coolant temperature TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 57 of 3000

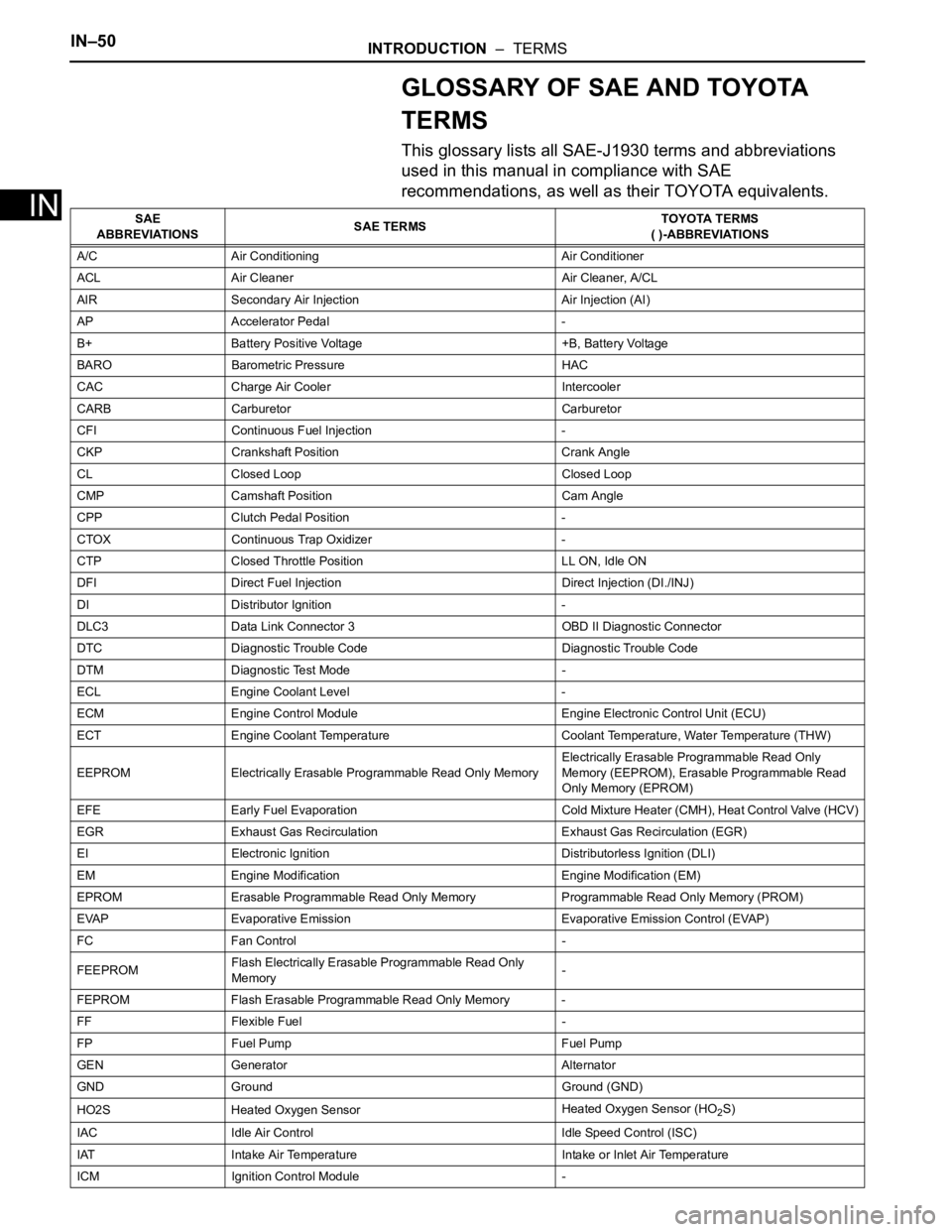

IN–50INTRODUCTION – TERMS

IN

GLOSSARY OF SAE AND TOYOTA

TERMS

This glossary lists all SAE-J1930 terms and abbreviations

used in this manual in compliance with SAE

recommendations, as well as their TOYOTA equivalents.

SAE

ABBREVIATIONSSAE TERMSTOYOTA TERMS

( )-ABBREVIATIONS

A/C Air Conditioning Air Conditioner

ACL Air Cleaner Air Cleaner, A/CL

AIR Secondary Air Injection Air Injection (AI)

AP Accelerator Pedal -

B+ Battery Positive Voltage +B, Battery Voltage

BARO Barometric Pressure HAC

CAC Charge Air Cooler Intercooler

CARB Carburetor Carburetor

CFI Continuous Fuel Injection -

CKP Crankshaft Position Crank Angle

CL Closed Loop Closed Loop

CMP Camshaft Position Cam Angle

CPP Clutch Pedal Position -

CTOX Continuous Trap Oxidizer -

CTP Closed Throttle Position LL ON, Idle ON

DFI Direct Fuel Injection Direct Injection (DI./INJ)

DI Distributor Ignition -

DLC3 Data Link Connector 3 OBD II Diagnostic Connector

DTC Diagnostic Trouble Code Diagnostic Trouble Code

DTM Diagnostic Test Mode -

ECL Engine Coolant Level -

ECM Engine Control Module Engine Electronic Control Unit (ECU)

ECT Engine Coolant Temperature Coolant Temperature, Water Temperature (THW)

EEPROM Electrically Erasable Programmable Read Only MemoryElectrically Erasable Programmable Read Only

Memory (EEPROM), Erasable Programmable Read

Only Memory (EPROM)

EFE Early Fuel Evaporation Cold Mixture Heater (CMH), Heat Control Valve (HCV)

EGR Exhaust Gas Recirculation Exhaust Gas Recirculation (EGR)

EI Electronic Ignition Distributorless Ignition (DLI)

EM Engine Modification Engine Modification (EM)

EPROM Erasable Programmable Read Only Memory Programmable Read Only Memory (PROM)

EVAP Evaporative Emission Evaporative Emission Control (EVAP)

FC Fan Control -

FEEPROMFlash Electrically Erasable Programmable Read Only

Memory-

FEPROM Flash Erasable Programmable Read Only Memory -

FF Flexible Fuel -

FP Fuel Pump Fuel Pump

GEN Generator Alternator

GND Ground Ground (GND)

HO2S Heated Oxygen SensorHeated Oxygen Sensor (HO

2S)

IAC Idle Air Control Idle Speed Control (ISC)

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module -

Page 76 of 3000

2GR-FE COOLING – COOLING FAN SYSTEMCO–5

CO

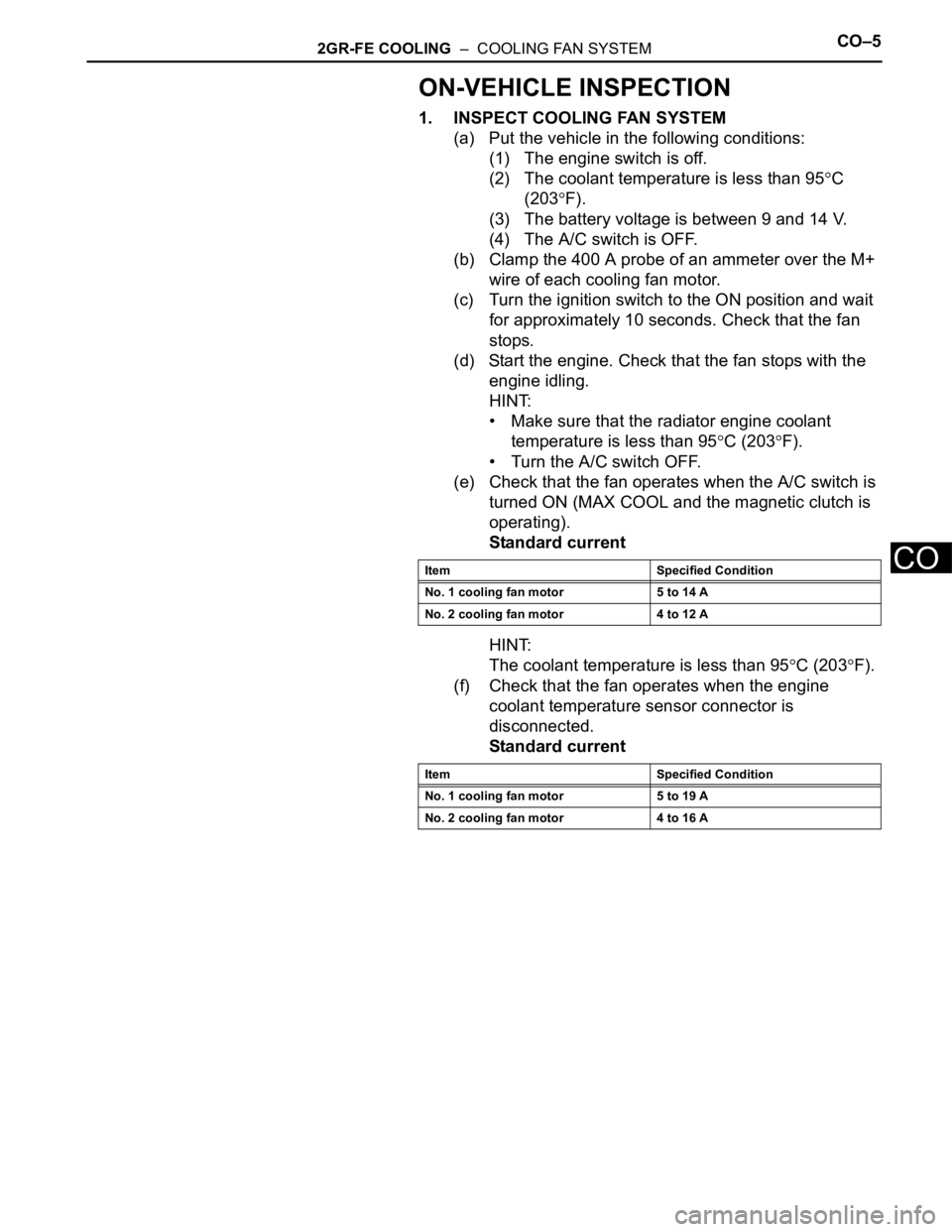

ON-VEHICLE INSPECTION

1. INSPECT COOLING FAN SYSTEM

(a) Put the vehicle in the following conditions:

(1) The engine switch is off.

(2) The coolant temperature is less than 95

C

(203

F).

(3) The battery voltage is between 9 and 14 V.

(4) The A/C switch is OFF.

(b) Clamp the 400 A probe of an ammeter over the M+

wire of each cooling fan motor.

(c) Turn the ignition switch to the ON position and wait

for approximately 10 seconds. Check that the fan

stops.

(d) Start the engine. Check that the fan stops with the

engine idling.

HINT:

• Make sure that the radiator engine coolant

temperature is less than 95

C (203F).

• Turn the A/C switch OFF.

(e) Check that the fan operates when the A/C switch is

turned ON (MAX COOL and the magnetic clutch is

operating).

Standard current

HINT:

The coolant temperature is less than 95

C (203F).

(f) Check that the fan operates when the engine

coolant temperature sensor connector is

disconnected.

Standard current

Item Specified Condition

No. 1 cooling fan motor 5 to 14 A

No. 2 cooling fan motor 4 to 12 A

Item Specified Condition

No. 1 cooling fan motor 5 to 19 A

No. 2 cooling fan motor 4 to 16 A

Page 77 of 3000

CO–62GR-FE COOLING – COOLING FAN SYSTEM

CO

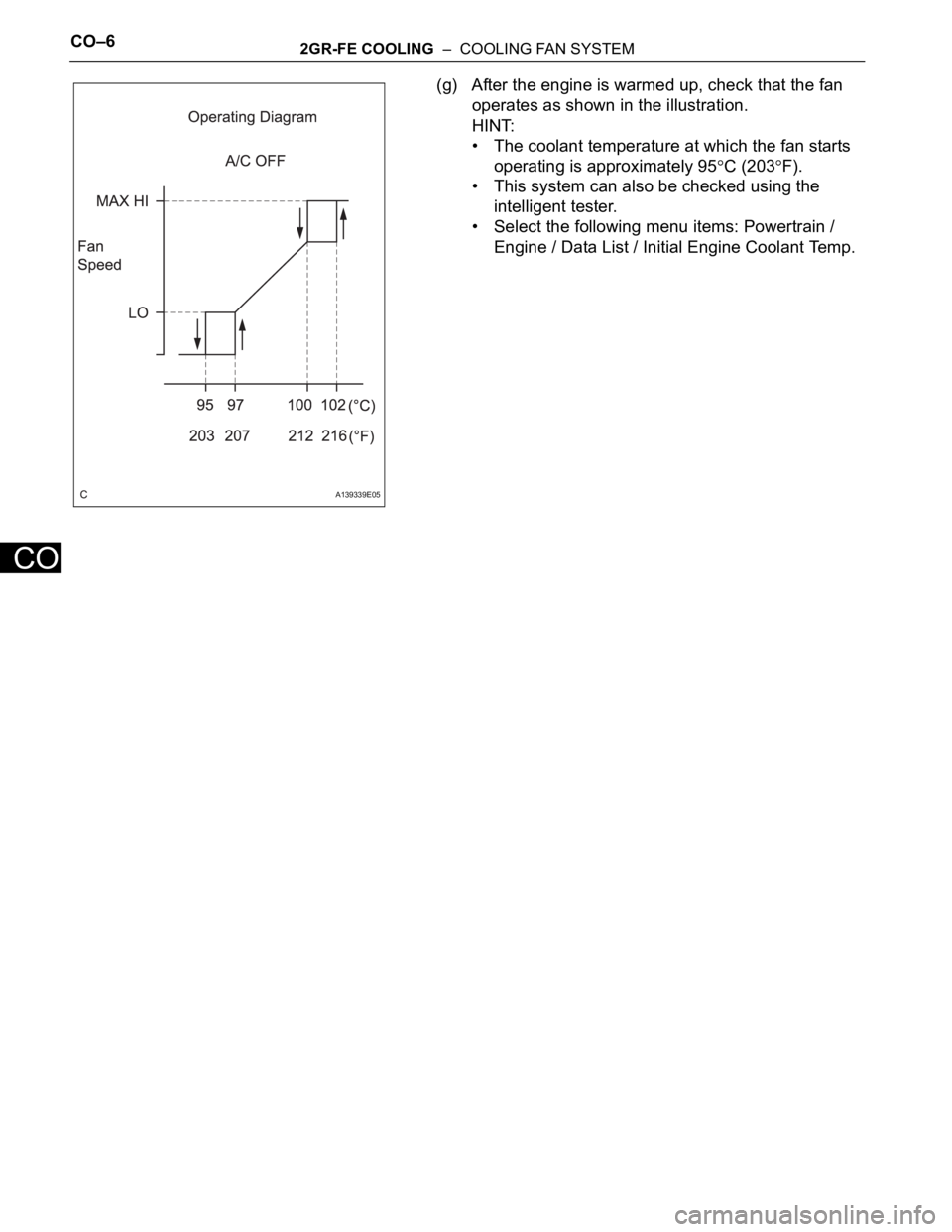

(g) After the engine is warmed up, check that the fan

operates as shown in the illustration.

HINT:

• The coolant temperature at which the fan starts

operating is approximately 95

C (203F).

• This system can also be checked using the

intelligent tester.

• Select the following menu items: Powertrain /

Engine / Data List / Initial Engine Coolant Temp.

A139339E05

Page 197 of 3000

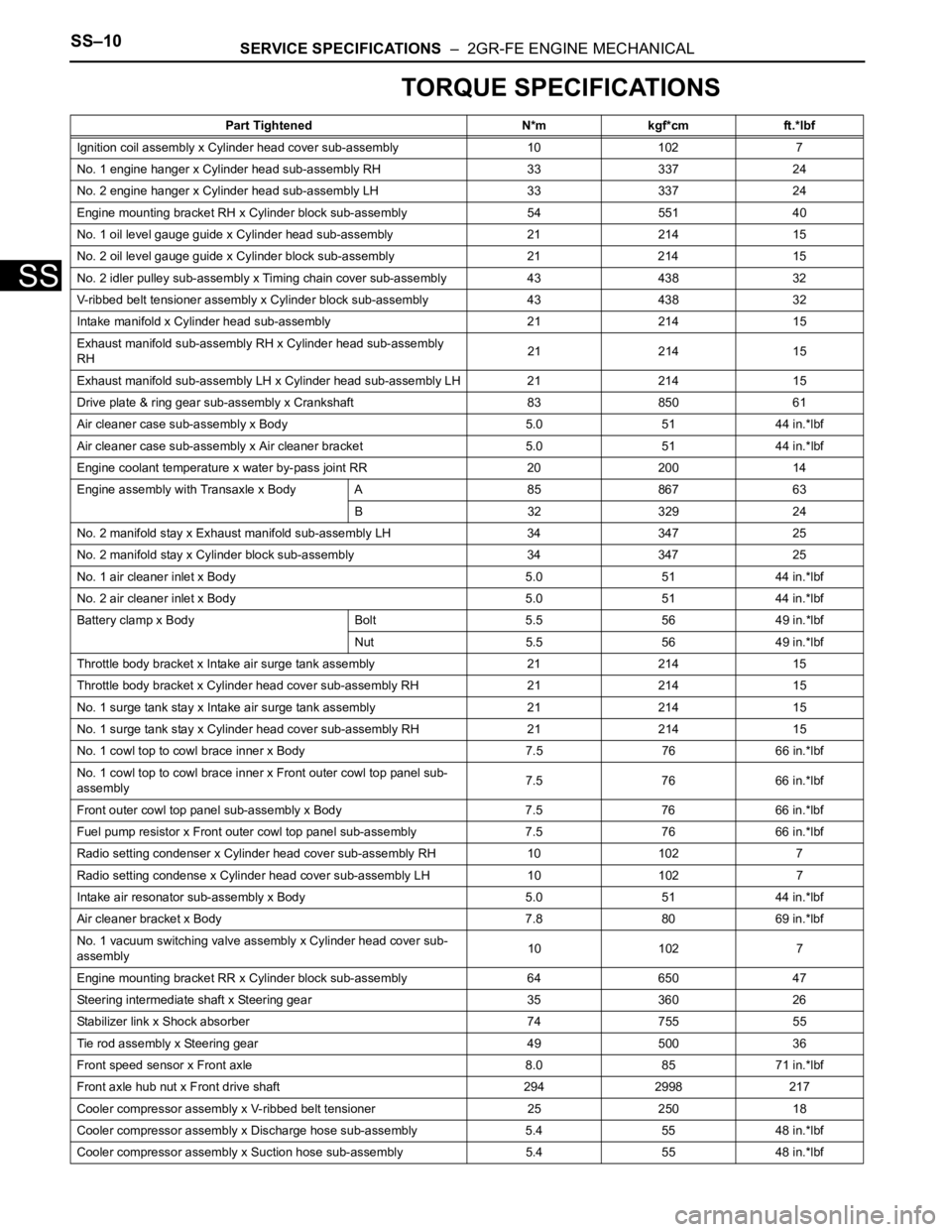

SS–10SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft.*lbf

Ignition coil assembly x Cylinder head cover sub-assembly 10 102 7

No. 1 engine hanger x Cylinder head sub-assembly RH 33 337 24

No. 2 engine hanger x Cylinder head sub-assembly LH 33 337 24

Engine mounting bracket RH x Cylinder block sub-assembly 54 551 40

No. 1 oil level gauge guide x Cylinder head sub-assembly 21 214 15

No. 2 oil level gauge guide x Cylinder block sub-assembly 21 214 15

No. 2 idler pulley sub-assembly x Timing chain cover sub-assembly 43 438 32

V-ribbed belt tensioner assembly x Cylinder block sub-assembly 43 438 32

Intake manifold x Cylinder head sub-assembly 21 214 15

Exhaust manifold sub-assembly RH x Cylinder head sub-assembly

RH21 214 15

Exhaust manifold sub-assembly LH x Cylinder head sub-assembly LH 21 214 15

Drive plate & ring gear sub-assembly x Crankshaft 83 850 61

Air cleaner case sub-assembly x Body 5.0 51 44 in.*lbf

Air cleaner case sub-assembly x Air cleaner bracket 5.0 51 44 in.*lbf

Engine coolant temperature x water by-pass joint RR 20 200 14

Engine assembly with Transaxle x Body A 85 867 63

B 32 329 24

No. 2 manifold stay x Exhaust manifold sub-assembly LH 34 347 25

No. 2 manifold stay x Cylinder block sub-assembly 34 347 25

No. 1 air cleaner inlet x Body 5.0 51 44 in.*lbf

No. 2 air cleaner inlet x Body 5.0 51 44 in.*lbf

Battery clamp x Body Bolt 5.5 56 49 in.*lbf

Nut 5.5 56 49 in.*lbf

Throttle body bracket x Intake air surge tank assembly 21 214 15

Throttle body bracket x Cylinder head cover sub-assembly RH 21 21415

No. 1 surge tank stay x Intake air surge tank assembly 21 214 15

No. 1 surge tank stay x Cylinder head cover sub-assembly RH 21 21415

No. 1 cowl top to cowl brace inner x Body 7.5 76 66 in.*lbf

No. 1 cowl top to cowl brace inner x Front outer cowl top panel sub-

assembly7.5 76 66 in.*lbf

Front outer cowl top panel sub-assembly x Body 7.5 76 66 in.*lbf

Fuel pump resistor x Front outer cowl top panel sub-assembly 7.576 66 in.*lbf

Radio setting condenser x Cylinder head cover sub-assembly RH 10102 7

Radio setting condense x Cylinder head cover sub-assembly LH 10 102 7

Intake air resonator sub-assembly x Body 5.0 51 44 in.*lbf

Air cleaner bracket x Body 7.8 80 69 in.*lbf

No. 1 vacuum switching valve assembly x Cylinder head cover sub-

assembly10 102 7

Engine mounting bracket RR x Cylinder block sub-assembly 64 650 47

Steering intermediate shaft x Steering gear 35 360 26

Stabilizer link x Shock absorber 74 755 55

Tie rod assembly x Steering gear 49 500 36

Front speed sensor x Front axle 8.0 85 71 in.*lbf

Front axle hub nut x Front drive shaft 294 2998 217

Cooler compressor assembly x V-ribbed belt tensioner 25 250 18

Cooler compressor assembly x Discharge hose sub-assembly 5.4 55 48 in.*lbf

Cooler compressor assembly x Suction hose sub-assembly 5.4 55 48 in.*lbf

Page 318 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–1

ES

SFI SYSTEM

PRECAUTION

1. INITIALIZATION

NOTICE:

• Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

• Perform REGISTRATION (VIN registration) when

replacing the ECM (See page ES-15).

HINT:

Initialization cannot be completed by only removing the

battery.

2. FOR USING INTELLIGENT TESTER

CAUTION:

Observe the following items for safety reasons:

• Before using the tester, read the instruction

manual.

• Prevent the tester cable from being caught on the

pedals, shift lever and steering wheel when

driving with the tester connected to the vehicle.

• When driving the vehicle for testing purposes

using the tester, two persons are required. One is

for driving the vehicle, and the other operates the

tester.

3. FOR USING BATTERY DURING INSPECTION

(a) While using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

4. COOLING FAN SYSTEM

NOTICE:

• When the ignition switch is turned off and the engine

temperature is high, the cooling fans may operate for

approximately 3 minutes.

• After turning the ignition switch off, keep hands and

objects away from the fans when they are operating.

HINT:

If all of the following are met for a certain period of time during

a few minute period immediately before the engine is

stopped, the electric fans will continue to operate for 3

minutes after the engine is stopped. This is performed to

ensure restartability and stabilize idle speed.

– The intelligent tester indicates a very high coolant

temperature.

– The intelligent tester indicates a high outside air

temperature.

– The vehicle has been driven under high load (driving on an

uphill or equivalent).

The following sensors are used for this control:

– Coolant temperature sensor

– Outside air temperature sensor

–MAF sensor

– Vehicle speed sensors

Page 326 of 3000

ES–2582GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

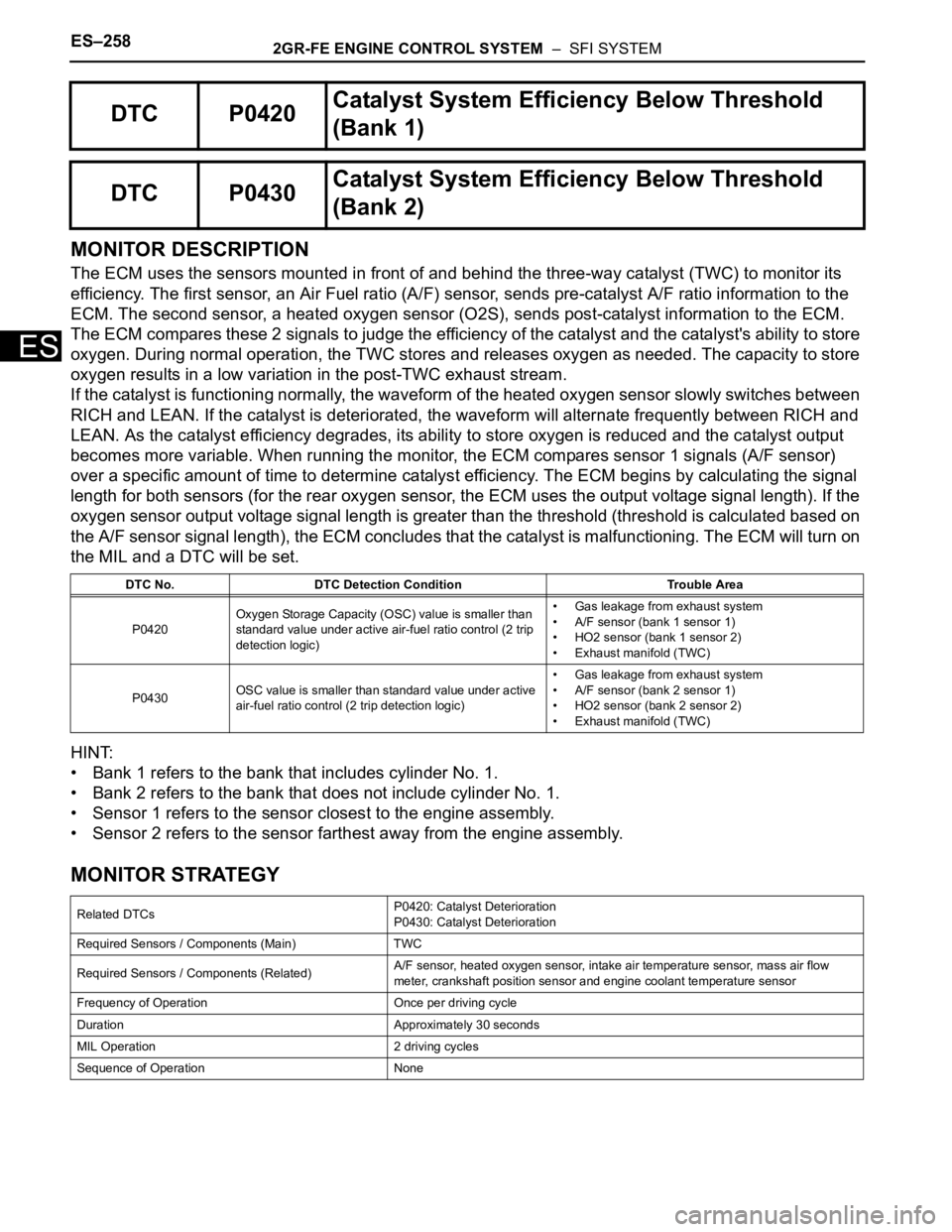

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and behind the three-way catalyst (TWC) to monitor its

efficiency. The first sensor, an Air Fuel ratio (A/F) sensor, sends pre-catalyst A/F ratio information to the

ECM. The second sensor, a heated oxygen sensor (O2S), sends post-catalyst information to the ECM.

The ECM compares these 2 signals to judge the efficiency of the catalyst and the catalyst's ability to store

oxygen. During normal operation, the TWC stores and releases oxygen as needed. The capacity to store

oxygen results in a low variation in the post-TWC exhaust stream.

If the catalyst is functioning normally, the waveform of the heated oxygen sensor slowly switches between

RICH and LEAN. If the catalyst is deteriorated, the waveform will alternate frequently between RICH and

LEAN. As the catalyst efficiency degrades, its ability to store oxygen is reduced and the catalyst output

becomes more variable. When running the monitor, the ECM compares sensor 1 signals (A/F sensor)

over a specific amount of time to determine catalyst efficiency. The ECM begins by calculating the signal

length for both sensors (for the rear oxygen sensor, the ECM uses the output voltage signal length). If the

oxygen sensor output voltage signal length is greater than the threshold (threshold is calculated based on

the A/F sensor signal length), the ECM concludes that the catalyst is malfunctioning. The ECM will turn on

the MIL and a DTC will be set.

HINT:

• Bank 1 refers to the bank that includes cylinder No. 1.

• Bank 2 refers to the bank that does not include cylinder No. 1.

• Sensor 1 refers to the sensor closest to the engine assembly.

• Sensor 2 refers to the sensor farthest away from the engine assembly.

MONITOR STRATEGY

DTC P0420Catalyst System Efficiency Below Threshold

(Bank 1)

DTC P0430Catalyst System Efficiency Below Threshold

(Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0420Oxygen Storage Capacity (OSC) value is smaller than

standard value under active air-fuel ratio control (2 trip

detection logic)• Gas leakage from exhaust system

• A/F sensor (bank 1 sensor 1)

• HO2 sensor (bank 1 sensor 2)

• Exhaust manifold (TWC)

P0430OSC value is smaller than standard value under active

air-fuel ratio control (2 trip detection logic)• Gas leakage from exhaust system

• A/F sensor (bank 2 sensor 1)

• HO2 sensor (bank 2 sensor 2)

• Exhaust manifold (TWC)

Related DTCsP0420: Catalyst Deterioration

P0430: Catalyst Deterioration

Required Sensors / Components (Main) TWC

Required Sensors / Components (Related)A/F sensor, heated oxygen sensor, intake air temperature sensor, mass air flow

meter, crankshaft position sensor and engine coolant temperature sensor

Frequency of Operation Once per driving cycle

Duration Approximately 30 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

Page 328 of 3000

ES–2602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

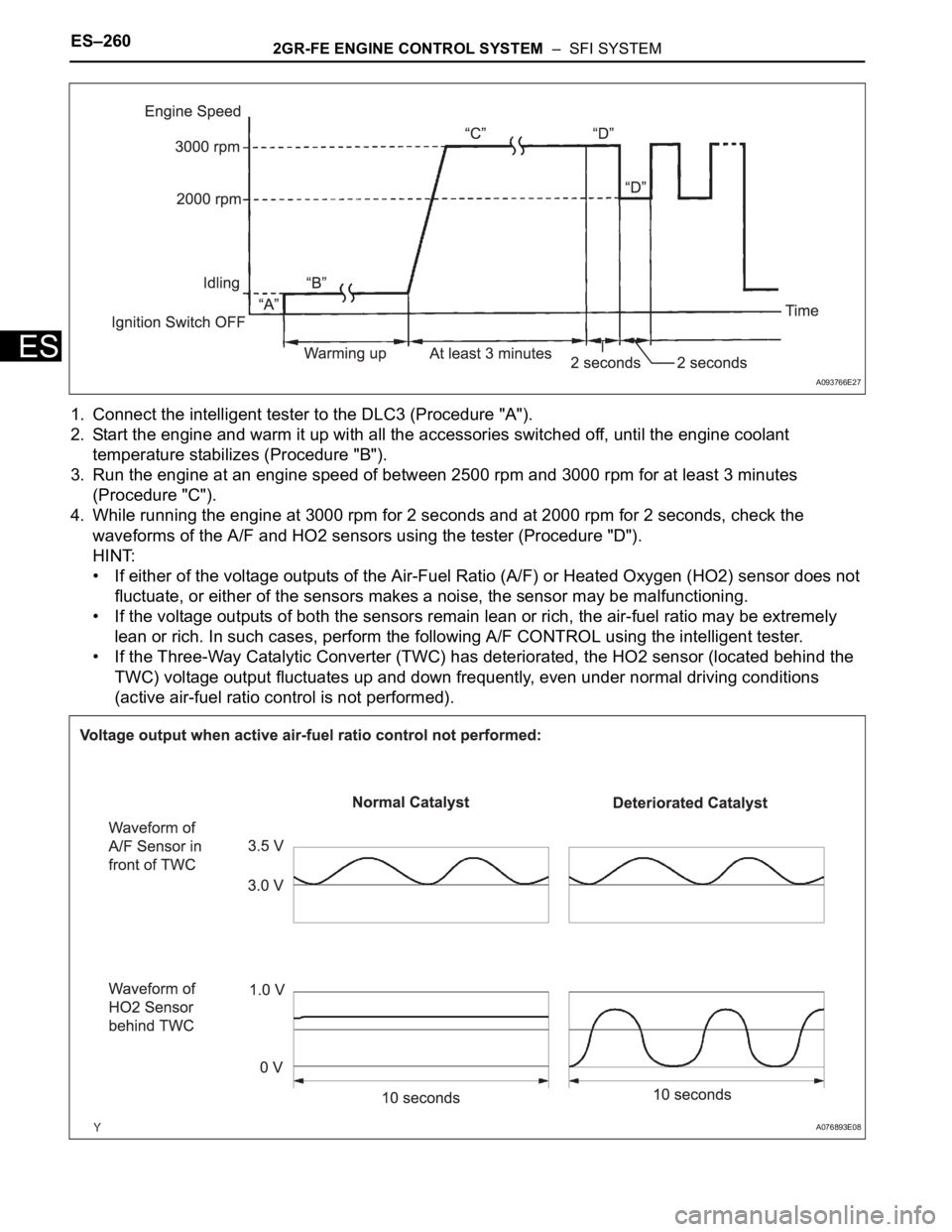

1. Connect the intelligent tester to the DLC3 (Procedure "A").

2. Start the engine and warm it up with all the accessories switched off, until the engine coolant

temperature stabilizes (Procedure "B").

3. Run the engine at an engine speed of between 2500 rpm and 3000 rpm for at least 3 minutes

(Procedure "C").

4. While running the engine at 3000 rpm for 2 seconds and at 2000 rpm for 2 seconds, check the

waveforms of the A/F and HO2 sensors using the tester (Procedure "D").

HINT:

• If either of the voltage outputs of the Air-Fuel Ratio (A/F) or Heated Oxygen (HO2) sensor does not

fluctuate, or either of the sensors makes a noise, the sensor may be malfunctioning.

• If the voltage outputs of both the sensors remain lean or rich, the air-fuel ratio may be extremely

lean or rich. In such cases, perform the following A/F CONTROL using the intelligent tester.

• If the Three-Way Catalytic Converter (TWC) has deteriorated, the HO2 sensor (located behind the

TWC) voltage output fluctuates up and down frequently, even under normal driving conditions

(active air-fuel ratio control is not performed).

A093766E27

A076893E08

Page 353 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

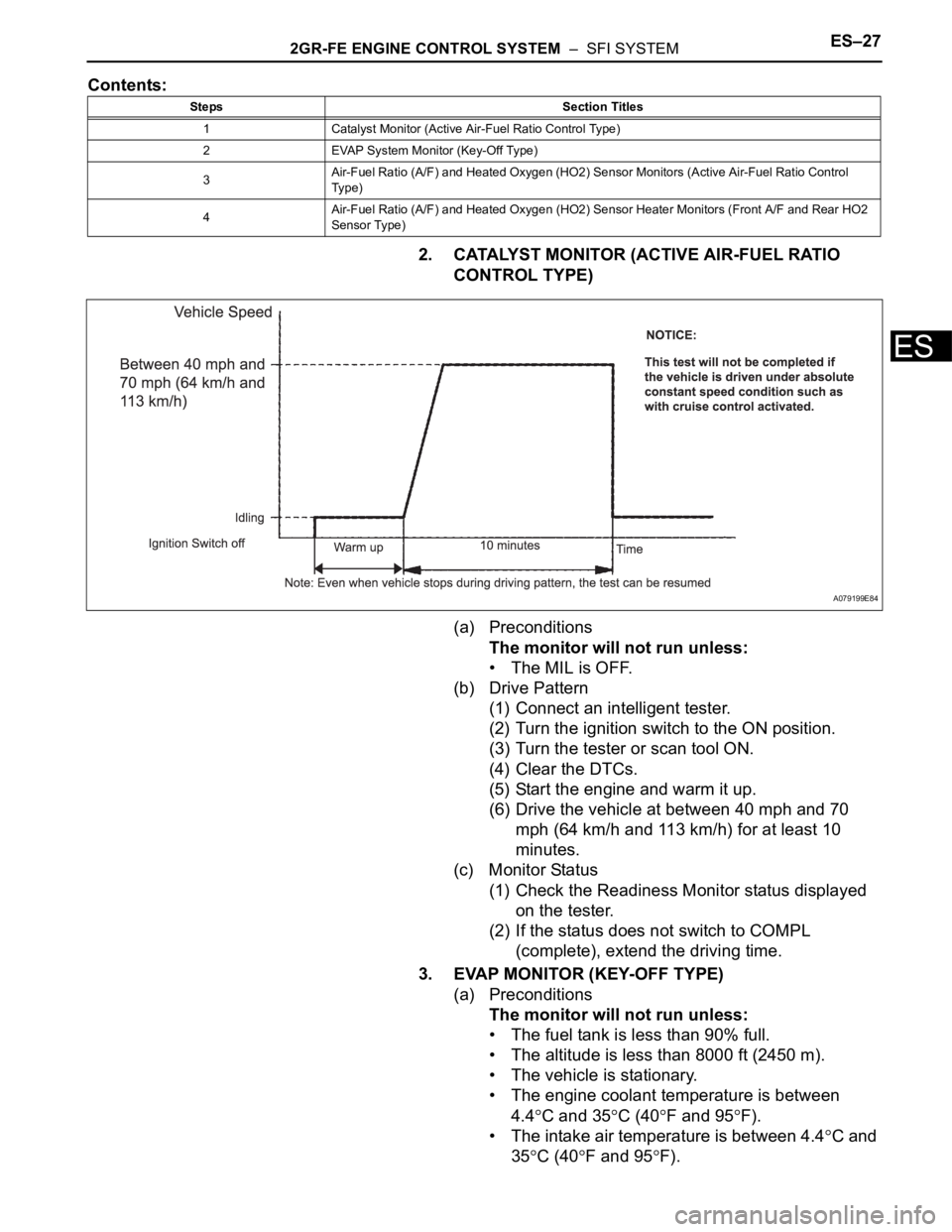

Contents:

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 354 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 357 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–31

ES

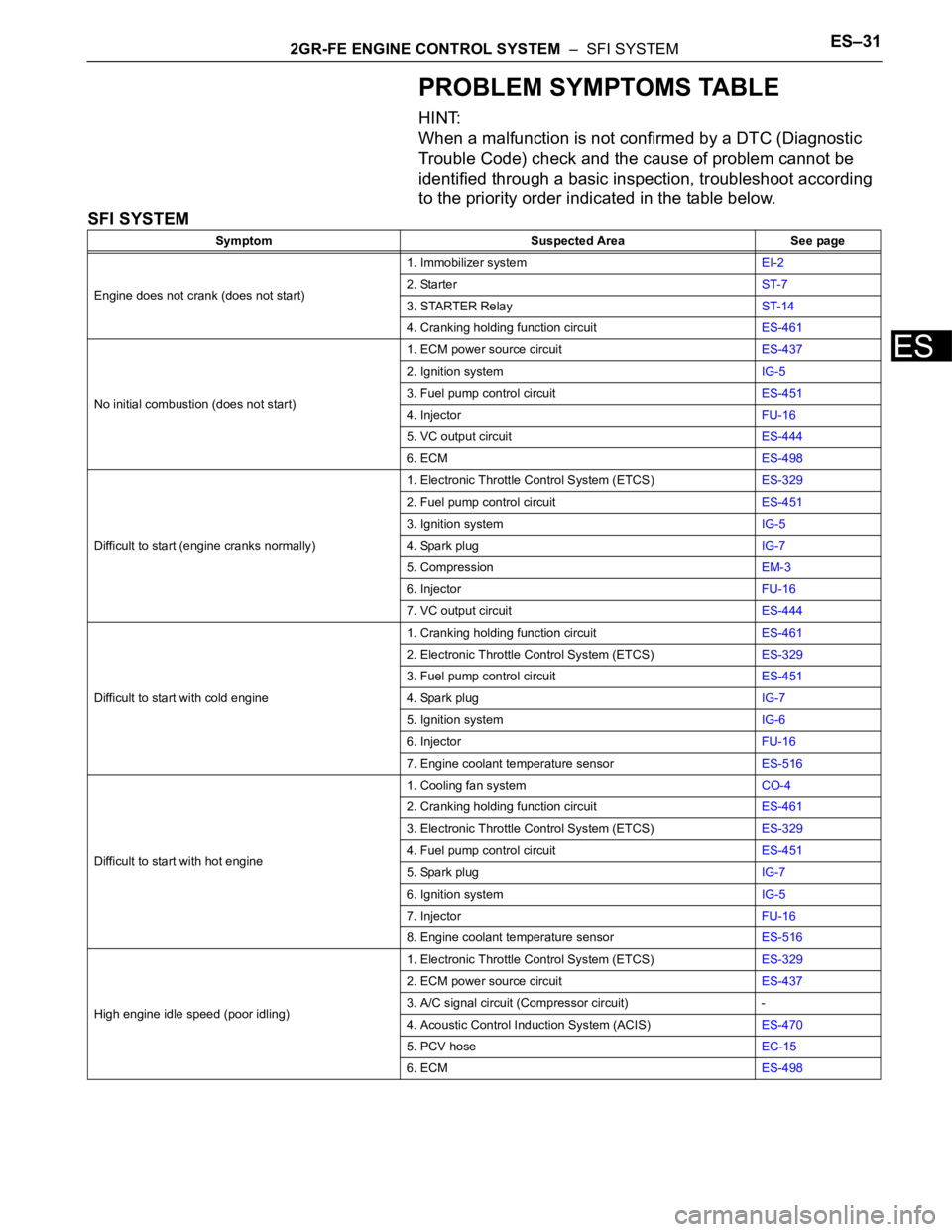

PROBLEM SYMPTOMS TABLE

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority order indicated in the table below.

SFI SYSTEM

Symptom Suspected Area See page

Engine does not crank (does not start)1. Immobilizer systemEI-2

2. StarterST-7

3. STARTER RelayST-14

4. Cranking holding function circuitES-461

No initial combustion (does not start)1. ECM power source circuitES-437

2. Ignition systemIG-5

3. Fuel pump control circuitES-451

4. InjectorFU-16

5. VC output circuitES-444

6. ECMES-498

Difficult to start (engine cranks normally)1. Electronic Throttle Control System (ETCS)ES-329

2. Fuel pump control circuitES-451

3. Ignition systemIG-5

4. Spark plugIG-7

5. CompressionEM-3

6. InjectorFU-16

7. VC output circuitES-444

Difficult to start with cold engine1. Cranking holding function circuitES-461

2. Electronic Throttle Control System (ETCS)ES-329

3. Fuel pump control circuitES-451

4. Spark plugIG-7

5. Ignition systemIG-6

6. InjectorFU-16

7. Engine coolant temperature sensorES-516

Difficult to start with hot engine1. Cooling fan systemCO-4

2. Cranking holding function circuitES-461

3. Electronic Throttle Control System (ETCS)ES-329

4. Fuel pump control circuitES-451

5. Spark plugIG-7

6. Ignition systemIG-5

7. InjectorFU-16

8. Engine coolant temperature sensorES-516

High engine idle speed (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. ECM power source circuitES-437

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS)ES-470

5. PCV hoseEC-15

6. ECMES-498