boot TOYOTA TERCEL 1985 User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 578 of 885

BRAKE SVSTEM - Front Brake8R.19

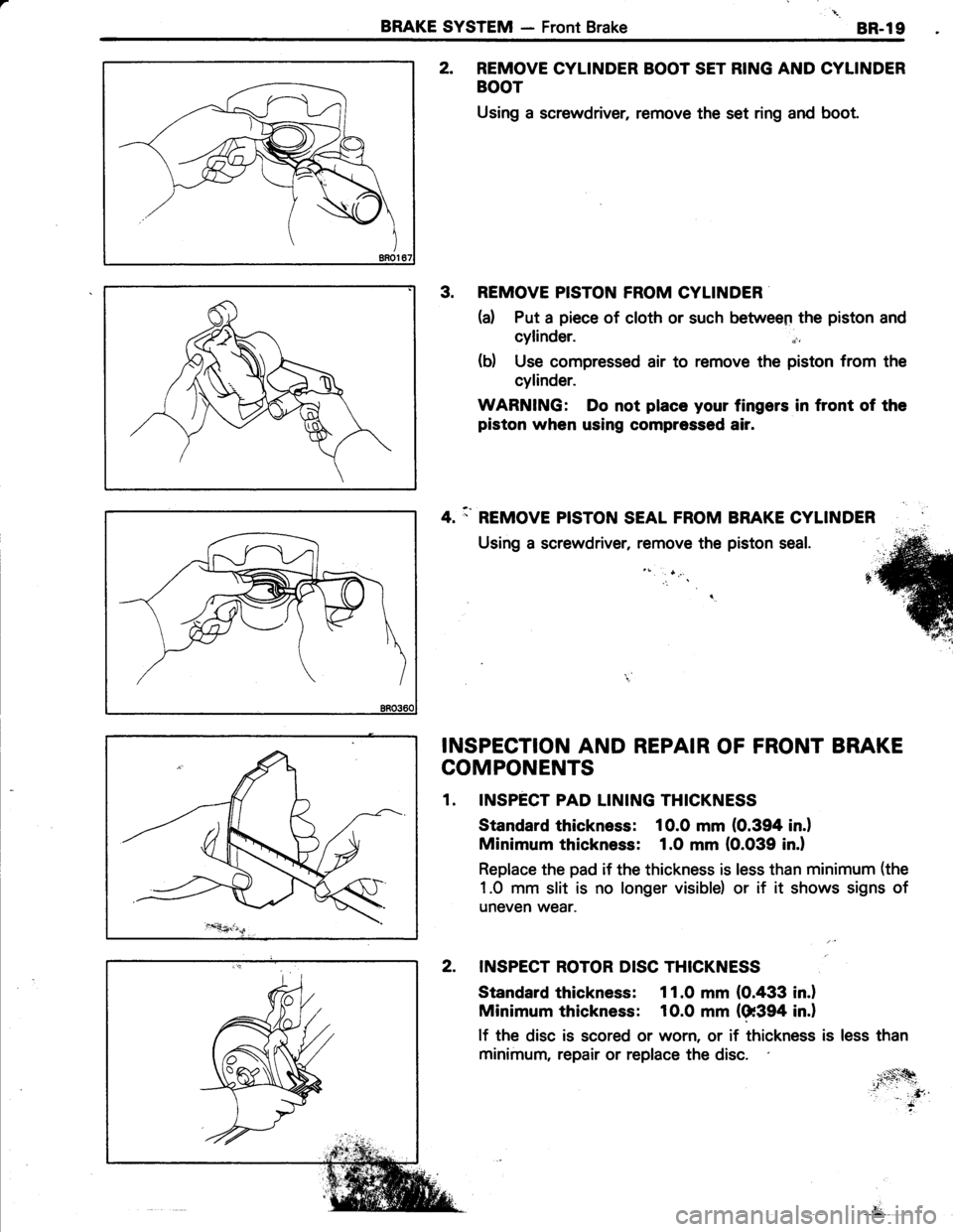

2. REMOVE CYLINDER BOOT SET RING AND CYLINDER

BOOT

Using a screwdriver, remove the set ring and boot.

3. REMOVE PISTON FROM CYLINDER

(a) Put a piece of cloth or such between the piston and

cylinder.

(d Use compressed air to remove the piston from the

cylinder.

WARNING: Do not place your fingers in front of the

piston when using compressed air.

- REMOVE PISTON SEAL FROM BRAKE CYLINDER

Using a screwdriver, remove the piston seal.

INSPECTION AND REPAIR OF FRONT BRAKE

COMPONENTS

1. TNSPECT PAD LINING THICKNESS

Standard thickness: 10.O mm (0.394 in.)

Minimum thickness: 1.0 mm (0.039 in.l

Replace the pad if the thickness is less than minimum (the

1.0 mm slit is no longer visible) or if it shows signs of

uneven wear.

INSPECT ROTOR DISC THICKNESS

Standard thickness: 1 1.0 mm (0.433 in.l

Minimum thickness: 10.0 mm {0r39a in.}

lf the disc is scored or worn, or if thickness is less than

minimum, repair or replace the disc.

4.

:t-$ixt:r- , . -rr,

*i,

Page 579 of 885

BR-2OBRAKE SYSTEM - Front Brake

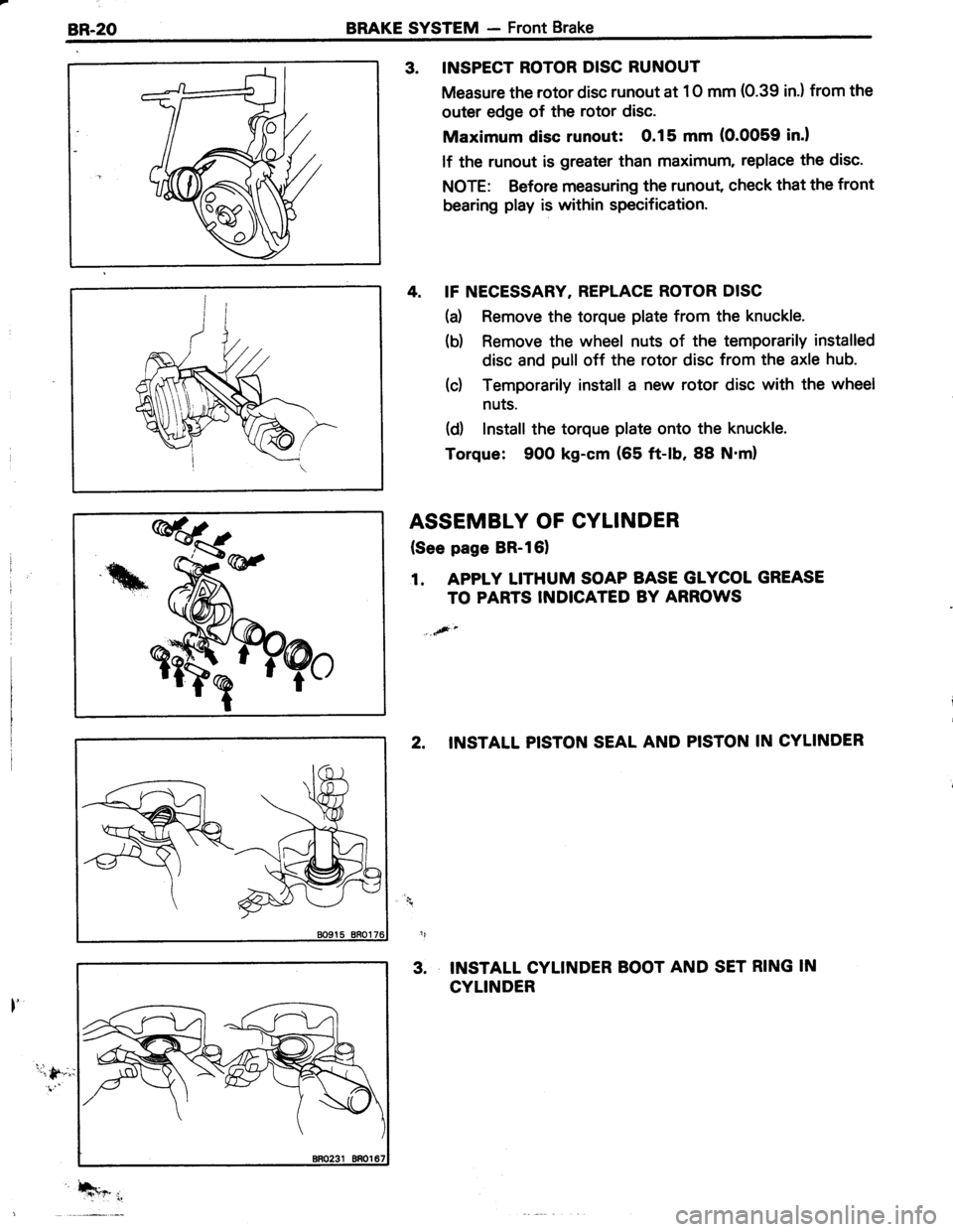

3. INSPECT ROTOR DISC RUNOUT

Measure the rotor disc runout at 1O mm (0.39 in.) from the

outer edge of the rotor disc.

Maximum disc runout: 0.15 mm (0.0059 in.l

lf the runout is greater than maximum, replace the disc.

NorE: Before measuring the runout check that the front

bearing play is within specification.

4. IF NECESSARY, REPLACE ROTOR DISC

(d Remove the torque plate from the knuckle.

(b) Remove the wheel nuts of the temporarily installed

disc and pull off the rotor disc from the axle hub.

(c) Temporarily install a new rotor disc with the wheel

nuts.

(d) Install the torque plate onto the knuckle.

Torque: 900 kg-cm (65 ft-lb, 88 N'm)

ASSEMBLY OF CYLINDER

(See page BR-161

1. APPLY LITHUM SOAP BASE GLYCOL GREASE

TO PARTS INDICATED BY ARROWS

2. INSTALL PISTON SEAL AND PISTON IN CYLINDER

INSTALL CYLINDER BOOT AND SET RING IN

CYLINDER

\

ti

3.

Q++, i,

Page 580 of 885

BRAKE SYSTEM - Front BrakeBR-2;1,,,":l-.,

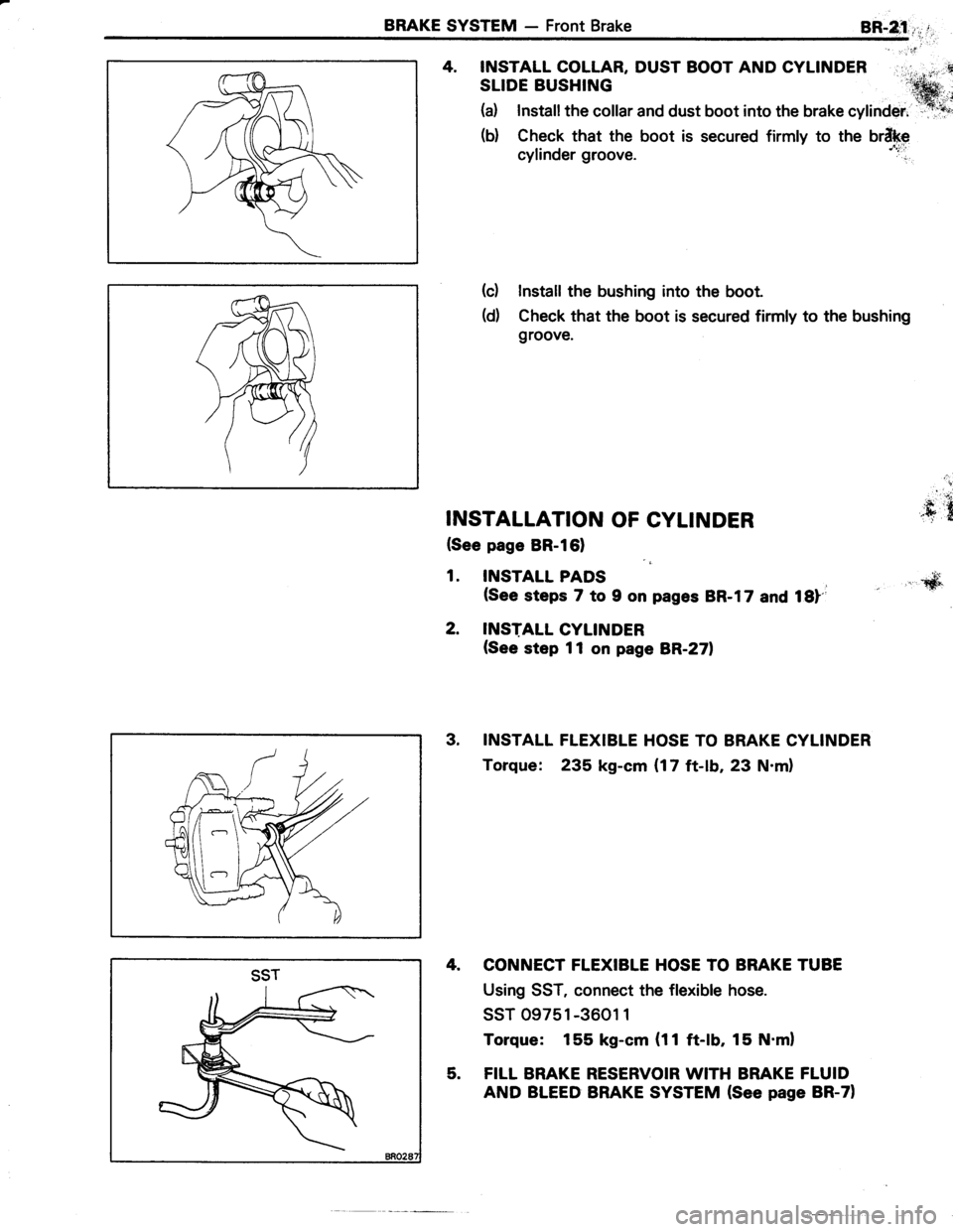

4. INSTALL COLLAR, DUST BOOT AND CYLINDER

SLIDE BUSHING

(a) Installthe collar and dust boot into the brake "VlinOer.'"'f,.@,*;

(b) Check that the boot is secured firmly to the brlkp

cylinder groove. ';1"t,

(c) Install the bushing into the boot.

(d) Check that the boot is secured firmly to the bushing

groove.

t:' t;

INSTALLATION OF CYLINDER JS .t

(See page BR-l61

1. INSTALL PADS ,,,\$,(See steps 7 to 9 on pag6s BR-17 and 18)-i

2. INSTALL CYLINDER(See step 11 on page BR-271

3. INSTALL FLEXIBLE HOSE TO BRAKE CYLINDER

Torque: 235 kg-cm (17 ft-lb, 23 N.m)

4. CONNECT FLEXIBLE HOSE TO BRAKE TUBE

Using SST, connect the flexible hose.

ssT 09751 -3601 1

Torque: 155 kg-cm (11 ft-lb, 15 N.ml

5. FILL BRAKE RESERVOIR WITH BRAKE FLUID

AND BLEED BRAKE SYSTEM (See page BR-71

SST

Page 583 of 885

.,ea-24BRAKE SYSTEM - Rear Brake (Sedan)

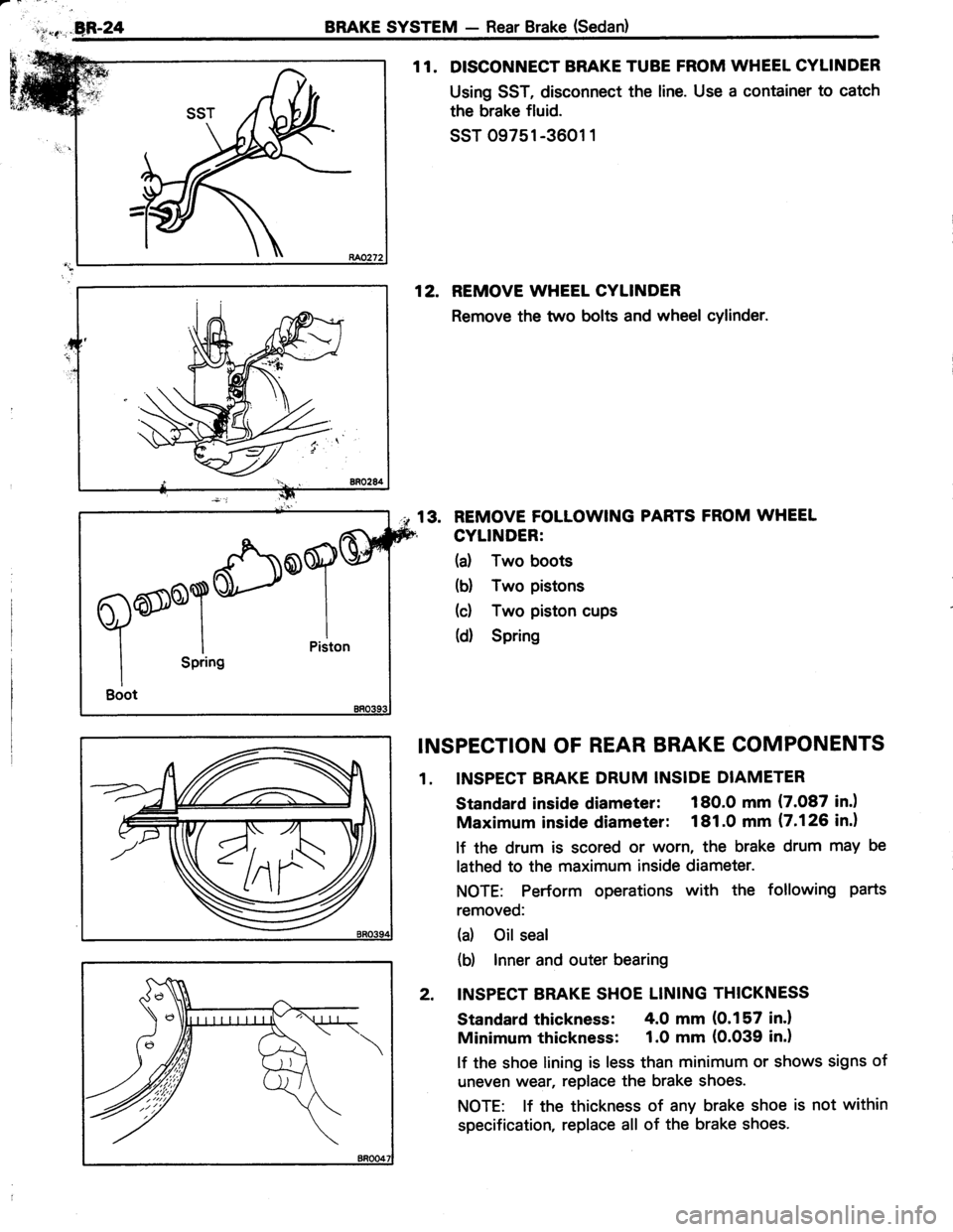

1 1. DISCONNECT BRAKE TUBE FROM WHEEL CYLINDER

Using SST, disconnect the line. Use a container to catch

the brake fluid.

ssr 09751-3601 1

12. REMOVE WHEET CYLINDER

Remove the two bolts and wheel cylinder.

REMOVE FOLLOWING

CYLINDER:

(d Two boots

(b) Two pistons

(c) Two piston cups

(d Spring

PARTS FROM WHEEL

INSPECTION OF REAR BRAKE COMPONENTS

1. INSPECT BRAKE DRUM INSIDE DIAMETER

Standard inside diameter: 180.0 mm (7.087 in.)

Maximum inside diameter: 181.0 mm (7.126 in.)

lf the drum is scored or worn, the brake drum may be

lathed to the maximum inside diameter.

NOTE: Perform operations with the following parts

removed:

(d Oil seal

(b) lnner and outer bearing

2. INSPECT BRAKE SHOE LINING THICKNESS

Standard thickness: 4.0 mm (0.157 in.l

Minimum thickness: 1.0 mm (0.039 in.)

lf the shoe lining is less than minimum or shows signs of

uneven wear, replace the brake shoes.

NOTE: lf the thickness of any brake shoe is not within

specification, replace all of the brake shoes.

.rS

Ao@(

fl@oTu"/ I

v/ll

| | Piston

I

sorins

Page 584 of 885

BRAKE SYSTEM - Rear Brake (Sedan)8R.25

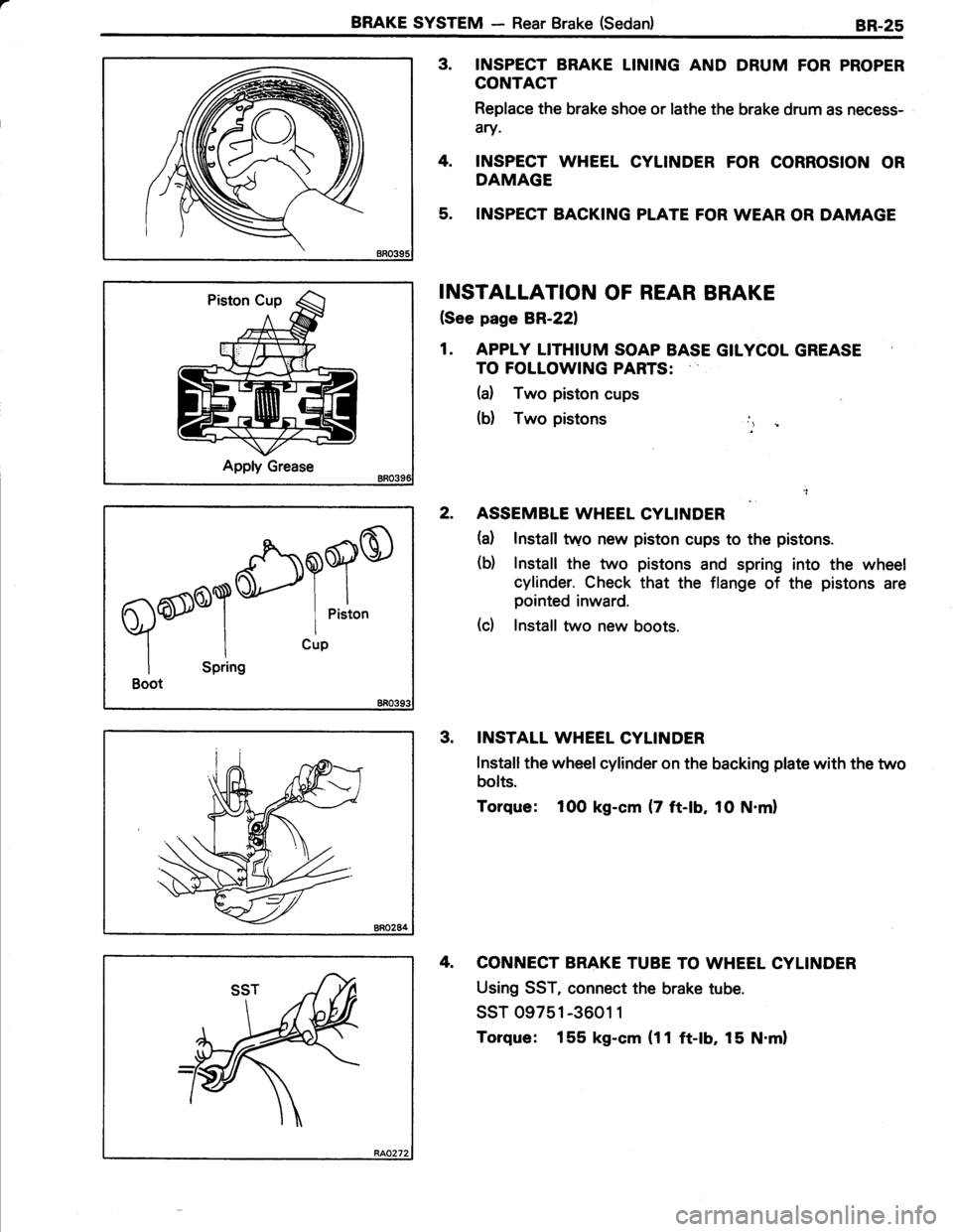

Apply Grease

3. INSPECT BRAKE LINING AND DRUM FOR PROPER

CONTACT

Replace the brake shoe or lathe the brake drum as necess-

4ry.

4. INSPECT WHEEL CYLINDER FOR CORROSION OR

DAMAGE

5. INSPECT BACKING PLATE FOR WEAR OR DAMAGE

INSTALLATION OF REAR BRAKE

(See page BR-221

1. APPLY LITHIUM SOAP BASE GILYCOL GREASE

TO FOTLOWING PARTS:

(d Two piston cups

(b) Two pistons ,, ,

.. 't

2. ASSEMBLE WHEEL CYLINDER

(a) Install two new piston cups to the pistons.

(b) Install the two pistons and spring into the wheet

cylinder. Check that the flange of the pistons are

pointed inward.

(c) Install two new boots.

3. INSTALL WHEEL CYLINDER

Install the wheel cylinder on the backing plate with the two

bolts.

Torque: lOO kg-cm (7 ft-lb, 1O N.ml

4. CONNECT BRAKE TUBE TO WHEEL CYLINDER

Using SST, connect the brake tube.

ssT 09751 -3601 1

Torque: 155 kg-cm (11ft-lb, 15 N.ml

Ao@O

o@rT*1,,i""llcuptt

I Spring

Boot

Page 590 of 885

BRAKE SYSTEM - Rear Brake (Wagon FWD)8R.31

9. DISCONNECT BRAKE TUBE FROM WHEEL

CYLINDER

Using SST, disconnect the line. Use a container to catch

the brake fluid.

10. REMOVE WHEEL CYLINDER

Remove the two bolts and wheel cylinder.

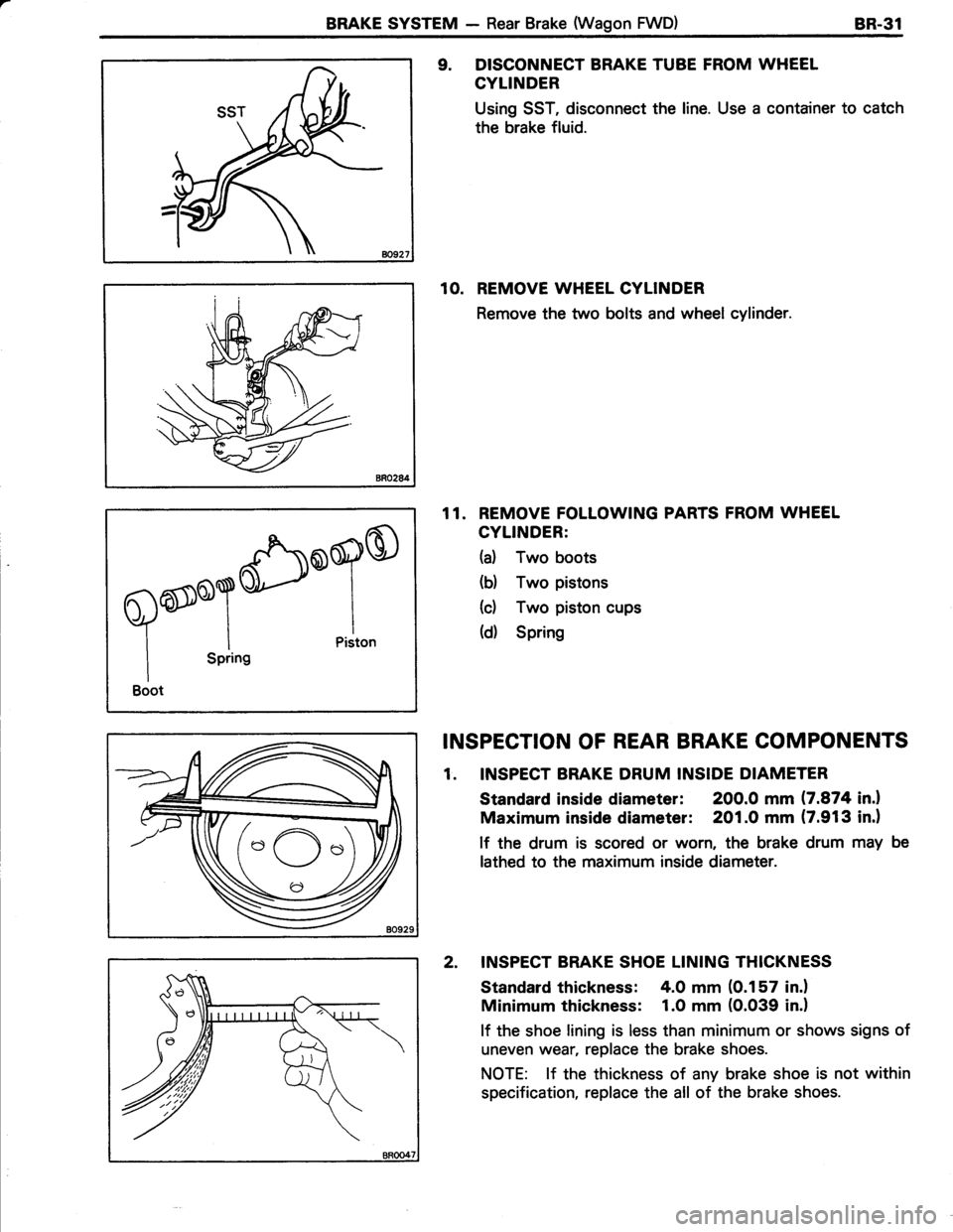

11. REMOVE FOLLOWING PARTS FROM WHEEL

CYLINDER:

(a) Two boots

(b) Two pistons

(c) Two piston cups

(d) Spring

INSPECTION OF REAR BRAKE COMPONENTS

1. INSPECT BRAKE DRUM INSIDE DIAMETER

Standard inside diameter: 200.0 mm (7.874 in.l

Maximum inside diameter: 201.0 mm (7.913 in.)

lf the drum is scored or worn, the brake drum may be

lathed to the maximum inside diameter.

2. INSPECT BRAKE SHOE LINING THICKNESS

Standard thickness: 4.0 mm (0.157 in.)

Minimum thickness: 1.O mm {0.039 in.l

lf the shoe lining is less than minimum or shows signs of

uneven wear, replace the brake shoes.

NOTE: lf the thickness of any brake shoe is not within

specification, replace the all of the brake shoes.

6)o9o

IPiston

Boot

oO"

Page 591 of 885

o/' \;z\o /

INSPECT BRAKE LINING AND DRUM FOR PROPER

CONTACT

Replace the brake shoe or lathe the brake drum as necess-

4ry.

INSPECT WHEET CYLINDER FOR CORROSION OR

DAMAGE

INSPECT BACKING PLATE FOR WEAR OR DAMAGE

INSTALLATION OF REAR BRAKE

(See page BR-291

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE

TO FOLLOWING PABTS:

(d Two piston cups

(b) Two pistons

2. ASSEMBLE WHEEL CYLINDER

(a) lnstall two new piston cups to each piston, check

that the flanges of the cups are pointed inward.

(b) Install the two pistons and spring into the wheel

cylinder.

(c) Install two new boots.

3. INSTALL WHEEL CYLINDER

Installthe wheelcylinder on the backing plate with the two

bolts.

Torque: 1OO kg-cm (7 ft-lb, 1O N.ml

4. CONNECT BRAKE TUBE TO WHEEL CYLINDER

Using SST, connect the brake tube

ssT 09751 -3601 1

Torque: 155 kg-cm (11 ft-lb, 15 N.ml

4.

5.

Pistoncu'

^cloqO

fl@6alA"

YrlI I Piston

I SPring

Boot

Page 597 of 885

8R.38BRAKE SYSTEM - Rear Brake (Wagon 4WD)

Piston cup

t'"fon

^,I

i *^m.GSDW)'"i.

lK3r)Y*

Am'Q)\gr---..- I

\J/ SPring

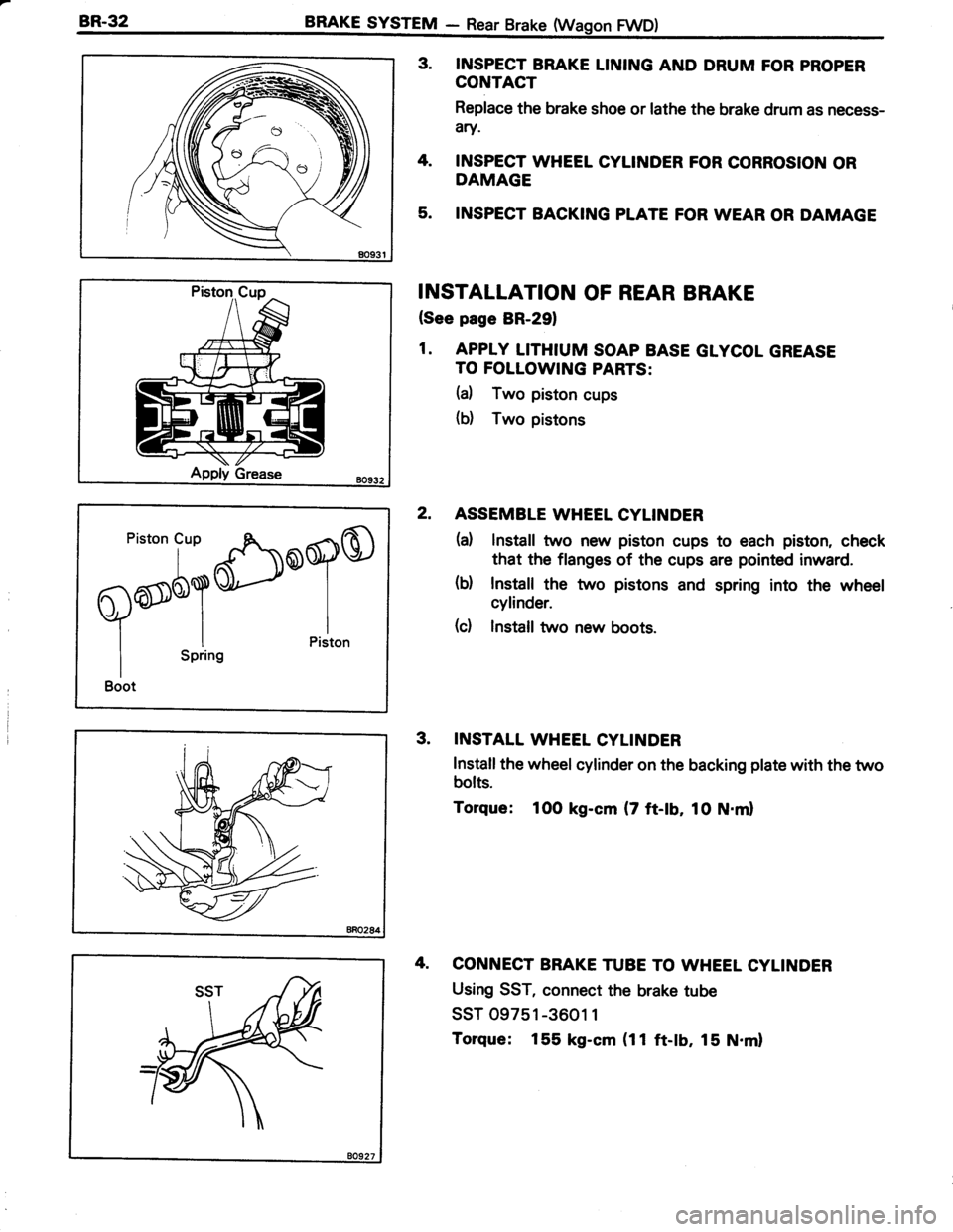

10. REMOVE FOLLOWING PARTS FROM WHEEL

CYLINDER:

(a) Two boots

b) Two pistons

(c) Spring

INSPECTION OF REAR BRAKE COMPONENTS

1. INSPECT BRAKE DRUM INSIDE DIAMETER

Standard inside diameter: 200.0 mm (7.874 in.l

Maximum inside diameter: 2O1.O mm (7.913 in.)

lf the drum is scored or worn, the brake drum may be

lathed to the maximum inside diameter.

2. INSPECT BRAKE SHOE LINING THICKNESS

Standard thickness: 4.0 mm (0.157 in.l

Minimum thickness: 1.0 mm {0.039 in.l

lf the shoe lining is less than minimum or shows signs of

uneven wear, replace the brake shoes.

NOTE: lf the thickness of any brake shoe is not within

specification, replace all of the brake shoes.

3. INSPECT BRAKE LINING AND DRUM FOR PROPER

CONTACT

Replace the brake shoe or lathe the brake drum as neces-

sary.

4. INSPECT WHEEL CYLINDER FOR CORROSION OR

DAMAGE

5. INSPECT BACKING PLATE FOR WEAR OR DAMAGE

,- a\-Z\�"

()

<)()

Page 598 of 885

BRAKE SYSTEM - Rear Brake (Wagon 4WD)8R.39

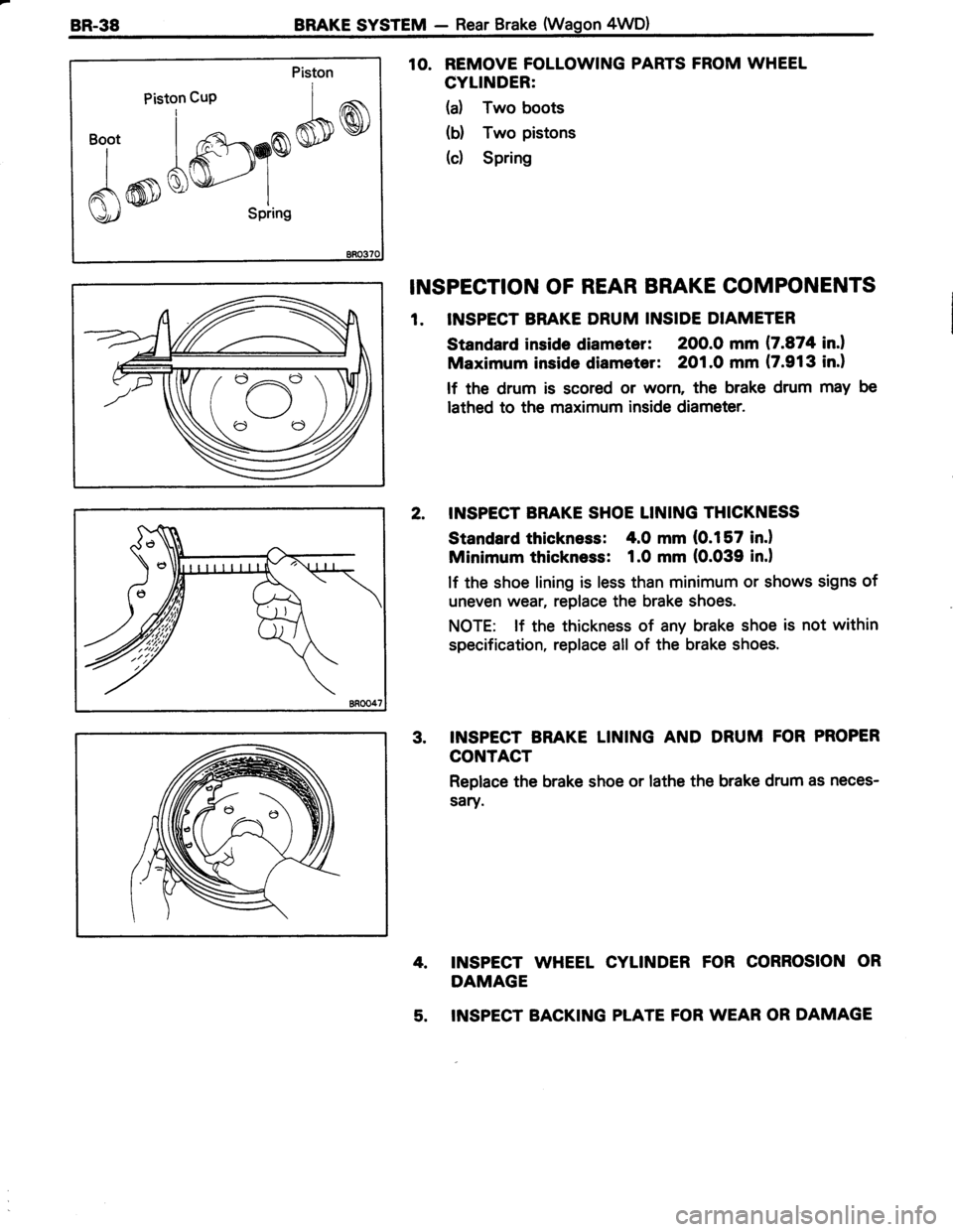

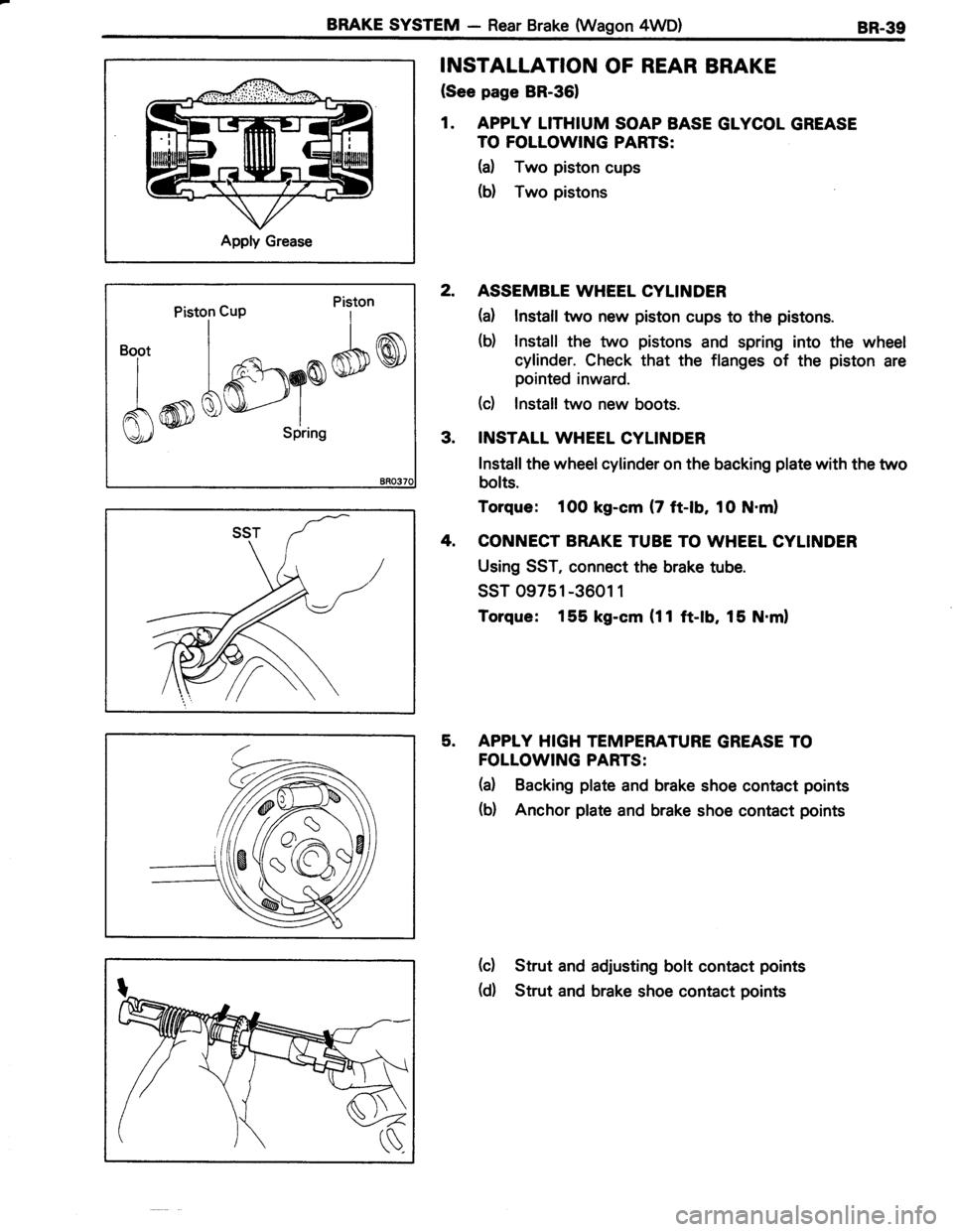

Apply Grease

INSTALLATION OF REAR BRAKE

(See page BR-361

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE

TO FOLLOWING PARTS:

H Two piston cups

(d Two pistons

2. ASSEMBLE WHEEL CYLINDER

(d Install two new piston cups to the pistons.

(d Install the two pistons and spring into the wheel

cylinder. Check that the flanges of the piston are

pointed inward.

(c) Install two new boots.

3. INSTALL WHEEL CYLINDER

Installthe wheelcylinder on the backing plate with the two

bolts.

Torque: lOO kg-cm (7 ft-lb, 1O N.ml

4. CONNECT BRAKE TUBE TO WHEEL CYLINDER

Using SST, connect the brake tube.

ssT 09751 -3601 1

Torque: 155 kg-cm (11 ft-lb, 15 N.ml

5. APPTY HIGH TEMPERATURE GREASE TO

FOLLOWING PARTS:

(a) Backing plate and brake shoe contact points

(b) Anchor plate and brake shoe contact points

(d Strut and adjusting bolt contact points

(d) Strut and brake shoe contact points

Piston cup Piston

'"i'

lKs^*@#@

d@*''*,J."n