TOYOTA SUPRA 1986 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1986, Model line: SUPRA, Model: TOYOTA SUPRA 1986Pages: 878, PDF Size: 20 MB

Page 581 of 878

2. INSTALL IDLER PULLEY

(See step 2 in timing belt installation in Engine Mechani-

cal)

3. 2JZ±GTE:

INSTALL WATER OUTLET AND NO.1 WATER BYPASS

PIPE

(a) Install 2 new O±rings to the No.1 water bypass pipe.

(b) Apply soapy water to the O±rings.

(c) Install the No.1 water pass pipe to the water pump.

(d) Install a new gasket and the water outlet with the 2 bolts.

Torque: 21 NVm (210 kgfVcm, 15 ftVlbf)

(e) Connect the ECT sensor and sender gauge connectors.

4. 2JZ±GE:

INSTALL WATER BYPASS OUTLET AND NO.1 WATER

BYPASS PIPE

(a) Install 2 new O±rings to the No.1 water bypass pipe.

(b) Install a new O±ring and the water bypass outlet with the 2

bolts.

Torque: 8.8 NVm (90 kgfVcm, 78 in.Vlbf)

5. 2JZ±GTE:

CONNECT TURBO WATER HOSES TO WATER OUTLET

6. 2JZ±GE Except California:

INSTALL EXHAUST MANIFOLD HEAT INSULATOR

7. 2JZ±GTE:

INSTALL GENERATOR

(See generator installation in Charging System)

8. INSTALL TIMING BELT

(See steps 10 to 14 in timing belt installation in Engine

Mechanical)

9. INSTALL WATER INLET AND LOWER RADIATOR HOSE

ASSEMBLY

(See thermostat installation)

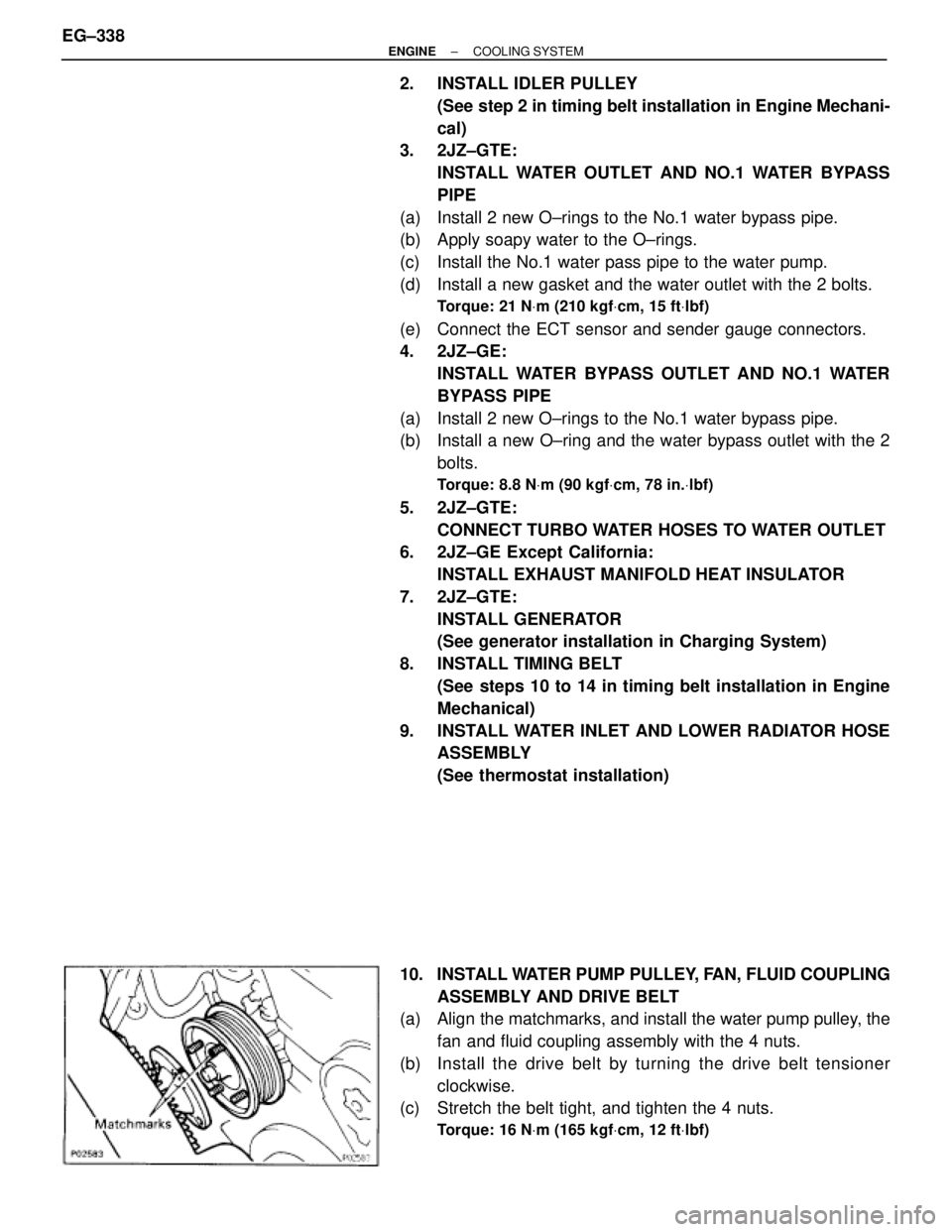

10. INSTALL WATER PUMP PULLEY, FAN, FLUID COUPLING

ASSEMBLY AND DRIVE BELT

(a) Align the matchmarks, and install the water pump pulley, the

fan and fluid coupling assembly with the 4 nuts.

(b) Install the drive belt by turning the drive belt tensioner

clockwise.

(c) Stretch the belt tight, and tighten the 4 nuts.

Torque: 16 NVm (165 kgfVcm, 12 ftVlbf)

EG±338± ENGINECOOLING SYSTEM

Page 582 of 878

11. 2JZ±GTE M/T:

INSTALL DRIVE BELT TENSIONER DAMPER

12. INSTALL RADIATOR ASSEMBLY

(See radiator installation)

13. 2JZ±GE:

INSTALL AIR CLEANER, VAF METER AND INTAKE AIR

CONNECTOR PIPE ASSEMBLY

14. 2JZ±GTE:

INSTALL AIR CLEANER AND MAF METER ASSEMBLY

15. 2JZ±GTE:

INSTALL NO.1 AIR HOSE

16. ROAD TEST VEHICLE

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

± ENGINECOOLING SYSTEMEG±339

Page 583 of 878

THERMOSTAT

COMPONENTS FOR REMOVAL AND

INSTALLATION

EG±340± ENGINECOOLING SYSTEM

Page 584 of 878

THERMOSTAT REMOVAL

HINT: Removal of the thermostat would have an adverse ef-

fect, causing a lowering of cooling efficiency.

Do not remove the thermostat, even if the engine tends to

overheat.

1. 2JZ±GTE:

REMOVE ENGINE UNDER COVER

2. DRAIN ENGINE COOLANT

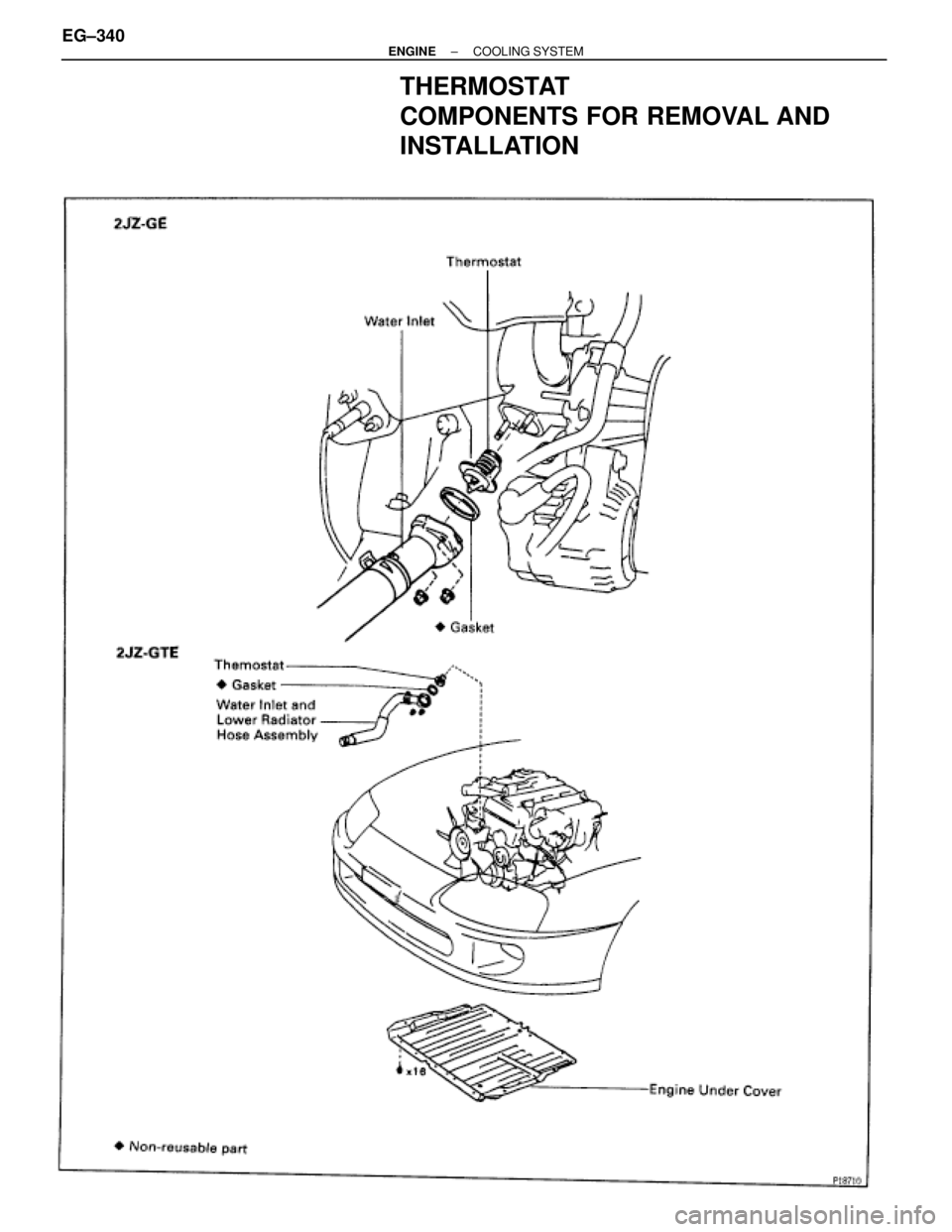

3. 2JZ±GE:

DISCONNECT WATER INLET FROM WATER PUMP, AND

REMOVE THERMOSTAT

(a) Remove the 2 nuts holding the water inlet to the water pump,

and disconnect the water inlet from the water pump.

(b) Remove the thermostat.

(c) Remove the gasket from the thermostat.

4. 2JZ±GTE:

REMOVE WATER INLET, LOWER RADIATOR HOSE AS-

SEMBLY AND THERMOSTAT

(a) Disconnect the lower radiator hose from the radiator.

(b) Remove the 2 nuts holding the water inlet to the water pump,

and disconnect the water inlet and lower radiator hose from

the water pump.

(c) Remove the thermostat.

(d) Remove the gasket from the thermostat.

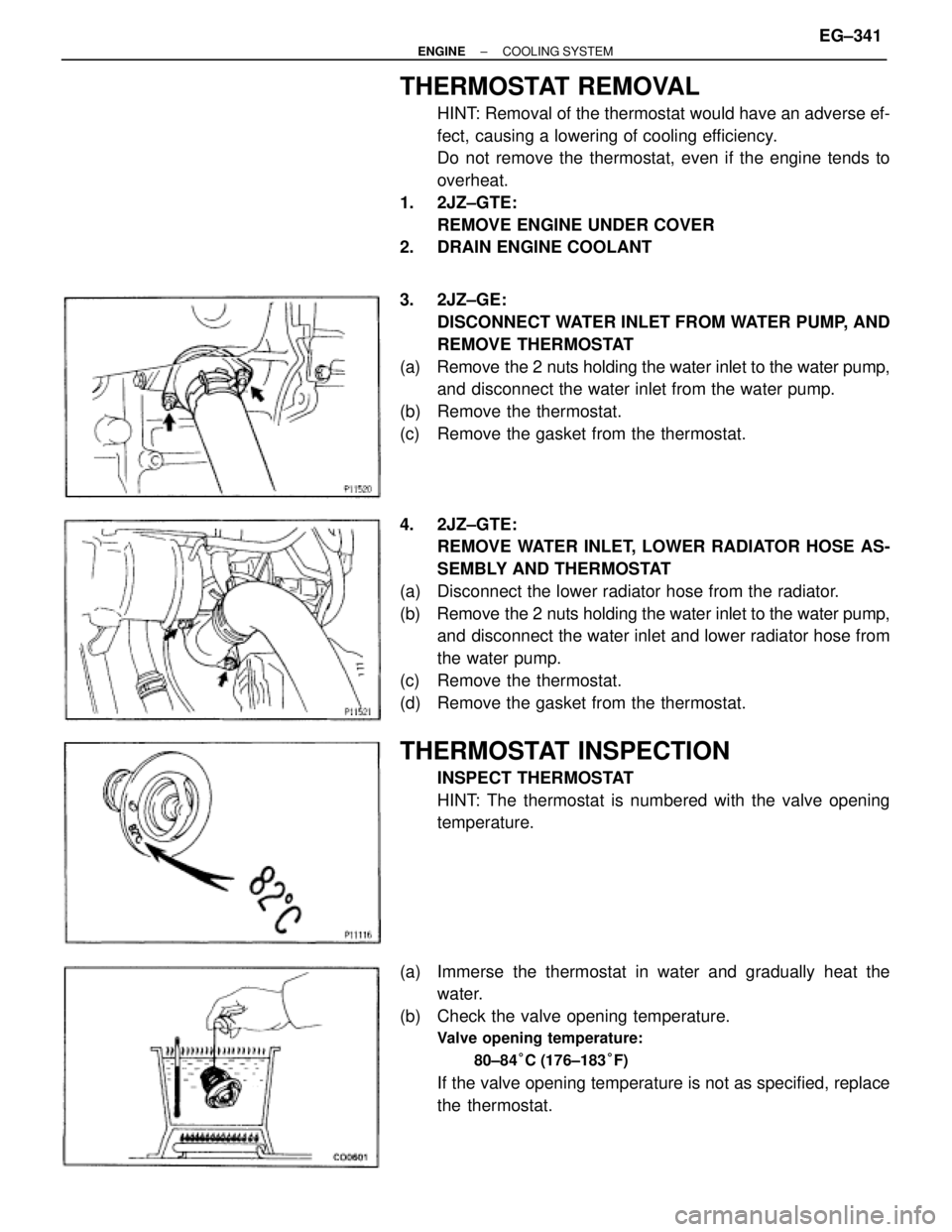

THERMOSTAT INSPECTION

INSPECT THERMOSTAT

HINT: The thermostat is numbered with the valve opening

temperature.

(a) Immerse the thermostat in water and gradually heat the

water.

(b) Check the valve opening temperature.

Valve opening temperature:

80±84°C (176±183°F)

If the valve opening temperature is not as specified, replace

the thermostat.

± ENGINECOOLING SYSTEMEG±341

Page 585 of 878

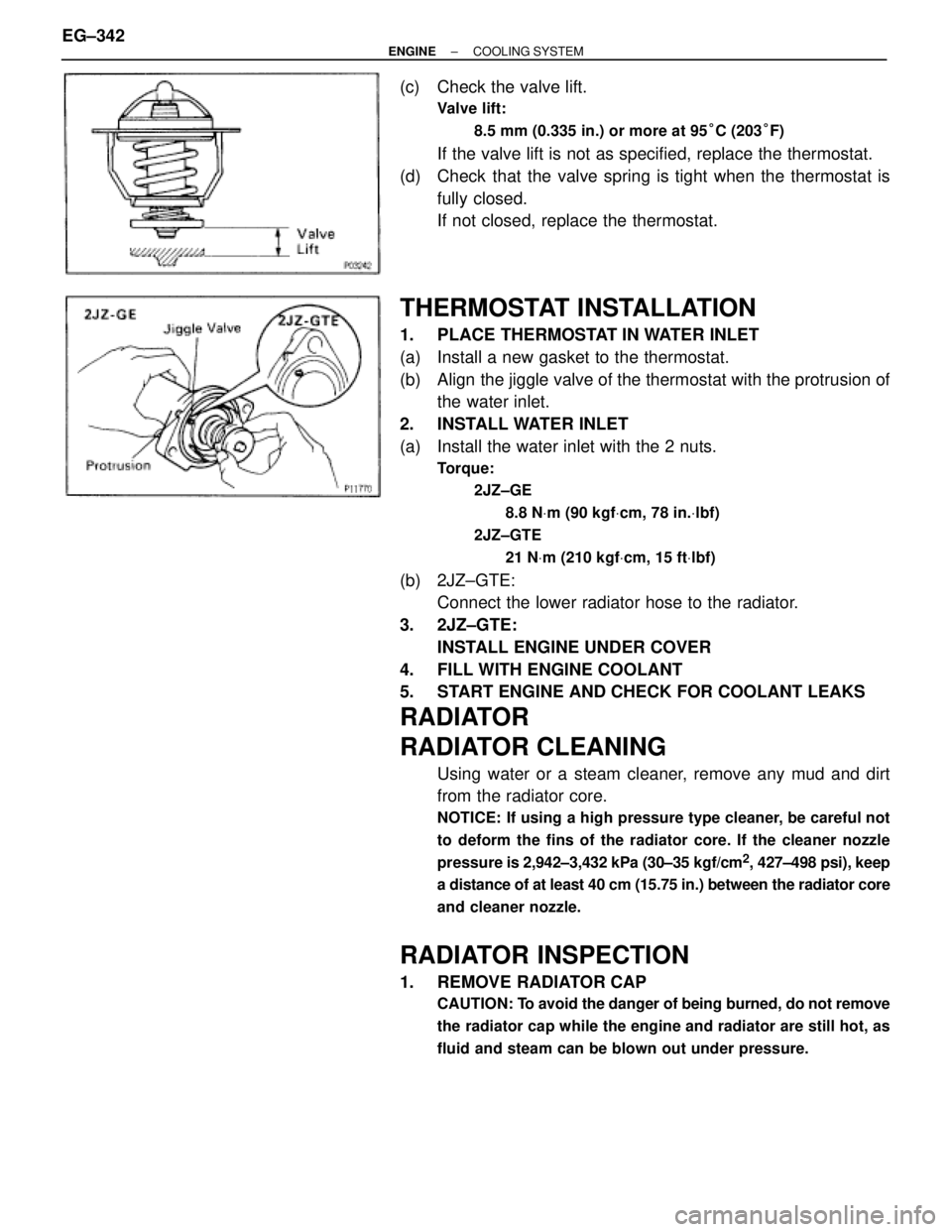

(c) Check the valve lift.

Valve lift:

8.5 mm (0.335 in.) or more at 95°C (203°F)

If the valve lift is not as specified, replace the thermostat.

(d) Check that the valve spring is tight when the thermostat is

fully closed.

If not closed, replace the thermostat.

THERMOSTAT INSTALLATION

1. PLACE THERMOSTAT IN WATER INLET

(a) Install a new gasket to the thermostat.

(b) Align the jiggle valve of the thermostat with the protrusion of

the water inlet.

2. INSTALL WATER INLET

(a) Install the water inlet with the 2 nuts.

Torque:

2JZ±GE

8.8 NVm (90 kgfVcm, 78 in.Vlbf)

2JZ±GTE

21 NVm (210 kgfVcm, 15 ftVlbf)

(b) 2JZ±GTE:

Connect the lower radiator hose to the radiator.

3. 2JZ±GTE:

INSTALL ENGINE UNDER COVER

4. FILL WITH ENGINE COOLANT

5. START ENGINE AND CHECK FOR COOLANT LEAKS

RADIATOR

RADIATOR CLEANING

Using water or a steam cleaner, remove any mud and dirt

from the radiator core.

NOTICE: If using a high pressure type cleaner, be careful not

to deform the fins of the radiator core. If the cleaner nozzle

pressure is 2,942±3,432 kPa (30±35 kgf/cm

2, 427±498 psi), keep

a distance of at least 40 cm (15.75 in.) between the radiator core

and cleaner nozzle.

RADIATOR INSPECTION

1. REMOVE RADIATOR CAP

CAUTION: To avoid the danger of being burned, do not remove

the radiator cap while the engine and radiator are still hot, as

fluid and steam can be blown out under pressure.

EG±342± ENGINECOOLING SYSTEM

Page 586 of 878

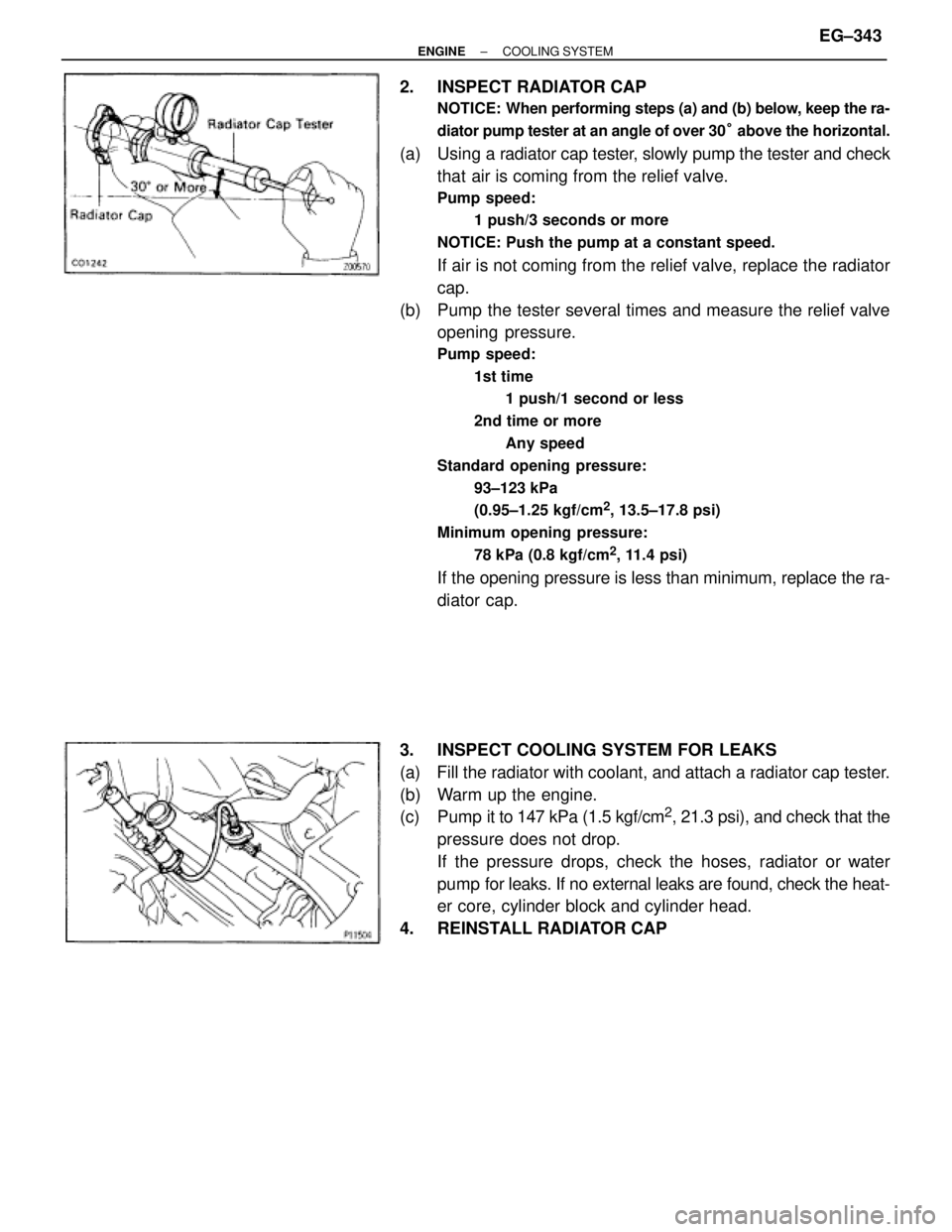

2. INSPECT RADIATOR CAP

NOTICE: When performing steps (a) and (b) below, keep the ra-

diator pump tester at an angle of over 30° above the horizontal.

(a) Using a radiator cap tester, slowly pump the tester and check

that air is coming from the relief valve.

Pump speed:

1 push/3 seconds or more

NOTICE: Push the pump at a constant speed.

If air is not coming from the relief valve, replace the radiator

cap.

(b) Pump the tester several times and measure the relief valve

opening pressure.

Pump speed:

1st time

1 push/1 second or less

2nd time or more

Any speed

Standard opening pressure:

93±123 kPa

(0.95±1.25 kgf/cm

2, 13.5±17.8 psi)

Minimum opening pressure:

78 kPa (0.8 kgf/cm

2, 11.4 psi)

If the opening pressure is less than minimum, replace the ra-

diator cap.

3. INSPECT COOLING SYSTEM FOR LEAKS

(a) Fill the radiator with coolant, and attach a radiator cap tester.

(b) Warm up the engine.

(c) Pump it to 147 kPa (1.5 kgf/cm

2, 21.3 psi), and check that the

pressure does not drop.

If the pressure drops, check the hoses, radiator or water

pump for leaks. If no external leaks are found, check the heat-

er core, cylinder block and cylinder head.

4. REINSTALL RADIATOR CAP

± ENGINECOOLING SYSTEMEG±343

Page 587 of 878

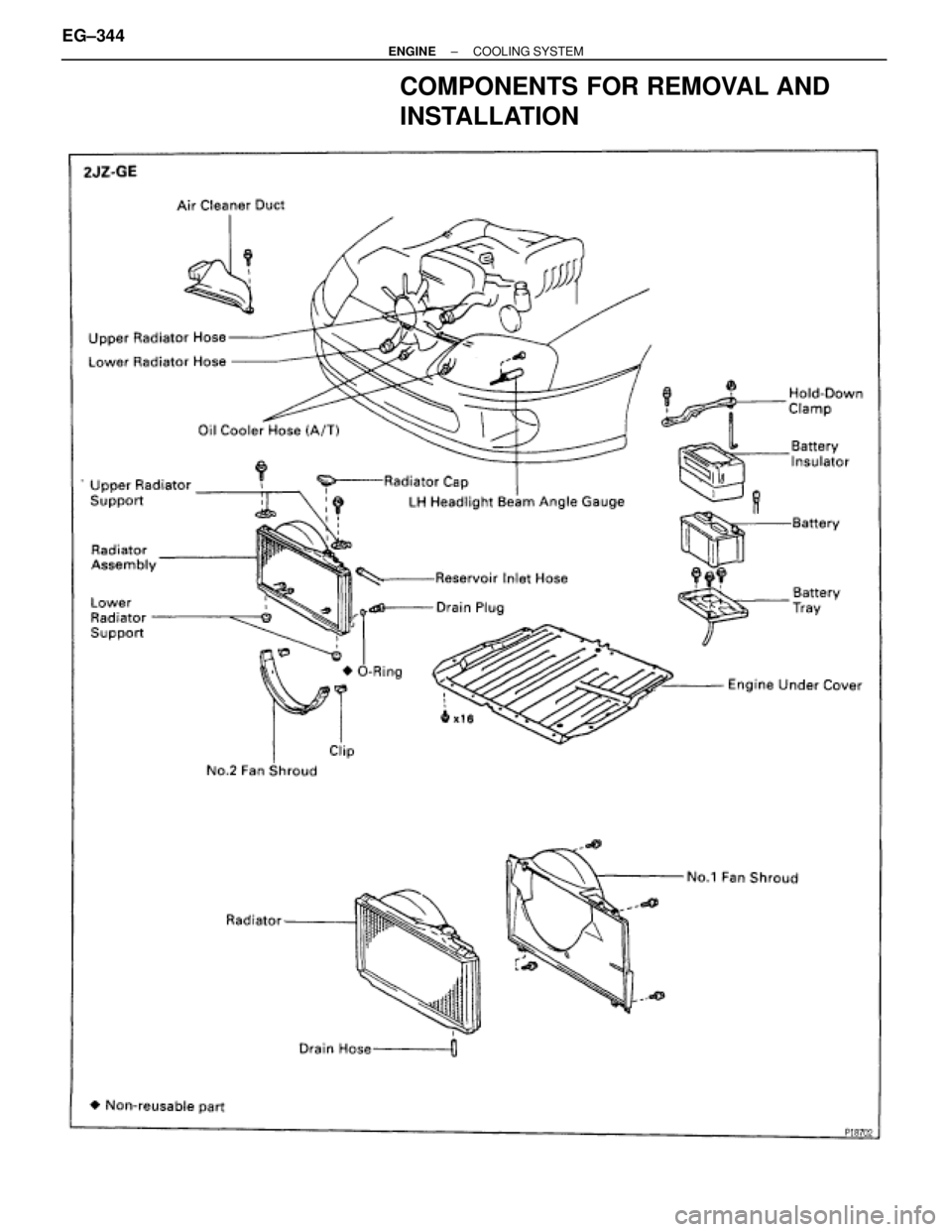

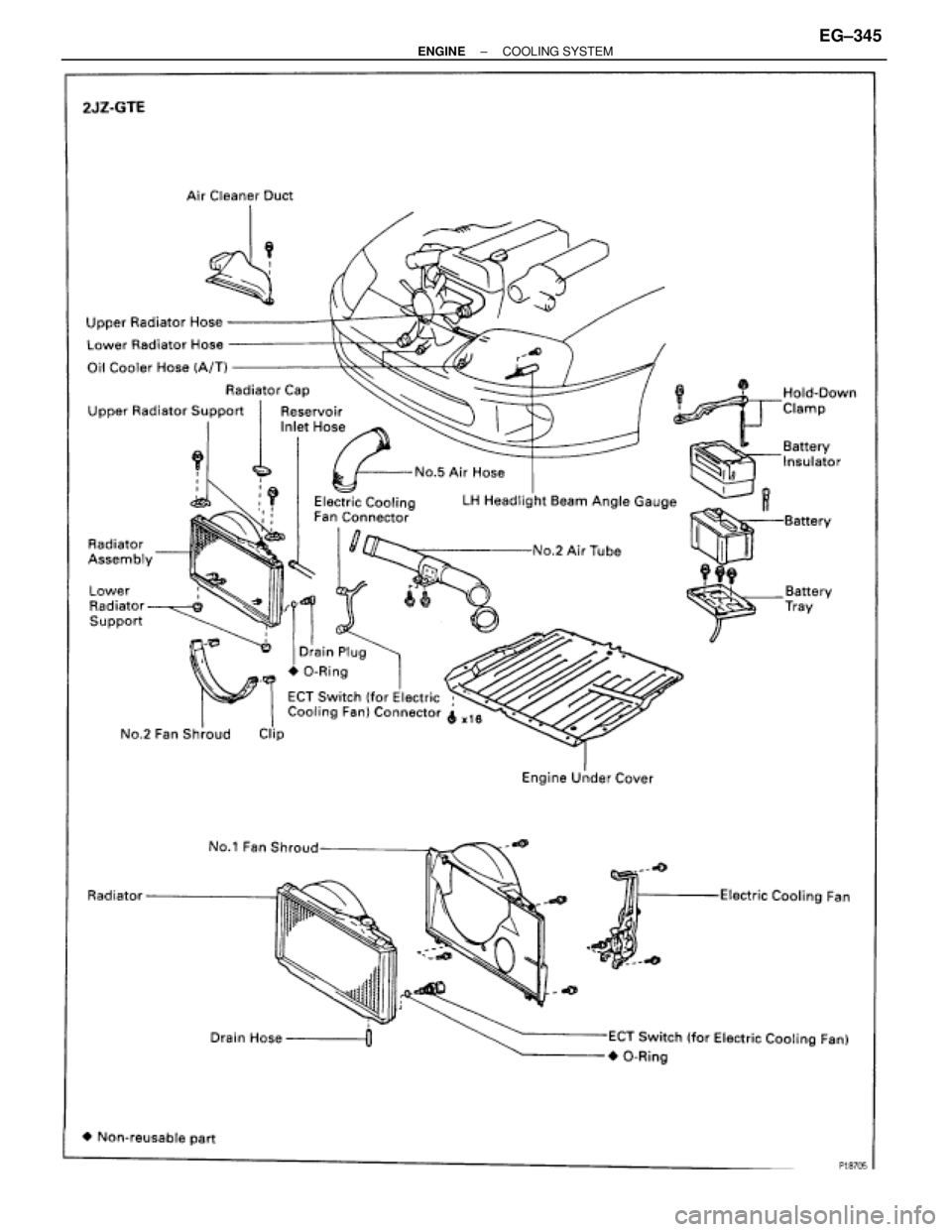

COMPONENTS FOR REMOVAL AND

INSTALLATION

EG±344± ENGINECOOLING SYSTEM

Page 588 of 878

± ENGINECOOLING SYSTEMEG±345

Page 589 of 878

RADIATOR REMOVAL

Installation is in the reverse order of removal.

1. REMOVE ENGINE UNDER COVER

INSTALLATION HINT: Start the engine, and check for cool-

ant and A/T fluid leaks.

2. REMOVE BATTERY AND BATTERY TRAY

3. DRAIN ENGINE COOLANT

4. 2JZ±GTE:

REMOVE NO.2 AIR TUBE

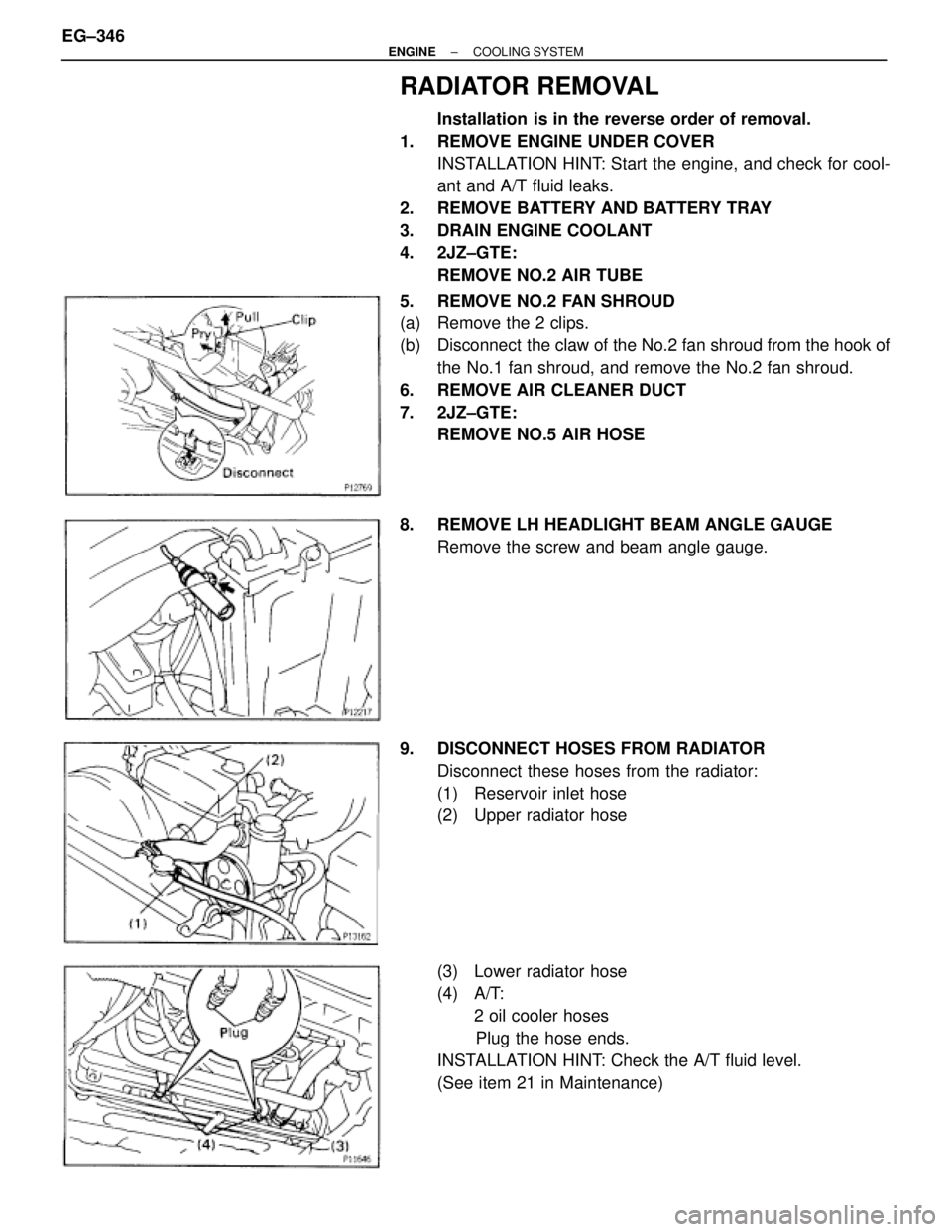

5. REMOVE NO.2 FAN SHROUD

(a) Remove the 2 clips.

(b) Disconnect the claw of the No.2 fan shroud from the hook of

the No.1 fan shroud, and remove the No.2 fan shroud.

6. REMOVE AIR CLEANER DUCT

7. 2JZ±GTE:

REMOVE NO.5 AIR HOSE

8. REMOVE LH HEADLIGHT BEAM ANGLE GAUGE

Remove the screw and beam angle gauge.

9. DISCONNECT HOSES FROM RADIATOR

Disconnect these hoses from the radiator:

(1) Reservoir inlet hose

(2) Upper radiator hose

(3) Lower radiator hose

(4) A/T:

2 oil cooler hoses

Plug the hose ends.

INSTALLATION HINT: Check the A/T fluid level.

(See item 21 in Maintenance) EG±346

± ENGINECOOLING SYSTEM

Page 590 of 878

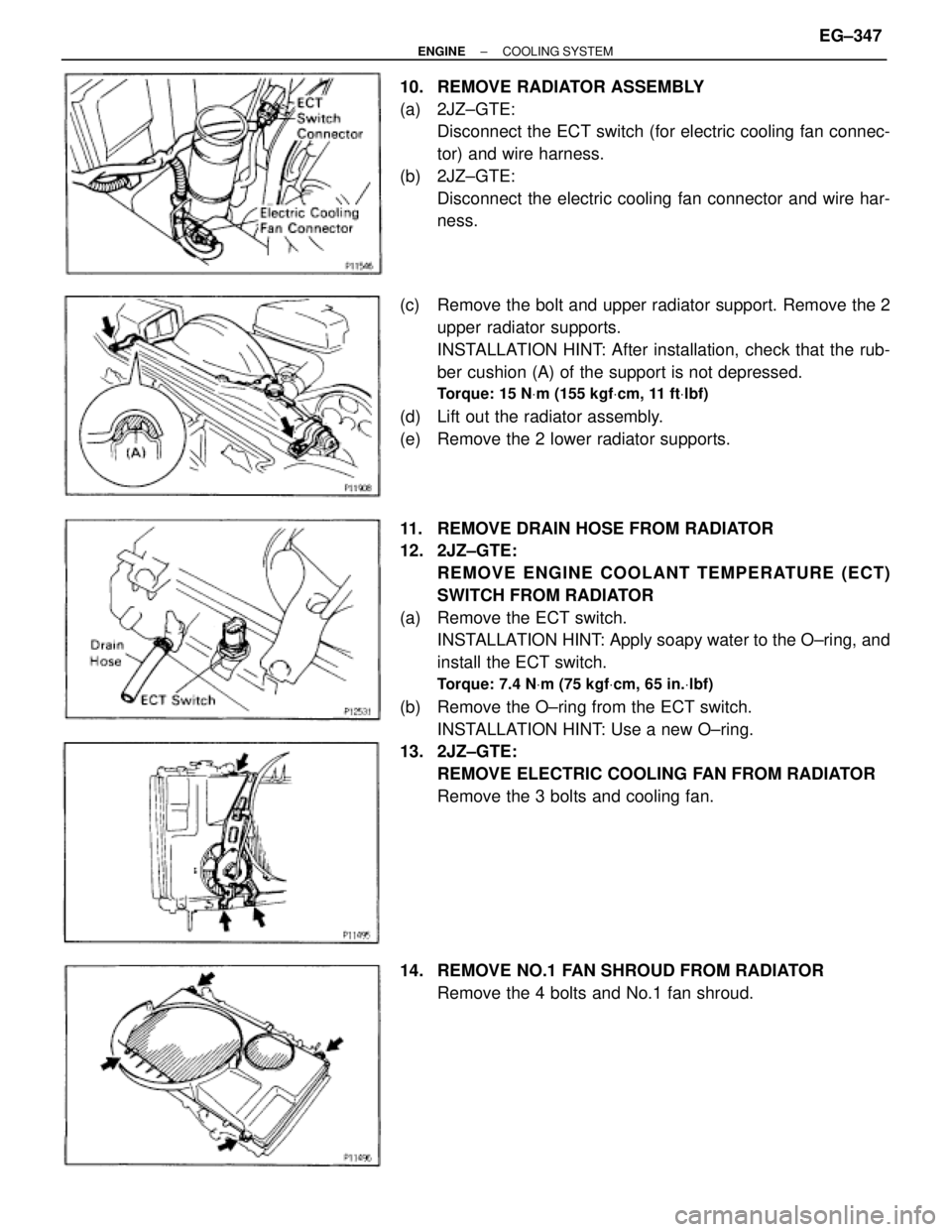

10. REMOVE RADIATOR ASSEMBLY

(a) 2JZ±GTE:

Disconnect the ECT switch (for electric cooling fan connec-

tor) and wire harness.

(b) 2JZ±GTE:

Disconnect the electric cooling fan connector and wire har-

ness.

(c) Remove the bolt and upper radiator support. Remove the 2

upper radiator supports.

INSTALLATION HINT: After installation, check that the rub-

ber cushion (A) of the support is not depressed.

Torque: 15 NVm (155 kgfVcm, 11 ftVlbf)

(d) Lift out the radiator assembly.

(e) Remove the 2 lower radiator supports.

11. REMOVE DRAIN HOSE FROM RADIATOR

12. 2JZ±GTE:

REMOVE ENGINE COOLANT TEMPERATURE (ECT)

SWITCH FROM RADIATOR

(a) Remove the ECT switch.

INSTALLATION HINT: Apply soapy water to the O±ring, and

install the ECT switch.

Torque: 7.4 NVm (75 kgfVcm, 65 in.Vlbf)

(b) Remove the O±ring from the ECT switch.

INSTALLATION HINT: Use a new O±ring.

13. 2JZ±GTE:

REMOVE ELECTRIC COOLING FAN FROM RADIATOR

Remove the 3 bolts and cooling fan.

14. REMOVE NO.1 FAN SHROUD FROM RADIATOR

Remove the 4 bolts and No.1 fan shroud.

± ENGINECOOLING SYSTEMEG±347