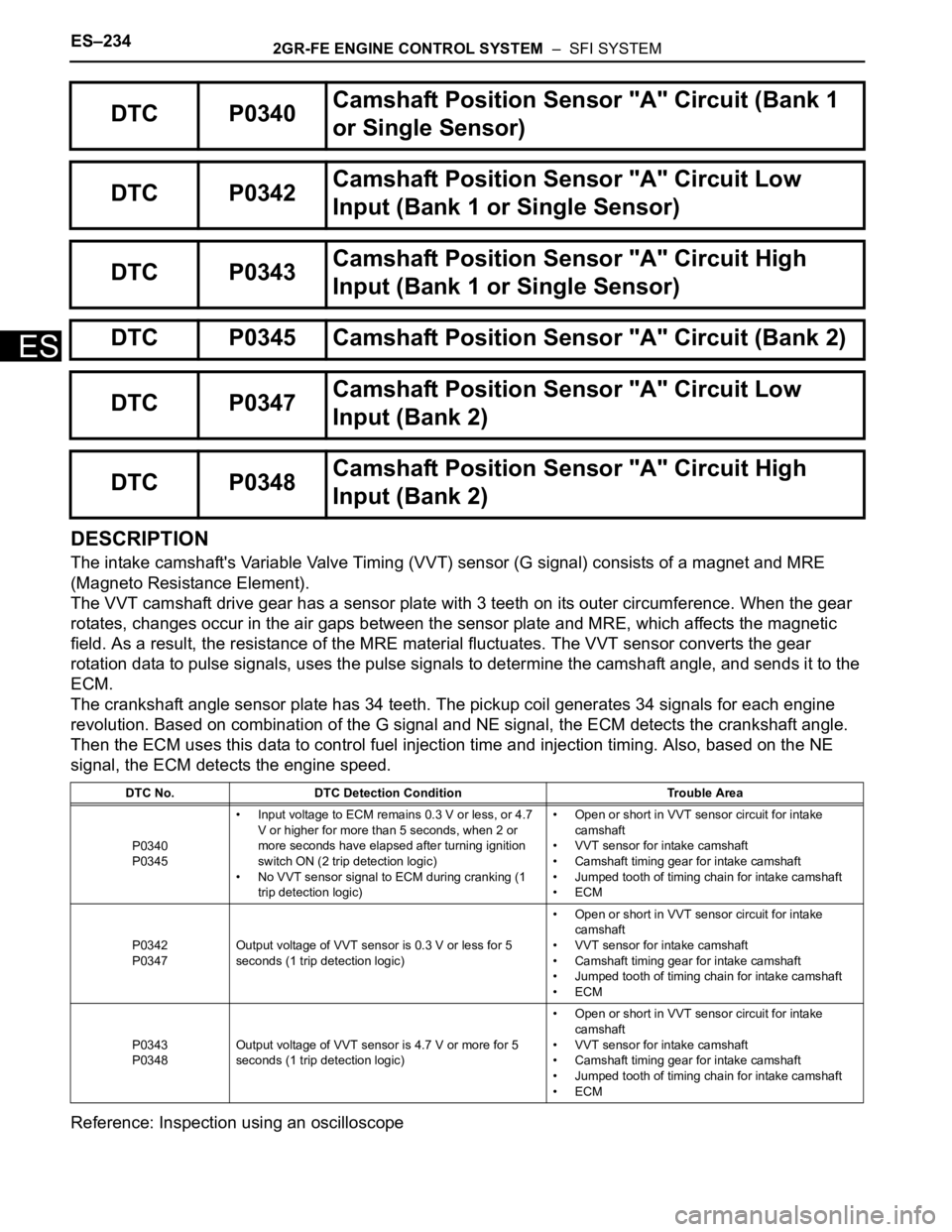

ES–2342GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

The intake camshaft's Variable Valve Timing (VVT) sensor (G signal) consists of a magnet and MRE

(Magneto Resistance Element).

The VVT camshaft drive gear has a sensor plate with 3 teeth on its outer circumference. When the gear

rotates, changes occur in the air gaps between the sensor plate and MRE, which affects the magnetic

field. As a result, the resistance of the MRE material fluctuates. The VVT sensor converts the gear

rotation data to pulse signals, uses the pulse signals to determine the camshaft angle, and sends it to the

ECM.

The crankshaft angle sensor plate has 34 teeth. The pickup coil generates 34 signals for each engine

revolution. Based on combination of the G signal and NE signal, the ECM detects the crankshaft angle.

Then the ECM uses this data to control fuel injection time and injection timing. Also, based on the NE

signal, the ECM detects the engine speed.

Reference: Inspection using an oscilloscope

DTC P0340Camshaft Position Sensor "A" Circuit (Bank 1

or Single Sensor)

DTC P0342Camshaft Position Sensor "A" Circuit Low

Input (Bank 1 or Single Sensor)

DTC P0343Camshaft Position Sensor "A" Circuit High

Input (Bank 1 or Single Sensor)

DTC P0345 Camshaft Position Sensor "A" Circuit (Bank 2)

DTC P0347Camshaft Position Sensor "A" Circuit Low

Input (Bank 2)

DTC P0348Camshaft Position Sensor "A" Circuit High

Input (Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0340

P0345• Input voltage to ECM remains 0.3 V or less, or 4.7

V or higher for more than 5 seconds, when 2 or

more seconds have elapsed after turning ignition

switch ON (2 trip detection logic)

• No VVT sensor signal to ECM during cranking (1

trip detection logic)• Open or short in VVT sensor circuit for intake

camshaft

• VVT sensor for intake camshaft

• Camshaft timing gear for intake camshaft

• Jumped tooth of timing chain for intake camshaft

•ECM

P0342

P0347Output voltage of VVT sensor is 0.3 V or less for 5

seconds (1 trip detection logic)• Open or short in VVT sensor circuit for intake

camshaft

• VVT sensor for intake camshaft

• Camshaft timing gear for intake camshaft

• Jumped tooth of timing chain for intake camshaft

•ECM

P0343

P0348Output voltage of VVT sensor is 4.7 V or more for 5

seconds (1 trip detection logic)• Open or short in VVT sensor circuit for intake

camshaft

• VVT sensor for intake camshaft

• Camshaft timing gear for intake camshaft

• Jumped tooth of timing chain for intake camshaft

•ECM

Page 561 of 3000

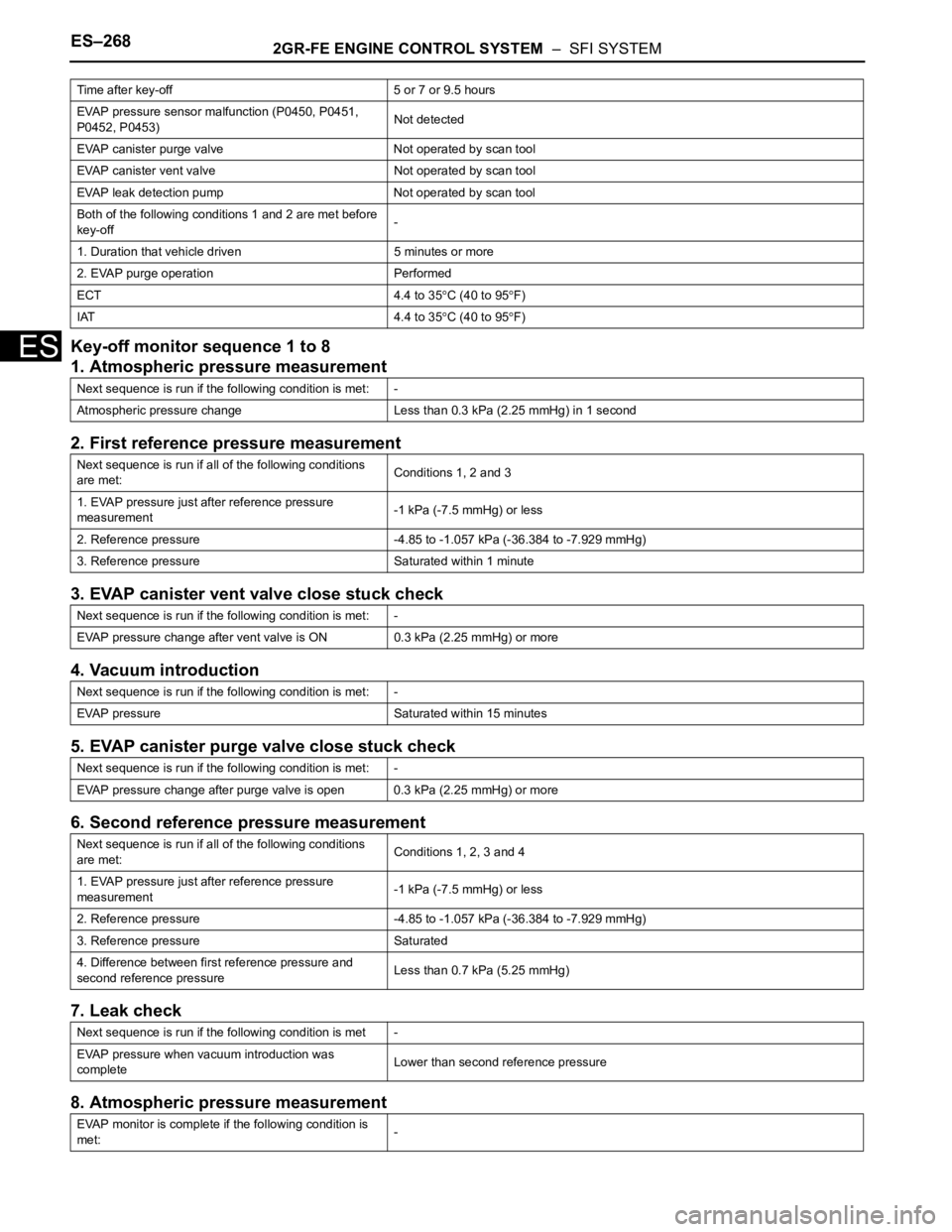

ES–2682GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ESKey-off monitor sequence 1 to 8

1. Atmospheric pressure measurement

2. First reference pressure measurement

3. EVAP canister vent valve close stuck check

4. Vacuum introduction

5. EVAP canister purge valve close stuck check

6. Second reference pressure measurement

7. Leak check

8. Atmospheric pressure measurement

Time after key-off 5 or 7 or 9.5 hours

EVAP pressure sensor malfunction (P0450, P0451,

P0452, P0453)Not detected

EVAP canister purge valve Not operated by scan tool

EVAP canister vent valve Not operated by scan tool

EVAP leak detection pump Not operated by scan tool

Both of the following conditions 1 and 2 are met before

key-off-

1. Duration that vehicle driven 5 minutes or more

2. EVAP purge operation Performed

ECT 4.4 to 35

C (40 to 95F)

IAT 4.4 to 35

C (40 to 95F)

Next sequence is run if the following condition is met: -

Atmospheric pressure change Less than 0.3 kPa (2.25 mmHg) in 1 second

Next sequence is run if all of the following conditions

are met:Conditions 1, 2 and 3

1. EVAP pressure just after reference pressure

measurement-1 kPa (-7.5 mmHg) or less

2. Reference pressure -4.85 to -1.057 kPa (-36.384 to -7.929 mmHg)

3. Reference pressure Saturated within 1 minute

Next sequence is run if the following condition is met: -

EVAP pressure change after vent valve is ON 0.3 kPa (2.25 mmHg) or more

Next sequence is run if the following condition is met: -

EVAP pressure Saturated within 15 minutes

Next sequence is run if the following condition is met: -

EVAP pressure change after purge valve is open 0.3 kPa (2.25 mmHg) or more

Next sequence is run if all of the following conditions

are met:Conditions 1, 2, 3 and 4

1. EVAP pressure just after reference pressure

measurement-1 kPa (-7.5 mmHg) or less

2. Reference pressure -4.85 to -1.057 kPa (-36.384 to -7.929 mmHg)

3. Reference pressure Saturated

4. Difference between first reference pressure and

second reference pressureLess than 0.7 kPa (5.25 mmHg)

Next sequence is run if the following condition is met -

EVAP pressure when vacuum introduction was

completeLower than second reference pressure

EVAP monitor is complete if the following condition is

met:-