TOYOTA SUPRA 1986 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1986, Model line: SUPRA, Model: TOYOTA SUPRA 1986Pages: 878, PDF Size: 20 MB

Page 591 of 878

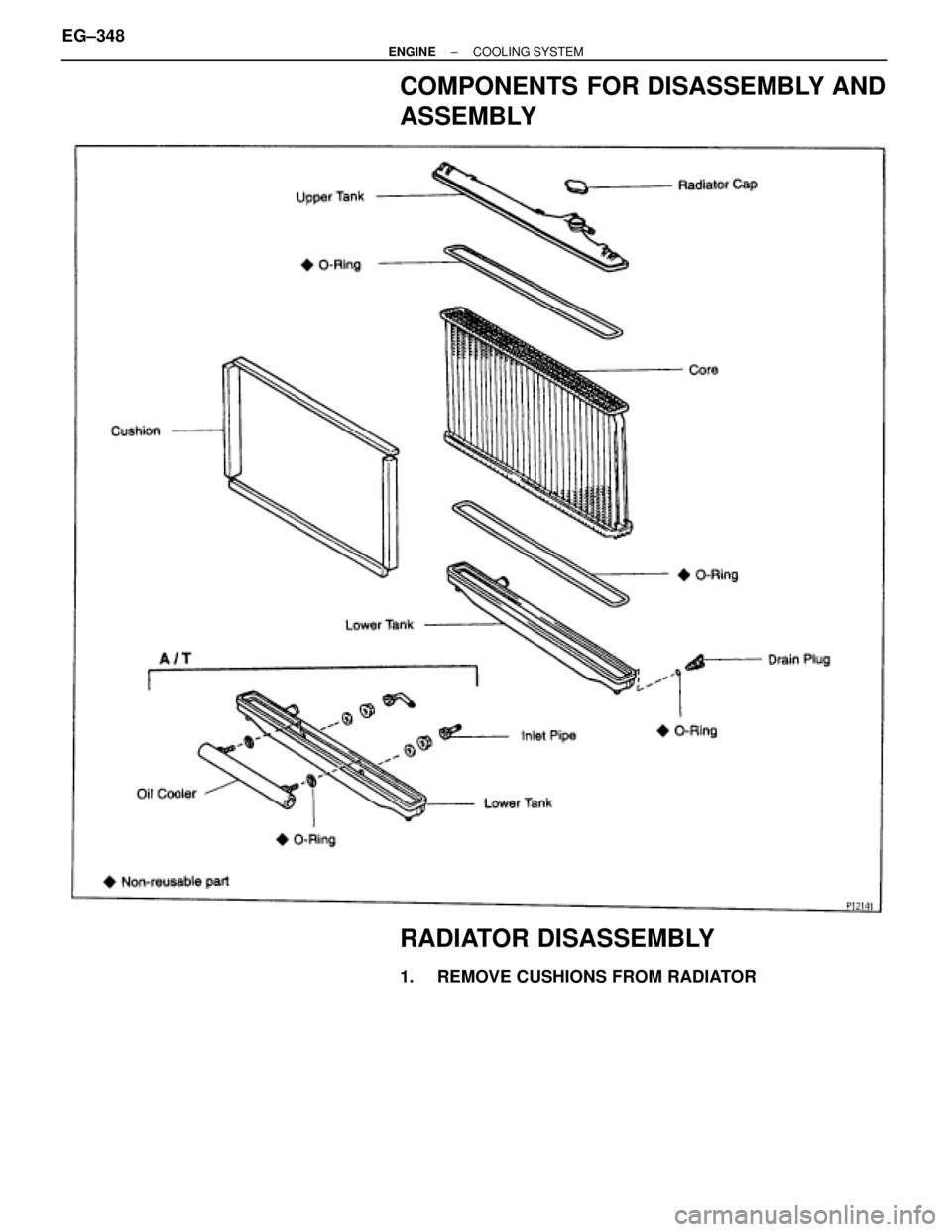

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY

RADIATOR DISASSEMBLY

1. REMOVE CUSHIONS FROM RADIATOR EG±348

± ENGINECOOLING SYSTEM

Page 592 of 878

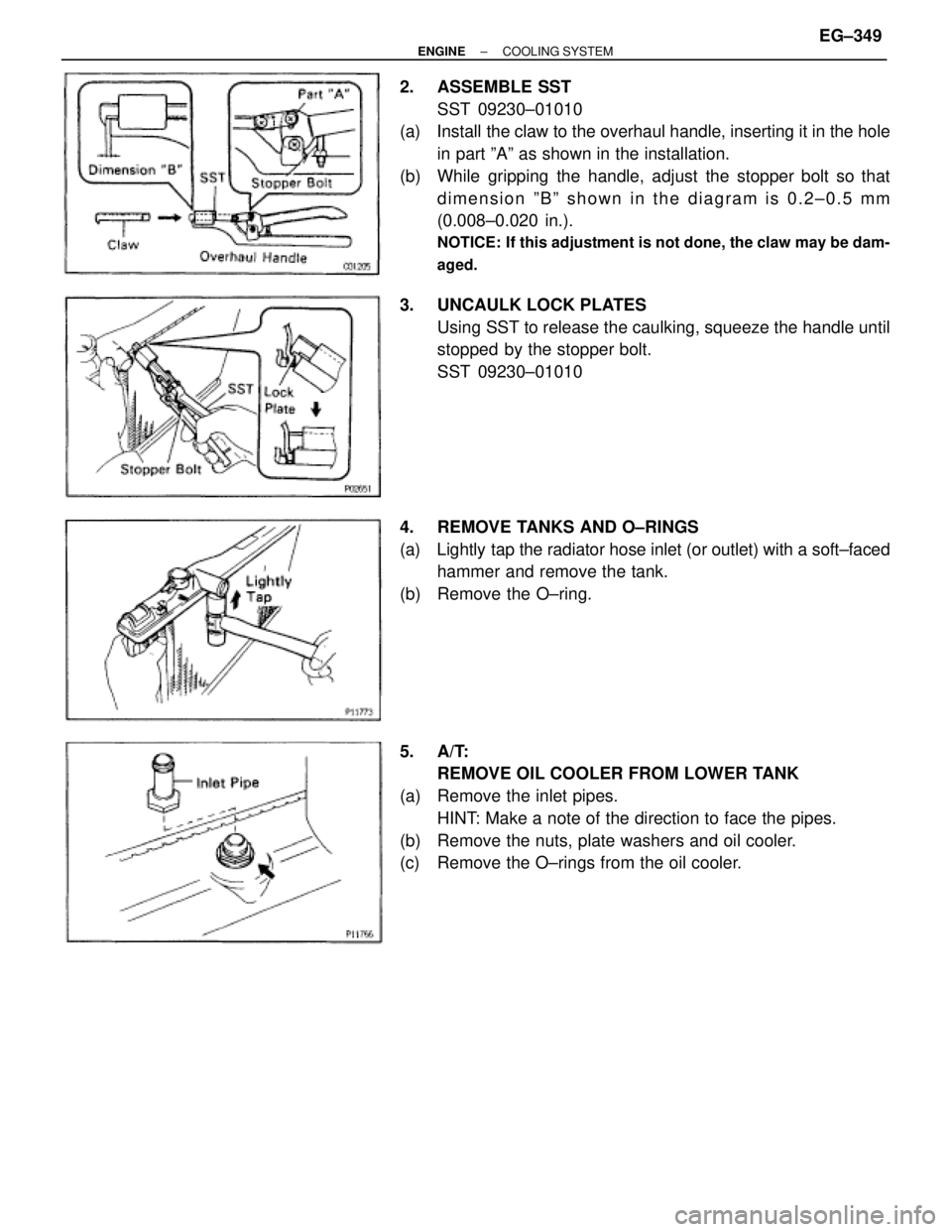

2. ASSEMBLE SST

SST 09230±01010

(a) Install the claw to the overhaul handle, inserting it in the hole

in part ºAº as shown in the installation.

(b) While gripping the handle, adjust the stopper bolt so that

dimension ºBº shown in the diagram is 0.2±0.5 mm

(0.008±0.020 in.).

NOTICE: If this adjustment is not done, the claw may be dam-

aged.

3. UNCAULK LOCK PLATES

Using SST to release the caulking, squeeze the handle until

stopped by the stopper bolt.

SST 09230±01010

4. REMOVE TANKS AND O±RINGS

(a) Lightly tap the radiator hose inlet (or outlet) with a soft±faced

hammer and remove the tank.

(b) Remove the O±ring.

5. A/T:

REMOVE OIL COOLER FROM LOWER TANK

(a) Remove the inlet pipes.

HINT: Make a note of the direction to face the pipes.

(b) Remove the nuts, plate washers and oil cooler.

(c) Remove the O±rings from the oil cooler.

± ENGINECOOLING SYSTEMEG±349

Page 593 of 878

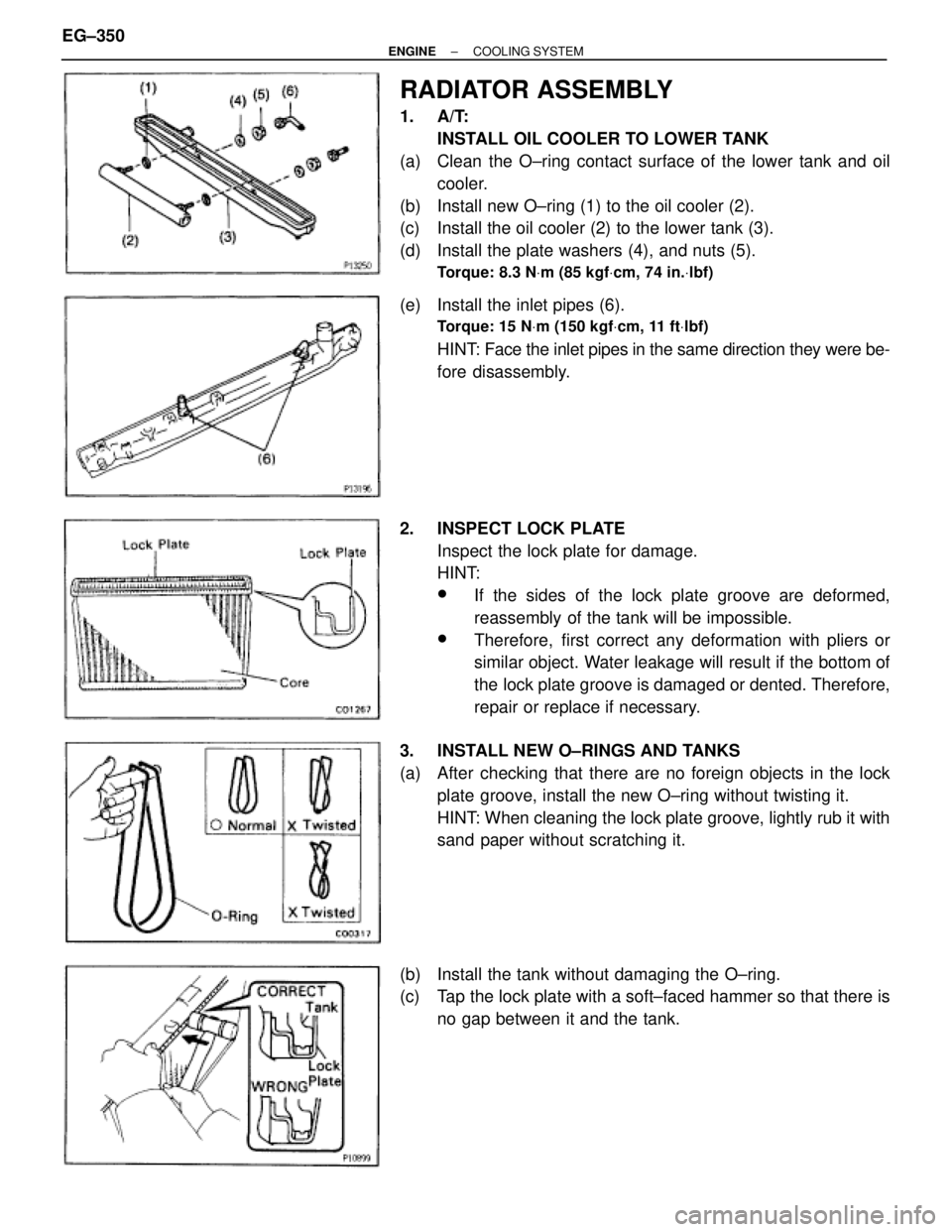

RADIATOR ASSEMBLY

1. A/T:

INSTALL OIL COOLER TO LOWER TANK

(a) Clean the O±ring contact surface of the lower tank and oil

cooler.

(b) Install new O±ring (1) to the oil cooler (2).

(c) Install the oil cooler (2) to the lower tank (3).

(d) Install the plate washers (4), and nuts (5).

Torque: 8.3 NVm (85 kgfVcm, 74 in.Vlbf)

(e) Install the inlet pipes (6).

Torque: 15 NVm (150 kgfVcm, 11 ftVlbf)

HINT: Face the inlet pipes in the same direction they were be-

fore disassembly.

2. INSPECT LOCK PLATE

Inspect the lock plate for damage.

HINT:

wIf the sides of the lock plate groove are deformed,

reassembly of the tank will be impossible.

wTherefore, first correct any deformation with pliers or

similar object. Water leakage will result if the bottom of

the lock plate groove is damaged or dented. Therefore,

repair or replace if necessary.

3. INSTALL NEW O±RINGS AND TANKS

(a) After checking that there are no foreign objects in the lock

plate groove, install the new O±ring without twisting it.

HINT: When cleaning the lock plate groove, lightly rub it with

sand paper without scratching it.

(b) Install the tank without damaging the O±ring.

(c) Tap the lock plate with a soft±faced hammer so that there is

no gap between it and the tank. EG±350

± ENGINECOOLING SYSTEM

Page 594 of 878

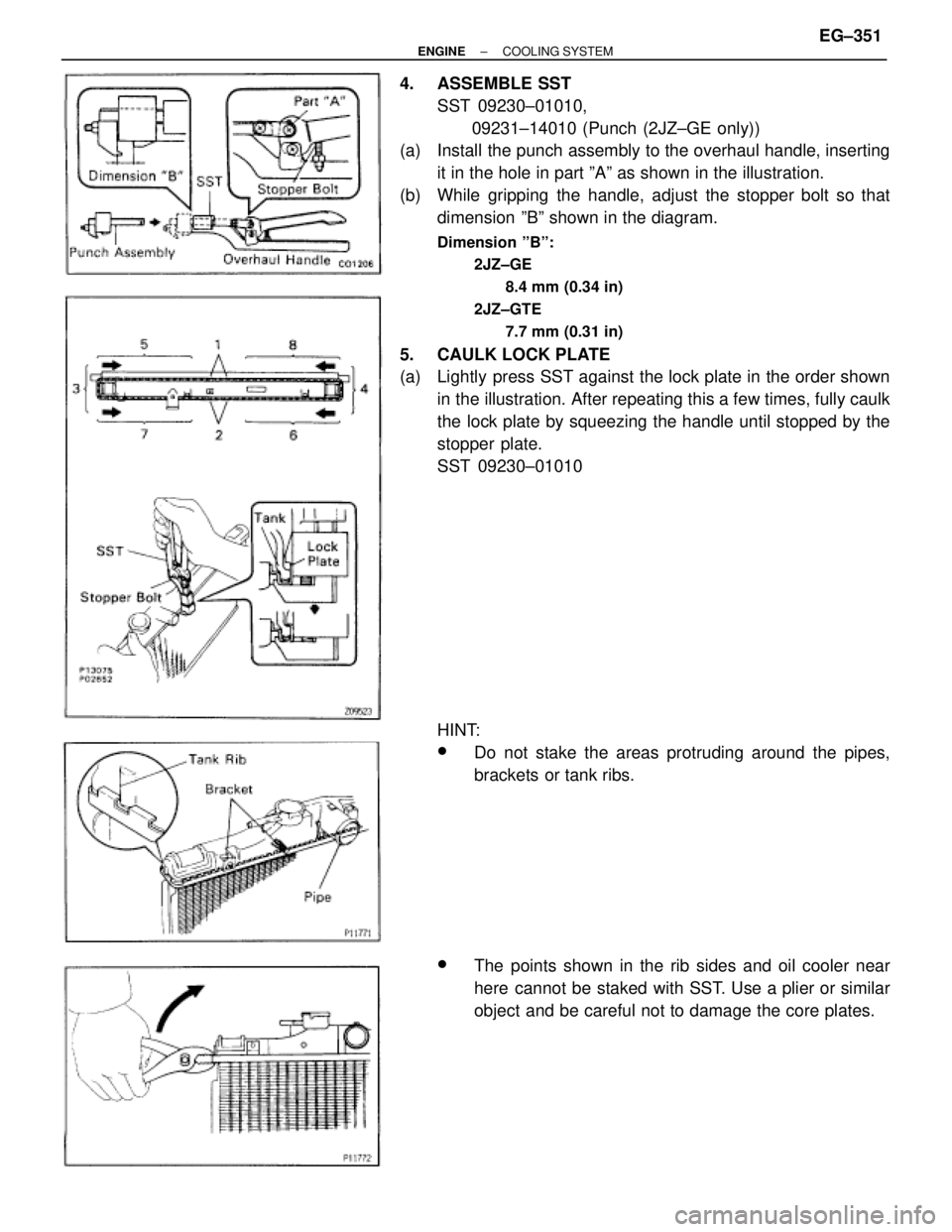

4. ASSEMBLE SST

SST 09230±01010,

09231±14010 (Punch (2JZ±GE only))

(a) Install the punch assembly to the overhaul handle, inserting

it in the hole in part ºAº as shown in the illustration.

(b) While gripping the handle, adjust the stopper bolt so that

dimension ºBº shown in the diagram.

Dimension ºBº:

2JZ±GE

8.4 mm (0.34 in)

2JZ±GTE

7.7 mm (0.31 in)

5. CAULK LOCK PLATE

(a) Lightly press SST against the lock plate in the order shown

in the illustration. After repeating this a few times, fully caulk

the lock plate by squeezing the handle until stopped by the

stopper plate.

SST 09230±01010

HINT:

wDo not stake the areas protruding around the pipes,

brackets or tank ribs.

wThe points shown in the rib sides and oil cooler near

here cannot be staked with SST. Use a plier or similar

object and be careful not to damage the core plates.

± ENGINECOOLING SYSTEMEG±351

Page 595 of 878

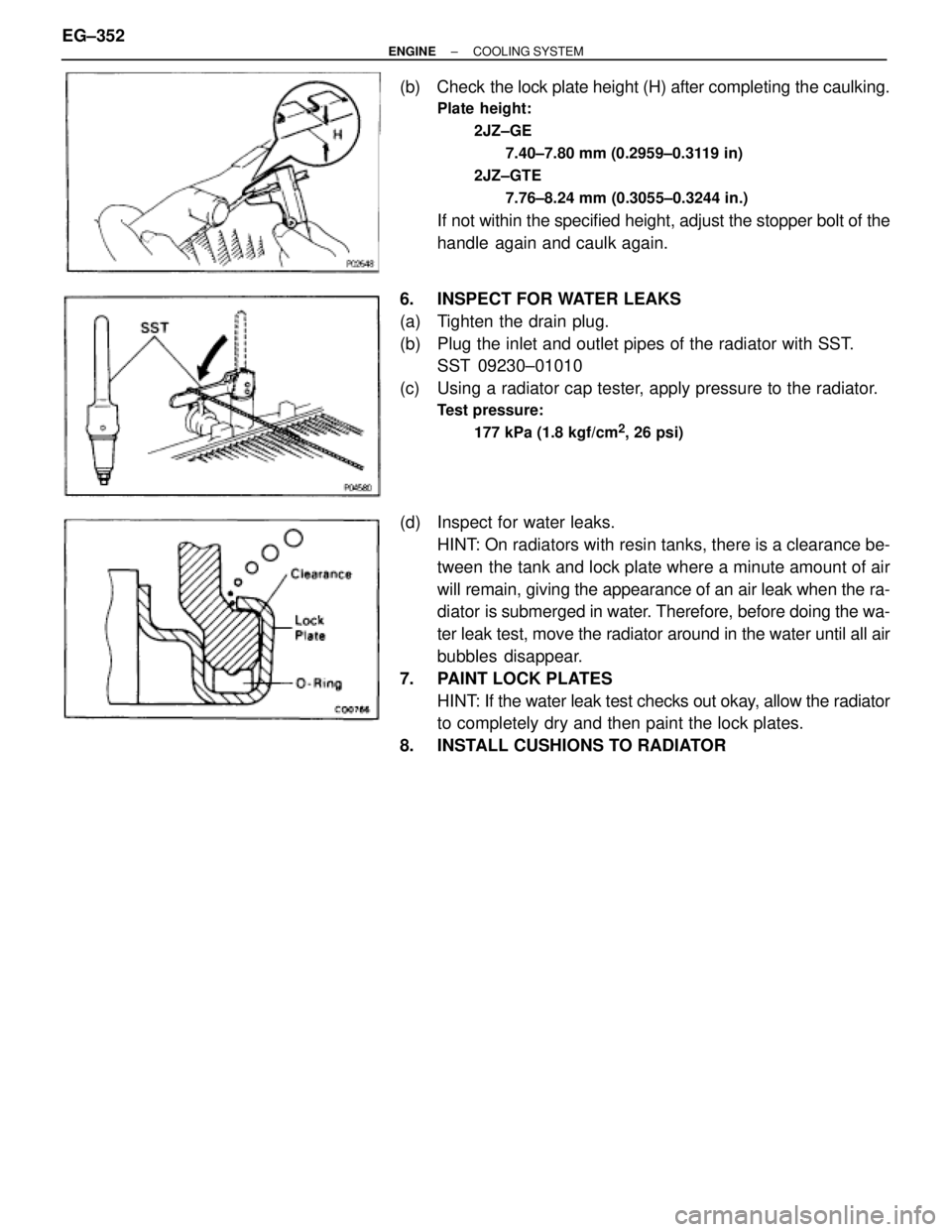

(b) Check the lock plate height (H) after completing the caulking.

Plate height:

2JZ±GE

7.40±7.80 mm (0.2959±0.3119 in)

2JZ±GTE

7.76±8.24 mm (0.3055±0.3244 in.)

If not within the specified height, adjust the stopper bolt of the

handle again and caulk again.

6. INSPECT FOR WATER LEAKS

(a) Tighten the drain plug.

(b) Plug the inlet and outlet pipes of the radiator with SST.

SST 09230±01010

(c) Using a radiator cap tester, apply pressure to the radiator.

Test pressure:

177 kPa (1.8 kgf/cm

2, 26 psi)

(d) Inspect for water leaks.

HINT: On radiators with resin tanks, there is a clearance be-

tween the tank and lock plate where a minute amount of air

will remain, giving the appearance of an air leak when the ra-

diator is submerged in water. Therefore, before doing the wa-

ter leak test, move the radiator around in the water until all air

bubbles disappear.

7. PAINT LOCK PLATES

HINT: If the water leak test checks out okay, allow the radiator

to completely dry and then paint the lock plates.

8. INSTALL CUSHIONS TO RADIATOR EG±352

± ENGINECOOLING SYSTEM

Page 596 of 878

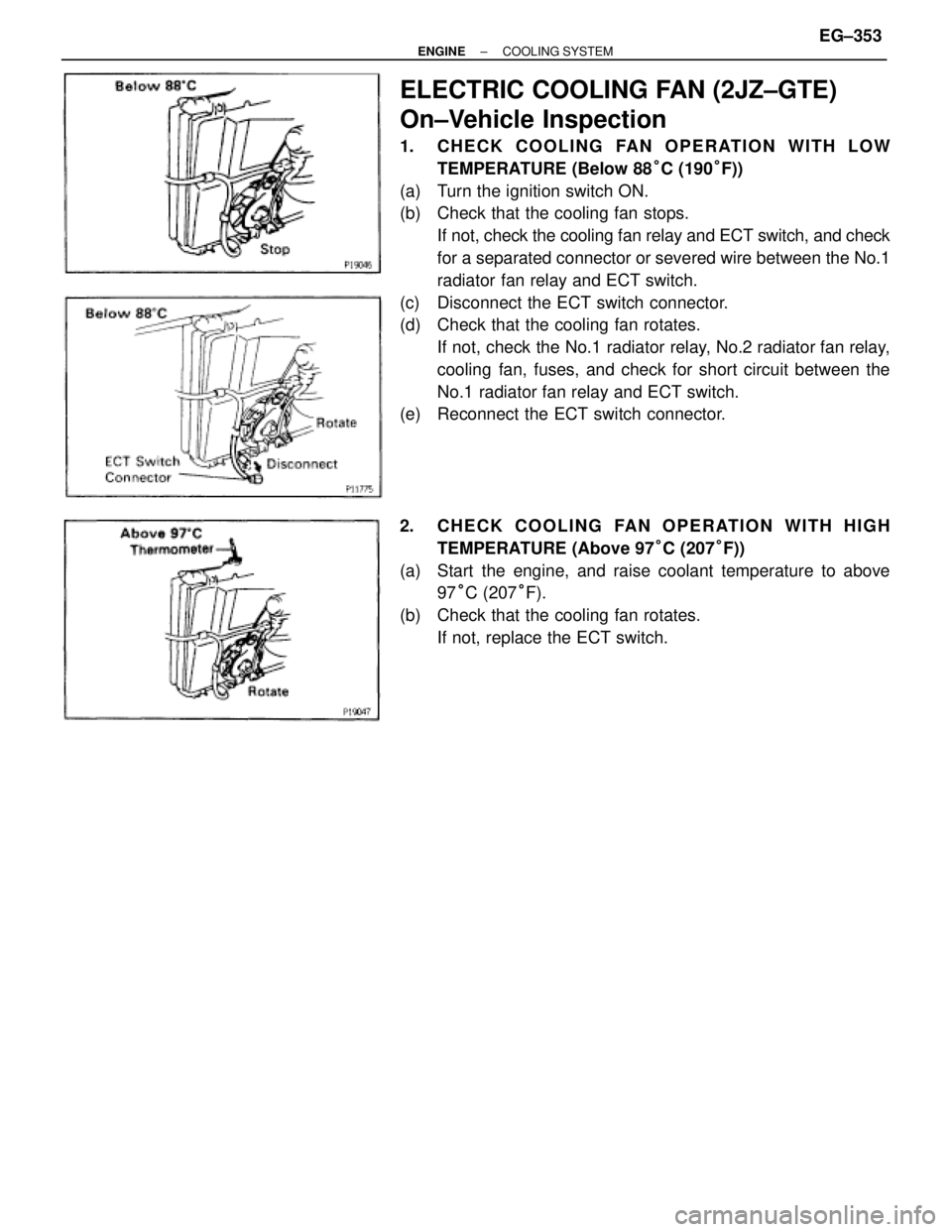

ELECTRIC COOLING FAN (2JZ±GTE)

On±Vehicle Inspection

1. C H E C K C O O L I N G FA N O P E R AT I O N W I T H L O W

TEMPERATURE (Below 88°C (190°F))

(a) Turn the ignition switch ON.

(b) Check that the cooling fan stops.

If not, check the cooling fan relay and ECT switch, and check

for a separated connector or severed wire between the No.1

radiator fan relay and ECT switch.

(c) Disconnect the ECT switch connector.

(d) Check that the cooling fan rotates.

If not, check the No.1 radiator relay, No.2 radiator fan relay,

cooling fan, fuses, and check for short circuit between the

No.1 radiator fan relay and ECT switch.

(e) Reconnect the ECT switch connector.

2. CHECK COOLING FAN OPERATION WITH HIGH

TEMPERATURE (Above 97°C (207°F))

(a) Start the engine, and raise coolant temperature to above

97°C (207°F).

(b) Check that the cooling fan rotates.

If not, replace the ECT switch.

± ENGINECOOLING SYSTEMEG±353

Page 597 of 878

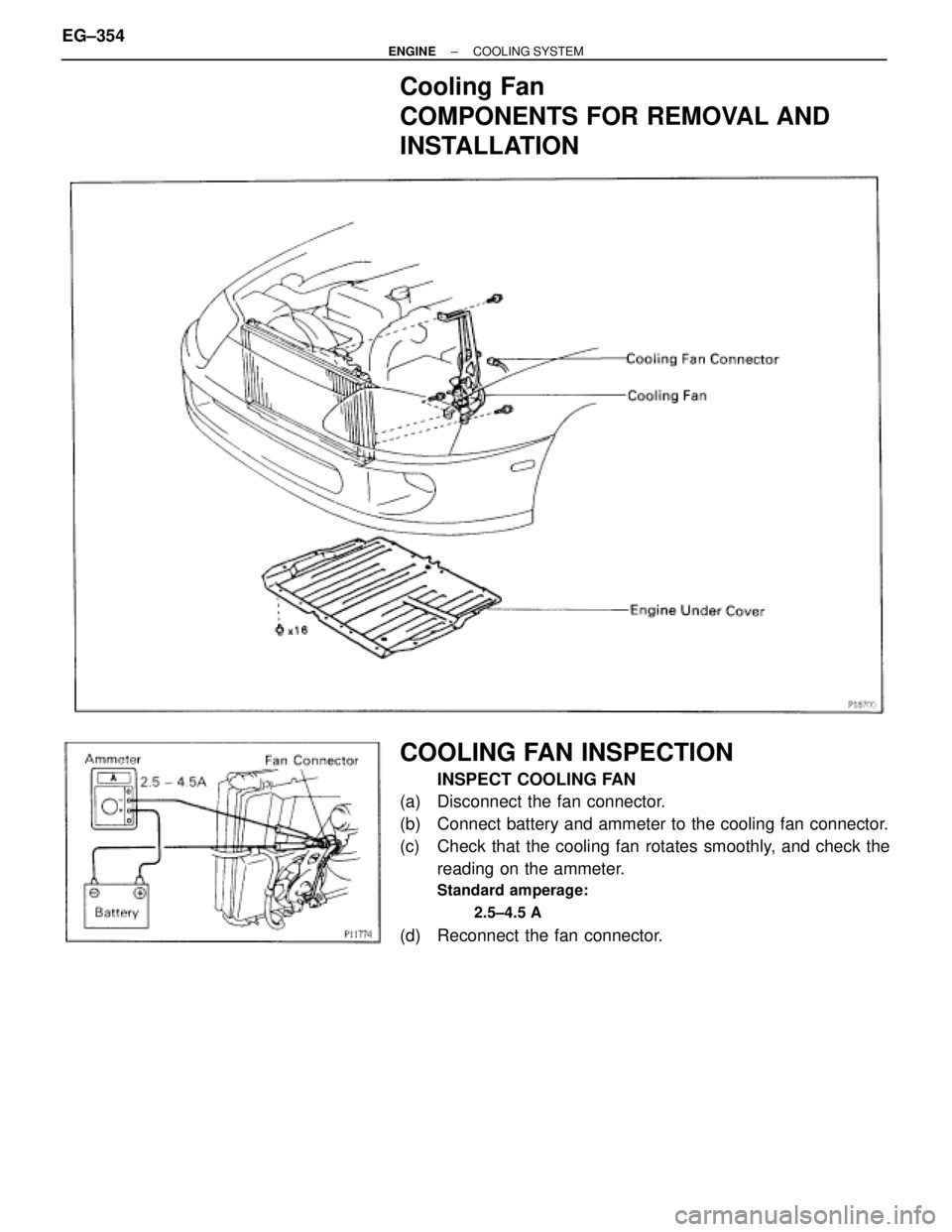

Cooling Fan

COMPONENTS FOR REMOVAL AND

INSTALLATION

COOLING FAN INSPECTION

INSPECT COOLING FAN

(a) Disconnect the fan connector.

(b) Connect battery and ammeter to the cooling fan connector.

(c) Check that the cooling fan rotates smoothly, and check the

reading on the ammeter.

Standard amperage:

2.5±4.5 A

(d) Reconnect the fan connector. EG±354

± ENGINECOOLING SYSTEM

Page 598 of 878

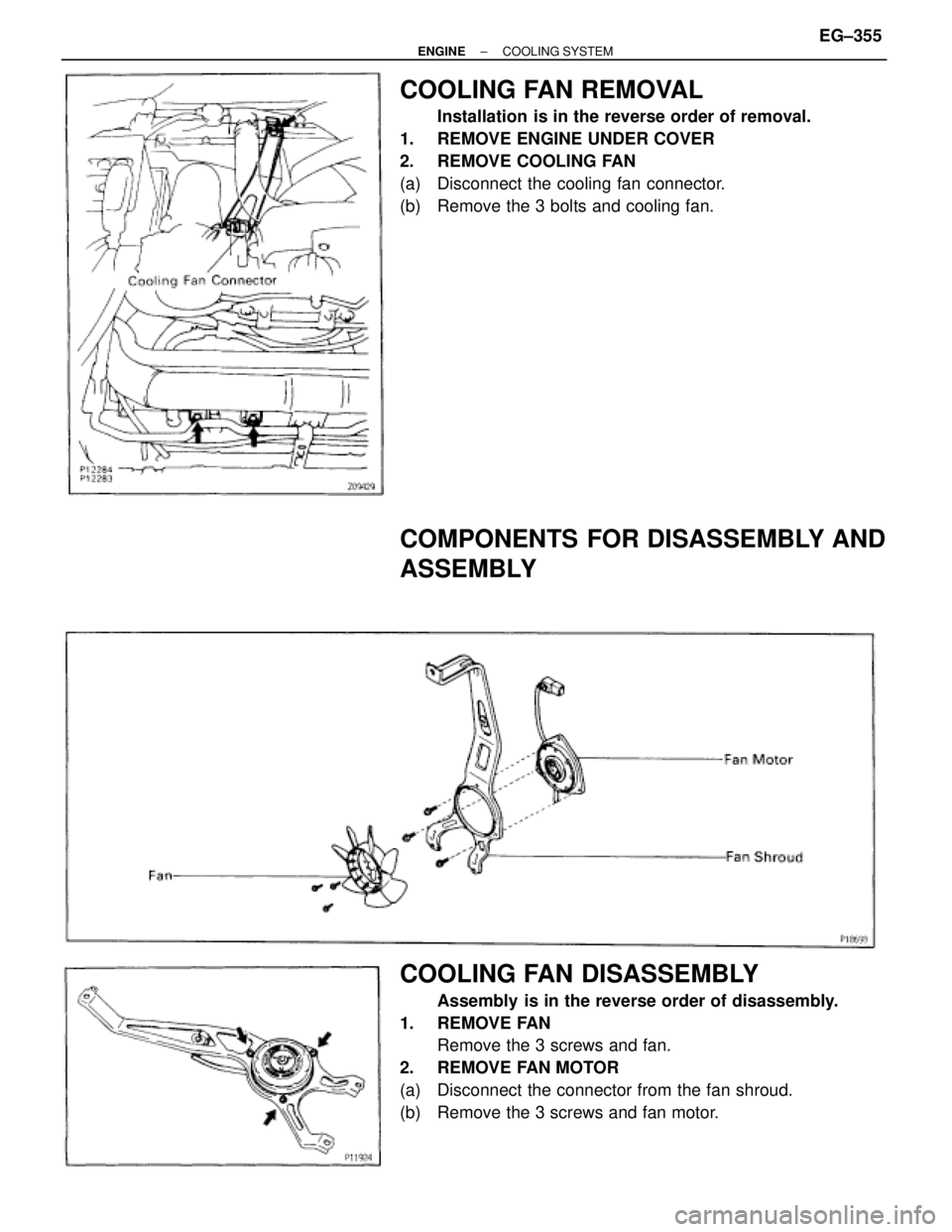

COOLING FAN REMOVAL

Installation is in the reverse order of removal.

1. REMOVE ENGINE UNDER COVER

2. REMOVE COOLING FAN

(a) Disconnect the cooling fan connector.

(b) Remove the 3 bolts and cooling fan.

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY

COOLING FAN DISASSEMBLY

Assembly is in the reverse order of disassembly.

1. REMOVE FAN

Remove the 3 screws and fan.

2. REMOVE FAN MOTOR

(a) Disconnect the connector from the fan shroud.

(b) Remove the 3 screws and fan motor.

± ENGINECOOLING SYSTEMEG±355

Page 599 of 878

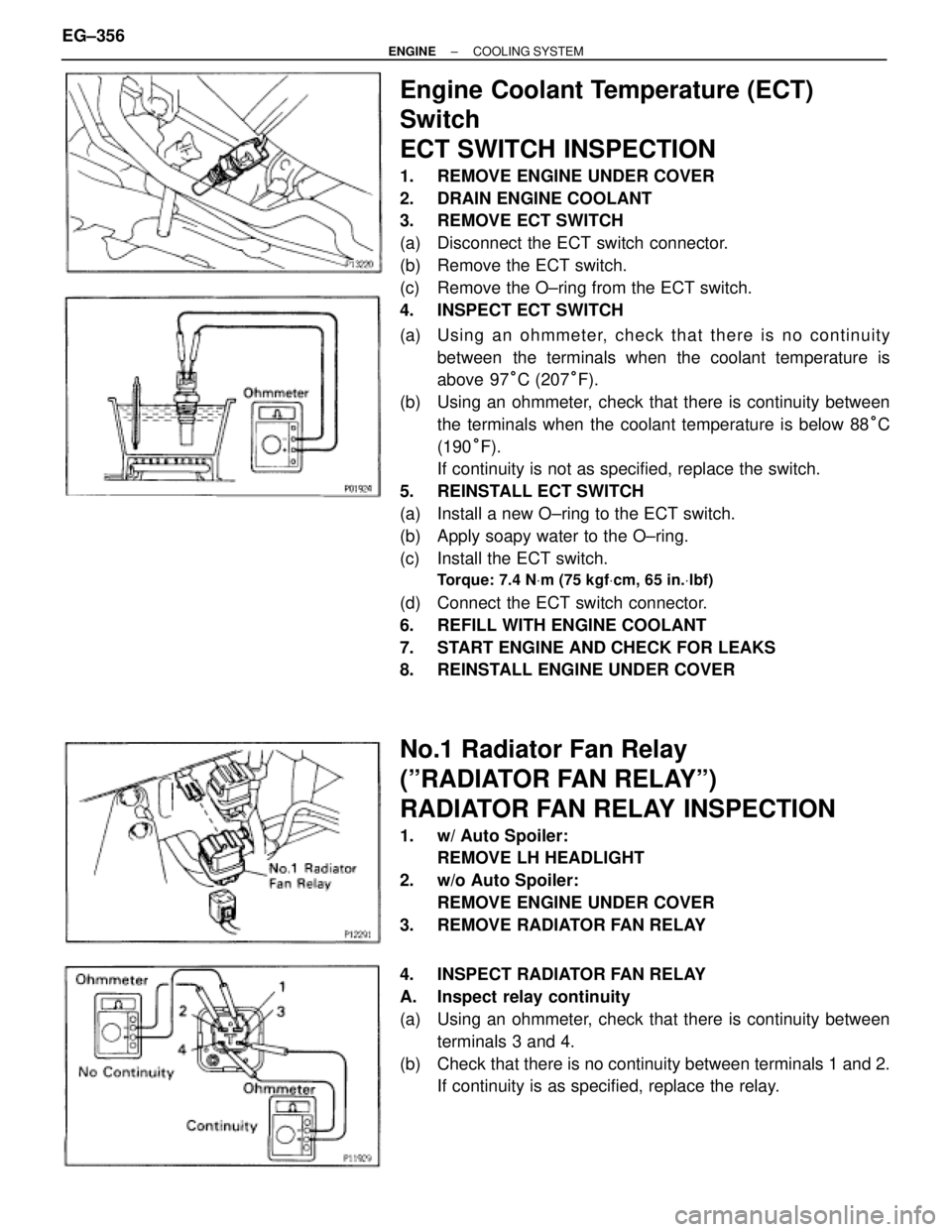

Engine Coolant Temperature (ECT)

Switch

ECT SWITCH INSPECTION

1. REMOVE ENGINE UNDER COVER

2. DRAIN ENGINE COOLANT

3. REMOVE ECT SWITCH

(a) Disconnect the ECT switch connector.

(b) Remove the ECT switch.

(c) Remove the O±ring from the ECT switch.

4. INSPECT ECT SWITCH

(a) Usin g an oh mme te r, ch e ck th a t th e re is no co n tin u ity

between the terminals when the coolant temperature is

above 97°C (207°F).

(b) Using an ohmmeter, check that there is continuity between

the terminals when the coolant temperature is below 88°C

(190°F).

If continuity is not as specified, replace the switch.

5. REINSTALL ECT SWITCH

(a) Install a new O±ring to the ECT switch.

(b) Apply soapy water to the O±ring.

(c) Install the ECT switch.

Torque: 7.4 NVm (75 kgfVcm, 65 in.Vlbf)

(d) Connect the ECT switch connector.

6. REFILL WITH ENGINE COOLANT

7. START ENGINE AND CHECK FOR LEAKS

8. REINSTALL ENGINE UNDER COVER

No.1 Radiator Fan Relay

(ºRADIATOR FAN RELAYº)

RADIATOR FAN RELAY INSPECTION

1. w/ Auto Spoiler:

REMOVE LH HEADLIGHT

2. w/o Auto Spoiler:

REMOVE ENGINE UNDER COVER

3. REMOVE RADIATOR FAN RELAY

4. INSPECT RADIATOR FAN RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuity between

terminals 3 and 4.

(b) Check that there is no continuity between terminals 1 and 2.

If continuity is as specified, replace the relay. EG±356

± ENGINECOOLING SYSTEM

Page 600 of 878

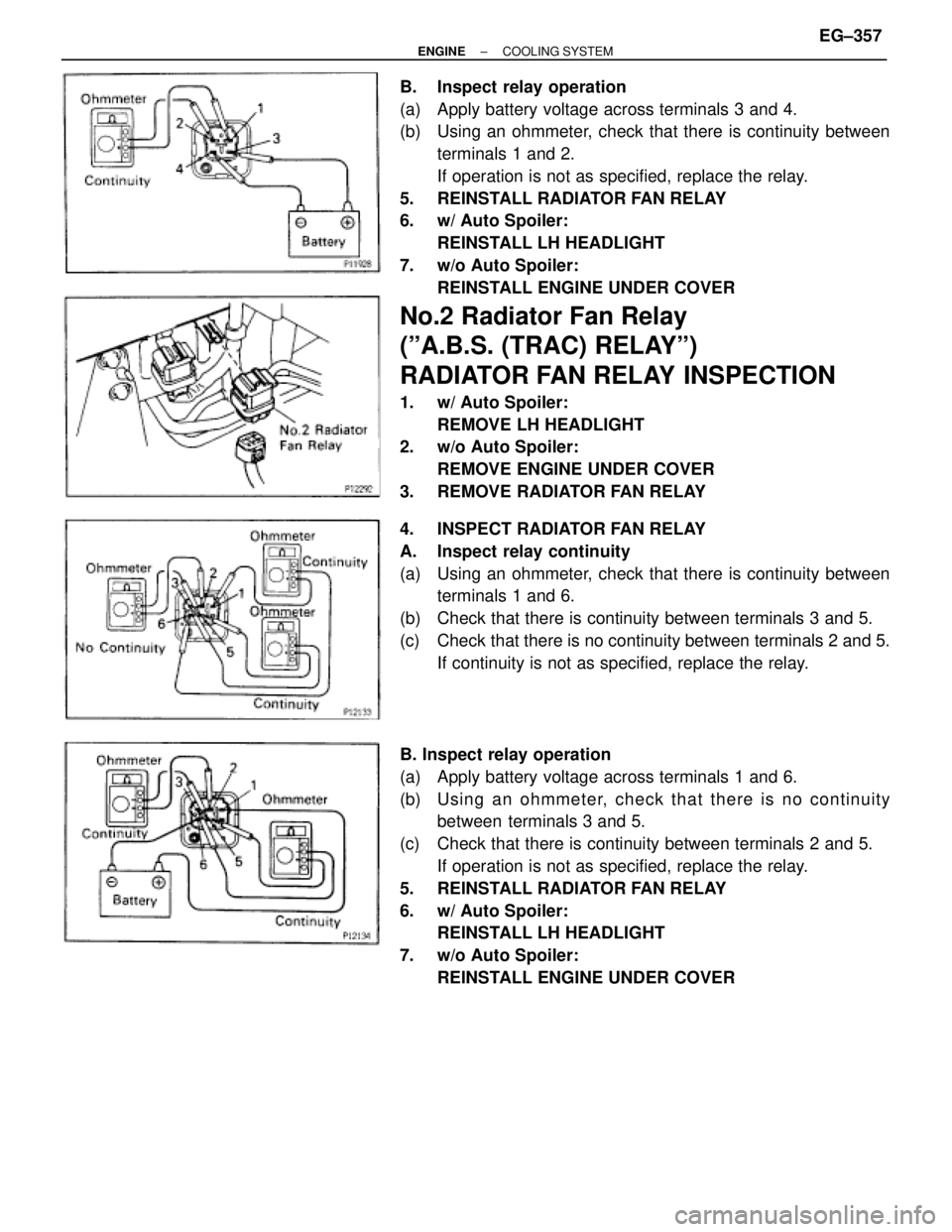

B. Inspect relay operation

(a) Apply battery voltage across terminals 3 and 4.

(b) Using an ohmmeter, check that there is continuity between

terminals 1 and 2.

If operation is not as specified, replace the relay.

5. REINSTALL RADIATOR FAN RELAY

6. w/ Auto Spoiler:

REINSTALL LH HEADLIGHT

7. w/o Auto Spoiler:

REINSTALL ENGINE UNDER COVER

No.2 Radiator Fan Relay

(ºA.B.S. (TRAC) RELAYº)

RADIATOR FAN RELAY INSPECTION

1. w/ Auto Spoiler:

REMOVE LH HEADLIGHT

2. w/o Auto Spoiler:

REMOVE ENGINE UNDER COVER

3. REMOVE RADIATOR FAN RELAY

4. INSPECT RADIATOR FAN RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuity between

terminals 1 and 6.

(b) Check that there is continuity between terminals 3 and 5.

(c) Check that there is no continuity between terminals 2 and 5.

If continuity is not as specified, replace the relay.

B. Inspect relay operation

(a) Apply battery voltage across terminals 1 and 6.

(b) Usin g an oh mme te r, ch e ck th a t th e re is no co n tin u ity

between terminals 3 and 5.

(c) Check that there is continuity between terminals 2 and 5.

If operation is not as specified, replace the relay.

5. REINSTALL RADIATOR FAN RELAY

6. w/ Auto Spoiler:

REINSTALL LH HEADLIGHT

7. w/o Auto Spoiler:

REINSTALL ENGINE UNDER COVER

± ENGINECOOLING SYSTEMEG±357