check oil TOYOTA TERCEL 1985 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 498 of 885

I

FA-l8FRONT AXLE AND SUSPENSION - Front Drive Shaft

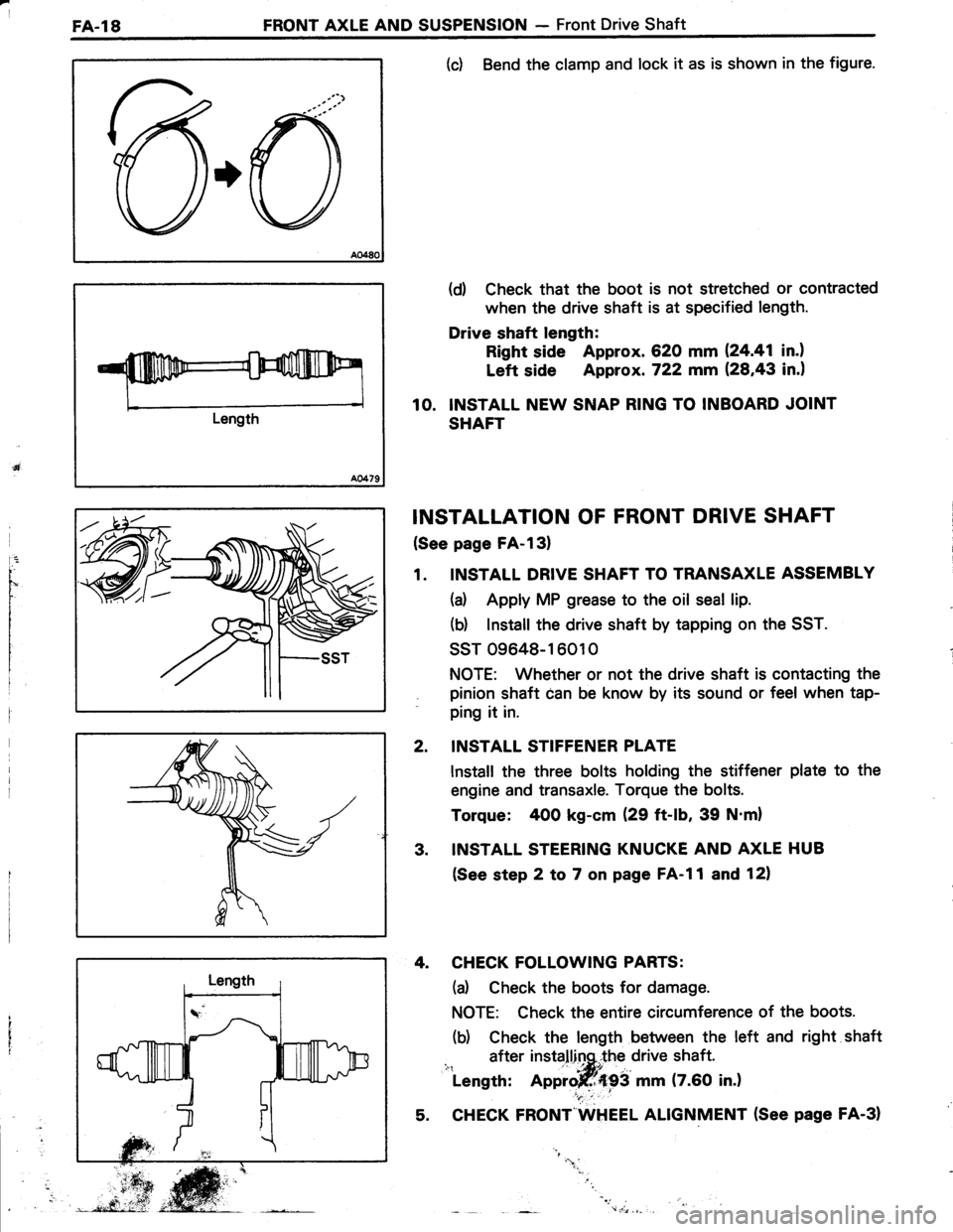

Length

(c) Bend the clamp and lock it as is shown in the figure.

(d) Check that the boot is not stretched or contracted

when the drive shaft is at specified length.

Drive shaft length:

Right side Approx. 620 mm 124.41 in.l

Left side Approx. 722 mm (28,43 in.)

10. INSTALL NEW SNAP RING TO INBOARD JOINT

SHAFT

INSTALLATION OF FRONT DRIVE SHAFT

(See page FA-l3)

1. INSTALL DRIVE SHAFT TO TRANSAXLE ASSEMBLY

(a) Apply MP grease to the oil seal lip.

(b) lnstall the drive shaft by tapping on the SST.

ssT 09648-16010

NOTE: Whether or not the drive shaft is contacting the

pinion shaft can be know by its sound or feel when tap-

ping it in.

INSTALL STIFFENER PLATE

lnstall the three bolts holding the stiffener plate to the

engine and transaxle. Torque the bolts.

Torque: 400 kg-cm (29 ft-lb, 39 N'm)

INSTALL STEERING KNUCKE AND AXLE HUB

(See step 2 to 7 on page FA-l1 and 12)

4. CHECK FOLLOWING PARTS:

(d Check the boots for damage.

NOTE: Check the entire circumference of the boots.

(b) Check the length between the left and right shaft

after installinq,.the drive shaft.i": ' -|*itLength: Approjff{93 mm (7.60 in.)

5. CHECK FRONT"WHEEL ALIGNMENT (See page FA-31

2.

3.

"1.

Page 501 of 885

FRONT AXLE AND SUSPENSION - Front Shock AbsorberFA.21

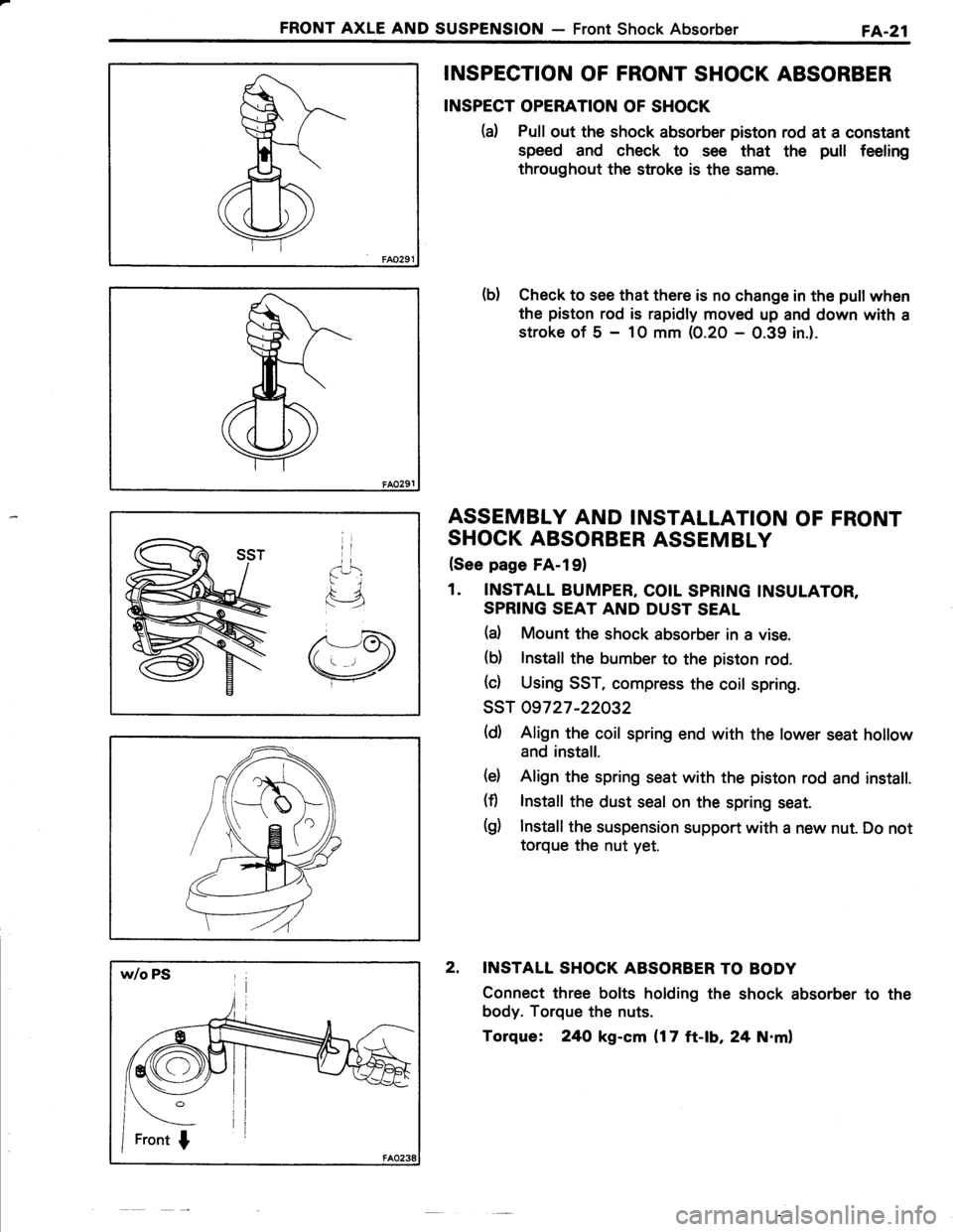

INSPECTION OF FRONT SHOCK ABSORBER

INSPECT OPERATION OF SHOCK

(d Pull out the shock absorber piston rod at a constant

speed and check to see that the pull feeling

throughout the stroke is the same.

b) Check to see that there is no change in the pull when

the piston rod is rapidly moved up and down with a

stroke of 5 - 1O mm (0.20 - 0.39 in.).

ASSEMBLY AND INSTALLATION OF FRONT

SHOCK ABSORBER ASSEMBLY

(See page FA-l91

1. INSTALL BUMPER, COIL SPRING INSULATOR,

SPRING SEAT AND DUST SEAL

(d Mount the shock absorber in a vise.

(b) lnstall the bumber to the piston rod.

(c) Using SST, compress the coil spring.

ssT 09727 -22032

(d) Align the coil spring end with the lower seat hollow

and install.

(d Align the spring seat with the piston rod and install.

(fl lnstall the dust seal on the spring seat.

(g) Install the suspension support with a new nut. Do not

torque the nut yet.

2. INSTALL SHOCK ABSORBER TO BODY

Connect three bolts holding the shock absorber to the

body. Torque the nuts.

Torque: 24O kg-cm {17 ft-lb, 24 N.ml

Page 503 of 885

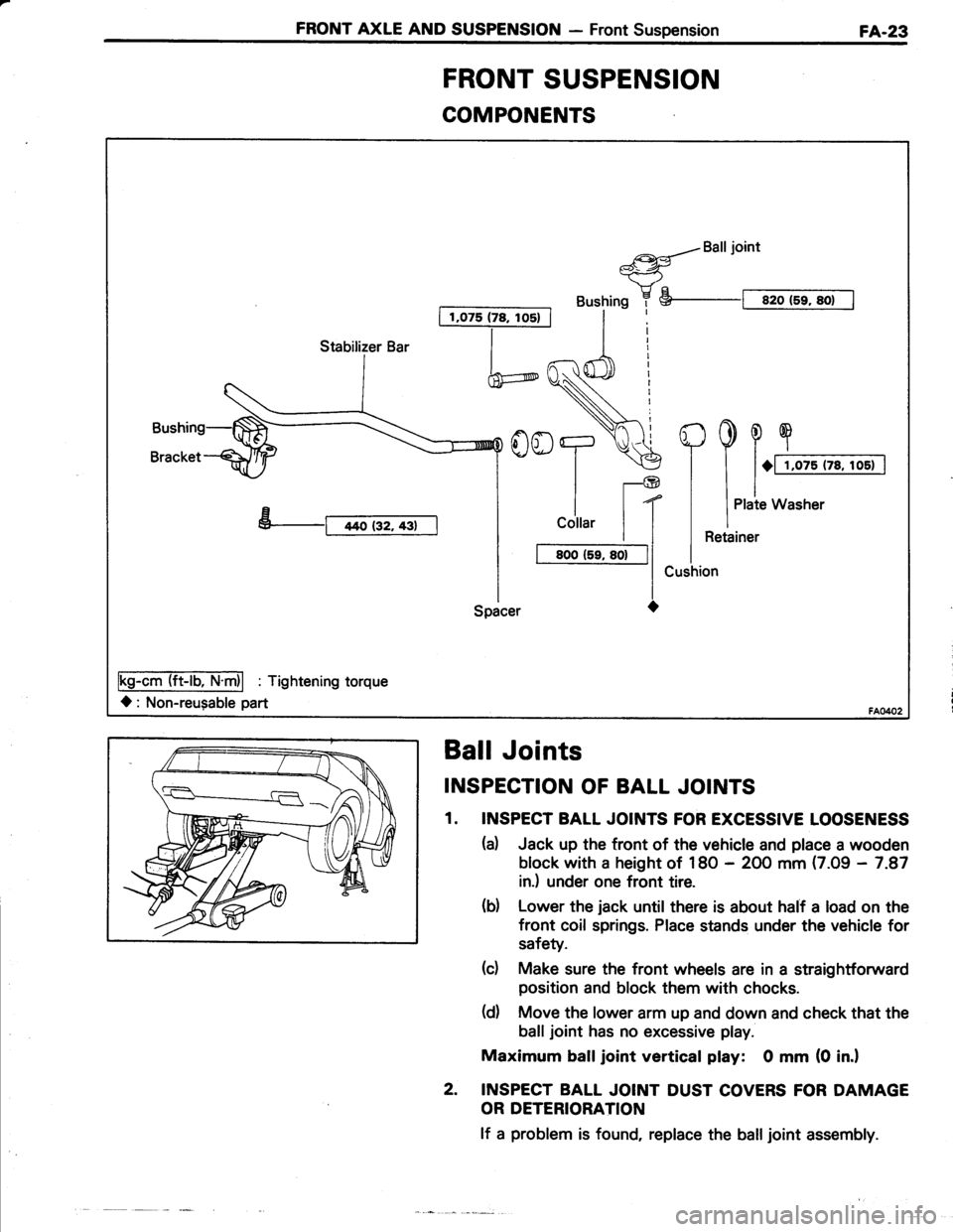

FRONT AXLE AND SUSPENSION - Front SuspensionFA-23

COMPONENTS

I 1,075 (78, los) |

a{Balljoint*-<-ry"

Bushing 7 S--t sro (5r, sot I

h

YooT.\€

ll-@

| | t(

I

cottar | |

I t BooCr, so-|l

l-lSpacer O

Fs-AmTliET'fri| : Tishtenins torque

l: Non-reugable part

Stabilizer Bar

FRONT SUSPENSION

Ball Joints

INSPECTION OF BALL JOINTS

1. INSPECT BALL JOINTS FOR EXCESSIVE LOOSENESS

(d Jack up the tront of the vehicle and place a wooden

block with a height of 18O - 2OO mm (7.09 - 7.87

in.) under one front tire.

(d Lower the jack until there is about half a load on the

front coil springs. Place stands under the vehicle for

safety.

(c) Make sure the front wheels are in a straightforward

position and block them with chocks.

(d) Move the lower arm up and down and check that the

balljoint has no excessive play.

Maximum balljoint vertical play: 0 mm (0 in.l

2. INSPECT BALL JOINT DUST COVERS FOR DAMAGE

OR DETERIORATION

lf a problem is found, replace the balljoint assembly.

Page 532 of 885

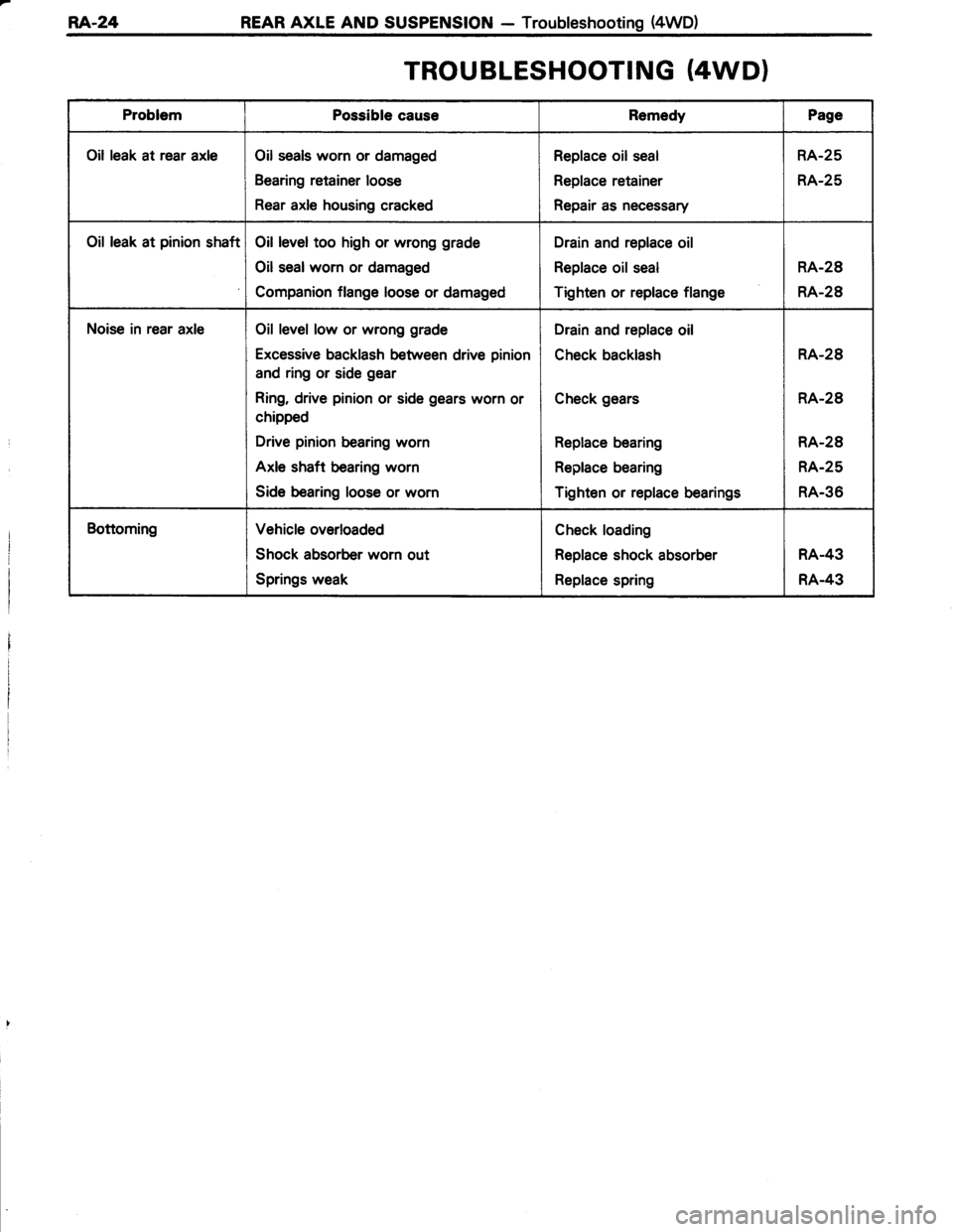

RA.24REAR AXLE AND SUSPENSION - Troubleshooting (4WD)

TROUBLESHOOTING (4WD}

ProblemPossible causeRemedyPage

Oil leak at rear axleOil seals worn or damaged

Bearing retainer loose

Rear axle housing cracked

Replace oil seal

Replace retainer

Repair as necessary

RA-25

RA-25

Oil leak at pinion shaftOil level too high or wrong grade

Oil sealworn or damaged

Companion flange loose or damaged

Drain and replace oil

Replace oil seal

Tighten or replace flange

RA-28

RA-28

Noise in rear axleOil level low or wrong grade

Excessive backlash between drive pinion

and ring or side gear

Ring, drive pinion or side gears worn or

chipped

Drive pinion bearing worn

Axle shaft bearing worn

Side bearing loose or worn

Drain and replace oil

Check backlash

Check gears

Replace bearing

Replace bearing

Tighten or replace bearings

RA-28

RA-28

RA-28

RA.25

RA-36

BottomingVehicle overloaded

Shock absorber worn out

Springs weak

Check loading

Replace shock absorber

Replace spring

RA.43

RA.43

Page 537 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.29

SST

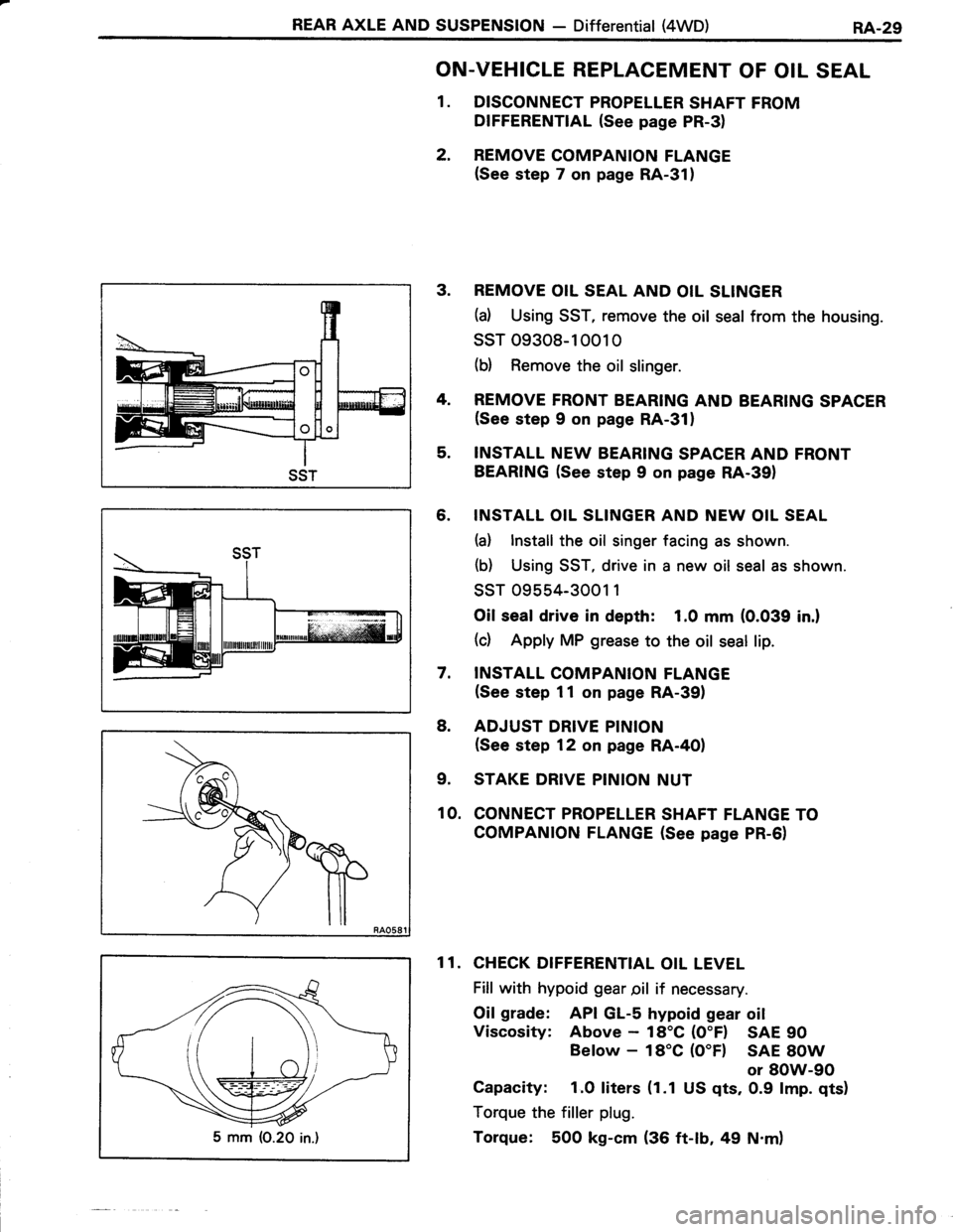

ON.VEHICLE REPLACEMENT OF OIL SEAL

1. DISCONNECT PROPELLER SHAFT FROM

DIFFERENTIAL (See page PR-3)

2. REMOVE COMPANION FLANGE(See step 7 on page RA-31)

3. REMOVE OIL SEAL AND OIL SLINGER

(d Using SST, remove the oil seal from the housing.

ssT 09308-10010

(b) Remove the oil slinger.

4. REMOVE FRONT BEARING AND BEARING SPACER(See step 9 on page RA-311

5. INSTALL NEW BEARING SPACER AND FRONT

BEARING (See step 9 on page RA-391

6. INSTALL OIL SLINGER AND NEW OIL SEAL

(a) lnstall the oil singer facing as shown.

(b) Using SST, drive in a new oil seal as shown.

ssr 09554-3001 1

Oil seal drive in depth: 1.0 mm (0.039 in.l

(c) Apply MP grease to the oil seal lip.

7, INSTALL COMPANION FLANGE(See step 11 on page RA-39)

8. ADJUST DRIVE PINION

(See step 12 on page RA-4OI

9. STAKE DRIVE PINION NUT

10. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE (See page PR-6)

1 1. CHECK DIFFERENTIAL OIL LEVEL

Fill with hypoid gear pil if necessary.

Oil grade: API GL-s hypoid gear oil

Viscosity: Above - 18'C (O"F) SAE 90

Below - 18'C (O"Fl SAE 8OW

or 8OW-90

Capacity: 1.O liters (1.1 US qts, 0.9 lmp. qts)

Torque the filler plug.

Torque: 500 kg-cm (36 ft-lb, 49 N.m)5 mm (O.20 in.)

Page 538 of 885

RA.30REAR AXLE AND SUSPENSION - Differential {4WD)

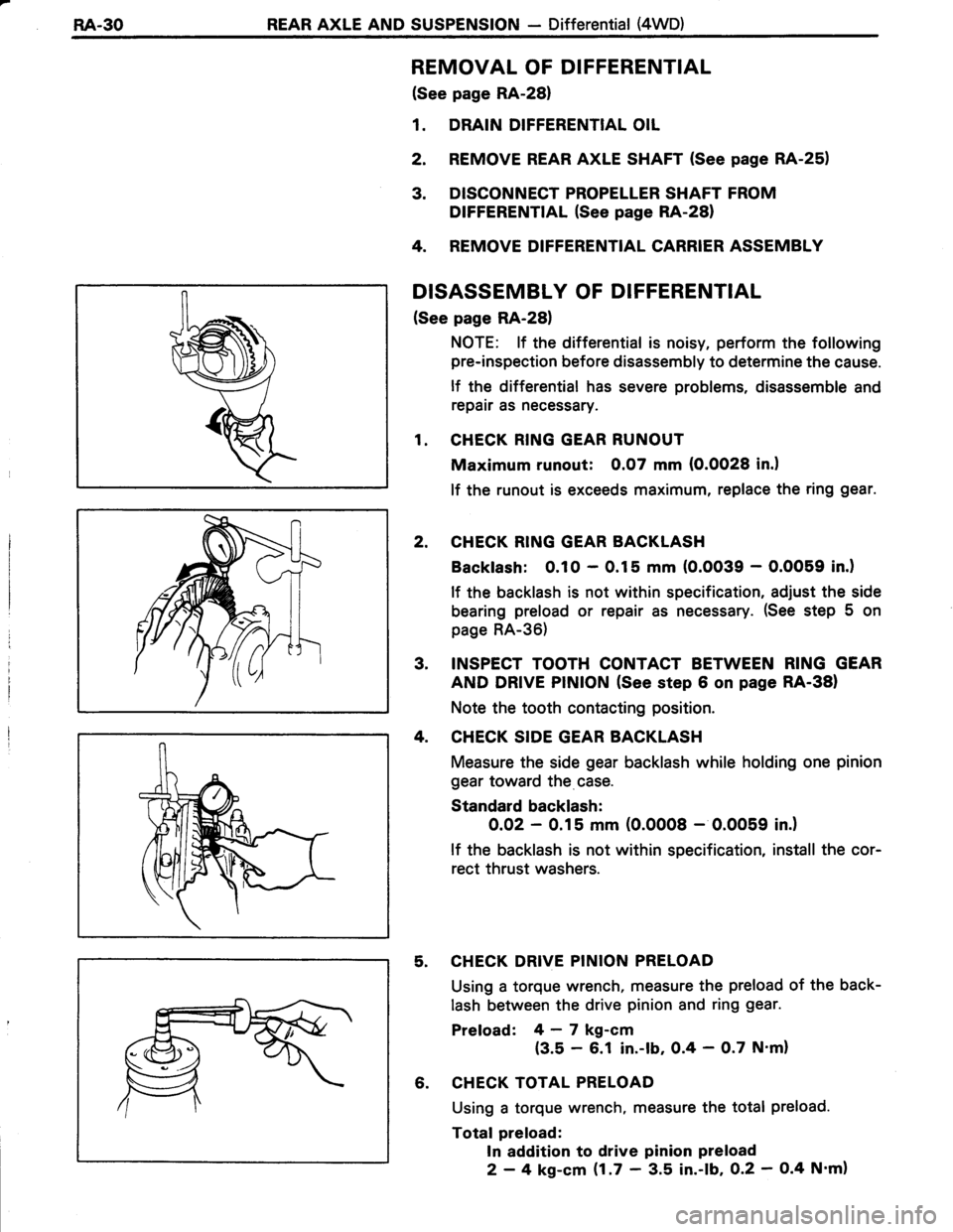

REMOVAL OF DIFFERENTIAL

(See page RA-28)

1. DRAIN DIFFERENTIAL OIL

2. REMOVE REAR AXLE SHAFT (See page RA-25)

3. DISCONNECT PROPELLER SHAFT FROM

DIFFERENTIAL (See page RA-28)

4. REMOVE DIFFERENTIAL CARRIER ASSEMBLY

DISASSEMBLY OF DIFFERENTIAL

(See page RA-281

NOTE: lf the differential is noisy, perform the following

pre-inspection before disassembly to determine the cause.

lf the differential has severe problems, disassemble and

repair as necessary.

1. CHECK RING GEAR RUNOUT

Maximum runout: 0.07 mm (O.OO28 in.l

lf the runout is exceeds maximum, replace the ring gear.

2. CHECK RING GEAR BACKLASH

Backlash: 0.10 - 0.15 mm (O.OO39 - O.OO59 in.)

lf the backlash is not within specification, adjust the side

bearing preload or repair as necessary. (See step 5 on

page RA-36)

3, INSPECT TOOTH CONTACT BETWEEN RING GEAR

AND DRIVE PINION (See step 6 on page RA-38)

Note the tooth contacting position.

4. CHECK SIDE GEAR BACKLASH

Measure the side gear backlash while holding one pinion

gear toward the case.

Standard backlash:

O.OZ - 0.15 mm (0.0008 - 0.0059 in.)

lf the backlash is not within specification, install the cor-

rect thrust washers.

5. CHECK DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the back-

lash between the drive pinion and ring gear.

Preload: 4-7 kg-cm

{3.5 - 6.1 in.-lb, 0.4 - O.7 N'm}

6. CHECK TOTAL PRELOAD

Using a torque wrench, measure the total preload.

Total preload:

In addition to drive pinion preload

2 - 4 kg-cm $.7 ' 3.5 in.-lb, O.2 - O.4 N'm)

Page 542 of 885

RA.34REAR AXLE AND SUSPENSION - Differential (4WD)

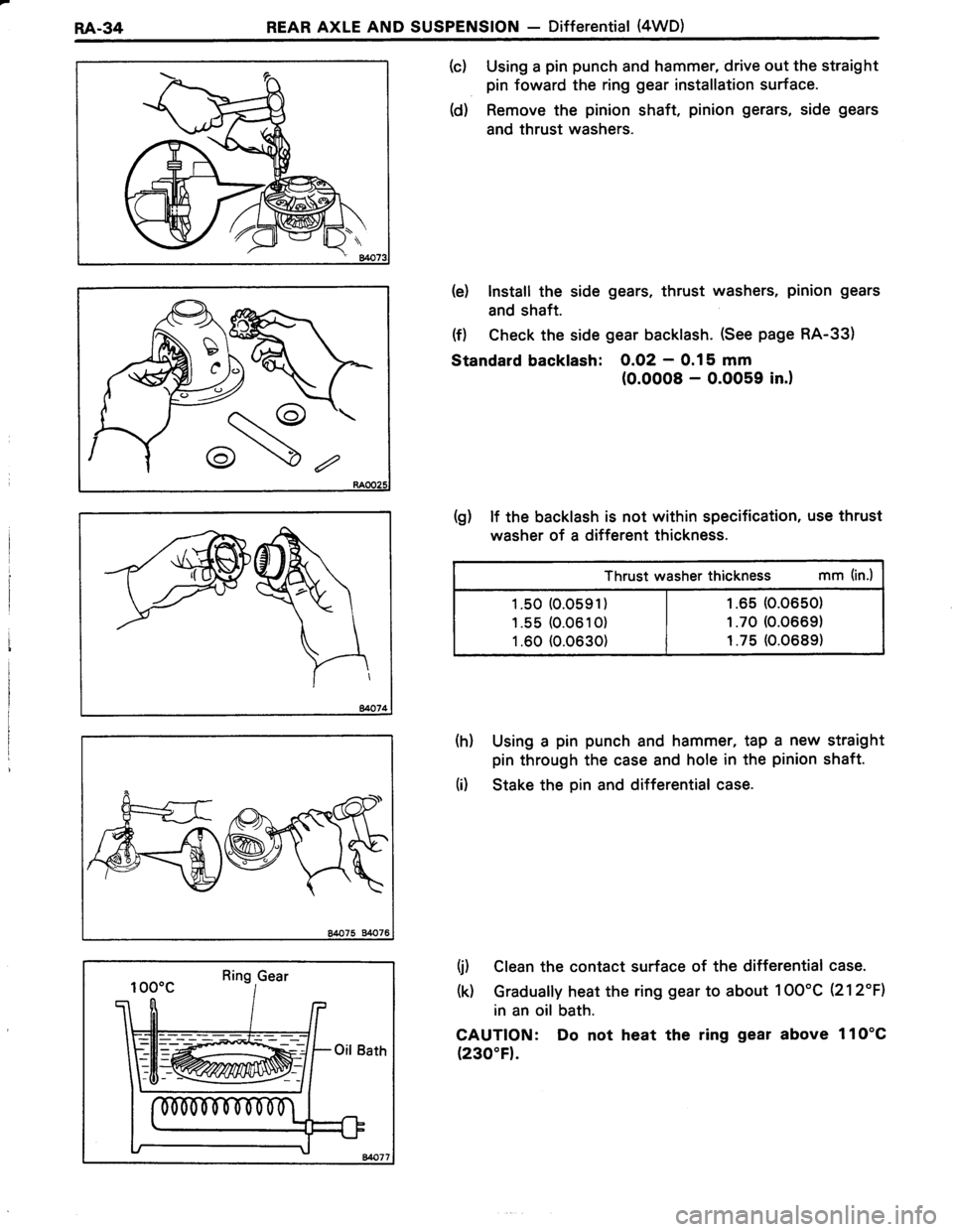

(c) Using a pin punch and hammer, drive out the straight

pin foward the ring gear installation surface.

(d) Remove the pinion shaft, pinion gerars, side gears

and thrust washers.

te) Install the side gears, thrust washers, pinion gears

and shaft.

(f) Check the side gear backlash. (See page RA-33)

Standard backlash: O.O2 - 0.15 mm

(0.0008 - O.OO59 in.)

(g) lf the backlash is not within specification, use thrust

washer of a different thickness.

Thrust washer thickness mm (in.)

1.50 (0.0591) | r.65 (0.0650)

1 .s5 (0.061 0) | t .70 (0.0669)

1.60 (0.0630) | r.75 (0.0689)

(h) Using a pin punch and hammer, tap a new straight

pin through the case and hole in the pinion shaft.

(i) Stake the pin and differential case.

(j) Clean the contact surface of the differential case.

(0 Gradually heat the ring gear to about 1OO'C (212"F1

in an oil bath.

CAUTION: Do not heat the ring gear above 1lO'C

(230"F).

Ring Gear

=-_-

&

Page 543 of 885

REAR AXIE AND SUSPENSION - Differential (4WD)RA-35

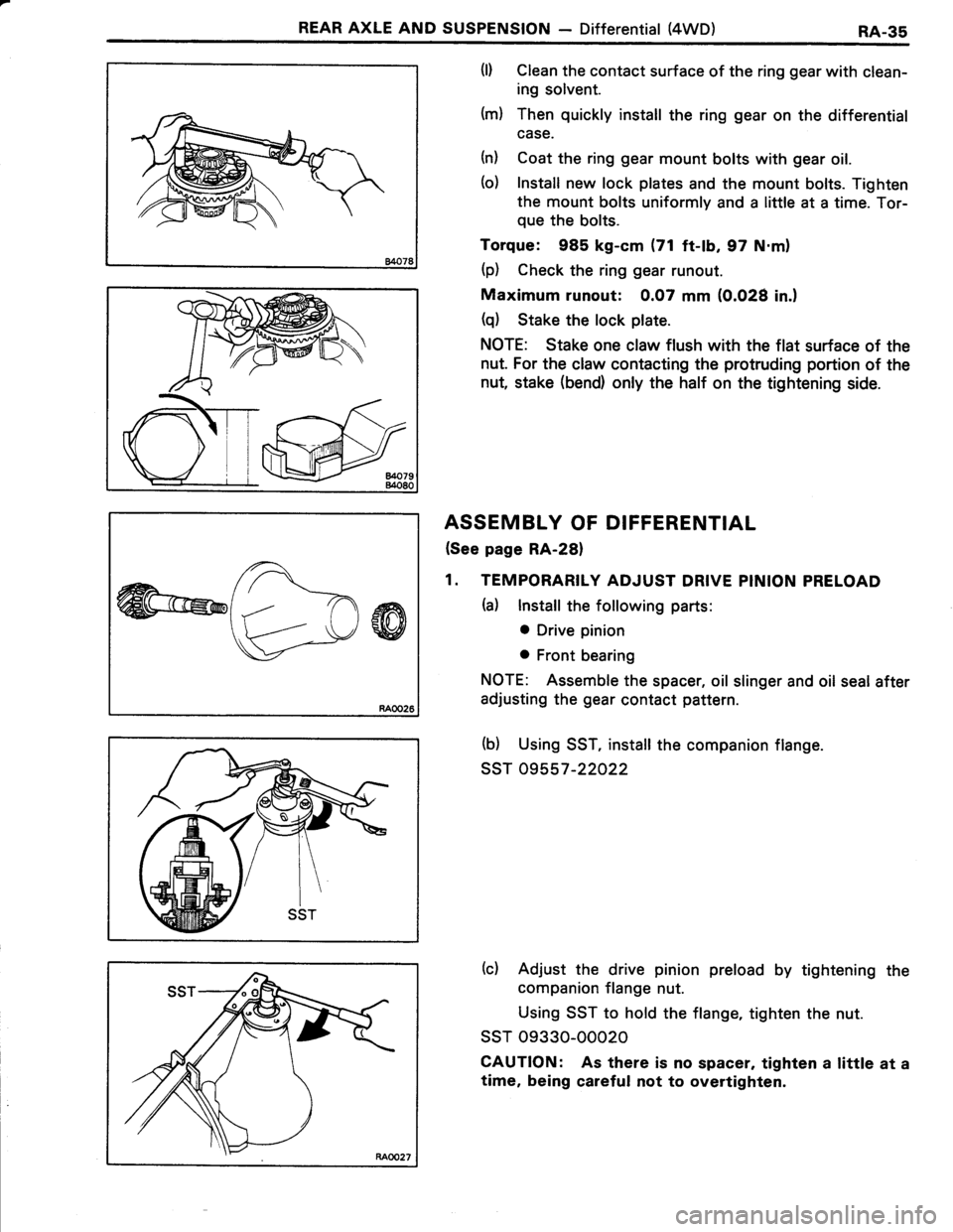

(l) Clean the contact surface of the ring gear with clean-

ing solvent.

(m) Then quickly install the ring gear on the differential

case.

(n) Coat the ring gear mount bolts with gear oil.

(o) Install new lock plates and the mount bolts. Tighten

the mount bolts uniformly and a little at a time. Tor-

que the bolts.

Torque: 985 kg-cm (71 ft-lb, 97 N.m)

(p) Check the ring gear runout.

Maximum runout: 0.07 mm (0.028 in.)

(q) Stake the lock plate.

NOTE: Stake one claw flush with the flat surface of the

nut. For the claw contacting the protruding portion of the

nut, stake (bend) only the half on the tightening side.

ASSEMBLY OF DIFFERENTIAL

(See page RA-28)

1. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) lnstall the following parts:

o Drive pinion

o Front bearing

NOTE: Assemble the spacer, oil slinger and oil seal after

adjusting the gear contact pattern.

(b) Using SST, install the companion flange.

ssT 09557-22022

(c) Adjust the drive pinion preload by tightening the

companion flange nut.

Using SST to hold the flange, tighten the nut.

ssT 09330-00020

CAUTION: As there is no spacer, taghten a little at a

time, being careful not to overtighten.

Page 552 of 885

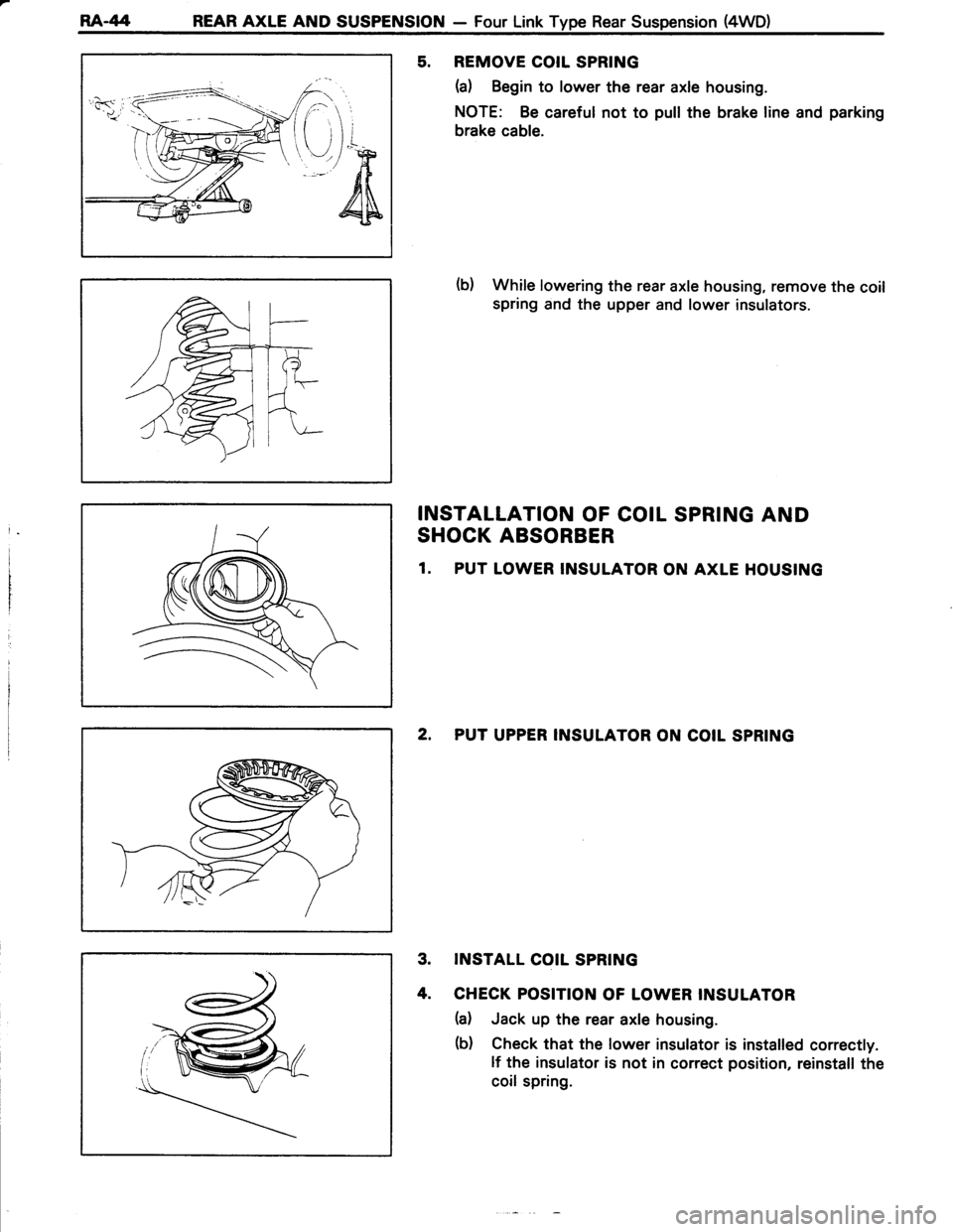

RA-/14 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

5. REMOVE COIL SPRING

(a) Begin to lower the rear axle housing.

NOTE: Be careful not to pull the brake line and parking

brake cable.

(b) While lowering the rear axle housing, remove the coil

spring and the upper and lower insulators.

INSTALLATION OF COIL SPRING AND

SHOCK ABSORBER

1. PUT LOWER INSULATOR ON AXLE HOUSING

2, PUT UPPER INSULATOR ON COIL SPRING

3. INSTALL COIL SPRING

4. CHECK POSITION OF LOWER INSULATOR

(a) Jack up the rear axle housing.

(b) Check that the lower insulator is installed correctly.

lf the insulator is not in correct position, reinstall the

coil spring.

Page 561 of 885

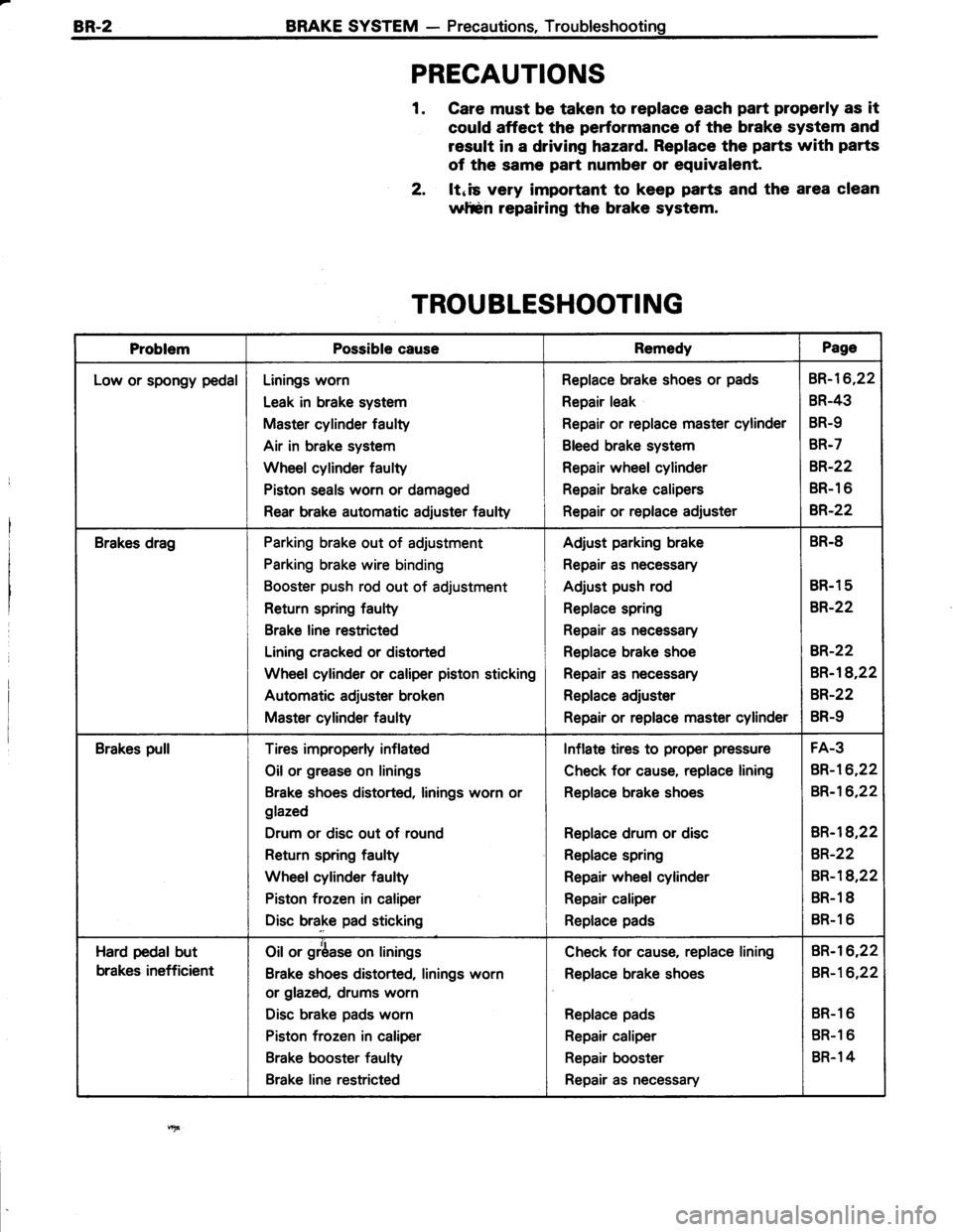

BR-2BRAKE SYSTEM - Precautions, Troubleshooting

PRECAUTIONS

1. Care must be taken to replace each part properly as it

could affect the performance of the brake system and

result in a driving hazard. Replace the parts with parts

of the same part number or equivalent.

2, ltnis very important to keep parts and the area clean

wltsn repairing the brake system.

TROUBLESHOOTING

ProblemPossible causeRemedyPage

Low or spongy pedalLinings worn

Leak in brake system

Master cylinder faulty

Air in brake system

Wheel cylinder faulty

Piston seals worn or damaged

Rear brake automatic adiuster faulty

Replace brake shoes or pads

Repair leak

Repair or replace master cylinder

Bleed brake system

Repair wheel cylinder

Repair brake calipers

Repair or replace adjuster

BR-16,22

BR-43

BR-9

BR-7

8R.22

BR-1 6

B,R.22

Brakes dragParking brake out of adjustment

Parking brake wire binding

Booster push rod out of adjustment

Return spring faulty

Brake line restricted

Lining cracked or distorted

Wheel cylinder or caliper piston sticking

Automatic adjuster broken

Master cylinder faulty

Adjust parking brake

Repair as necessary

Adjust push rod

Replace spring

Repair as necessary

Replace brake shoe

Repair as necessary

Replace adjuster

Repair or replace master cylinder

BR.8

BR.1 5

BR-22

BR-22

BR-18,22

BR-22

BR-9

Brakes pullTires improperly inflated

Oil or grease on linings

Brake shoes distorted, linings worn or

glazed

Drum or disc out of round

Return spring faulty

Wheel cylinder faulty

Piston frozen in caliper

Disc brake pad sticking

Inflate tires to proper pressure

Check for cause, replace lining

Replace brake shoes

Replace drum or disc

Replace spring

Repair wheel cylinder

Repair caliper

Replace pads

FA-3

BR-16,22

BR-16,22

BR-l8,22

BR-22

BR-18,22

BR.1 8

BR-1 6

Hard pedal but

brakes inefficient

Oil or grbase on linings

Brake shoes distorted, linings worn

or glazed, drums worn

Disc brake pads worn

Piston frozen in caliper

Brake booster faulty

Brake line restricted

Check for cause, replace lining

Replace brake shoes

Replace pads

Repair caliper

Repair booster

Repair as necessary

BR-I6,22

BR-16,22

BR-1 6

BR-1 6

BR.1 4