engine overheat TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 61 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–31

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20

C (68F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

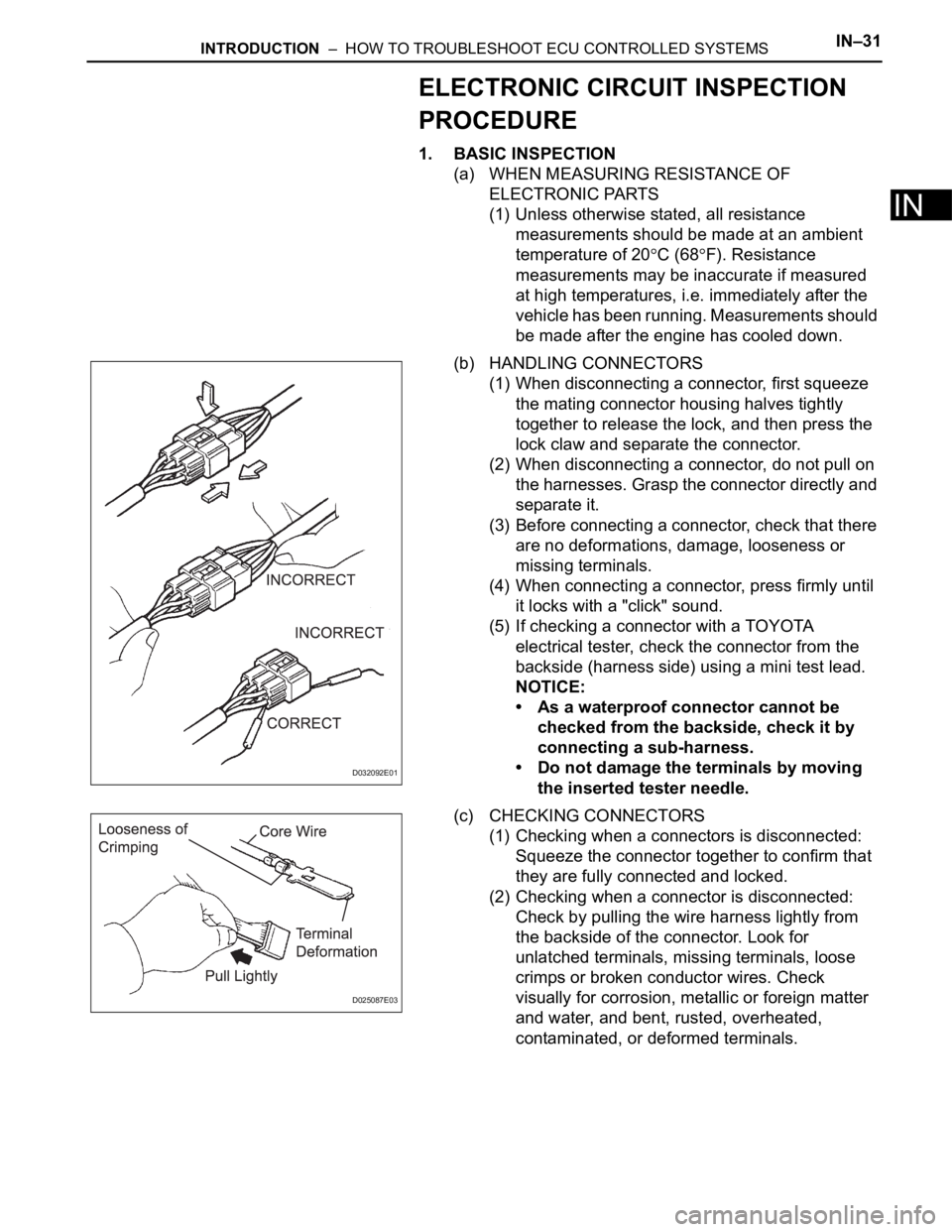

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating connector housing halves tightly

together to release the lock, and then press the

lock claw and separate the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformations, damage, looseness or

missing terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connectors is disconnected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Check by pulling the wire harness lightly from

the backside of the connector. Look for

unlatched terminals, missing terminals, loose

crimps or broken conductor wires. Check

visually for corrosion, metallic or foreign matter

and water, and bent, rusted, overheated,

contaminated, or deformed terminals.

D032092E01

D025087E03

Page 369 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–51

ES

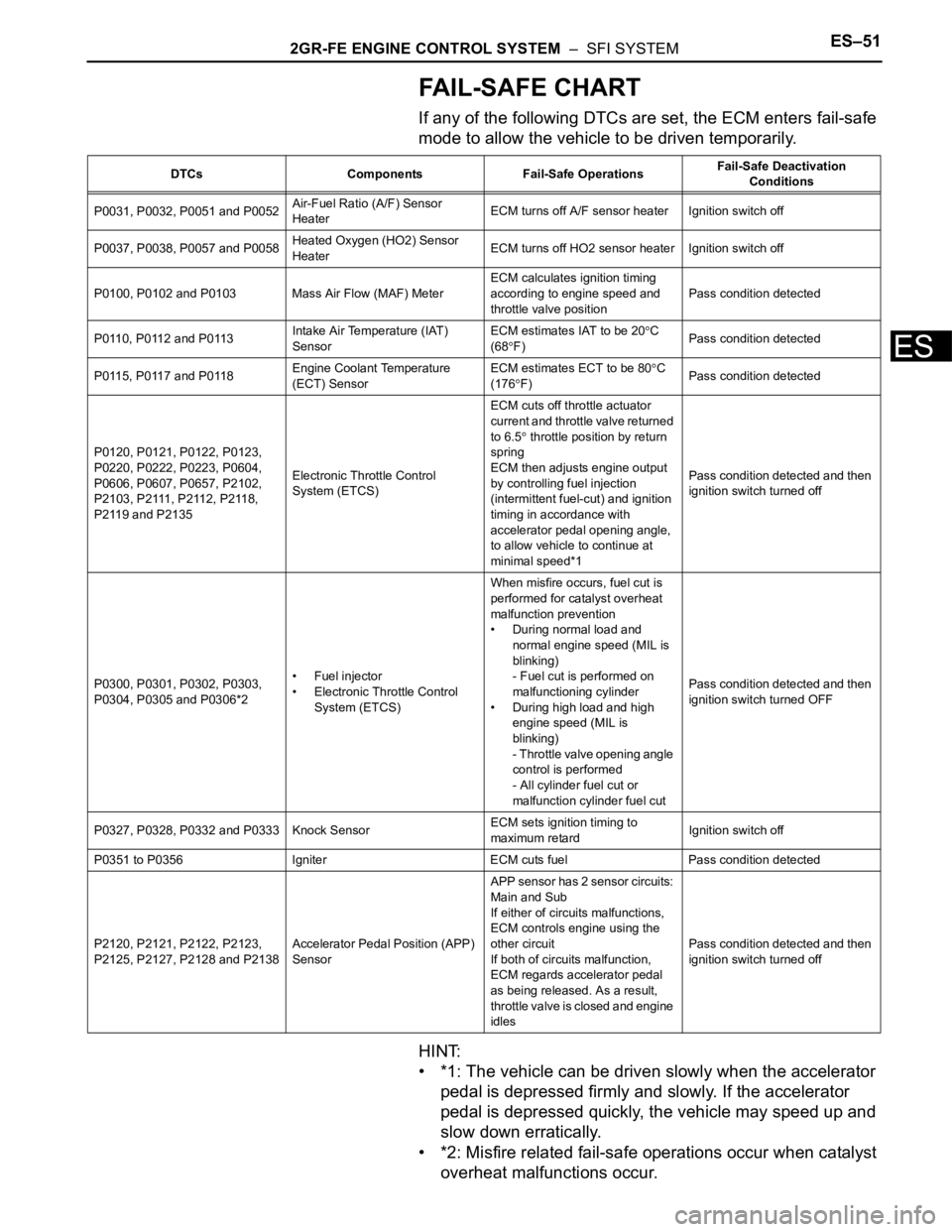

FAIL-SAFE CHART

If any of the following DTCs are set, the ECM enters fail-safe

mode to allow the vehicle to be driven temporarily.

HINT:

• *1: The vehicle can be driven slowly when the accelerator

pedal is depressed firmly and slowly. If the accelerator

pedal is depressed quickly, the vehicle may speed up and

slow down erratically.

• *2: Misfire related fail-safe operations occur when catalyst

overheat malfunctions occur.

DTCs Components Fail-Safe OperationsFail-Safe Deactivation

Conditions

P0031, P0032, P0051 and P0052Air-Fuel Ratio (A/F) Sensor

HeaterECM turns off A/F sensor heater Ignition switch off

P0037, P0038, P0057 and P0058Heated Oxygen (HO2) Sensor

HeaterECM turns off HO2 sensor heater Ignition switch off

P0100, P0102 and P0103 Mass Air Flow (MAF) MeterECM calculates ignition timing

according to engine speed and

throttle valve positionPass condition detected

P0110, P0112 and P0113Intake Air Temperature (IAT)

SensorECM estimates IAT to be 20

C

(68

F)Pass condition detected

P0115, P0117 and P0118Engine Coolant Temperature

(ECT) SensorECM estimates ECT to be 80

C

(176

F)Pass condition detected

P0120, P0121, P0122, P0123,

P0220, P0222, P0223, P0604,

P0606, P0607, P0657, P2102,

P2103, P2111, P2112, P2118,

P2119 and P2135Electronic Throttle Control

System (ETCS)ECM cuts off throttle actuator

current and throttle valve returned

to 6.5

throttle position by return

spring

ECM then adjusts engine output

by controlling fuel injection

(intermittent fuel-cut) and ignition

timing in accordance with

accelerator pedal opening angle,

to allow vehicle to continue at

minimal speed*1Pass condition detected and then

ignition switch turned off

P0300, P0301, P0302, P0303,

P0304, P0305 and P0306*2• Fuel injector

• Electronic Throttle Control

System (ETCS)When misfire occurs, fuel cut is

performed for catalyst overheat

malfunction prevention

• During normal load and

normal engine speed (MIL is

blinking)

- Fuel cut is performed on

malfunctioning cylinder

• During high load and high

engine speed (MIL is

blinking)

- Throttle valve opening angle

control is performed

- All cylinder fuel cut or

malfunction cylinder fuel cutPass condition detected and then

ignition switch turned OFF

P0327, P0328, P0332 and P0333 Knock SensorECM sets ignition timing to

maximum retardIgnition switch off

P0351 to P0356 Igniter ECM cuts fuel Pass condition detected

P2120, P2121, P2122, P2123,

P2125, P2127, P2128 and P2138Accelerator Pedal Position (APP)

SensorAPP sensor has 2 sensor circuits:

Main and Sub

If either of circuits malfunctions,

ECM controls engine using the

other circuit

If both of circuits malfunction,

ECM regards accelerator pedal

as being released. As a result,

throttle valve is closed and engine

idlesPass condition detected and then

ignition switch turned off

Page 1254 of 3000

CO–82GR-FE COOLING – COOLANT

CO

(j) Bleed air from the cooling system.

(1) Warm up the engine until the thermostat opens.

While the thermostat is open, circulate the

coolant for several minutes.

HINT:

The thermostat open timing can be confirmed

by squeezing the inlet radiator hose by hand,

and checking when the engine coolant starts to

flow inside the hose.

(2) Maintain the engine speed at 2500 to 3000

rpm.

(3) Squeeze the inlet and outlet radiator hoses

several times by hand to bleed air.

CAUTION:

When squeezing the radiator hoses:

• Wear protective gloves.

• Be careful as the radiator hoses are hot.

• Keep your hands away from the radiator

fan.

NOTICE:

• Make sure that the radiator reservoir still

has some coolant in it.

• If the coolant temperature gauge

indicates an excessive temperature, turn

off the engine and let it cool.

• If there is not enough coolant, the engine

may overheat or be seriously damaged.

• If the radiator reservoir does not have

enough coolant, perform the following: 1)

stop the engine, 2) wait until the coolant

has cooled down, and 3) add coolant

until the coolant is filled to the FULL line.

(k) Stop the engine and wait until the engine coolant

cools down.

(l) Add engine coolant to the FULL line on the radiator

reservoir.

5. INSPECT FOR COOLANT LEAK (See page CO-1)

6. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

7. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)