sensor TOYOTA SUPRA 1995 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1995, Model line: SUPRA, Model: TOYOTA SUPRA 1995Pages: 2543, PDF Size: 53.25 MB

Page 138 of 2543

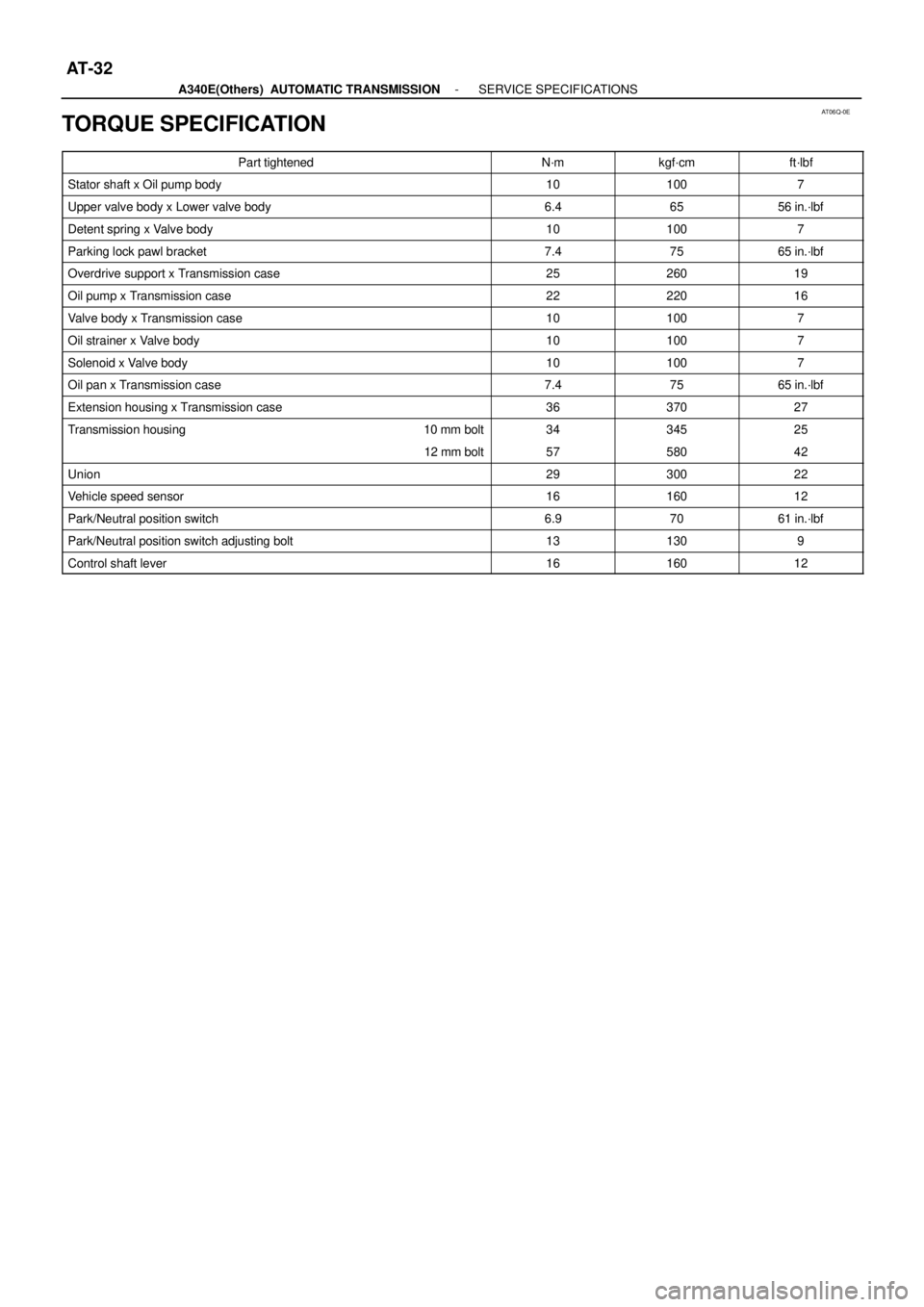

A340E(Others) AUTOMATIC TRANSMISSIONSERVICE SPECIFICATIONS -

AT-32

TORQUE SPECIFICATION

Part tightenedN´mkgf´cmft´lbf

Stator shaft x Oil pump body101007

Upper valve body x Lower valve body6.46556 in.´lbf

Detent spring x Valve body101007

Parking lock pawl bracket7.47565 in.´lbf

Overdrive support x Transmission case2526019

Oil pump x Transmission case2222016

Valve body x Transmission case101007

Oil strainer x Valve body101007

Solenoid x Valve body101007

Oil pan x Transmission case7.47565 in.´lbf

Extension housing x Transmission case3637027

Transmission housing 10 mm bolt

12 mm bolt34

57345

58025

42

Union2930022

Vehicle speed sensor1616012

Park/Neutral position switch6.97061 in.´lbf

Park/Neutral position switch adjusting bolt131309

Control shaft lever1616012

AT06Q-0E

Page 144 of 2543

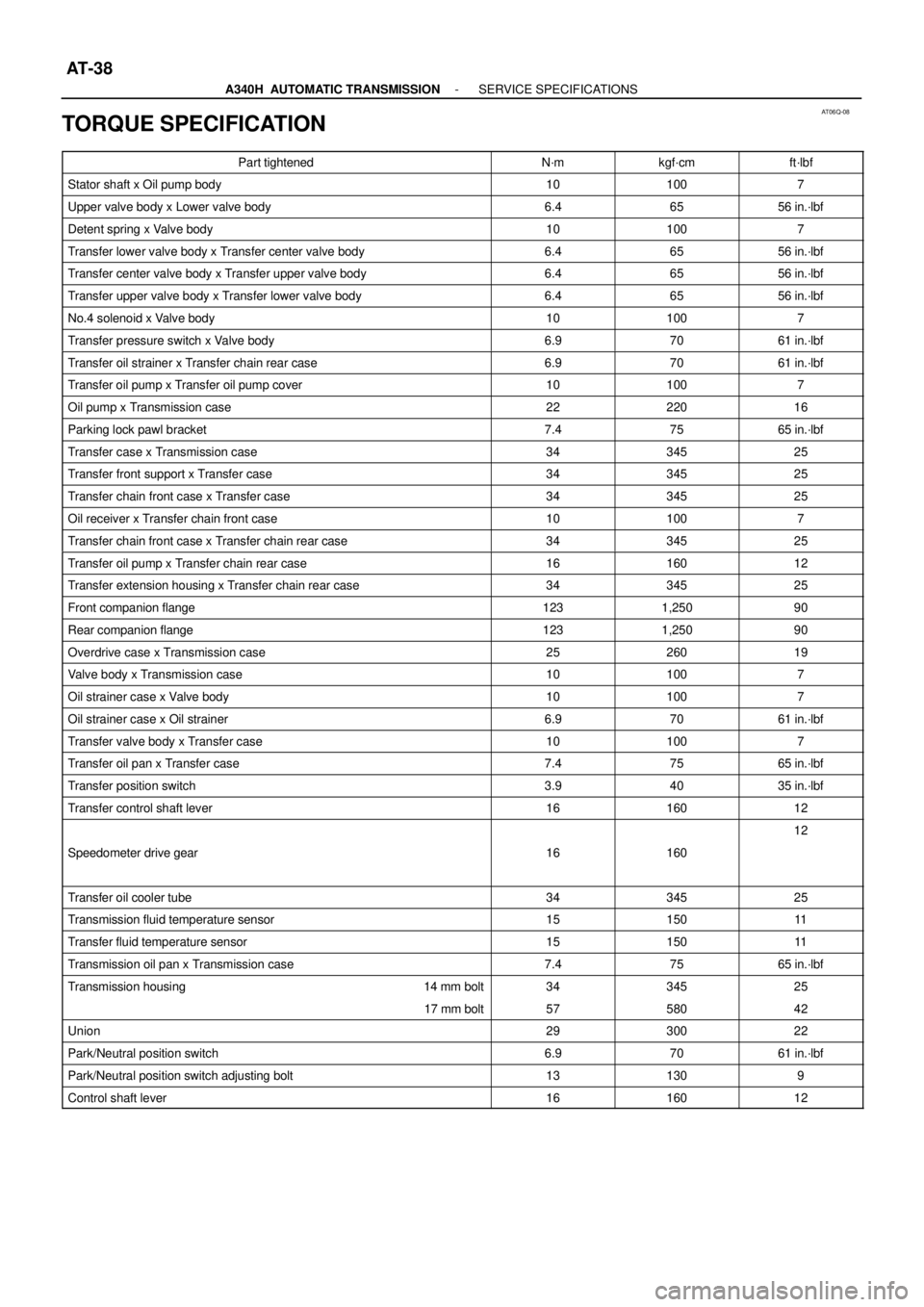

A340H AUTOMATIC TRANSMISSIONSERVICE SPECIFICATIONS -

AT-38

TORQUE SPECIFICATION

Part tightenedN´mkgf´cmft´lbf

Stator shaft x Oil pump body101007

Upper valve body x Lower valve body6.46556 in.´lbf

Detent spring x Valve body101007

Transfer lower valve body x Transfer center valve body6.46556 in.´lbf

Transfer center valve body x Transfer upper valve body6.46556 in.´lbf

Transfer upper valve body x Transfer lower valve body6.46556 in.´lbf

No.4 solenoid x Valve body101007

Transfer pressure switch x Valve body6.97061 in.´lbf

Transfer oil strainer x Transfer chain rear case6.97061 in.´lbf

Transfer oil pump x Transfer oil pump cover101007

Oil pump x Transmission case2222016

Parking lock pawl bracket7.47565 in.´lbf

Transfer case x Transmission case3434525

Transfer front support x Transfer case3434525

Transfer chain front case x Transfer case3434525

Oil receiver x Transfer chain front case101007

Transfer chain front case x Transfer chain rear case3434525

Transfer oil pump x Transfer chain rear case1616012

Transfer extension housing x Transfer chain rear case3434525

Front companion flange1231,25090

Rear companion flange1231,25090

Overdrive case x Transmission case2526019

Valve body x Transmission case101007

Oil strainer case x Valve body101007

Oil strainer case x Oil strainer6.97061 in.´lbf

Transfer valve body x Transfer case101007

Transfer oil pan x Transfer case7.47565 in.´lbf

Transfer position switch3.94035 in.´lbf

Transfer control shaft lever1616012

Speedometer drive gear16160

12

Transfer oil cooler tube3434525

Transmission fluid temperature sensor1515011

Transfer fluid temperature sensor1515011

Transmission oil pan x Transmission case7.47565 in.´lbf

Transmission housing 14 mm bolt

17 mm bolt34

57345

58025

42

Union2930022

Park/Neutral position switch6.97061 in.´lbf

Park/Neutral position switch adjusting bolt131309

Control shaft lever1616012

AT06Q-08

Page 148 of 2543

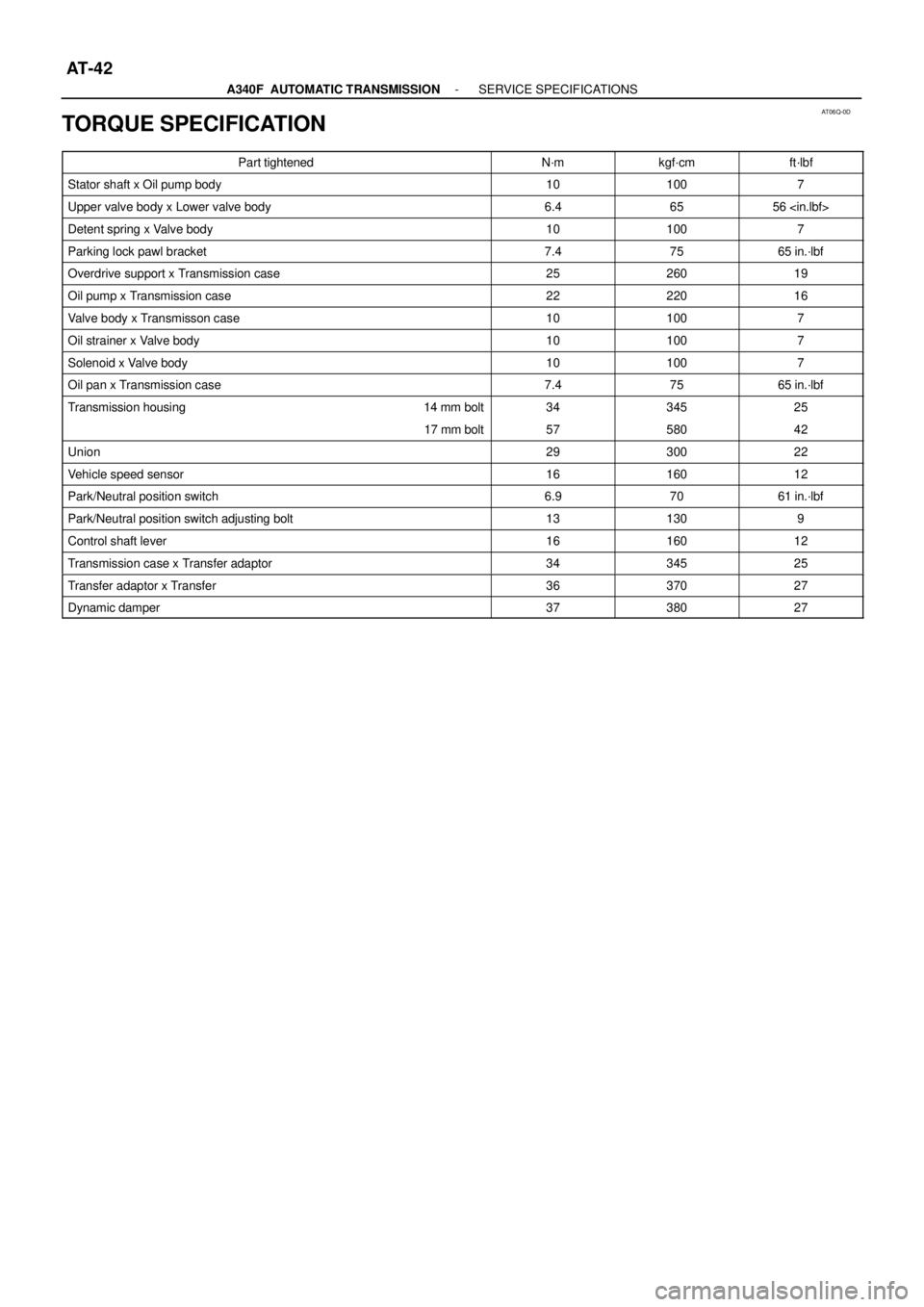

A340F AUTOMATIC TRANSMISSIONSERVICE SPECIFICATIONS -

AT-42

TORQUE SPECIFICATION

Part tightenedN´mkgf´cmft´lbf

Stator shaft x Oil pump body101007

Upper valve body x Lower valve body6.46556

Detent spring x Valve body101007

Parking lock pawl bracket7.47565 in.´lbf

Overdrive support x Transmission case2526019

Oil pump x Transmission case2222016

Valve body x Transmisson case101007

Oil strainer x Valve body101007

Solenoid x Valve body101007

Oil pan x Transmission case7.47565 in.´lbf

Transmission housing 14 mm bolt

17 mm bolt34

57345

58025

42

Union2930022

Vehicle speed sensor1616012

Park/Neutral position switch6.97061 in.´lbf

Park/Neutral position switch adjusting bolt131309

Control shaft lever1616012

Transmission case x Transfer adaptor3434525

Transfer adaptor x Transfer3637027

Dynamic damper3738027

AT06Q-0D

Page 156 of 2543

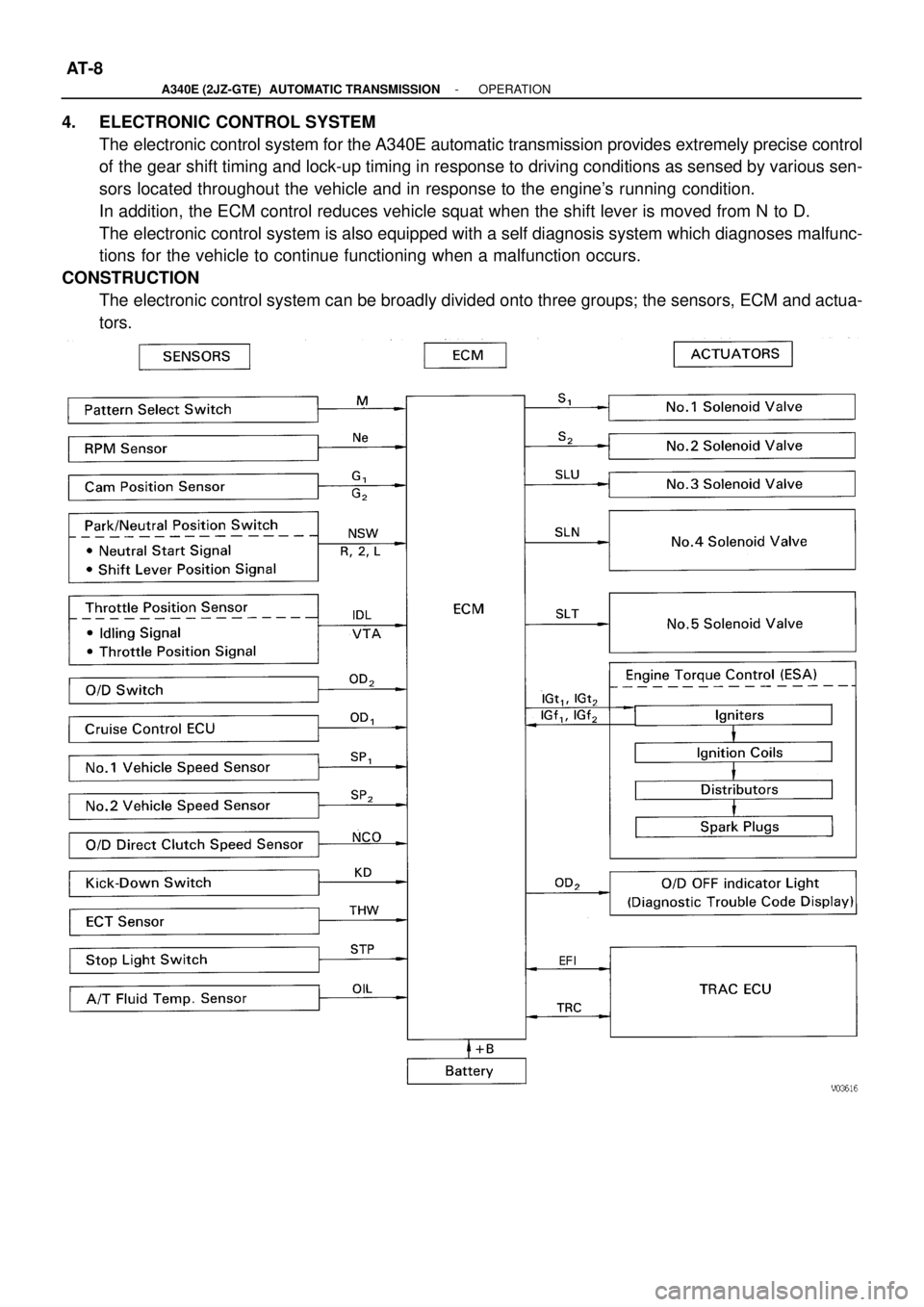

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONOPERATION -

AT-8

4. ELECTRONIC CONTROL SYSTEM

The electronic control system for the A340E automatic transmission provides extremely precise control

of the gear shift timing and lock-up timing in response to driving conditions as sensed by various sen-

sors located throughout the vehicle and in response to the engine's running condition.

In addition, the ECM control reduces vehicle squat when the shift lever is moved from N to D.

The electronic control system is also equipped with a self diagnosis system which diagnoses malfunc-

tions for the vehicle to continue functioning when a malfunction occurs.

CONSTRUCTION

The electronic control system can be broadly divided onto three groups; the sensors, ECM and actua-

tors.

Page 159 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-1 1

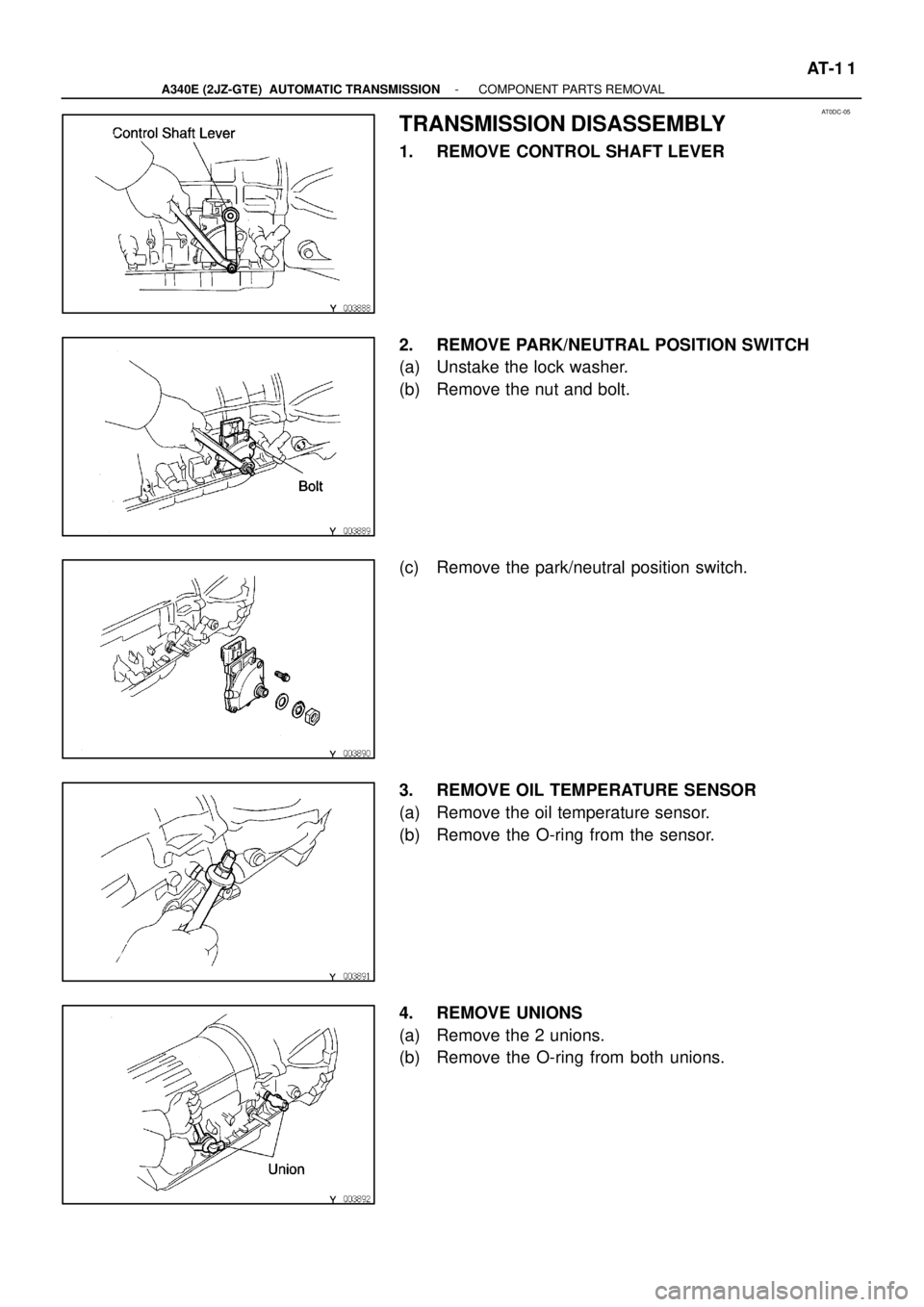

TRANSMISSION DISASSEMBLY

1. REMOVE CONTROL SHAFT LEVER

2. REMOVE PARK/NEUTRAL POSITION SWITCH

(a) Unstake the lock washer.

(b) Remove the nut and bolt.

(c) Remove the park/neutral position switch.

3. REMOVE OIL TEMPERATURE SENSOR

(a) Remove the oil temperature sensor.

(b) Remove the O-ring from the sensor.

4. REMOVE UNIONS

(a) Remove the 2 unions.

(b) Remove the O-ring from both unions.

AT0DC-05

Page 160 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-12

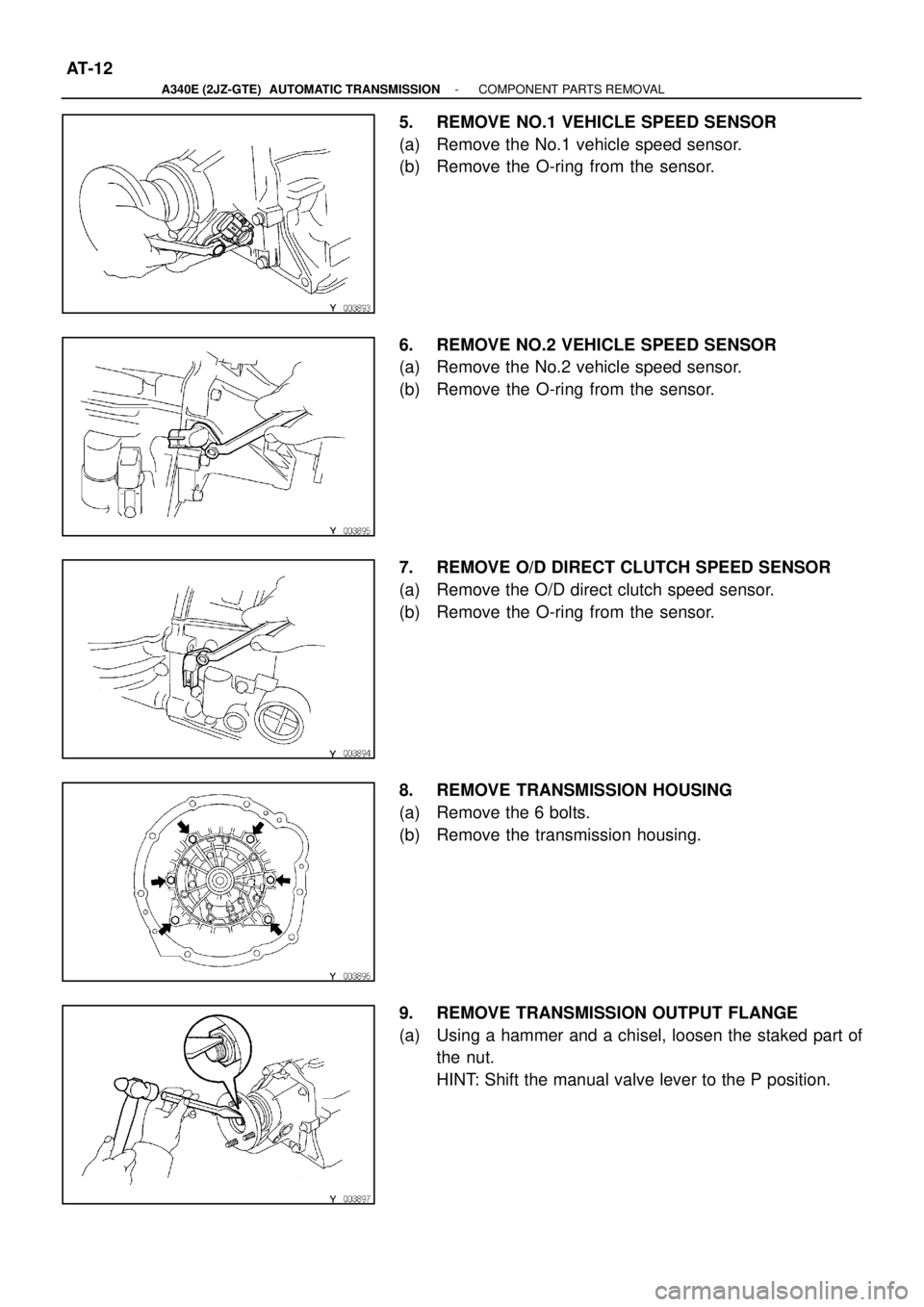

5. REMOVE NO.1 VEHICLE SPEED SENSOR

(a) Remove the No.1 vehicle speed sensor.

(b) Remove the O-ring from the sensor.

6. REMOVE NO.2 VEHICLE SPEED SENSOR

(a) Remove the No.2 vehicle speed sensor.

(b) Remove the O-ring from the sensor.

7. REMOVE O/D DIRECT CLUTCH SPEED SENSOR

(a) Remove the O/D direct clutch speed sensor.

(b) Remove the O-ring from the sensor.

8. REMOVE TRANSMISSION HOUSING

(a) Remove the 6 bolts.

(b) Remove the transmission housing.

9. REMOVE TRANSMISSION OUTPUT FLANGE

(a) Using a hammer and a chisel, loosen the staked part of

the nut.

HINT: Shift the manual valve lever to the P position.

Page 161 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS REMOVAL -

AT-13

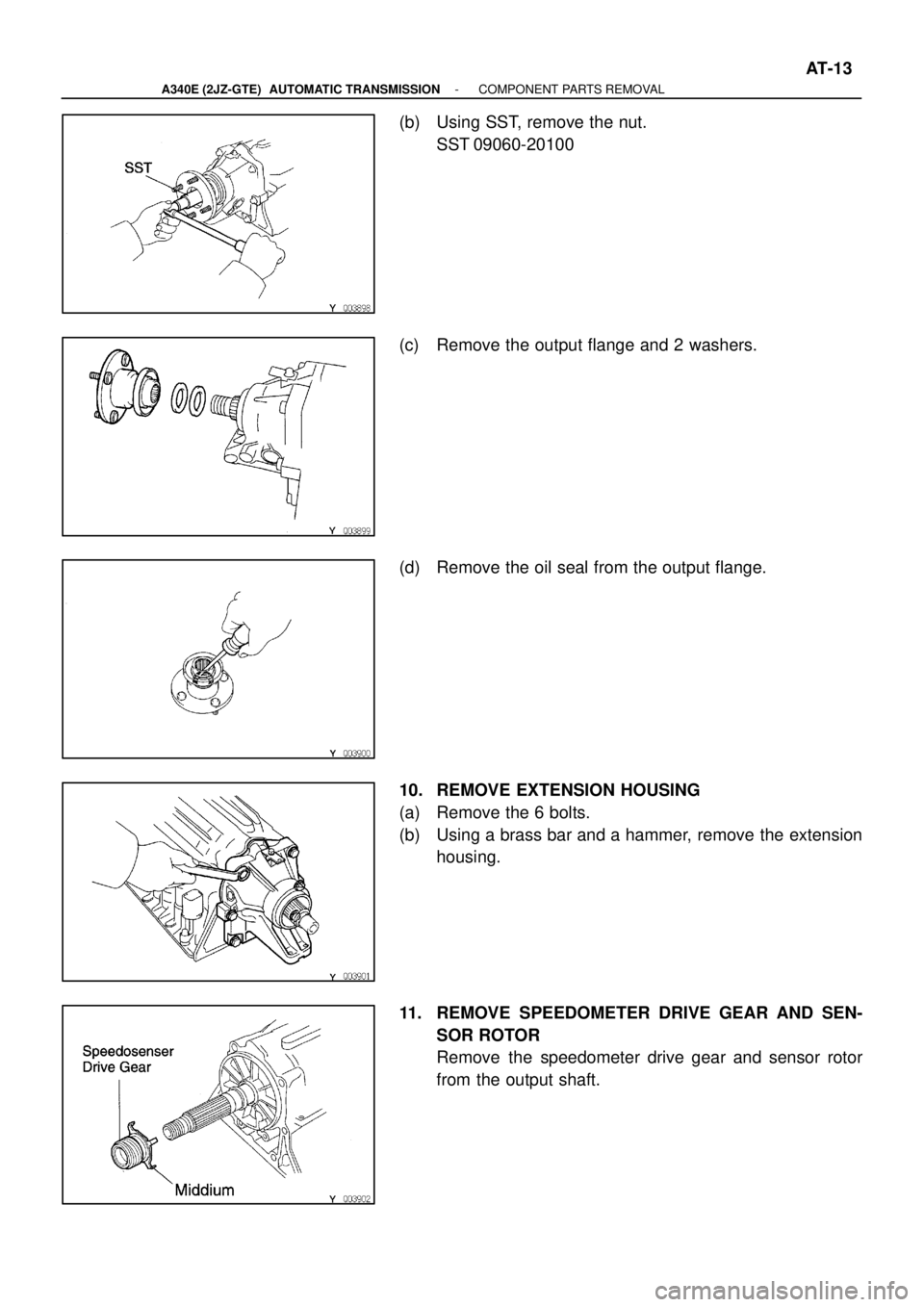

(b) Using SST, remove the nut.

SST 09060-20100

(c) Remove the output flange and 2 washers.

(d) Remove the oil seal from the output flange.

10. REMOVE EXTENSION HOUSING

(a) Remove the 6 bolts.

(b) Using a brass bar and a hammer, remove the extension

housing.

11. REMOVE SPEEDOMETER DRIVE GEAR AND SEN-

SOR ROTOR

Remove the speedometer drive gear and sensor rotor

from the output shaft.

Page 255 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS INSTALLATION -

AT-107

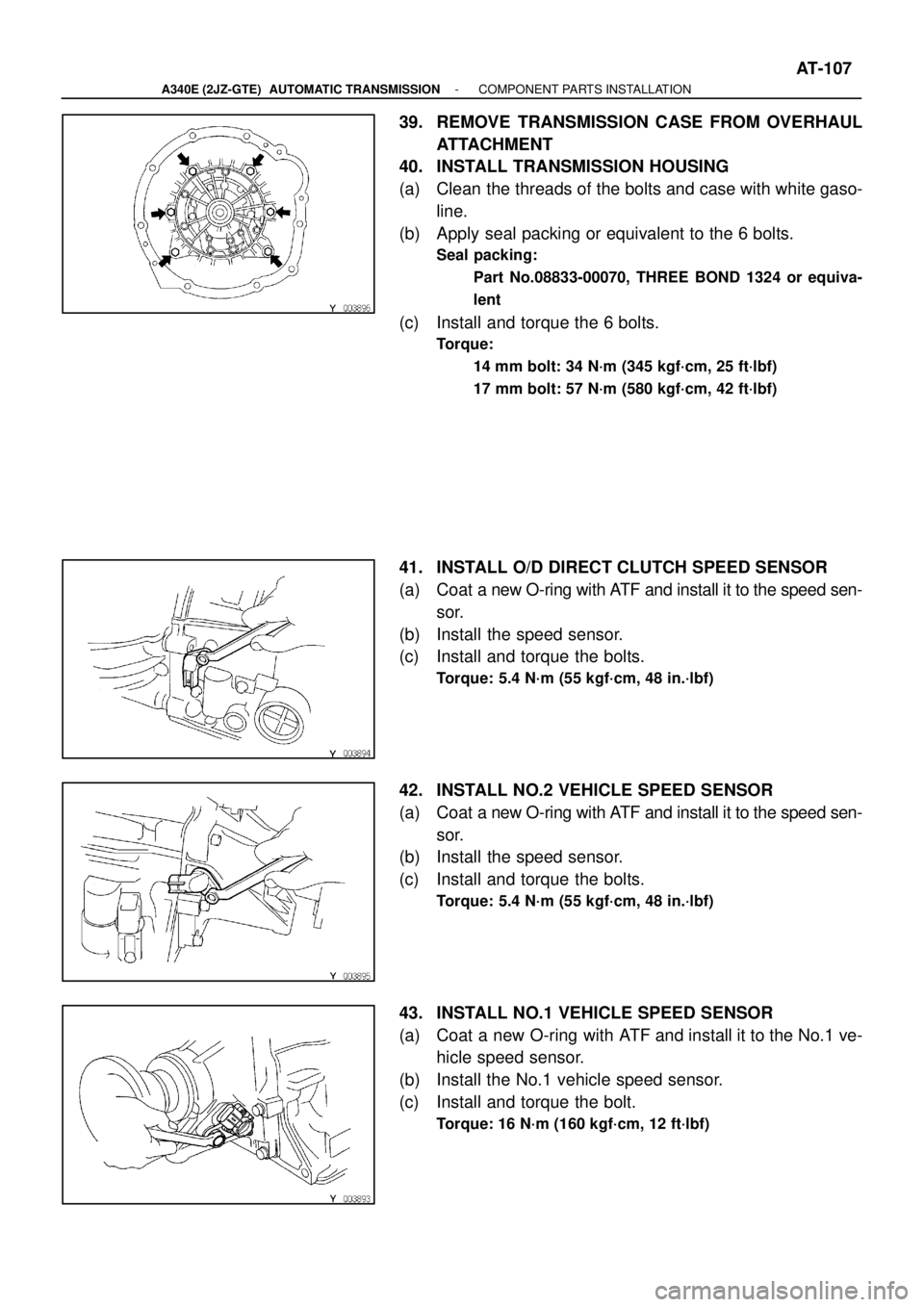

39. REMOVE TRANSMISSION CASE FROM OVERHAUL

ATTACHMENT

40. INSTALL TRANSMISSION HOUSING

(a) Clean the threads of the bolts and case with white gaso-

line.

(b) Apply seal packing or equivalent to the 6 bolts.

Seal packing:

Part No.08833-00070, THREE BOND 1324 or equiva-

lent

(c) Install and torque the 6 bolts.

Torque:

14 mm bolt: 34 N´m (345 kgf´cm, 25 ft´lbf)

17 mm bolt: 57 N´m (580 kgf´cm, 42 ft´lbf)

41. INSTALL O/D DIRECT CLUTCH SPEED SENSOR

(a) Coat a new O-ring with ATF and install it to the speed sen-

sor.

(b) Install the speed sensor.

(c) Install and torque the bolts.

Torque: 5.4 N´m (55 kgf´cm, 48 in.´lbf)

42. INSTALL NO.2 VEHICLE SPEED SENSOR

(a) Coat a new O-ring with ATF and install it to the speed sen-

sor.

(b) Install the speed sensor.

(c) Install and torque the bolts.

Torque: 5.4 N´m (55 kgf´cm, 48 in.´lbf)

43. INSTALL NO.1 VEHICLE SPEED SENSOR

(a) Coat a new O-ring with ATF and install it to the No.1 ve-

hicle speed sensor.

(b) Install the No.1 vehicle speed sensor.

(c) Install and torque the bolt.

Torque: 16 N´m (160 kgf´cm, 12 ft´lbf)

Page 256 of 2543

A340E (2JZ-GTE) AUTOMATIC TRANSMISSIONCOMPONENT PARTS INSTALLATION -

AT-108

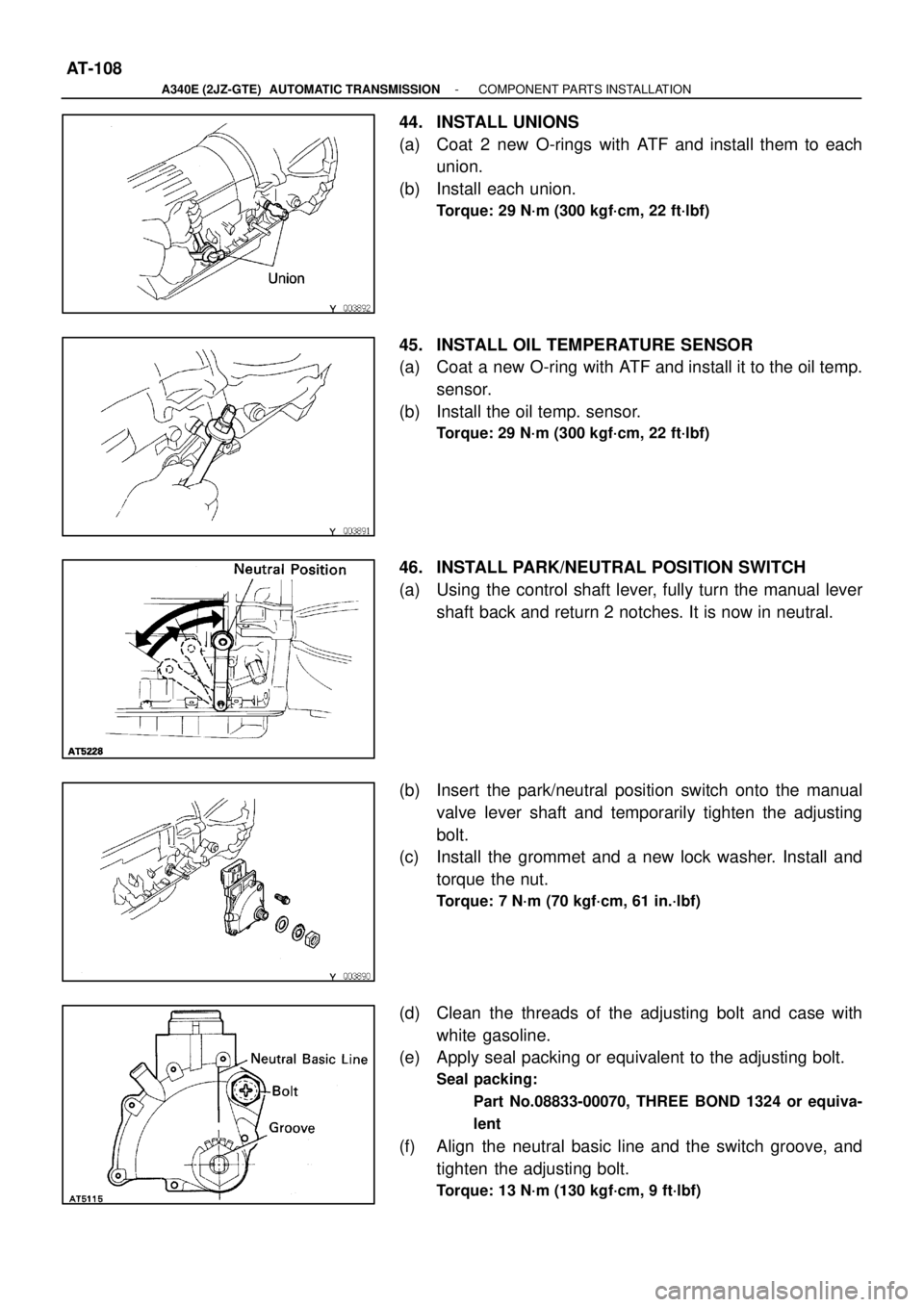

44. INSTALL UNIONS

(a) Coat 2 new O-rings with ATF and install them to each

union.

(b) Install each union.

Torque: 29 N´m (300 kgf´cm, 22 ft´lbf)

45. INSTALL OIL TEMPERATURE SENSOR

(a) Coat a new O-ring with ATF and install it to the oil temp.

sensor.

(b) Install the oil temp. sensor.

Torque: 29 N´m (300 kgf´cm, 22 ft´lbf)

46. INSTALL PARK/NEUTRAL POSITION SWITCH

(a) Using the control shaft lever, fully turn the manual lever

shaft back and return 2 notches. It is now in neutral.

(b) Insert the park/neutral position switch onto the manual

valve lever shaft and temporarily tighten the adjusting

bolt.

(c) Install the grommet and a new lock washer. Install and

torque the nut.

Torque: 7 N´m (70 kgf´cm, 61 in.´lbf)

(d) Clean the threads of the adjusting bolt and case with

white gasoline.

(e) Apply seal packing or equivalent to the adjusting bolt.

Seal packing:

Part No.08833-00070, THREE BOND 1324 or equiva-

lent

(f) Align the neutral basic line and the switch groove, and

tighten the adjusting bolt.

Torque: 13 N´m (130 kgf´cm, 9 ft´lbf)

Page 266 of 2543

A340E(Others) AUTOMATIC TRANSMISSIONOPERATION -

AT-9

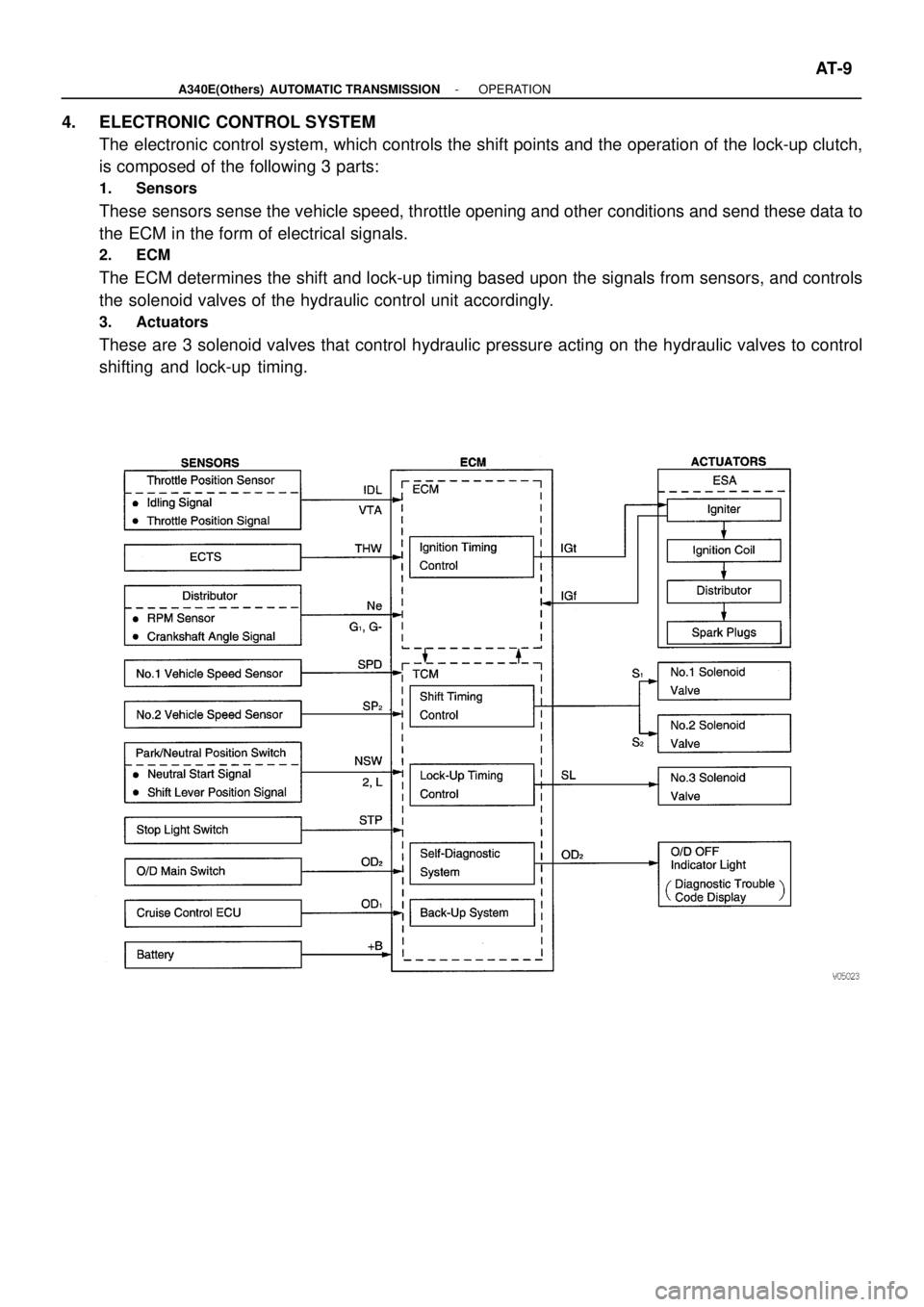

4. ELECTRONIC CONTROL SYSTEM

The electronic control system, which controls the shift points and the operation of the lock-up clutch,

is composed of the following 3 parts:

1. Sensors

These sensors sense the vehicle speed, throttle opening and other conditions and send these data to

the ECM in the form of electrical signals.

2. ECM

The ECM determines the shift and lock-up timing based upon the signals from sensors, and controls

the solenoid valves of the hydraulic control unit accordingly.

3. Actuators

These are 3 solenoid valves that control hydraulic pressure acting on the hydraulic valves to control

shifting and lock-up timing.