set clock TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 414 of 3000

ES–1082GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

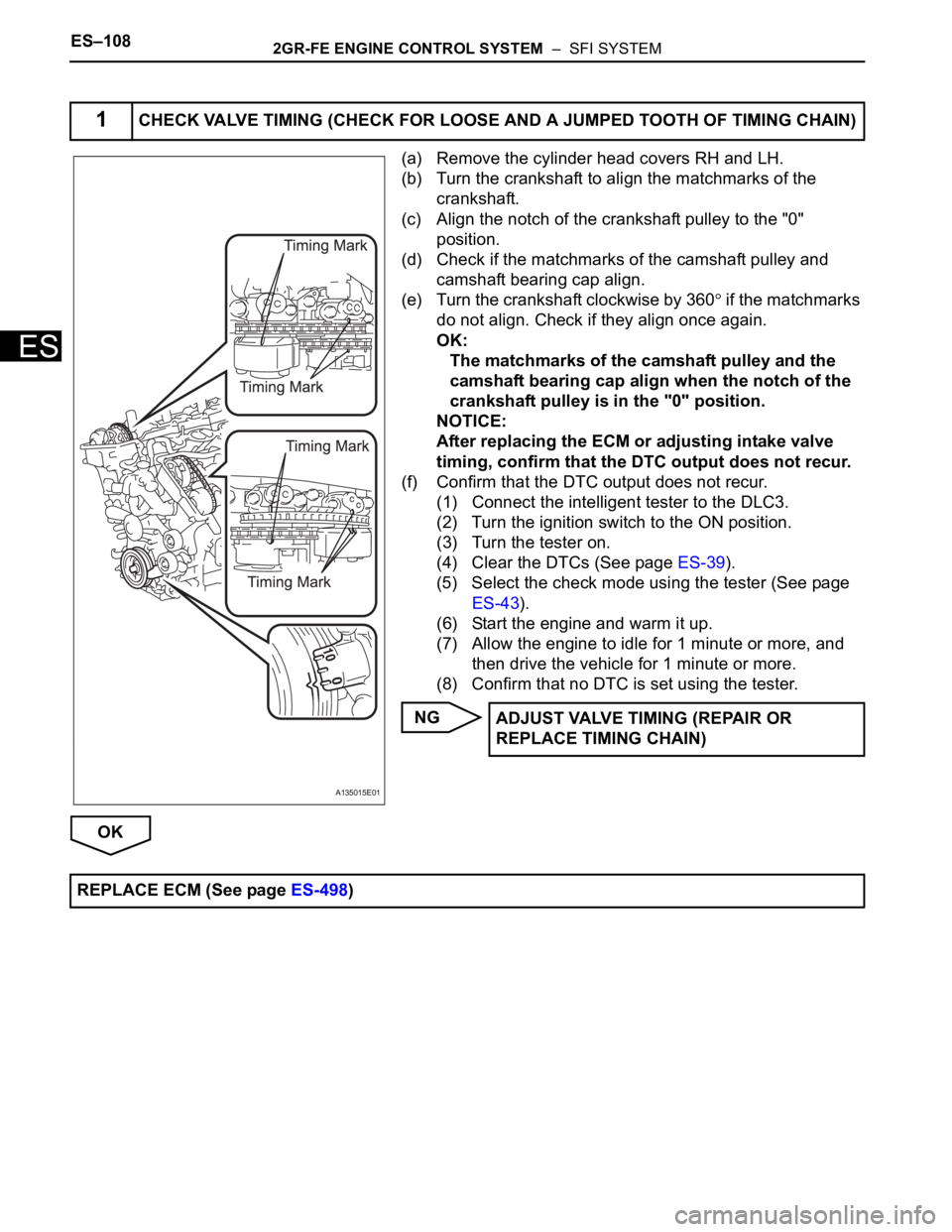

(a) Remove the cylinder head covers RH and LH.

(b) Turn the crankshaft to align the matchmarks of the

crankshaft.

(c) Align the notch of the crankshaft pulley to the "0"

position.

(d) Check if the matchmarks of the camshaft pulley and

camshaft bearing cap align.

(e) Turn the crankshaft clockwise by 360

if the matchmarks

do not align. Check if they align once again.

OK:

The matchmarks of the camshaft pulley and the

camshaft bearing cap align when the notch of the

crankshaft pulley is in the "0" position.

NOTICE:

After replacing the ECM or adjusting intake valve

timing, confirm that the DTC output does not recur.

(f) Confirm that the DTC output does not recur.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester on.

(4) Clear the DTCs (See page ES-39).

(5) Select the check mode using the tester (See page

ES-43).

(6) Start the engine and warm it up.

(7) Allow the engine to idle for 1 minute or more, and

then drive the vehicle for 1 minute or more.

(8) Confirm that no DTC is set using the tester.

NG

OK

1CHECK VALVE TIMING (CHECK FOR LOOSE AND A JUMPED TOOTH OF TIMING CHAIN)

A135015E01

ADJUST VALVE TIMING (REPAIR OR

REPLACE TIMING CHAIN)

REPLACE ECM (See page ES-498)

Page 686 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–393

ES

MONITOR DESCRIPTION

5 hours after the ignition switch is turned off, the soak timer activates the ECM to begin the EVAP system

monitor. While the engine is running, the ECM monitors the synchronization of the soak timer and the

CPU clock. If these two are not synchronized, the ECM interprets this as a malfunction, illuminates the

MIL and sets the DTC (2 trip detection logic).

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

• DTC P2610 is set if an internal ECM problem is detected. Diagnostic procedures are not required.

ECM replacement is required.

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Replace the ECM (See page ES-498).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and wait for 10 minutes or more.

Required Sensors / Components ECM

Frequency of Operation Once per driving cycle

Duration 10 minutes

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Ignition switch ON

Engine Running

Battery voltage 8 V or more

Sta r t e r OF F

Soak timer measurement when ECM CPU clock counts

10 minutesLess than 7 minutes or more than 13 minutes

1REPLACE ECM

2CHECK WHETHER DTC OUTPUT RECURS

Page 892 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–87

EM

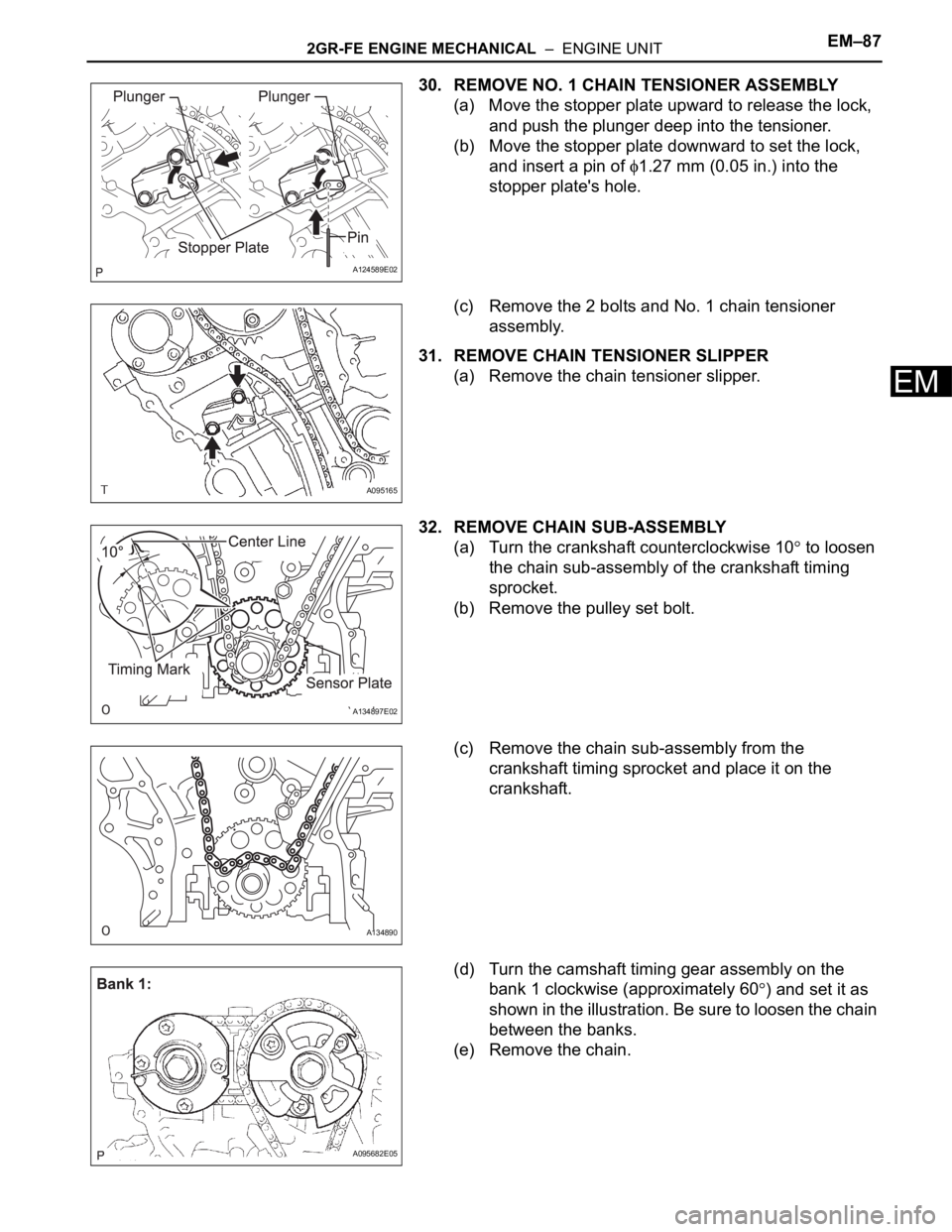

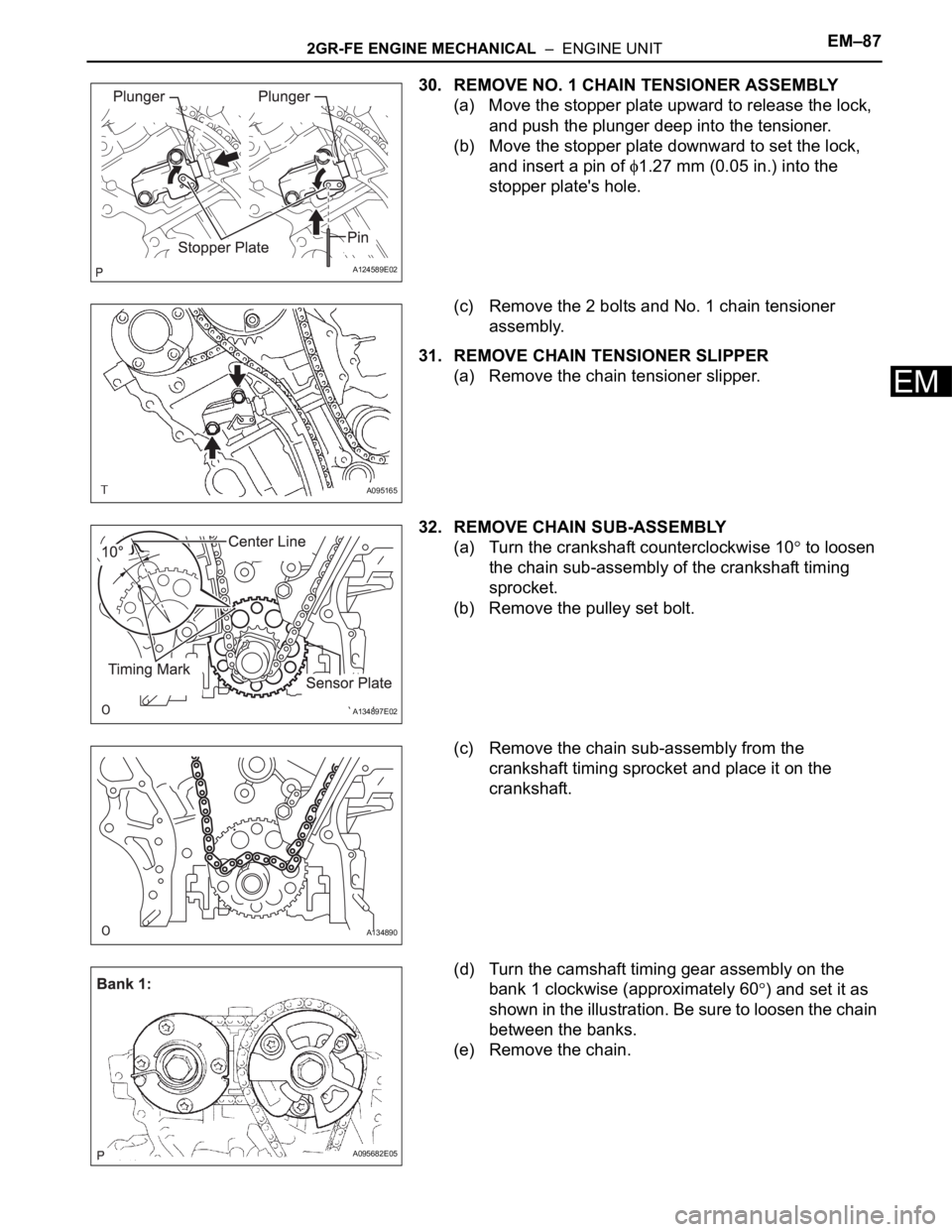

30. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a pin of

1.27 mm (0.05 in.) into the

stopper plate's hole.

(c) Remove the 2 bolts and No. 1 chain tensioner

assembly.

31. REMOVE CHAIN TENSIONER SLIPPER

(a) Remove the chain tensioner slipper.

32. REMOVE CHAIN SUB-ASSEMBLY

(a) Turn the crankshaft counterclockwise 10

to loosen

the chain sub-assembly of the crankshaft timing

sprocket.

(b) Remove the pulley set bolt.

(c) Remove the chain sub-assembly from the

crankshaft timing sprocket and place it on the

crankshaft.

(d) Turn the camshaft timing gear assembly on the

bank 1 clockwise (approximately 60

) and set it as

shown in the illustration. Be sure to loosen the chain

between the banks.

(e) Remove the chain.

A124589E02

A095165

A134897E02

A134890

A095682E05

Page 960 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–151

EM

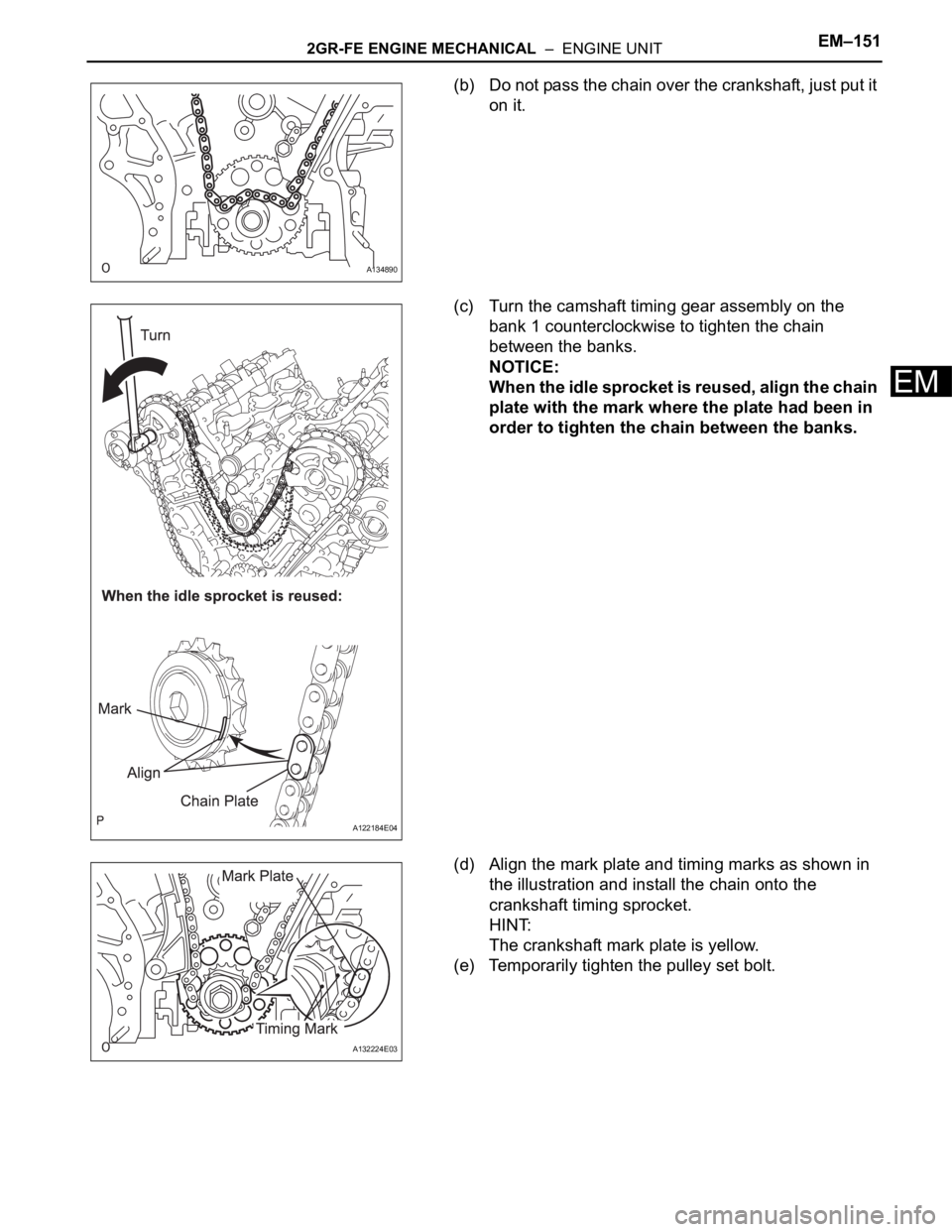

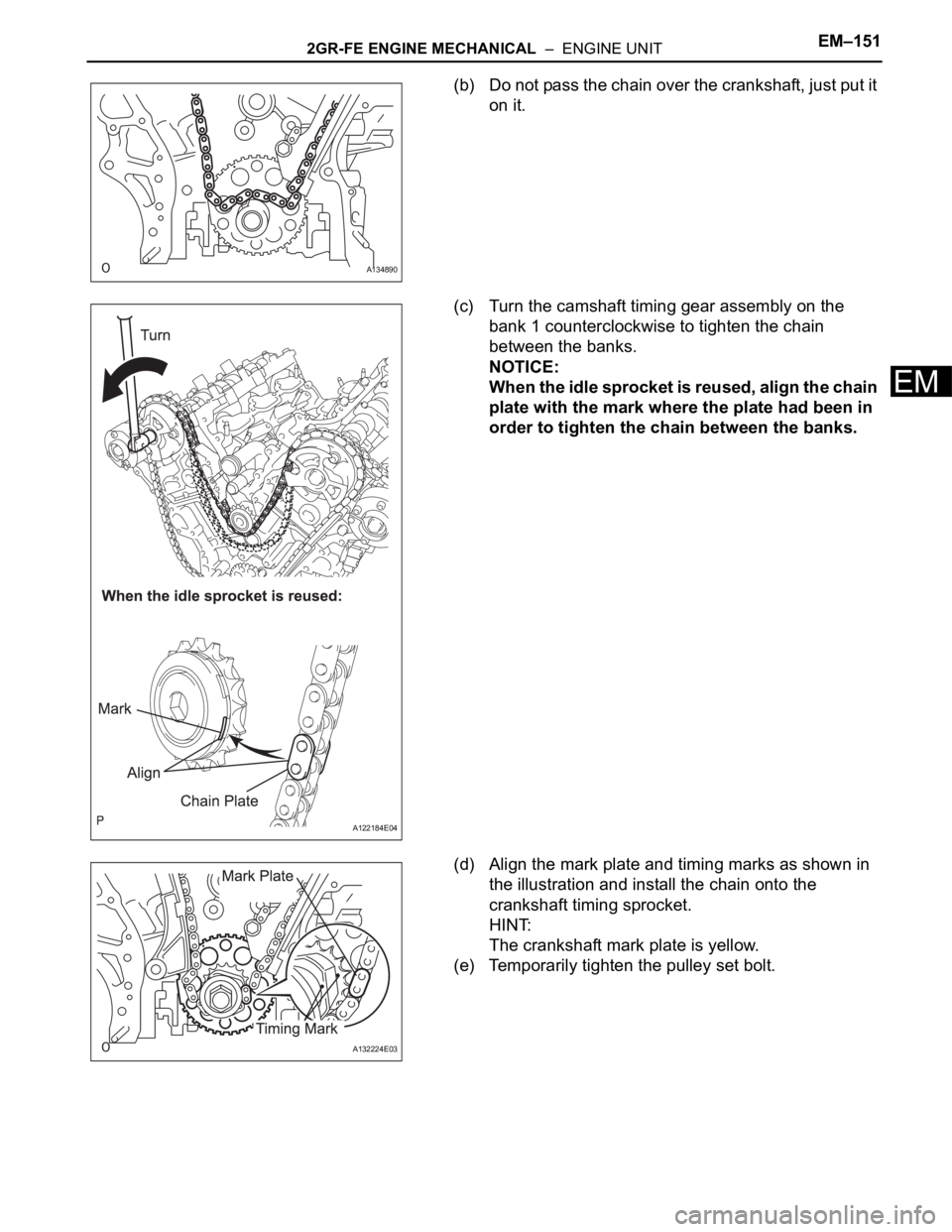

(b) Do not pass the chain over the crankshaft, just put it

on it.

(c) Turn the camshaft timing gear assembly on the

bank 1 counterclockwise to tighten the chain

between the banks.

NOTICE:

When the idle sprocket is reused, align the chain

plate with the mark where the plate had been in

order to tighten the chain between the banks.

(d) Align the mark plate and timing marks as shown in

the illustration and install the chain onto the

crankshaft timing sprocket.

HINT:

The crankshaft mark plate is yellow.

(e) Temporarily tighten the pulley set bolt.

A134890

A122184E04

A132224E03

Page 961 of 3000

EM–1522GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

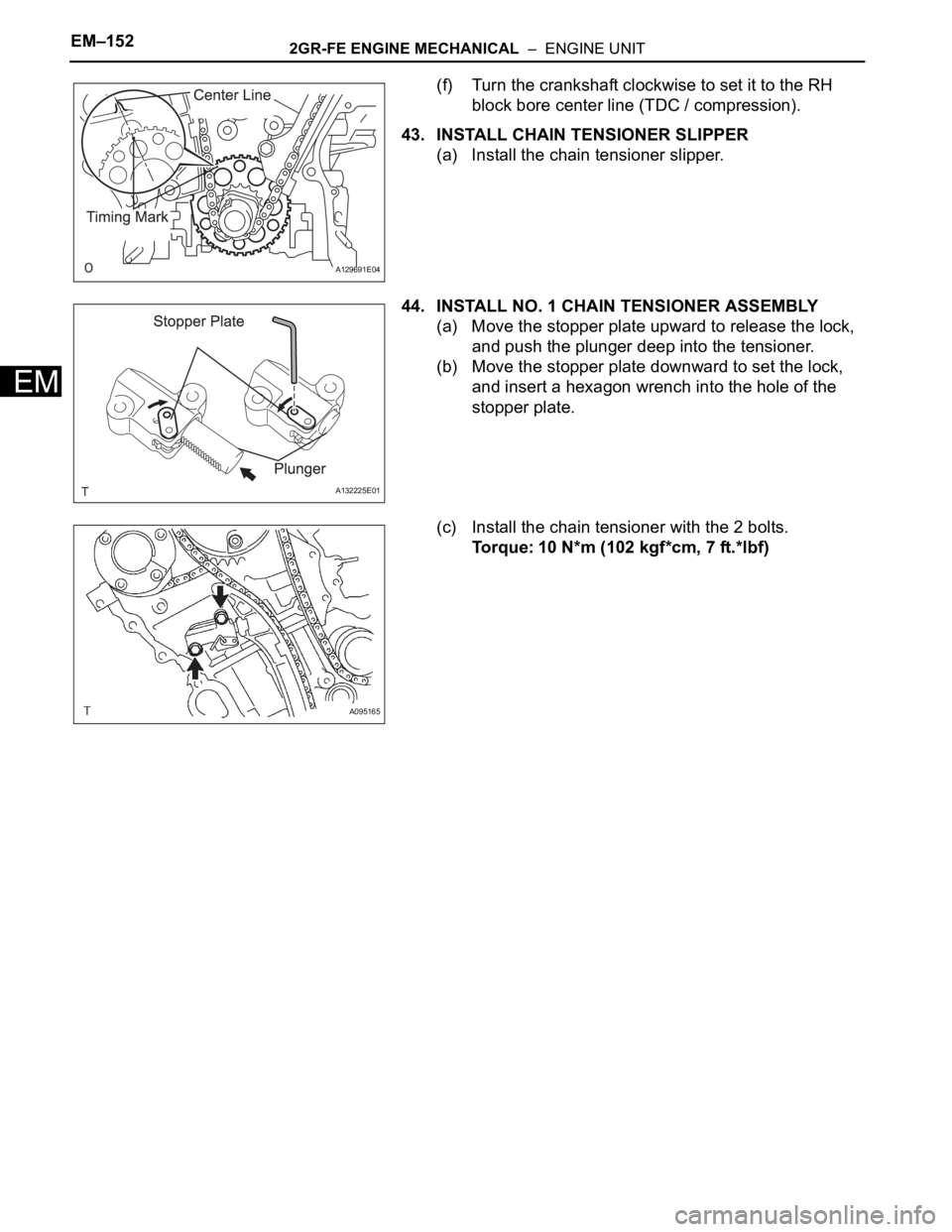

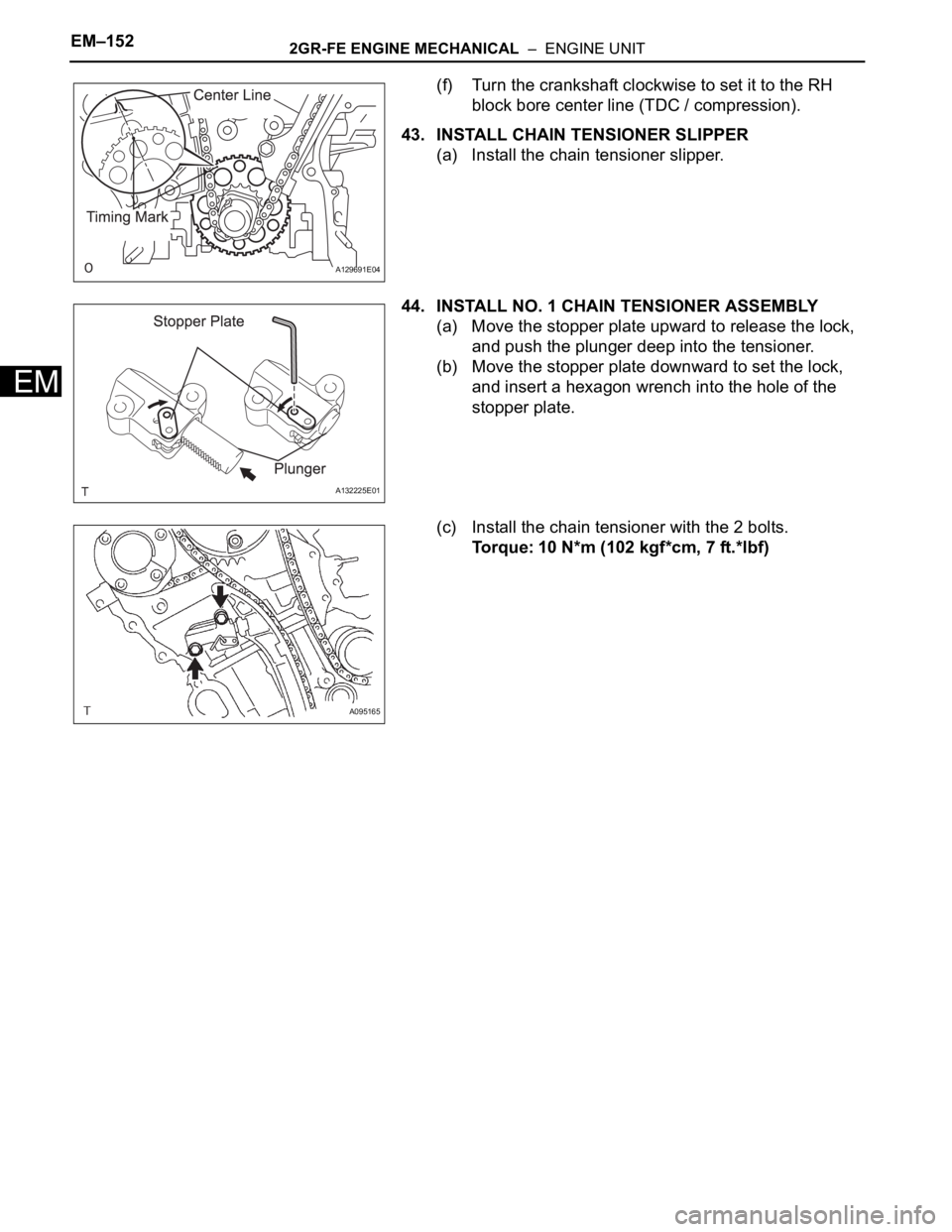

(f) Turn the crankshaft clockwise to set it to the RH

block bore center line (TDC / compression).

43. INSTALL CHAIN TENSIONER SLIPPER

(a) Install the chain tensioner slipper.

44. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a hexagon wrench into the hole of the

stopper plate.

(c) Install the chain tensioner with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A129691E04

A132225E01

A095165

Page 981 of 3000

2GR-FE ENGINE MECHANICAL – DRIVE BELTEM–7

EM

INSTALLATION

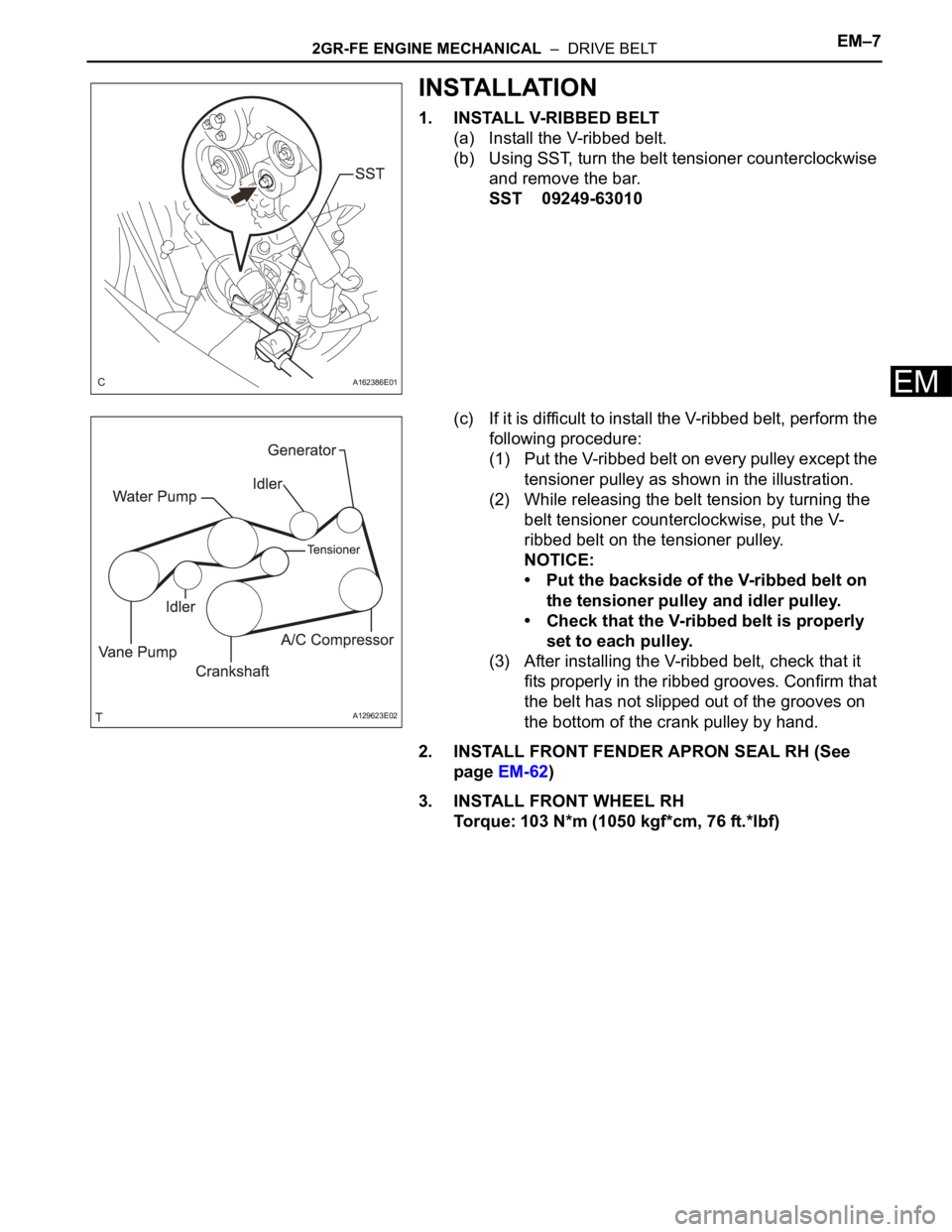

1. INSTALL V-RIBBED BELT

(a) Install the V-ribbed belt.

(b) Using SST, turn the belt tensioner counterclockwise

and remove the bar.

SST 09249-63010

(c) If it is difficult to install the V-ribbed belt, perform the

following procedure:

(1) Put the V-ribbed belt on every pulley except the

tensioner pulley as shown in the illustration.

(2) While releasing the belt tension by turning the

belt tensioner counterclockwise, put the V-

ribbed belt on the tensioner pulley.

NOTICE:

• Put the backside of the V-ribbed belt on

the tensioner pulley and idler pulley.

• Check that the V-ribbed belt is properly

set to each pulley.

(3) After installing the V-ribbed belt, check that it

fits properly in the ribbed grooves. Confirm that

the belt has not slipped out of the grooves on

the bottom of the crank pulley by hand.

2. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

3. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

A162386E01

A129623E02

Page 1034 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–87

EM

30. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a pin of

1.27 mm (0.05 in.) into the

stopper plate's hole.

(c) Remove the 2 bolts and No. 1 chain tensioner

assembly.

31. REMOVE CHAIN TENSIONER SLIPPER

(a) Remove the chain tensioner slipper.

32. REMOVE CHAIN SUB-ASSEMBLY

(a) Turn the crankshaft counterclockwise 10

to loosen

the chain sub-assembly of the crankshaft timing

sprocket.

(b) Remove the pulley set bolt.

(c) Remove the chain sub-assembly from the

crankshaft timing sprocket and place it on the

crankshaft.

(d) Turn the camshaft timing gear assembly on the

bank 1 clockwise (approximately 60

) and set it as

shown in the illustration. Be sure to loosen the chain

between the banks.

(e) Remove the chain.

A124589E02

A095165

A134897E02

A134890

A095682E05

Page 1098 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–151

EM

(b) Do not pass the chain over the crankshaft, just put it

on it.

(c) Turn the camshaft timing gear assembly on the

bank 1 counterclockwise to tighten the chain

between the banks.

NOTICE:

When the idle sprocket is reused, align the chain

plate with the mark where the plate had been in

order to tighten the chain between the banks.

(d) Align the mark plate and timing marks as shown in

the illustration and install the chain onto the

crankshaft timing sprocket.

HINT:

The crankshaft mark plate is yellow.

(e) Temporarily tighten the pulley set bolt.

A134890

A122184E04

A132224E03

Page 1099 of 3000

EM–1522GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(f) Turn the crankshaft clockwise to set it to the RH

block bore center line (TDC / compression).

43. INSTALL CHAIN TENSIONER SLIPPER

(a) Install the chain tensioner slipper.

44. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a hexagon wrench into the hole of the

stopper plate.

(c) Install the chain tensioner with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A129691E04

A132225E01

A095165

Page 1618 of 3000

AX–170U151E AUTOMATIC TRANSAXLE – TORQUE CONVERTER CLUTCH AND DRIVE PLATE

AX

TORQUE CONVERTER CLUTCH

AND DRIVE PLATE

INSPECTION

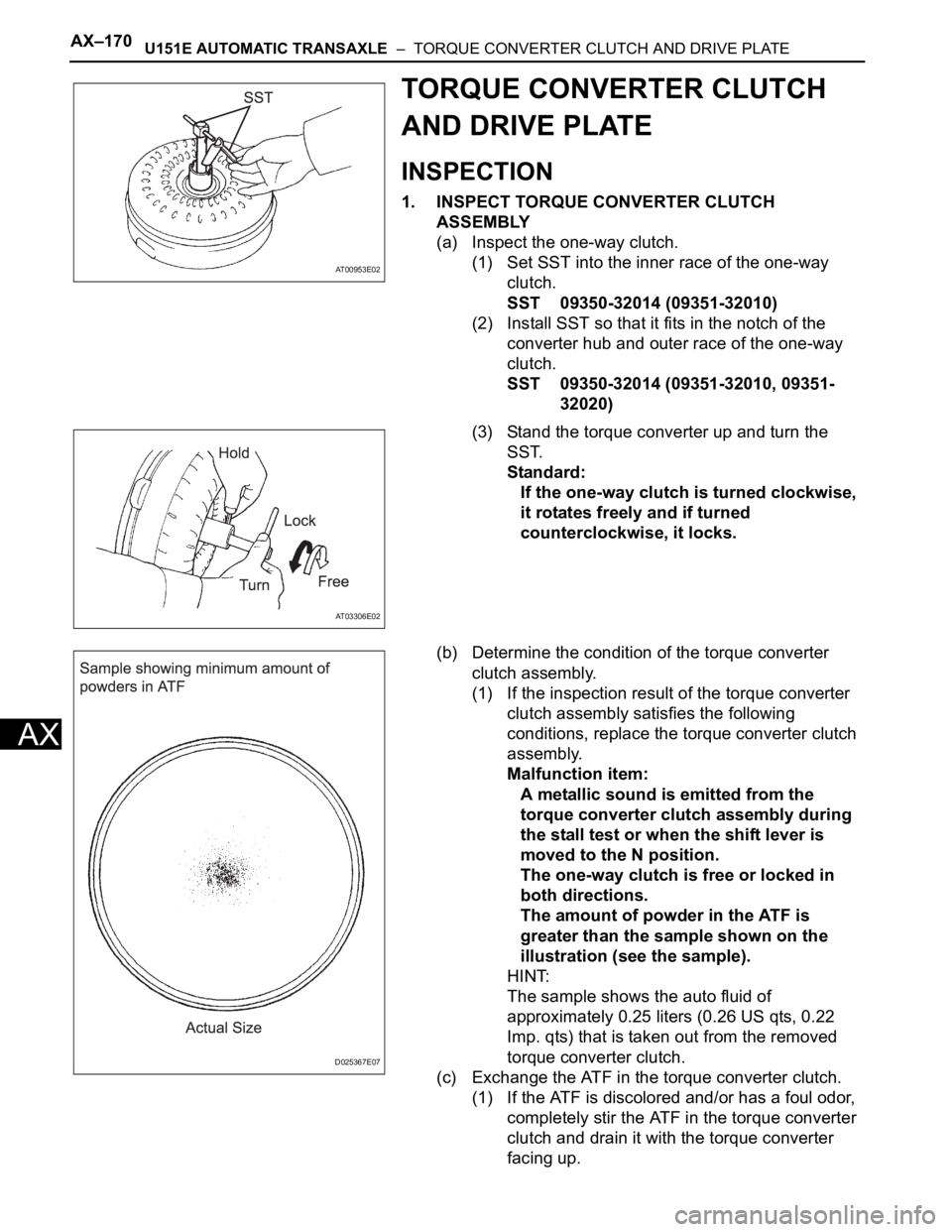

1. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

(a) Inspect the one-way clutch.

(1) Set SST into the inner race of the one-way

clutch.

SST 09350-32014 (09351-32010)

(2) Install SST so that it fits in the notch of the

converter hub and outer race of the one-way

clutch.

SST 09350-32014 (09351-32010, 09351-

32020)

(3) Stand the torque converter up and turn the

SST.

Standard:

If the one-way clutch is turned clockwise,

it rotates freely and if turned

counterclockwise, it locks.

(b) Determine the condition of the torque converter

clutch assembly.

(1) If the inspection result of the torque converter

clutch assembly satisfies the following

conditions, replace the torque converter clutch

assembly.

Malfunction item:

A metallic sound is emitted from the

torque converter clutch assembly during

the stall test or when the shift lever is

moved to the N position.

The one-way clutch is free or locked in

both directions.

The amount of powder in the ATF is

greater than the sample shown on the

illustration (see the sample).

HINT:

The sample shows the auto fluid of

approximately 0.25 liters (0.26 US qts, 0.22

Imp. qts) that is taken out from the removed

torque converter clutch.

(c) Exchange the ATF in the torque converter clutch.

(1) If the ATF is discolored and/or has a foul odor,

completely stir the ATF in the torque converter

clutch and drain it with the torque converter

facing up.

AT00953E02

AT03306E02

D025367E07