brake light TOYOTA TERCEL 1985 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 565 of 885

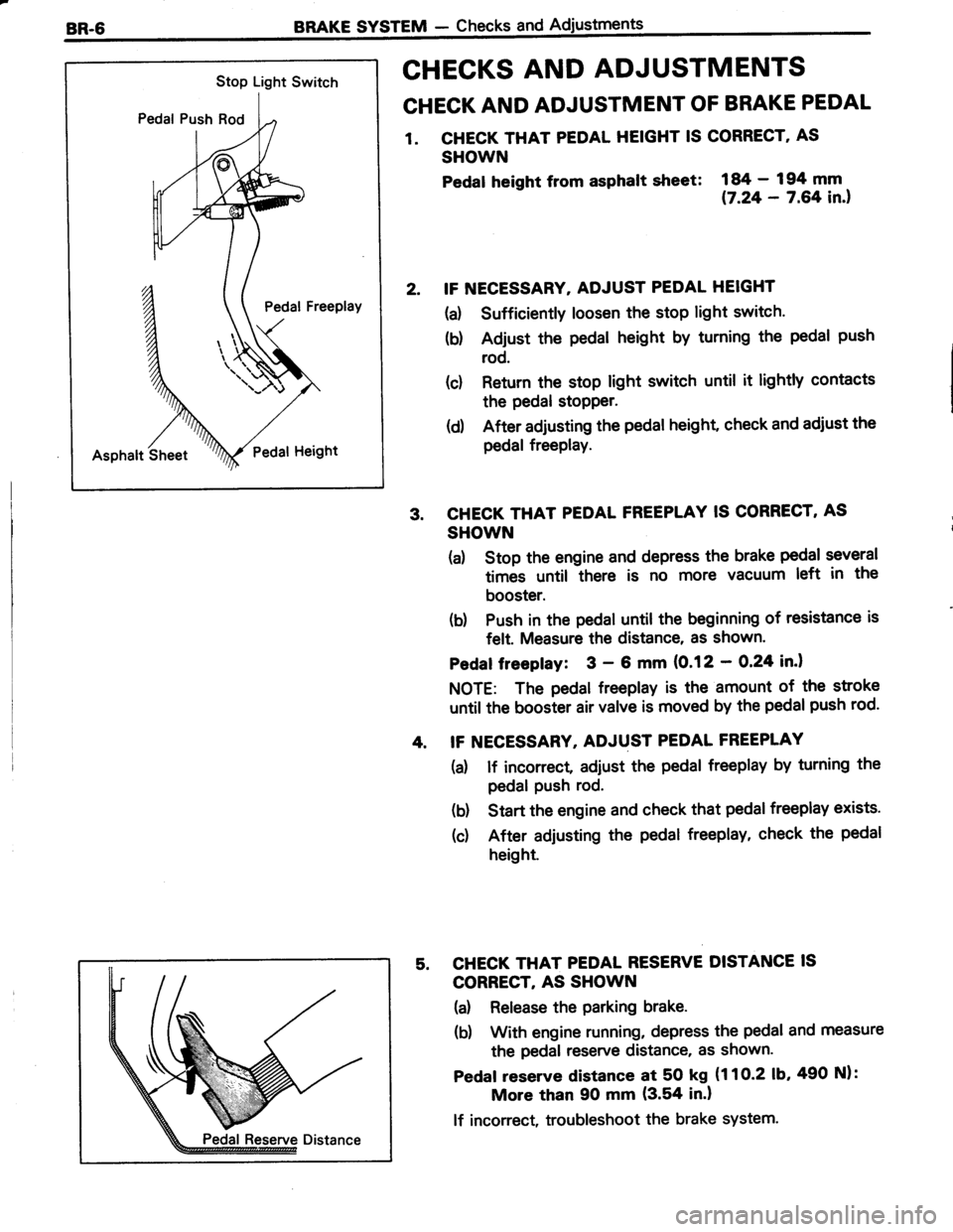

Stop Light Switch

Pedal Push Rod

Pedal Freeplay

Asphalt SheetPedat Height

BRAKE SYSTEM - Checks and

CHECKS AND ADJUSTMENTS

CHECK AND ADJUSTMENT OF BRAKE PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT' AS

SHOWN

Pedat heisht from asphalt slreet:

i#;:?ifil.,

IF NECESSARY. ADJUST PEDAL HEIGHT

(a) Sufficiently loosen the stop light switch.

(b) Adjust the pedal height by turning the pedal push

rod.

(c) Return the stop light switch until it lightly contacts

the pedal stopper.

(d) After adjusting the pedal height, check and adiust the

pedal freePlay.

CHECK THAT PEDAL FREEPLAY IS CORRECT, AS

SHOWN

(a) Stop the engine and depress the brake pedal several

times until there is no more vacuum left in the

booster.

(b) Push in the pedal until the beginning of resistance is

felt. Measure the distance, as shown'

Pedaf freepfay: 3 - 6 mm (0.12 - O,24 in.l

NOTE: The pedal freeplay is the amount of the stroke

until the booster air valve is moved by the pedal push rod.

IF NECESSARY, ADJUST PEDAL FREEPLAY

(a) lf incorrect adiust the pedal freeplay by turning the

pedal Push rod.

(b) Start the engine and check that pedal freeplay exists.

(c) After adjusting the pedal freeplay, check the pedal

height.

CHECK THAT PEDAL RESERVE DISTANCE IS

CORRECT, AS SHOWN

(a) Release the parking brake.

(b) With engine running, depress the pedal and measure

the pedal reserve distance, as shown.

Pedaf reserve distance at 50 kg (1 1 O-2 1b,490 Nl:

More than 90 mm (3.54 in.l

lf incorrect, troubleshoot the brake system.

Page 566 of 885

BRAKE SYSTEM - Checks and AdjustmentsBR-7

@@

VV

1 st 2nd

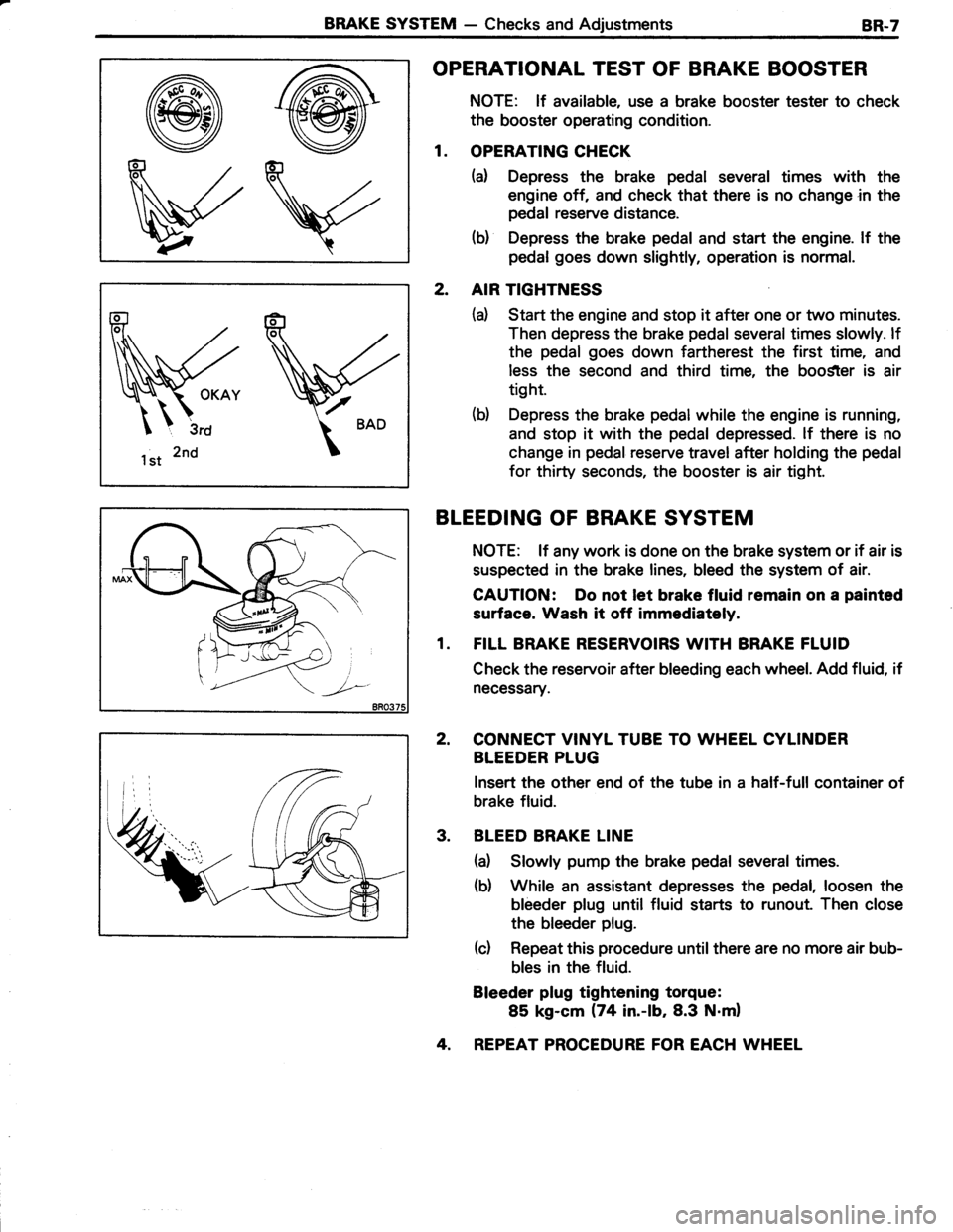

OPERATIONAL TEST OF BRAKE BOOSTER

NOTE: lf available, use a brake booster tester to check

the booster operating condition.

1. OPERATING CHECK

(a) Depress the brake pedal several times with the

engine off, and check that there is no change in the

pedal reserve distance.

(b) Depress the brake pedal and start the engine. lf the

pedal goes down slightly, operation is normal.

2. AIR TIGHTNESS

(d Start the engine and stop it after one or two minutes.

Then depress the brake pedal several times slowly. lf

the pedal goes down fartherest the first time, and

less the second and third time, the boo$ter is air

tight.

(b) Depress the brake pedal while the engine is running,

and stop it with the pedal depressed. lf there is no

change in pedal reserve travel after holding the pedal

for thirty seconds, the booster is air tight.

BLEEDING OF BRAKE SYSTEM

NOTE: lf any work is done on the brake system or if air is

suspected in the brake lines, bleed the system of air.

CAUTION: Do not let brake fluid remain on a painted

surface. Wash it off immediataly.

1. FILL BRAKE RESERVOIRS WITH BRAKE FLUID

Check the reservoir after bleeding each wheel. Add fluid, if

necessary.

2, CONNECT VINYL TUBE TO WHEEL CYLINDER

BLEEDER PLUG

lnsert the other end of the tube in a half-full container of

brake fluid.

3. BLEED BRAKE LINE

(a) Slowly pump the brake pedal several times.

(b) While an assistant depresses the pedal, loosen the

bleeder plug until fluid starts to runout. Then close

the bleeder plug.

(c) Repeat this procedure until there are no more air bub-

bles in the fluid.

Bleeder plug tightening torque:

85 kg-cm (74 in.-lb,8.3 N.m)

4. REPEAT PROCEDURE FOR EACH WHEEL

Page 570 of 885

BRAKE SYSTEM - Master CylinderBR-11

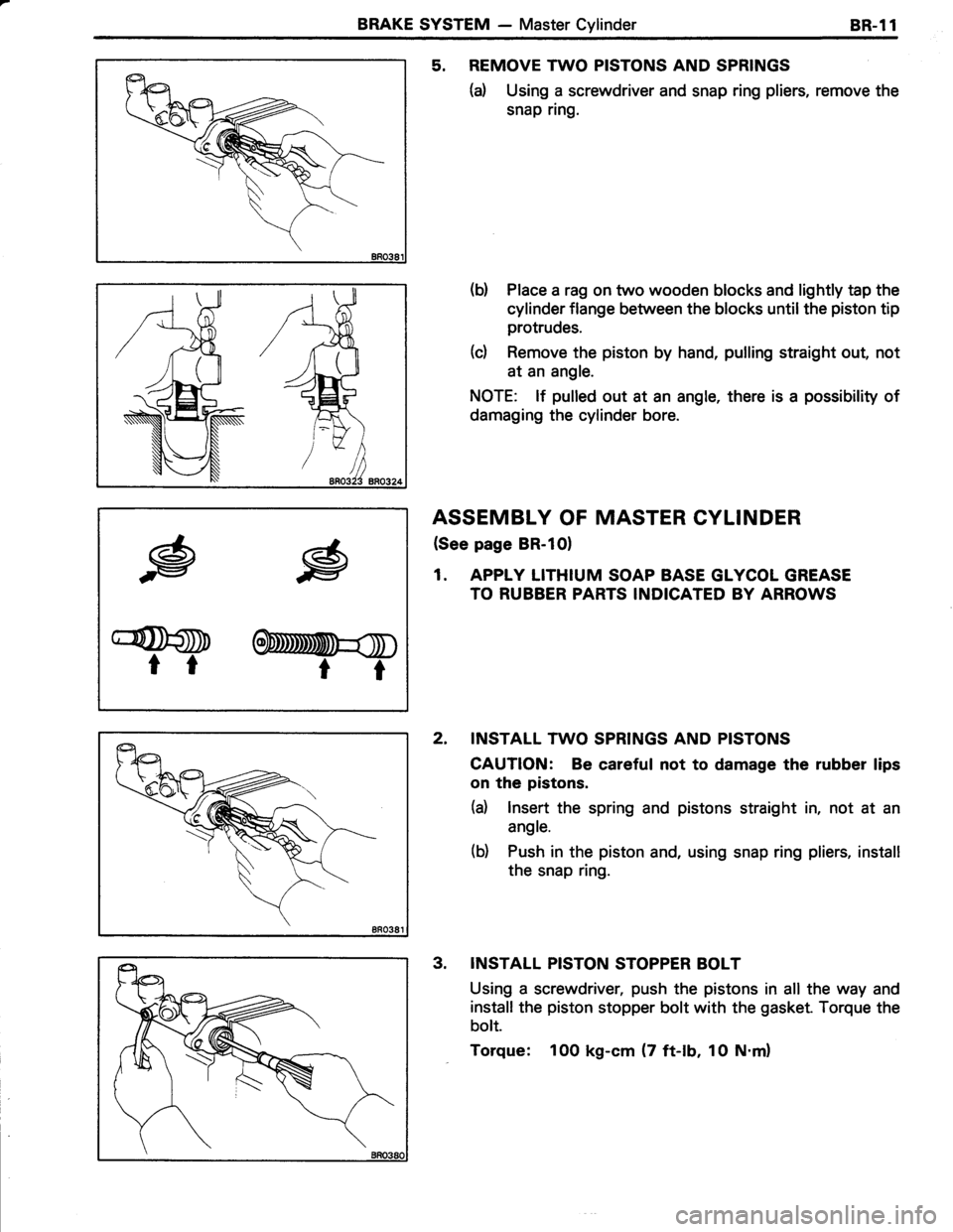

5. REMOVE TWO PISTONS AND SPRINGS

(d Using a screwdriver and snap ring pliers, remove the

snap ring.

(b) Place a rag on two wooden blocks and lightly tap the

cylinder flange between the blocks until the piston tip

protrudes.

(c) Remove the piston by hand, pulling straight out, not

at an angle.

NOTE: lf pulled out at an angle, there is a possibility of

damaging the cylinder bore.

ASSEMBLY OF MASTER CYLINDER

(See page BR-10)

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE

TO RUBBER PARTS INDICATED BY ARROWS

2. INSTALL TWO SPRINGS AND PISTONS

CAUTION: Be careful not to damage the rubber lips

on the pistons.

(d lnsert the spring and pistons straight in, not at an

angle.

(b) Push in the piston and, using snap ring pliers, install

the snap ring.

INSTALL PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and

install the piston stopper bolt with the gasket. Torque the

bolt.

Torque: 100 kg-cm (7 ft-lb, 1O N.m)

.g

G@D

tr

.g

OnmmU=$

rt

3.

Page 574 of 885

BRAKE SYSTEM - Brake Booster8R.15

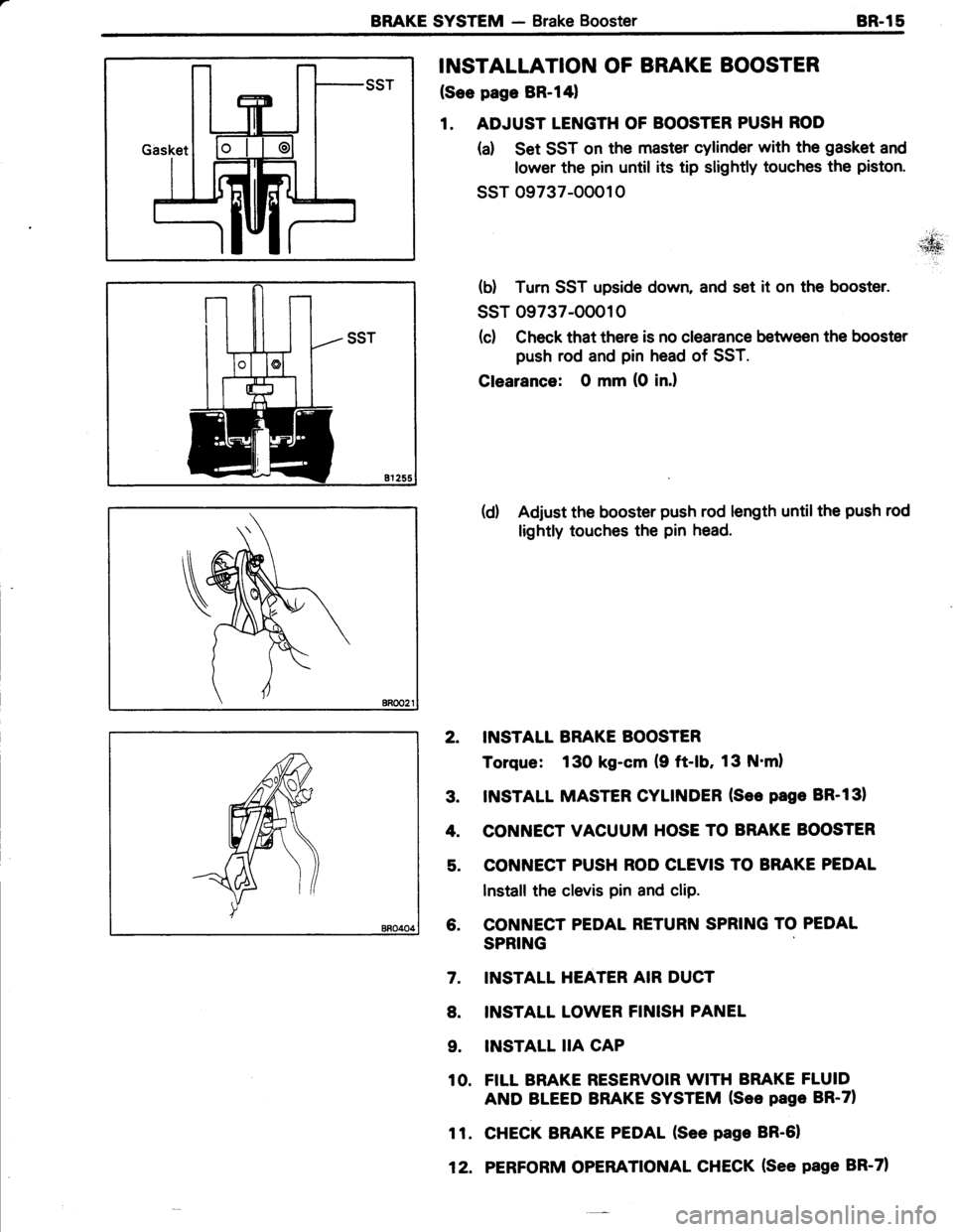

INSTALLATION OF BRAKE BOOSTER

(See page BR-l41

1. ADJUST LENGTH OF BOOSTER PUSH ROD

(a) Set SST on the master cylinder with the gasket and

lower the pin until its tip slightly touches the piston.

ssr 09737-00010

(d Tum SST upside down, and set it on the booster.

ssT 09737-OOO10

(c) Check that there is no clearance between the booster

push rod and pin head of SST.

Clearance: O mm (0 in.l

(d) Adjust the booster push rod length untilthe push rod

lightly touches the pin head.

2. INSTALL BRAKE BOOSTER

Torque: 130 kg-cm (9 ft-lb, 13 N'ml

3. INSTALL MASTER CYLINDER (See page BR-131

4. CONNECT VACUUM HOSE TO BRAKE BOOSTER

5. CONNECT PUSH ROD CLEVIS TO BRAKE PEDAL

Install the clevis pin and clip.

6. CONNECT PEDAL RETURN SPRING TO PEDAL

SPRING

INSTALL HEATER AIR DUCT

INSTALL LOWER FINISH PANEL

INSTALL IIA CAP

FILL BRAKE RESERVOIR WITH BRAKE FLUID

AND BLEED BRAKE SYSTEM (See page BR-71

CHECK BRAKE PEDAL (See page BR-61

PERFORM OPERATIONAL CHECK (See page BR-71

7.

8.

9.

10.

11.

12.