ecu wiring TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 55 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–43

IN

(d) HIGH ELECTRICAL LOAD METHOD: When a

malfunction seems to occur when electrical load is

excessive.

(1) Turn on the heater blower, headlight, rear

window defogger and all other electrical loads.

Check if the malfunction reoccurs.

5. DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the

DTC checks) in the appropriate section's Diagnostic Trouble

Code Chart. Use the chart to determine the trouble area and

the proper inspection procedure. A description of each of the

chart's columns is shown in the table below.

6. PROBLEM SYMPTOMS TABLE

When a "Normal" code is output during a DTC check but

the problem still occurs, use the Problem Symptoms

Table. The suspected areas (circuits or parts) for each

problem symptoms are in the table. The suspected areas

are listed in order of probability. A description of each of

the chart's columns is shown in the table below.

HINT:

In some cases, the problem is not detected by the

diagnostic system even though a problem symptom

occurs. It is possible that the problem is occurring

outside the detection range of the diagnostic system, or

that the problem occurs in a completely different system.

7. CIRCUIT INSPECTION

A description of the main areas of each circuit inspection

is shown in the table below.

B107149

Item Description

DTC No. Indicates the diagnostic trouble code

Detection Item Indicates the system or details of the problem

Trouble Area Indicates the suspect areas of the problem

See Page Indicates the page where the inspection procedures for each circuit is

to be found, or gives instruction for checking and repairs.

Item Description

Problem Symptom -

Circuit Inspection, Inspection Order Indicates the order in which the circuits need to be checked

Circuit or Part Name Indicates the circuit or part which needs to be checked

See Page Indicates the page where the flowchart for each circuit is located

Item Description

Circuit Description The major role, operation of the circuit and its component parts are

explained.

Diagnostic Trouble Code No. and Detection item Indicates the diagnostic trouble codes, diagnostic trouble code

settings and suspected areas for a problem

Wiring diagram This shows a wiring diagram of the circuit.

Use this diagram together with ELECTRICAL WIRING DIAGRAM to

thoroughly understand the circuit.

Wire colors are indicated by an alphabetical code. B = Black, L = Blue,

R = Red, BR = Brown, LG = Light Green, V = Violet, G = Green, O =

Orange, W = White, GR = Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter

indicates the color of the stripe.

Page 62 of 3000

IN–32INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

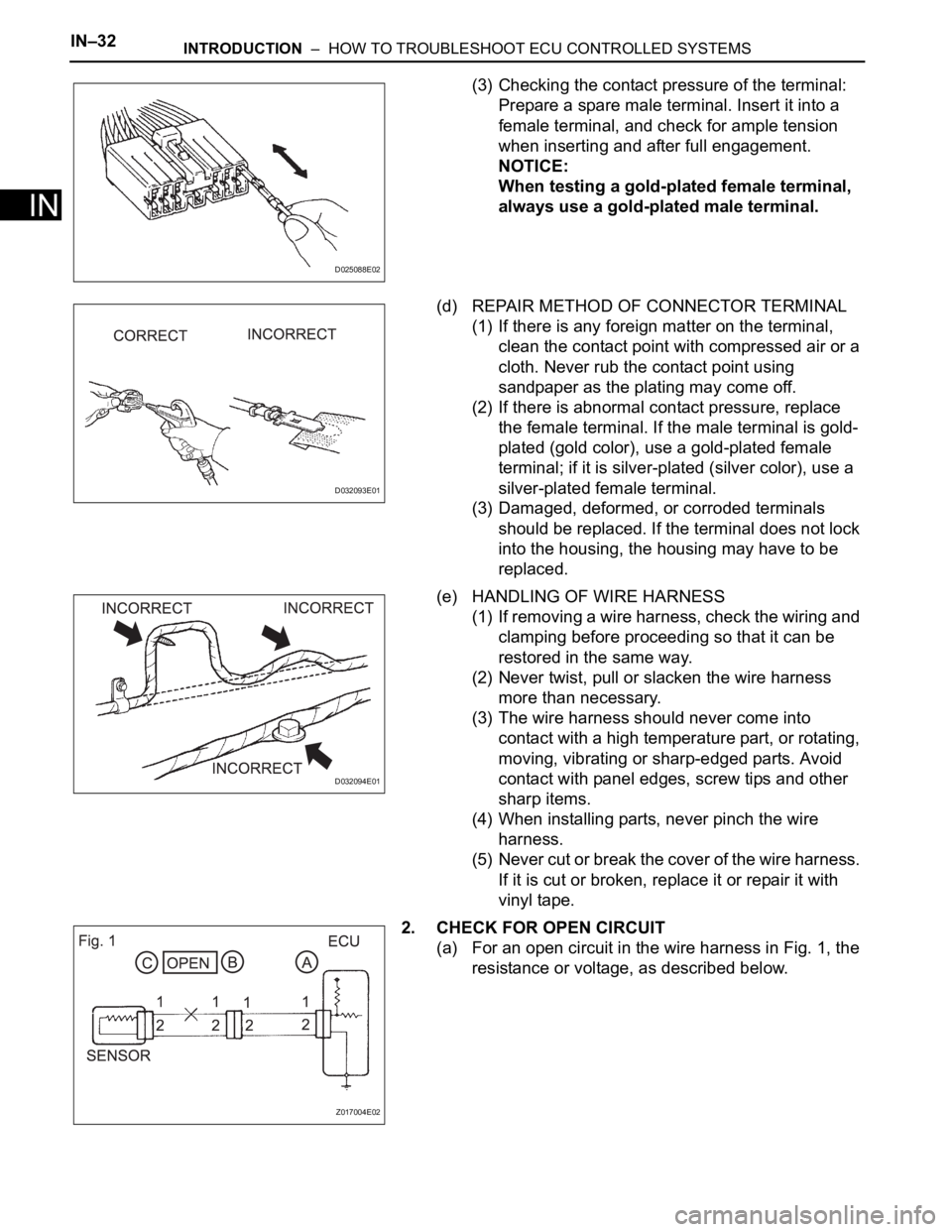

(3) Checking the contact pressure of the terminal:

Prepare a spare male terminal. Insert it into a

female terminal, and check for ample tension

when inserting and after full engagement.

NOTICE:

When testing a gold-plated female terminal,

always use a gold-plated male terminal.

(d) REPAIR METHOD OF CONNECTOR TERMINAL

(1) If there is any foreign matter on the terminal,

clean the contact point with compressed air or a

cloth. Never rub the contact point using

sandpaper as the plating may come off.

(2) If there is abnormal contact pressure, replace

the female terminal. If the male terminal is gold-

plated (gold color), use a gold-plated female

terminal; if it is silver-plated (silver color), use a

silver-plated female terminal.

(3) Damaged, deformed, or corroded terminals

should be replaced. If the terminal does not lock

into the housing, the housing may have to be

replaced.

(e) HANDLING OF WIRE HARNESS

(1) If removing a wire harness, check the wiring and

clamping before proceeding so that it can be

restored in the same way.

(2) Never twist, pull or slacken the wire harness

more than necessary.

(3) The wire harness should never come into

contact with a high temperature part, or rotating,

moving, vibrating or sharp-edged parts. Avoid

contact with panel edges, screw tips and other

sharp items.

(4) When installing parts, never pinch the wire

harness.

(5) Never cut or break the cover of the wire harness.

If it is cut or broken, replace it or repair it with

vinyl tape.

2. CHECK FOR OPEN CIRCUIT

(a) For an open circuit in the wire harness in Fig. 1, the

resistance or voltage, as described below.

D025088E02

D032093E01

D032094E01

Z017004E02

Page 73 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–43

IN

(d) HIGH ELECTRICAL LOAD METHOD: When a

malfunction seems to occur when electrical load is

excessive.

(1) Turn on the heater blower, headlight, rear

window defogger and all other electrical loads.

Check if the malfunction reoccurs.

5. DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the

DTC checks) in the appropriate section's Diagnostic Trouble

Code Chart. Use the chart to determine the trouble area and

the proper inspection procedure. A description of each of the

chart's columns is shown in the table below.

6. PROBLEM SYMPTOMS TABLE

When a "Normal" code is output during a DTC check but

the problem still occurs, use the Problem Symptoms

Table. The suspected areas (circuits or parts) for each

problem symptoms are in the table. The suspected areas

are listed in order of probability. A description of each of

the chart's columns is shown in the table below.

HINT:

In some cases, the problem is not detected by the

diagnostic system even though a problem symptom

occurs. It is possible that the problem is occurring

outside the detection range of the diagnostic system, or

that the problem occurs in a completely different system.

7. CIRCUIT INSPECTION

A description of the main areas of each circuit inspection

is shown in the table below.

B107149

Item Description

DTC No. Indicates the diagnostic trouble code

Detection Item Indicates the system or details of the problem

Trouble Area Indicates the suspect areas of the problem

See Page Indicates the page where the inspection procedures for each circuit is

to be found, or gives instruction for checking and repairs.

Item Description

Problem Symptom -

Circuit Inspection, Inspection Order Indicates the order in which the circuits need to be checked

Circuit or Part Name Indicates the circuit or part which needs to be checked

See Page Indicates the page where the flowchart for each circuit is located

Item Description

Circuit Description The major role, operation of the circuit and its component parts are

explained.

Diagnostic Trouble Code No. and Detection item Indicates the diagnostic trouble codes, diagnostic trouble code

settings and suspected areas for a problem

Wiring diagram This shows a wiring diagram of the circuit.

Use this diagram together with ELECTRICAL WIRING DIAGRAM to

thoroughly understand the circuit.

Wire colors are indicated by an alphabetical code. B = Black, L = Blue,

R = Red, BR = Brown, LG = Light Green, V = Violet, G = Green, O =

Orange, W = White, GR = Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter

indicates the color of the stripe.

Page 413 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–107

ES

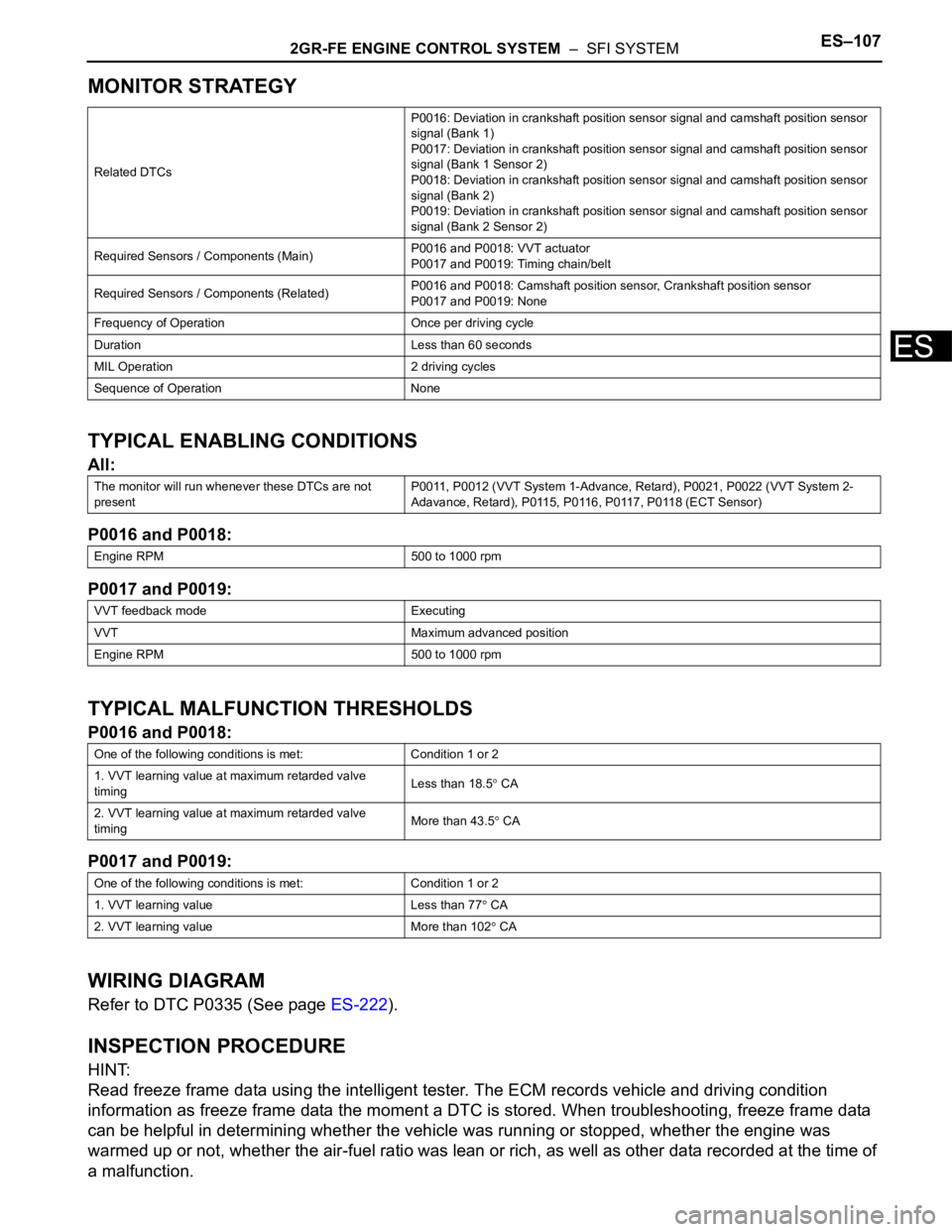

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

P0016 and P0018:

P0017 and P0019:

TYPICAL MALFUNCTION THRESHOLDS

P0016 and P0018:

P0017 and P0019:

WIRING DIAGRAM

Refer to DTC P0335 (See page ES-222).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

Related DTCsP0016: Deviation in crankshaft position sensor signal and camshaft position sensor

signal (Bank 1)

P0017: Deviation in crankshaft position sensor signal and camshaft position sensor

signal (Bank 1 Sensor 2)

P0018: Deviation in crankshaft position sensor signal and camshaft position sensor

signal (Bank 2)

P0019: Deviation in crankshaft position sensor signal and camshaft position sensor

signal (Bank 2 Sensor 2)

Required Sensors / Components (Main)P0016 and P0018: VVT actuator

P0017 and P0019: Timing chain/belt

Required Sensors / Components (Related)P0016 and P0018: Camshaft position sensor, Crankshaft position sensor

P0017 and P0019: None

Frequency of Operation Once per driving cycle

Duration Less than 60 seconds

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0011, P0012 (VVT System 1-Advance, Retard), P0021, P0022 (VVT System 2-

Adavance, Retard), P0115, P0116, P0117, P0118 (ECT Sensor)

Engine RPM 500 to 1000 rpm

VVT feedback mode Executing

VVT Maximum advanced position

Engine RPM 500 to 1000 rpm

One of the following conditions is met: Condition 1 or 2

1. VVT learning value at maximum retarded valve

timingLess than 18.5

CA

2. VVT learning value at maximum retarded valve

timingMore than 43.5

CA

One of the following conditions is met: Condition 1 or 2

1. VVT learning value Less than 77

CA

2. VVT learning value More than 102

CA

Page 496 of 3000

ES–1902GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

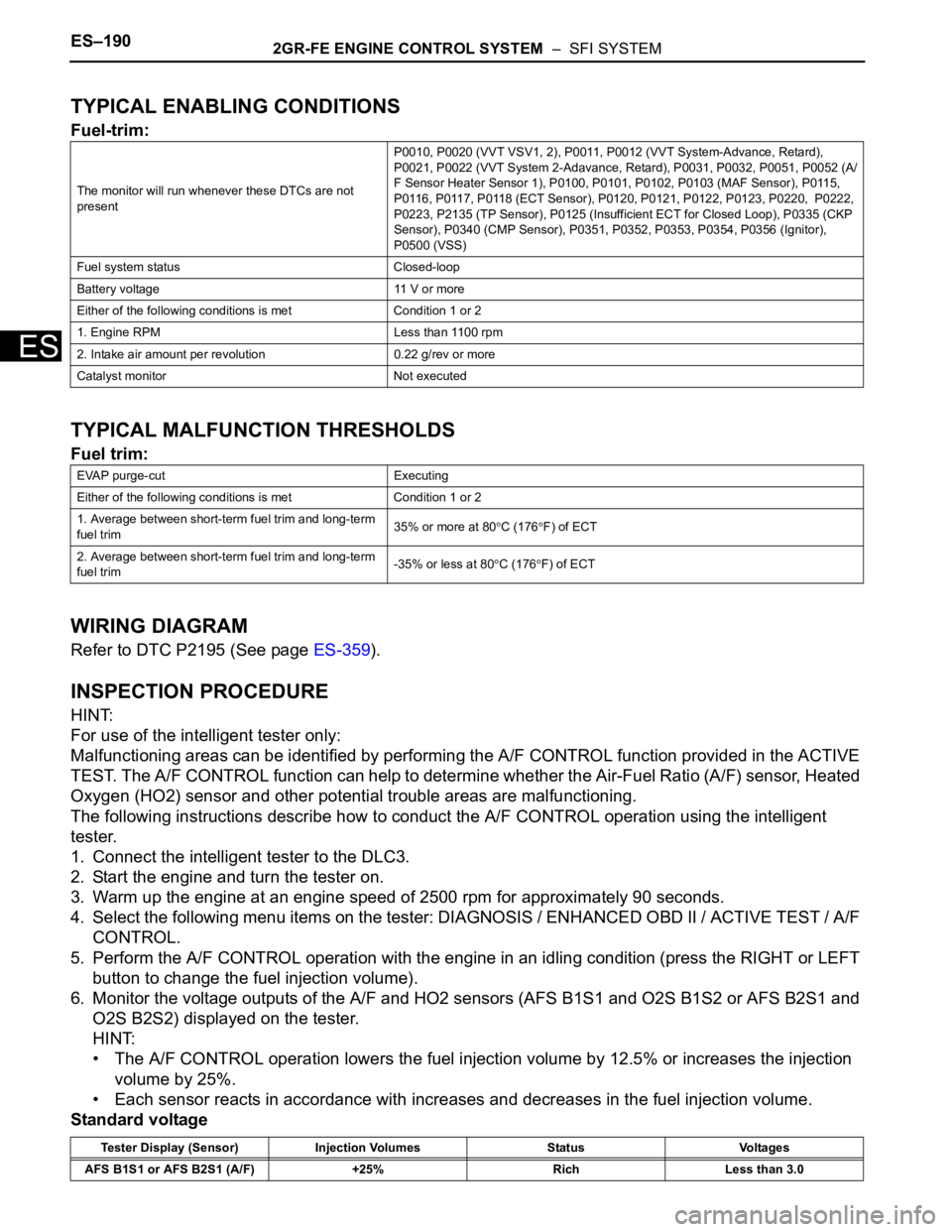

TYPICAL ENABLING CONDITIONS

Fuel-trim:

TYPICAL MALFUNCTION THRESHOLDS

Fuel trim:

WIRING DIAGRAM

Refer to DTC P2195 (See page ES-359).

INSPECTION PROCEDURE

HINT:

For use of the intelligent tester only:

Malfunctioning areas can be identified by performing the A/F CONTROL function provided in the ACTIVE

TEST. The A/F CONTROL function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated

Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the A/F CONTROL operation using the intelligent

tester.

1. Connect the intelligent tester to the DLC3.

2. Start the engine and turn the tester on.

3. Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

4. Select the following menu items on the tester: DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/F

CONTROL.

5. Perform the A/F CONTROL operation with the engine in an idling condition (press the RIGHT or LEFT

button to change the fuel injection volume).

6. Monitor the voltage outputs of the A/F and HO2 sensors (AFS B1S1 and O2S B1S2 or AFS B2S1 and

O2S B2S2) displayed on the tester.

HINT:

• The A/F CONTROL operation lowers the fuel injection volume by 12.5% or increases the injection

volume by 25%.

• Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

Standard voltage

The monitor will run whenever these DTCs are not

presentP0010, P0020 (VVT VSV1, 2), P0011, P0012 (VVT System-Advance, Retard),

P0021, P0022 (VVT System 2-Adavance, Retard), P0031, P0032, P0051, P0052 (A/

F Sensor Heater Sensor 1), P0100, P0101, P0102, P0103 (MAF Sensor), P0115,

P0116, P0117, P0118 (ECT Sensor), P0120, P0121, P0122, P0123, P0220, P0222,

P0223, P2135 (TP Sensor), P0125 (Insufficient ECT for Closed Loop), P0335 (CKP

Sensor), P0340 (CMP Sensor), P0351, P0352, P0353, P0354, P0356 (Ignitor),

P0500 (VSS)

Fuel system status Closed-loop

Battery voltage 11 V or more

Either of the following conditions is met Condition 1 or 2

1. Engine RPM Less than 1100 rpm

2. Intake air amount per revolution 0.22 g/rev or more

Catalyst monitor Not executed

EVAP purge-cut Executing

Either of the following conditions is met Condition 1 or 2

1. Average between short-term fuel trim and long-term

fuel trim35% or more at 80

C (176F) of ECT

2. Average between short-term fuel trim and long-term

fuel trim-35% or less at 80

C (176F) of ECT

Tester Display (Sensor) Injection Volumes Status Voltages

AFS B1S1 or AFS B2S1 (A/F) +25% Rich Less than 3.0

Page 635 of 3000

ES–3422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

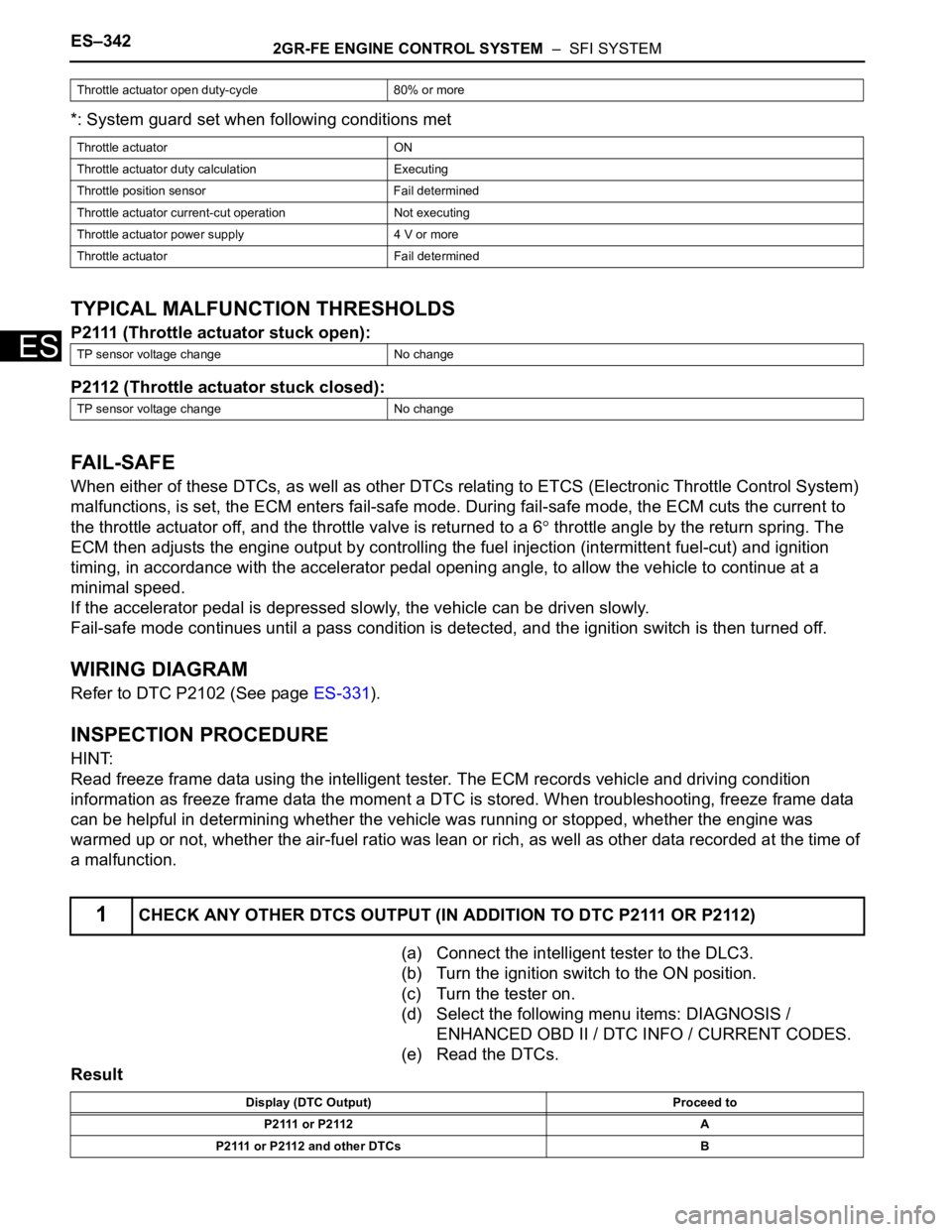

*: System guard set when following conditions met

TYPICAL MALFUNCTION THRESHOLDS

P2111 (Throttle actuator stuck open):

P2112 (Throttle actuator stuck closed):

FA I L - S A F E

When either of these DTCs, as well as other DTCs relating to ETCS (Electronic Throttle Control System)

malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to

the throttle actuator off, and the throttle valve is returned to a 6

throttle angle by the return spring. The

ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition

timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a

minimal speed.

If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

WIRING DIAGRAM

Refer to DTC P2102 (See page ES-331).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

Throttle actuator open duty-cycle 80% or more

Throttle actuator ON

Throttle actuator duty calculation Executing

Throttle position sensor Fail determined

Throttle actuator current-cut operation Not executing

Throttle actuator power supply 4 V or more

Throttle actuator Fail determined

TP sensor voltage change No change

TP sensor voltage change No change

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2111 OR P2112)

Display (DTC Output) Proceed to

P2111 or P2112 A

P2111 or P2112 and other DTCs B

Page 642 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–349

ES

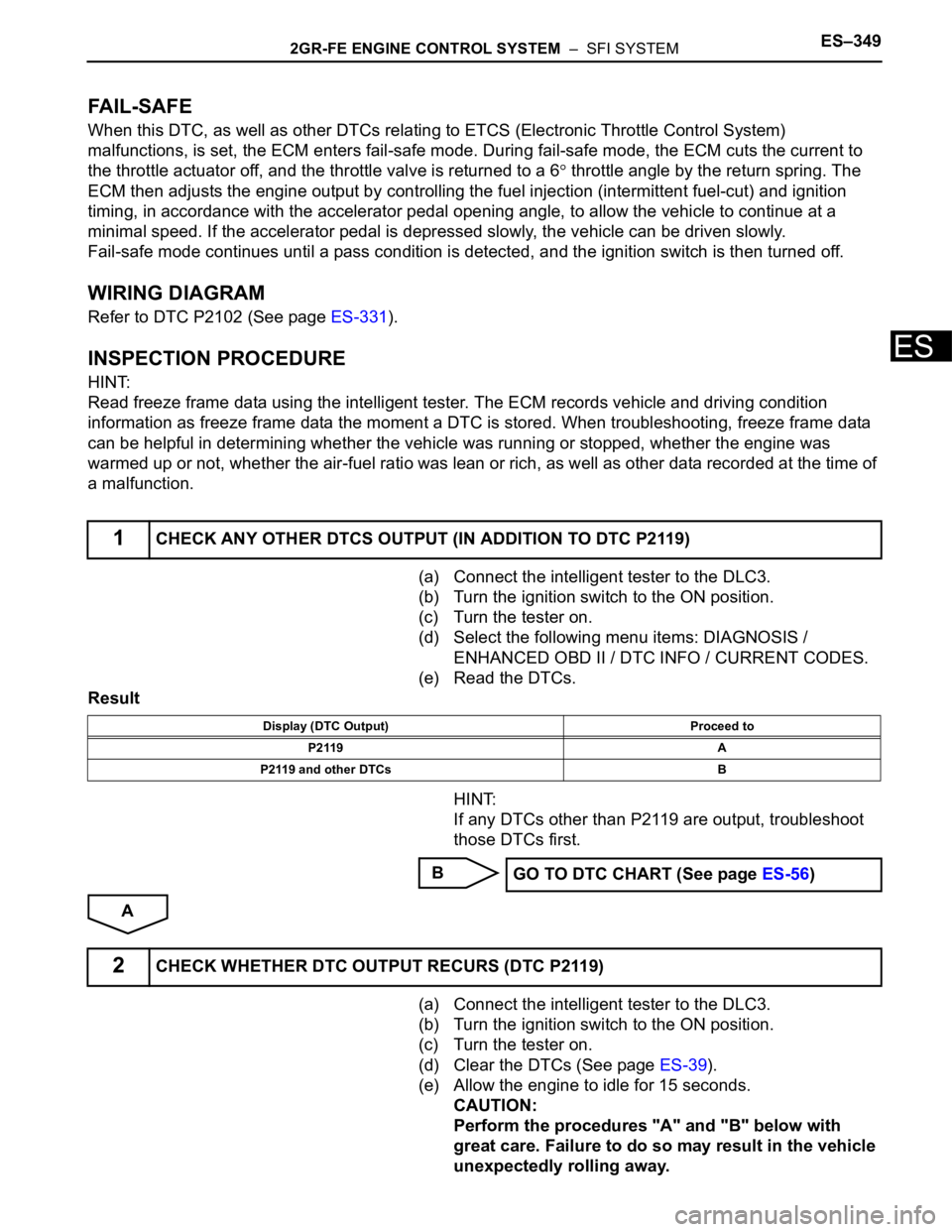

FAIL-SAFE

When this DTC, as well as other DTCs relating to ETCS (Electronic Throttle Control System)

malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to

the throttle actuator off, and the throttle valve is returned to a 6

throttle angle by the return spring. The

ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition

timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a

minimal speed. If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

WIRING DIAGRAM

Refer to DTC P2102 (See page ES-331).

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTCs.

Result

HINT:

If any DTCs other than P2119 are output, troubleshoot

those DTCs first.

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Clear the DTCs (See page ES-39).

(e) Allow the engine to idle for 15 seconds.

CAUTION:

Perform the procedures "A" and "B" below with

great care. Failure to do so may result in the vehicle

unexpectedly rolling away.

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2119)

Display (DTC Output) Proceed to

P2119 A

P2119 and other DTCs B

GO TO DTC CHART (See page ES-56)

2CHECK WHETHER DTC OUTPUT RECURS (DTC P2119)

Page 848 of 3000

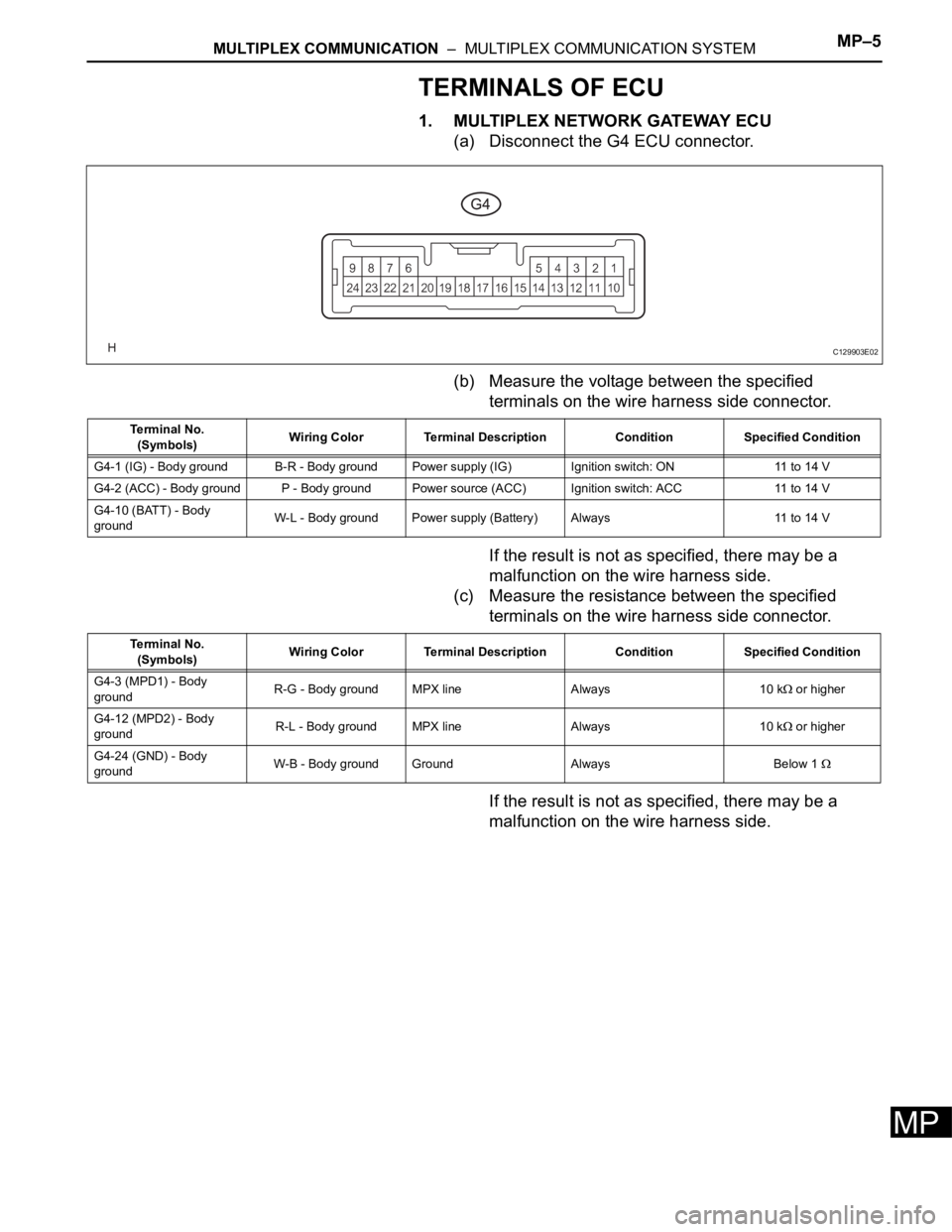

MULTIPLEX COMMUNICATION – MULTIPLEX COMMUNICATION SYSTEMMP–5

MP

TERMINALS OF ECU

1. MULTIPLEX NETWORK GATEWAY ECU

(a) Disconnect the G4 ECU connector.

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Measure the resistance between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

C129903E02

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

G4-1 (IG) - Body ground B-R - Body ground Power supply (IG) Ignition switch: ON 11 to 14 V

G4-2 (ACC) - Body ground P - Body ground Power source (ACC) Ignition switch: ACC 11 to 14 V

G4-10 (BATT) - Body

groundW-L - Body ground Power supply (Battery) Always 11 to 14 V

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

G4-3 (MPD1) - Body

groundR-G - Body ground MPX line Always 10 k

or higher

G4-12 (MPD2) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

G4-24 (GND) - Body

groundW-B - Body ground Ground Always Below 1

Page 850 of 3000

MULTIPLEX COMMUNICATION – MULTIPLEX COMMUNICATION SYSTEMMP–7

MP

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Measure the resistance between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

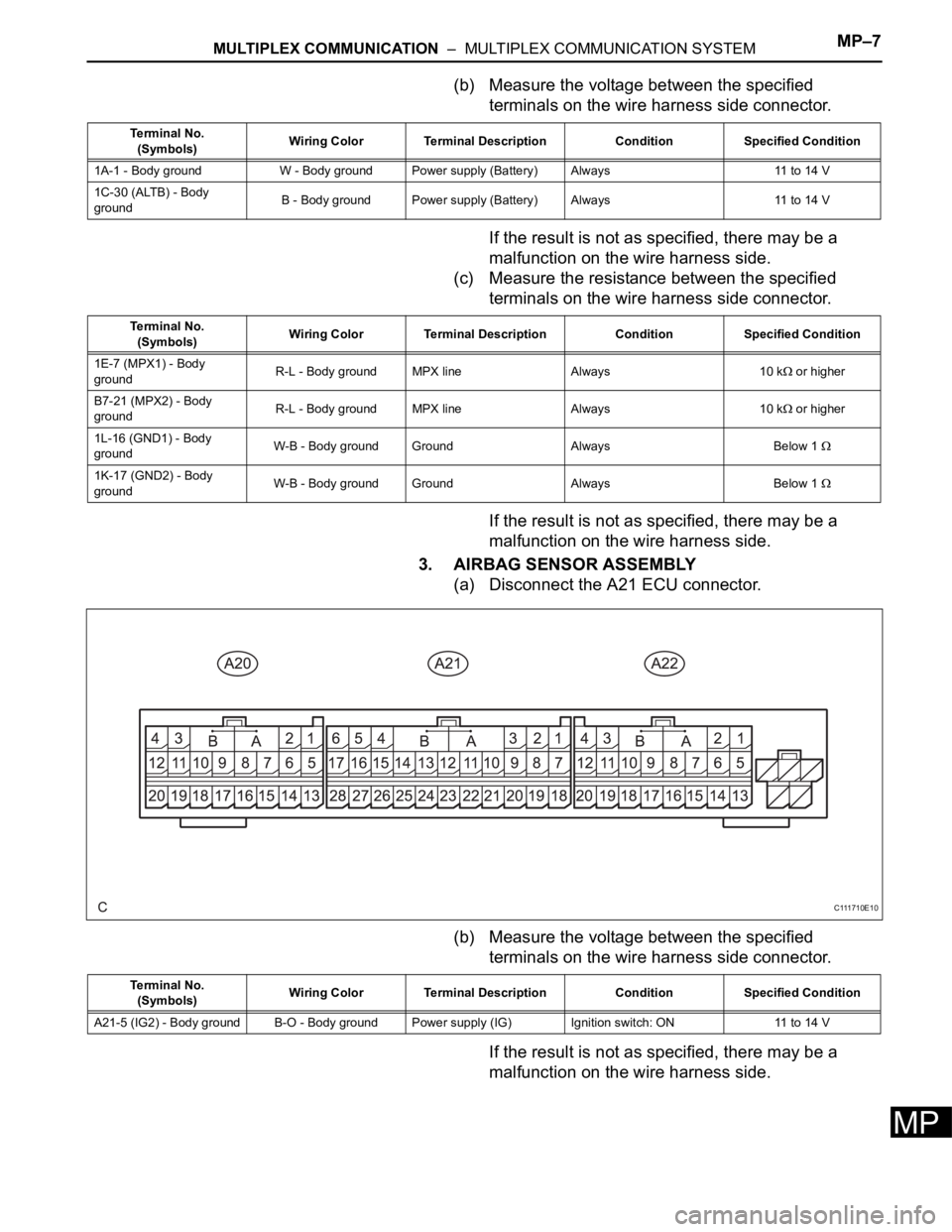

3. AIRBAG SENSOR ASSEMBLY

(a) Disconnect the A21 ECU connector.

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

1A-1 - Body ground W - Body ground Power supply (Battery) Always 11 to 14 V

1C-30 (ALTB) - Body

groundB - Body ground Power supply (Battery) Always 11 to 14 V

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

1E-7 (MPX1) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

B7-21 (MPX2) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

1L-16 (GND1) - Body

groundW-B - Body ground Ground Always Below 1

1K-17 (GND2) - Body

groundW-B - Body ground Ground Always Below 1

C111710E10

Terminal No.

(Symbols)Wiring Color Terminal Description Condition Specified Condition

A21-5 (IG2) - Body ground B-O - Body ground Power supply (IG) Ignition switch: ON 11 to 14 V

Page 851 of 3000

MP–8MULTIPLEX COMMUNICATION – MULTIPLEX COMMUNICATION SYSTEM

MP

(c) Measure the resistance between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

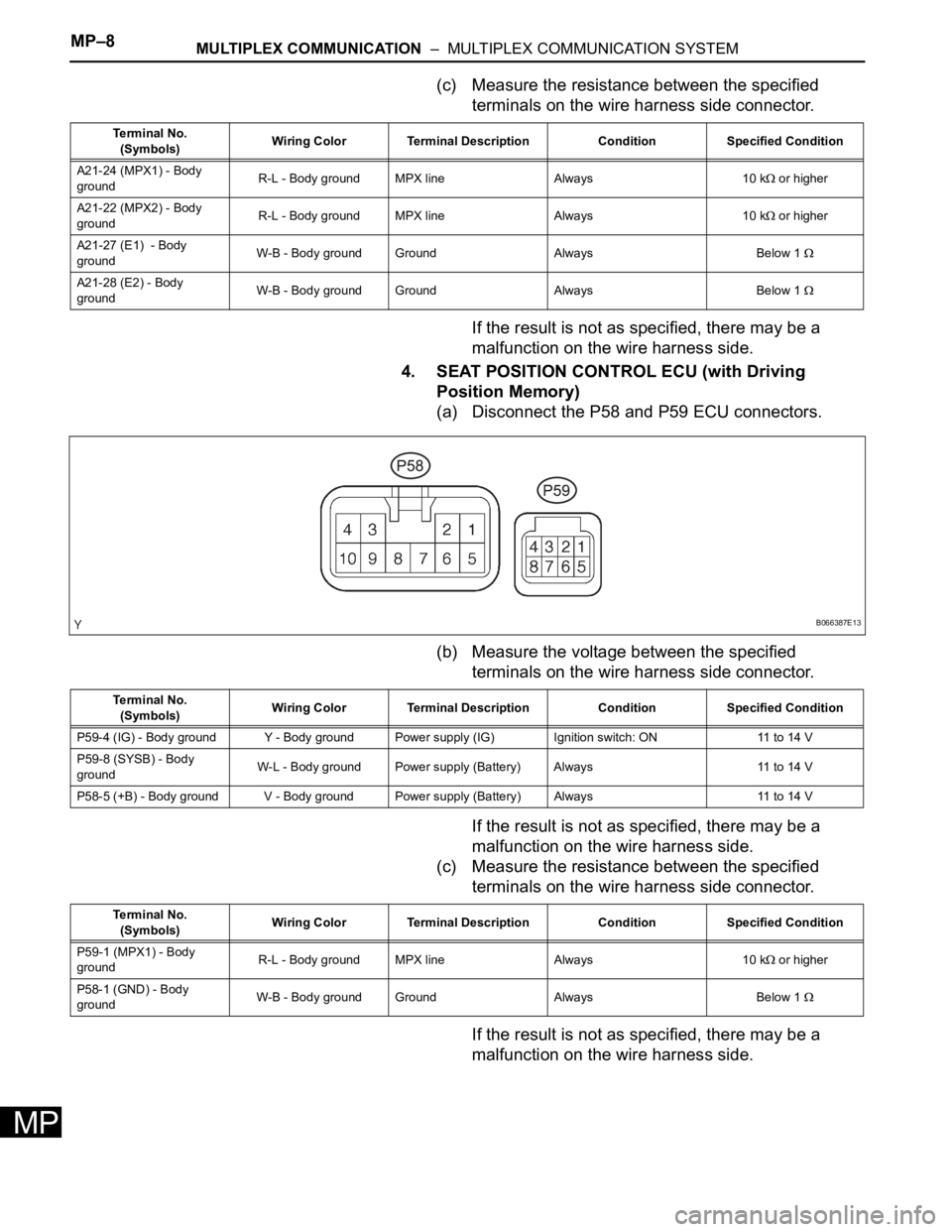

4. SEAT POSITION CONTROL ECU (with Driving

Position Memory)

(a) Disconnect the P58 and P59 ECU connectors.

(b) Measure the voltage between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Measure the resistance between the specified

terminals on the wire harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

Te r m i n a l N o .

(Symbols)Wiring Color Terminal Description Condition Specified Condition

A21-24 (MPX1) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

A21-22 (MPX2) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

A21-27 (E1) - Body

groundW-B - Body ground Ground Always Below 1

A21-28 (E2) - Body

groundW-B - Body ground Ground Always Below 1

B066387E13

Te r m i n a l N o .

(Symbols)Wiring Color Terminal Description Condition Specified Condition

P59-4 (IG) - Body ground Y - Body ground Power supply (IG) Ignition switch: ON 11 to 14 V

P59-8 (SYSB) - Body

groundW-L - Body ground Power supply (Battery) Always 11 to 14 V

P58-5 (+B) - Body ground V - Body ground Power supply (Battery) Always 11 to 14 V

Te r m i n a l N o .

(Symbols)Wiring Color Terminal Description Condition Specified Condition

P59-1 (MPX1) - Body

groundR-L - Body ground MPX line Always 10 k

or higher

P58-1 (GND) - Body

groundW-B - Body ground Ground Always Below 1