bulb TOYOTA TERCEL 1996 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: TERCEL, Model: TOYOTA TERCEL 1996Pages: 1202, PDF Size: 17.43 MB

Page 1019 of 1202

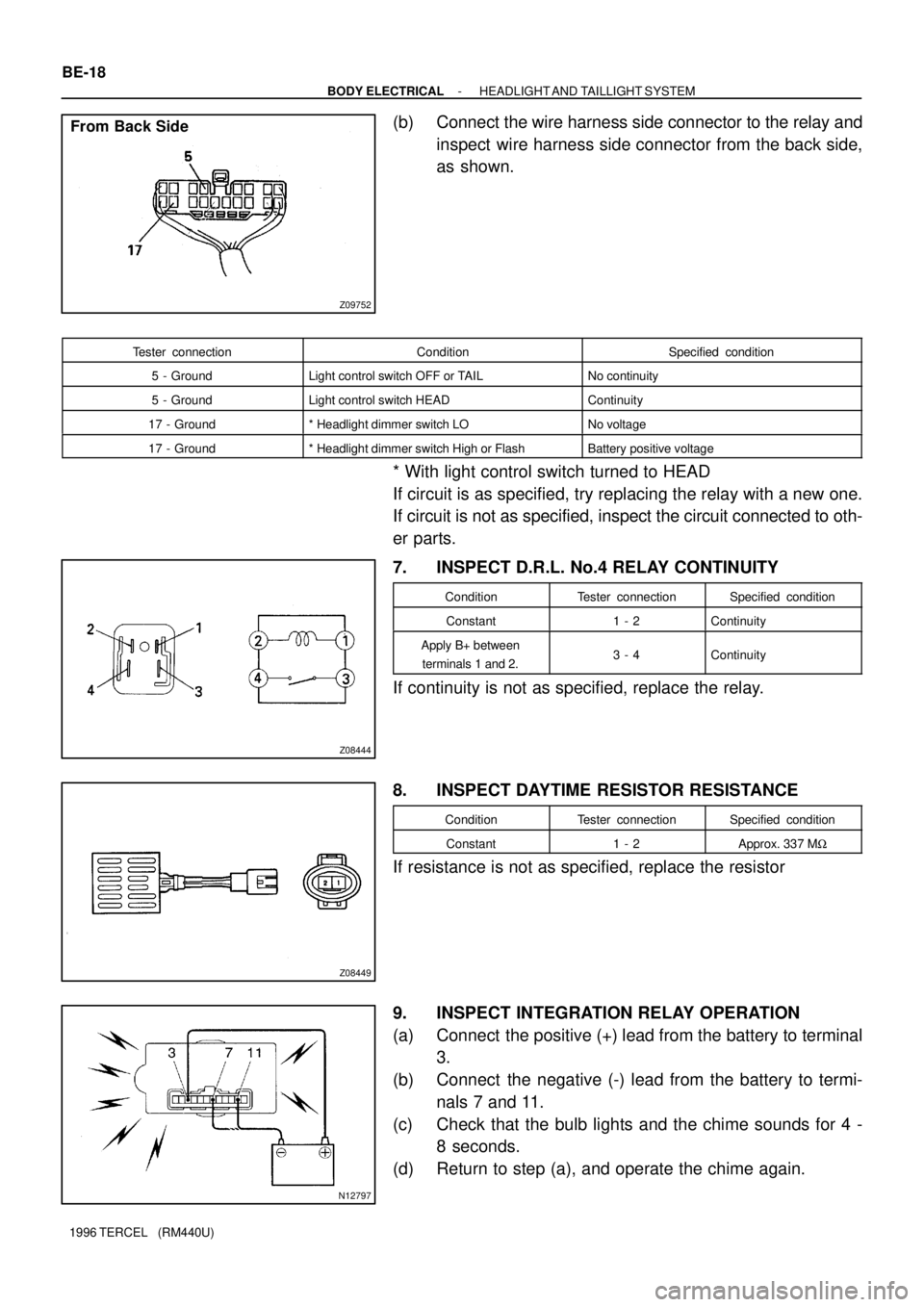

Z09752

From Back Side

Z08444

Z08449

N12797

BE-18

- BODY ELECTRICALHEADLIGHT AND TAILLIGHT SYSTEM

1996 TERCEL (RM440U)

(b) Connect the wire harness side connector to the relay and

inspect wire harness side connector from the back side,

as shown.

Tester connectionConditionSpecified condition

5 - GroundLight control switch OFF or TAILNo continuity

5 - GroundLight control switch HEADContinuity

17 - Ground* Headlight dimmer switch LONo voltage

17 - Ground* Headlight dimmer switch High or FlashBattery positive voltage

* With light control switch turned to HEAD

If circuit is as specified, try replacing the relay with a new one.

If circuit is not as specified, inspect the circuit connected to oth-

er parts.

7. INSPECT D.R.L. No.4 RELAY CONTINUITY

ConditionTester connectionSpecified condition

Constant1 - 2Continuity

Apply B+ between

terminals 1 and 2.3 - 4Continuity

If continuity is not as specified, replace the relay.

8. INSPECT DAYTIME RESISTOR RESISTANCE

ConditionTester connectionSpecified condition

Constant1 - 2Approx. 337 MW

If resistance is not as specified, replace the resistor

9. INSPECT INTEGRATION RELAY OPERATION

(a) Connect the positive (+) lead from the battery to terminal

3.

(b) Connect the negative (-) lead from the battery to termi-

nals 7 and 11.

(c) Check that the bulb lights and the chime sounds for 4 -

8 seconds.

(d) Return to step (a), and operate the chime again.

Page 1023 of 1202

BE0R1-02

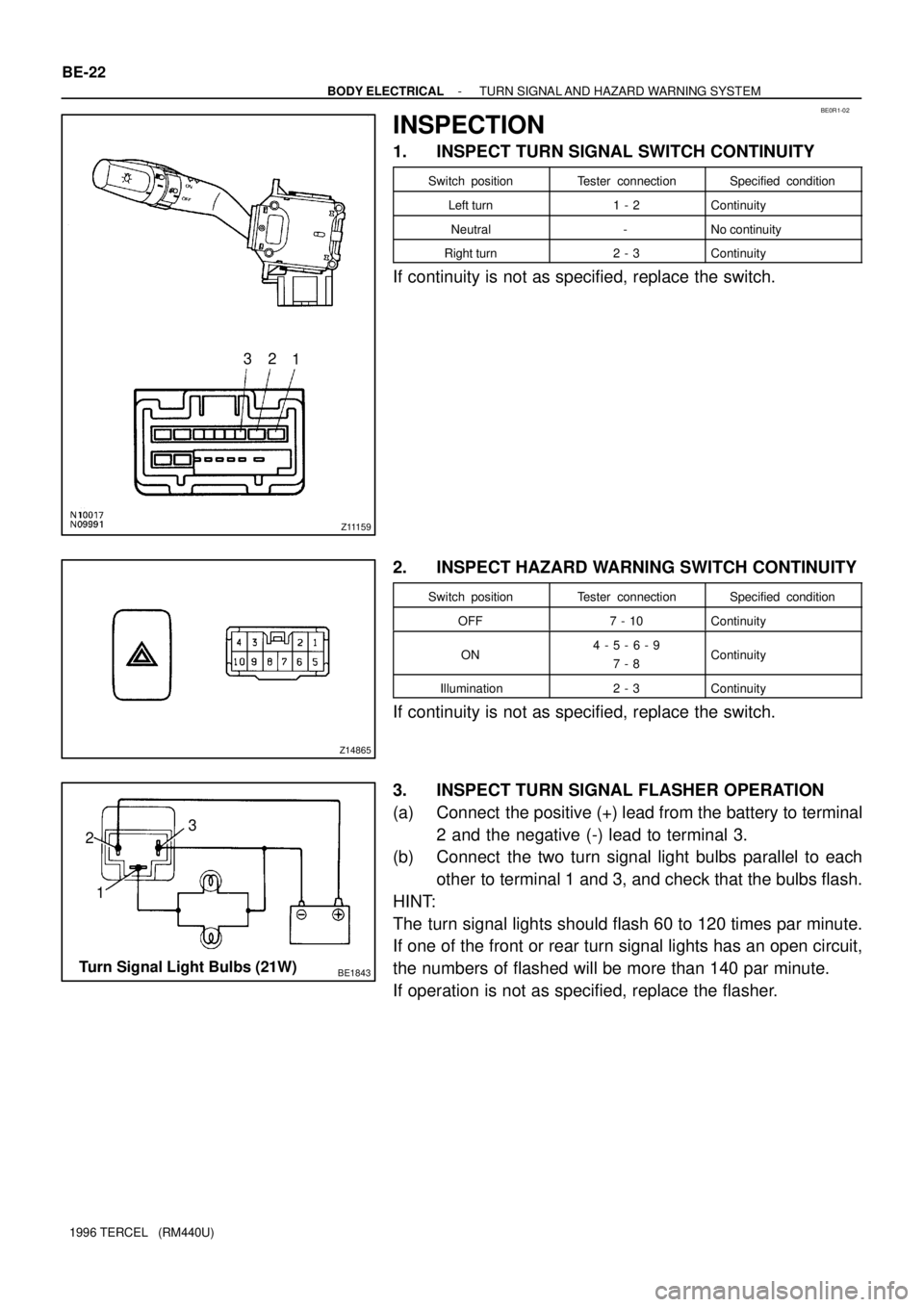

Z11159

1 2 3

Z14865

BE1843

1 23

Turn Signal Light Bulbs (21W) BE-22

- BODY ELECTRICALTURN SIGNAL AND HAZARD WARNING SYSTEM

1996 TERCEL (RM440U)

INSPECTION

1. INSPECT TURN SIGNAL SWITCH CONTINUITY

Switch positionTester connectionSpecified condition

Left turn1 - 2Continuity

Neutral-No continuity

Right turn2 - 3Continuity

If continuity is not as specified, replace the switch.

2. INSPECT HAZARD WARNING SWITCH CONTINUITY

Switch positionTester connectionSpecified condition

OFF7 - 10Continuity

ON4 - 5 - 6 - 9

7 - 8Continuity

Illumination2 - 3Continuity

If continuity is not as specified, replace the switch.

3. INSPECT TURN SIGNAL FLASHER OPERATION

(a) Connect the positive (+) lead from the battery to terminal

2 and the negative (-) lead to terminal 3.

(b) Connect the two turn signal light bulbs parallel to each

other to terminal 1 and 3, and check that the bulbs flash.

HINT:

The turn signal lights should flash 60 to 120 times par minute.

If one of the front or rear turn signal lights has an open circuit,

the numbers of flashed will be more than 140 par minute.

If operation is not as specified, replace the flasher.

Page 1036 of 1202

BE1OR-01

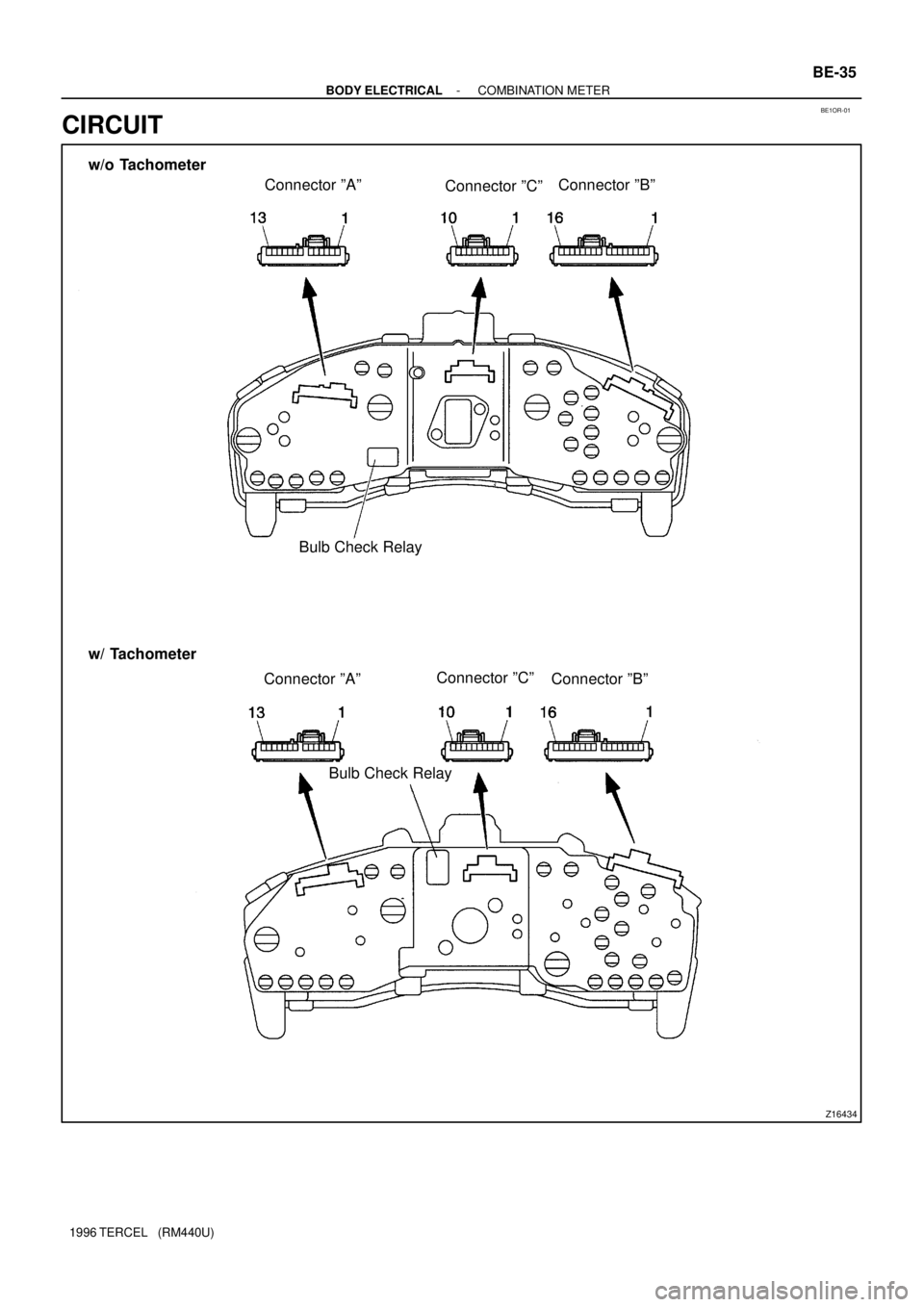

Z16434

w/o Tachometer

Connector ºAº

Bulb Check Relay

Bulb Check Relay w/ TachometerConnector ºBº

Connector ºCº

Connector ºAºConnector ºCº

Connector ºBº

- BODY ELECTRICALCOMBINATION METER

BE-35

1996 TERCEL (RM440U)

CIRCUIT

Page 1037 of 1202

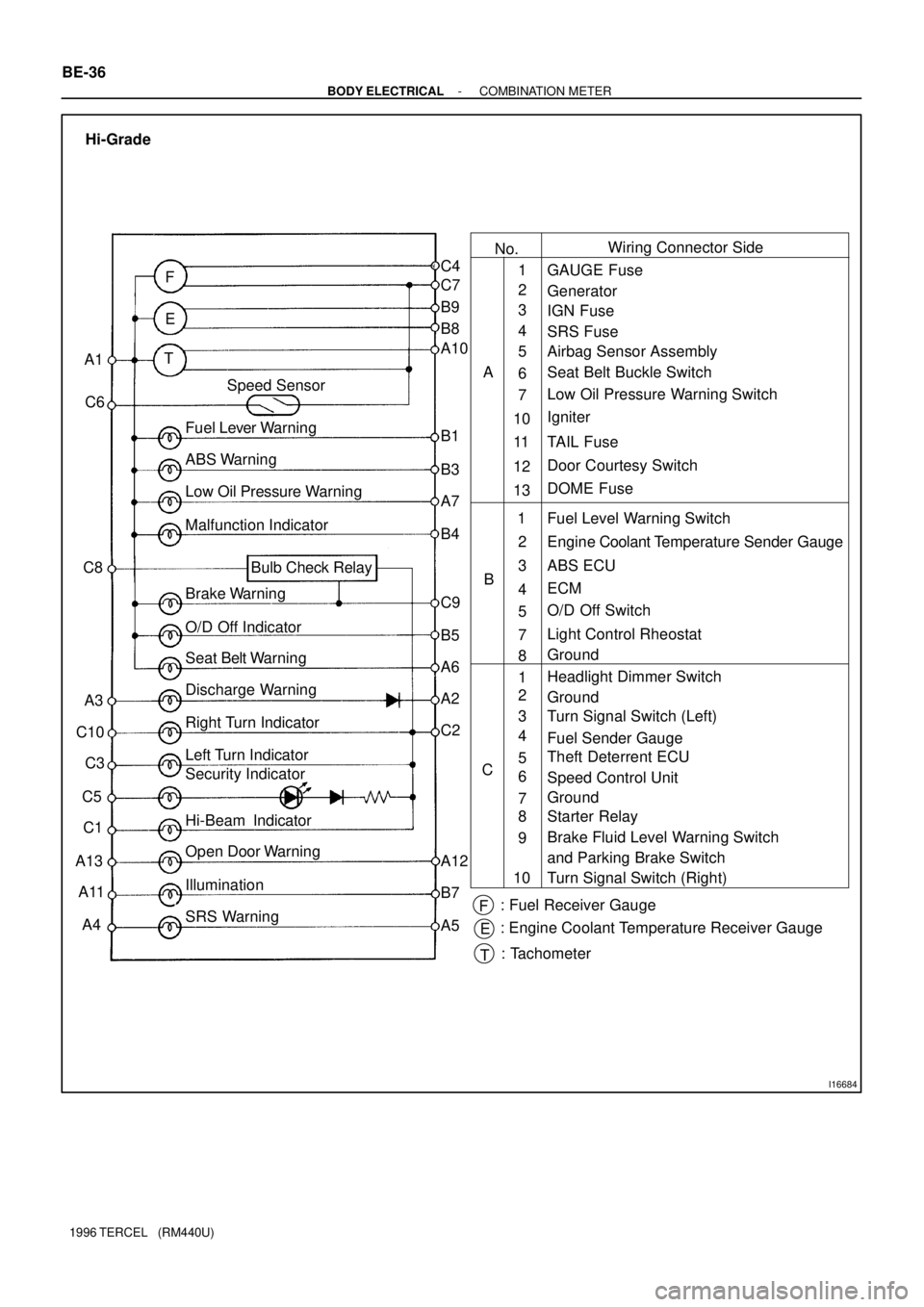

I16684

No.Wiring Connector Side

1

2

3

4

5

6

7GAUGE Fuse

10

11

12

13

1

2

3

4

5

7

8

1

2

3

4

5

6

7

8

9

10Generator

IGN Fuse

SRS Fuse

Airbag Sensor Assembly

Seat Belt Buckle Switch

Low Oil Pressure Warning Switch

Igniter

TAIL Fuse

Door Courtesy Switch

DOME Fuse

Fuel Level Warning Switch

Engine Coolant Temperature Sender Gauge

ABS ECU

ECM

O/D Off Switch

Light Control Rheostat

Ground

Headlight Dimmer Switch

Turn Signal Switch (Left) Ground

Fuel Sender Gauge

Theft Deterrent ECU

Speed Control Unit

Ground

Starter Relay

Brake Fluid Level Warning Switch

and Parking Brake Switch

Turn Signal Switch (Right) A

B

C

F

E

T: Fuel Receiver Gauge

: Engine Coolant Temperature Receiver Gauge

: Tachometer

Hi-Grade

SRS Warning Illumination Open Door Warning Hi-Beam Indicator Security Indicator Left Turn Indicator Right Turn Indicator Discharge Warning Seat Belt Warning O/D Off Indicator Brake WarningBulb Check Relay Malfunction Indicator Low Oil Pressure Warning ABS Warning Fuel Lever Warning Speed Sensor

A5 B7 A12 C2 A2

A6

B5 C9 B4 A7 B3 B1 A10 B8 B9 C7 C4

A4 A11 A13C1 C5C3 C10A3 C8C6 A1TE F BE-36

- BODY ELECTRICALCOMBINATION METER

1996 TERCEL (RM440U)

Page 1038 of 1202

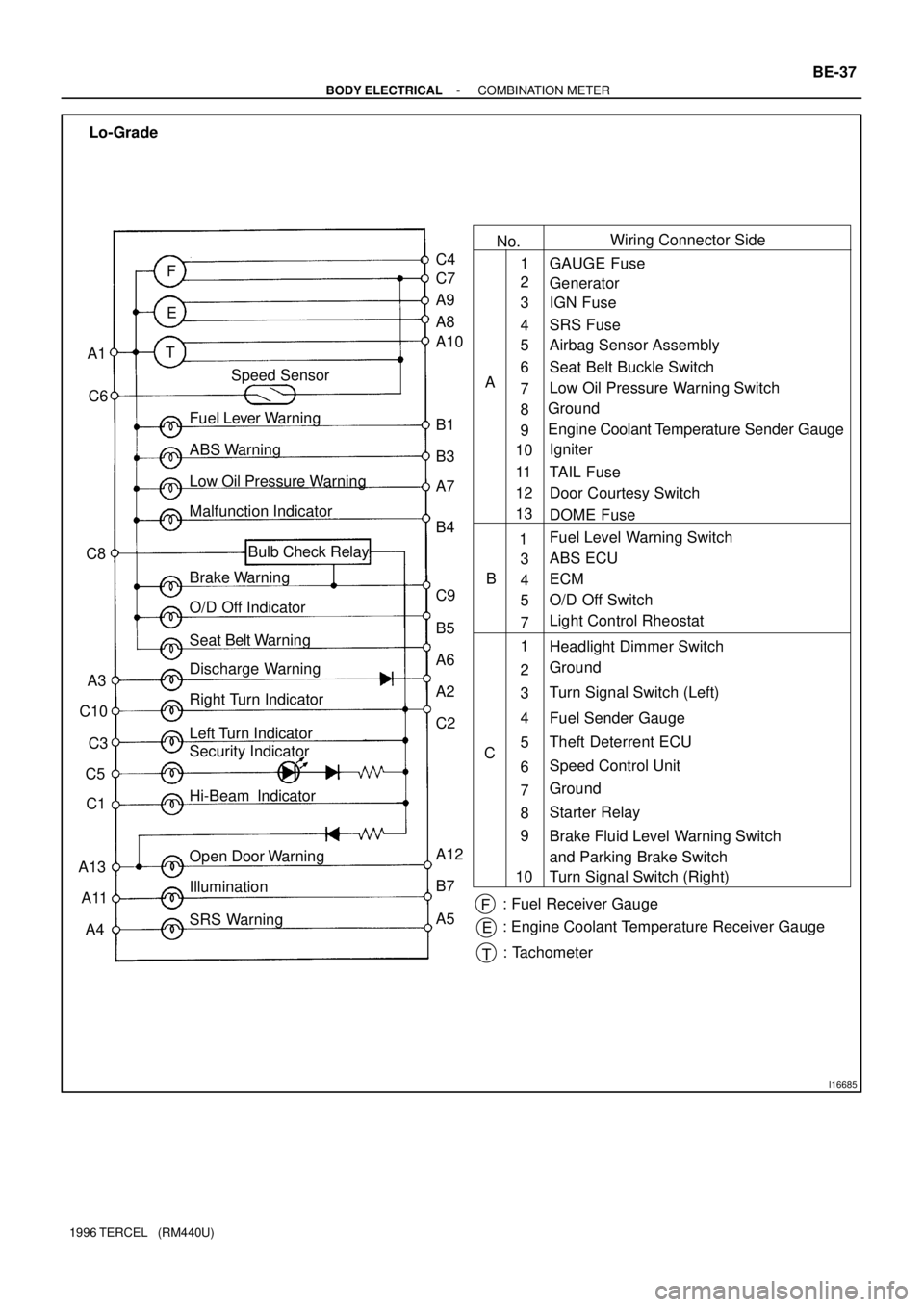

I16685

No.Wiring Connector Side

1

2

3

4

5

6

7GAUGE Fuse

10

11

12

13

1

3

4

5

7

1

2

3

4

5

6

7

8

9

10Generator

IGN Fuse

SRS Fuse

Airbag Sensor Assembly

Seat Belt Buckle Switch

Low Oil Pressure Warning Switch

Igniter

TAIL Fuse

Door Courtesy Switch

DOME Fuse

Fuel Level Warning Switch

ABS ECU

ECM

O/D Off Switch

Light Control Rheostat

Headlight Dimmer Switch

Turn Signal Switch (Left) Ground

Fuel Sender Gauge

Theft Deterrent ECU

Speed Control Unit

Ground

Starter Relay

Brake Fluid Level Warning Switch

and Parking Brake Switch

Turn Signal Switch (Right) A

B

C

F

E

T: Fuel Receiver Gauge

: Engine Coolant Temperature Receiver Gauge

: Tachometer

8

9Ground

Engine Coolant Temperature Sender Gauge

A4 A11 A13C1 C5C3 C10A3 C8C6 A1

A5 B7 A12 C2 A2

A6

B5 C9 B4 A7 B3 B1 A10 A8 A9 C7 C4

SRS Warning Illumination Open Door Warning Hi-Beam Indicator Security Indicator Left Turn Indicator Right Turn Indicator Discharge Warning Seat Belt Warning O/D Off Indicator Brake WarningBulb Check Relay Malfunction Indicator Low Oil Pressure Warning ABS Warning

Fuel Lever Warning Speed Sensor TE F Lo-Grade

- BODY ELECTRICALCOMBINATION METER

BE-37

1996 TERCEL (RM440U)

Page 1039 of 1202

BE26Q-01

N12803N12541I22670

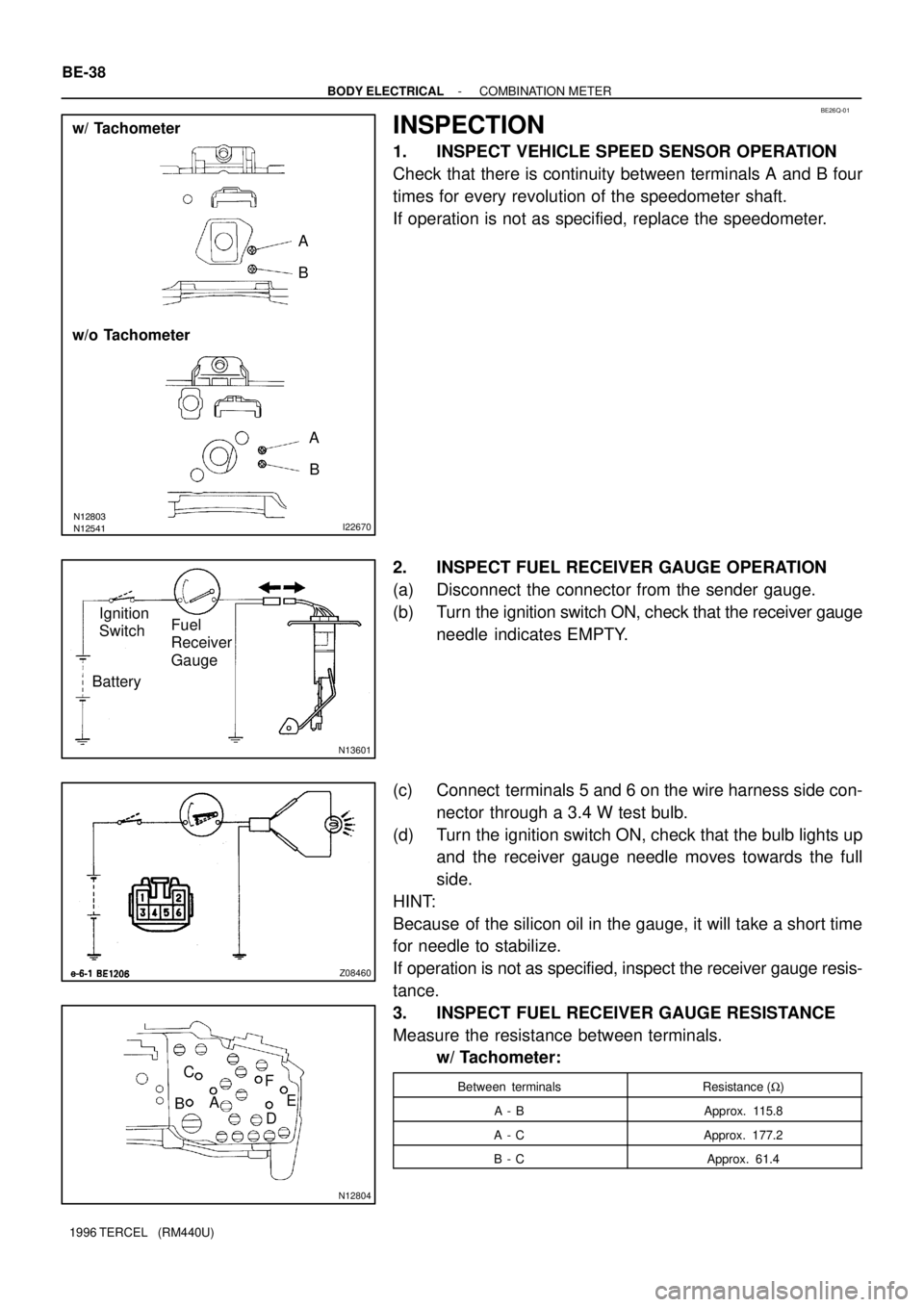

w/ Tachometer

A

B

w/o Tachometer

A

B

N13601

Ignition

Switch

BatteryFuel

Receiver

Gauge

Z08460

N12804

A

BC

DE F BE-38

- BODY ELECTRICALCOMBINATION METER

1996 TERCEL (RM440U)

INSPECTION

1. INSPECT VEHICLE SPEED SENSOR OPERATION

Check that there is continuity between terminals A and B four

times for every revolution of the speedometer shaft.

If operation is not as specified, replace the speedometer.

2. INSPECT FUEL RECEIVER GAUGE OPERATION

(a) Disconnect the connector from the sender gauge.

(b) Turn the ignition switch ON, check that the receiver gauge

needle indicates EMPTY.

(c) Connect terminals 5 and 6 on the wire harness side con-

nector through a 3.4 W test bulb.

(d) Turn the ignition switch ON, check that the bulb lights up

and the receiver gauge needle moves towards the full

side.

HINT:

Because of the silicon oil in the gauge, it will take a short time

for needle to stabilize.

If operation is not as specified, inspect the receiver gauge resis-

tance.

3. INSPECT FUEL RECEIVER GAUGE RESISTANCE

Measure the resistance between terminals.

w/ Tachometer:

Between terminalsResistance (W)

A - BApprox. 115.8

A - CApprox. 177.2

B - CApprox. 61.4

Page 1040 of 1202

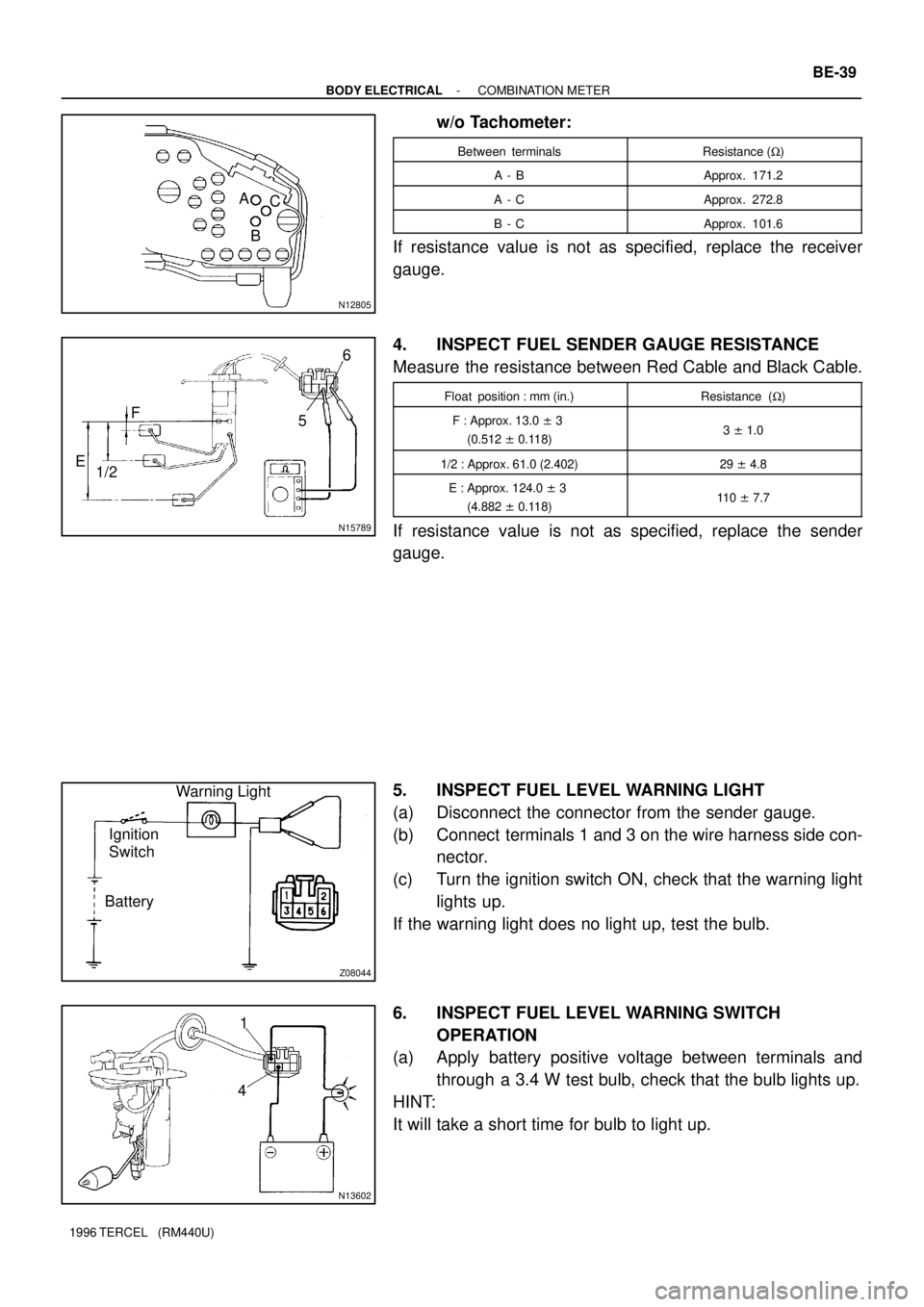

N12805

A

BC

N15789

EF

1/256

Z08044

Ignition

Switch

BatteryWarning Light

N13602

1

4

- BODY ELECTRICALCOMBINATION METER

BE-39

1996 TERCEL (RM440U)

w/o Tachometer:

Between terminalsResistance (W)

A - BApprox. 171.2

A - CApprox. 272.8

B - CApprox. 101.6

If resistance value is not as specified, replace the receiver

gauge.

4. INSPECT FUEL SENDER GAUGE RESISTANCE

Measure the resistance between Red Cable and Black Cable.

Float position : mm (in.)Resistance (W)

F : Approx. 13.0 ± 3

(0.512 ± 0.118)3 ± 1.0

1/2 : Approx. 61.0 (2.402)29 ± 4.8

E : Approx. 124.0 ± 3

(4.882 ± 0.118)110 ± 7.7

If resistance value is not as specified, replace the sender

gauge.

5. INSPECT FUEL LEVEL WARNING LIGHT

(a) Disconnect the connector from the sender gauge.

(b) Connect terminals 1 and 3 on the wire harness side con-

nector.

(c) Turn the ignition switch ON, check that the warning light

lights up.

If the warning light does no light up, test the bulb.

6. INSPECT FUEL LEVEL WARNING SWITCH

OPERATION

(a) Apply battery positive voltage between terminals and

through a 3.4 W test bulb, check that the bulb lights up.

HINT:

It will take a short time for bulb to light up.

Page 1041 of 1202

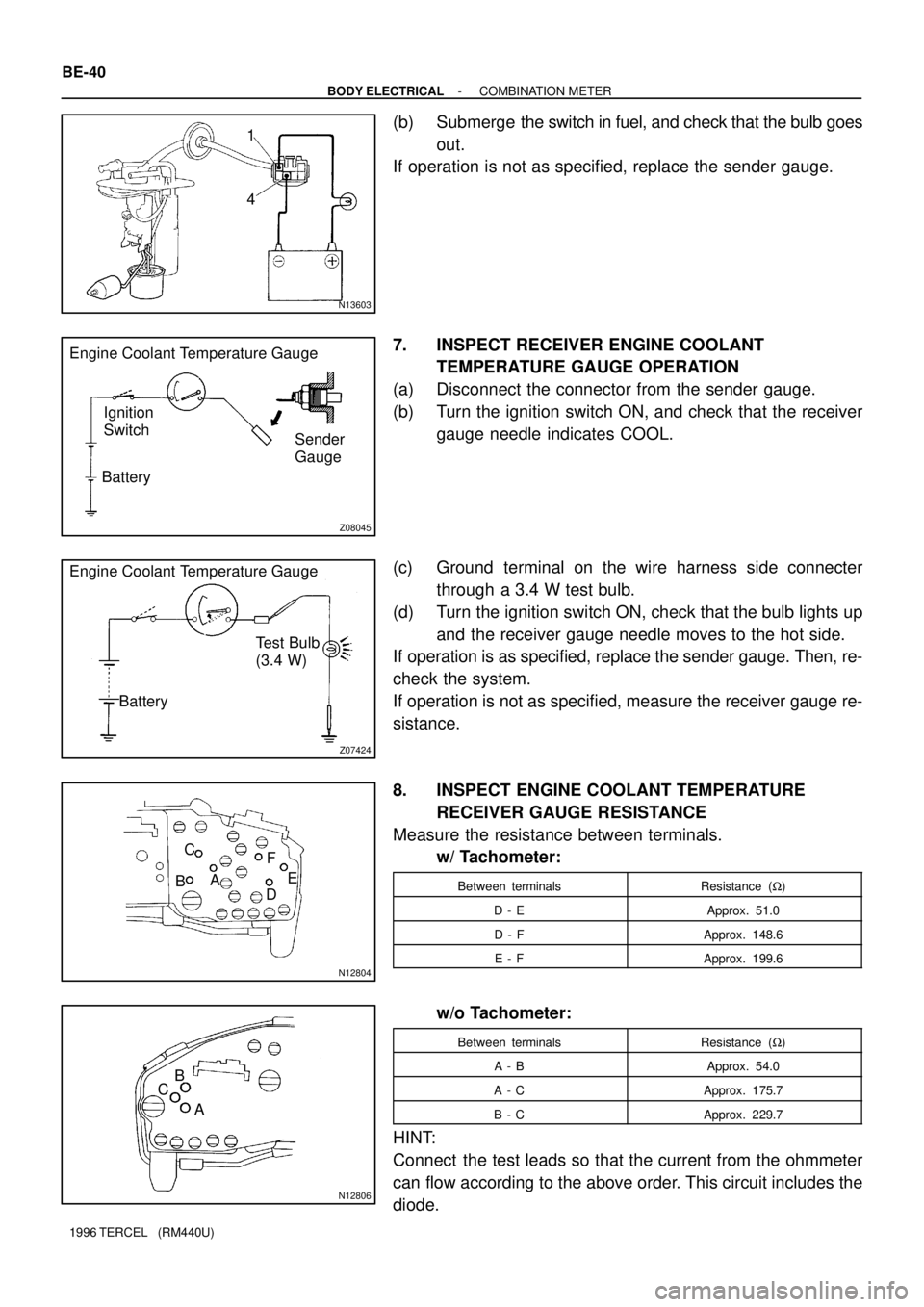

N13603

1

4

Z08045

Engine Coolant Temperature Gauge

Ignition

Switch

BatterySender

Gauge

Z07424

Engine Coolant Temperature Gauge

BatteryTest Bulb

(3.4 W)

N12804

A

BC

DE F

N12806

A B

C BE-40

- BODY ELECTRICALCOMBINATION METER

1996 TERCEL (RM440U)

(b) Submerge the switch in fuel, and check that the bulb goes

out.

If operation is not as specified, replace the sender gauge.

7. INSPECT RECEIVER ENGINE COOLANT

TEMPERATURE GAUGE OPERATION

(a) Disconnect the connector from the sender gauge.

(b) Turn the ignition switch ON, and check that the receiver

gauge needle indicates COOL.

(c) Ground terminal on the wire harness side connecter

through a 3.4 W test bulb.

(d) Turn the ignition switch ON, check that the bulb lights up

and the receiver gauge needle moves to the hot side.

If operation is as specified, replace the sender gauge. Then, re-

check the system.

If operation is not as specified, measure the receiver gauge re-

sistance.

8. INSPECT ENGINE COOLANT TEMPERATURE

RECEIVER GAUGE RESISTANCE

Measure the resistance between terminals.

w/ Tachometer:

Between terminalsResistance (W)

D - EApprox. 51.0

D - FApprox. 148.6

E - FApprox. 199.6

w/o Tachometer:

Between terminalsResistance (W)

A - BApprox. 54.0

A - CApprox. 175.7

B - CApprox. 229.7

HINT:

Connect the test leads so that the current from the ohmmeter

can flow according to the above order. This circuit includes the

diode.

Page 1042 of 1202

BE0044

Ignition

Switch

BatteryWarning Light

BE0146

BE1217

Ignition

Switch

BatteryWarning Light

BE1601

ON OFF

- BODY ELECTRICALCOMBINATION METER

BE-41

1996 TERCEL (RM440U)

If resistance value is not as specified, replace the receiver

gauge.

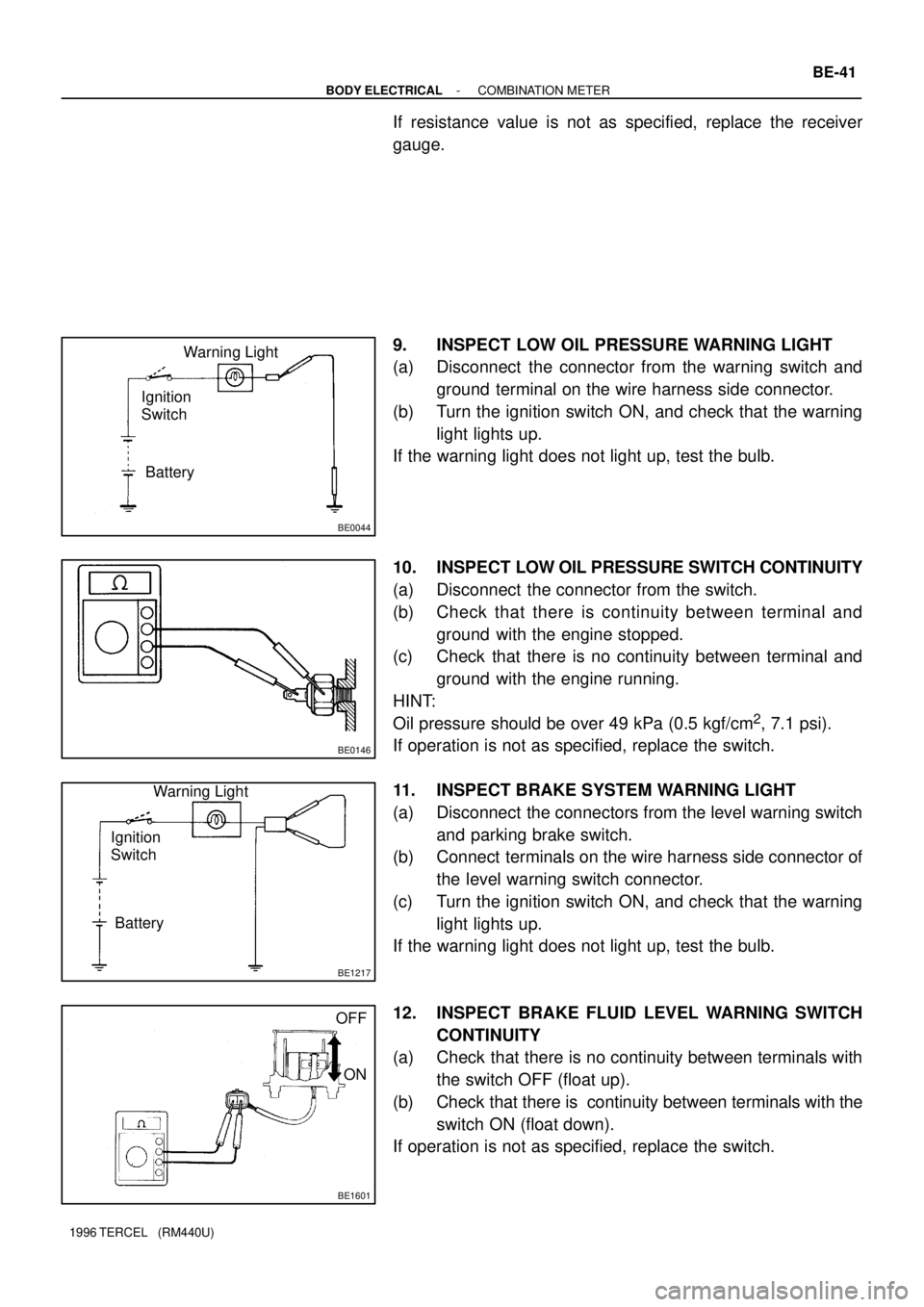

9. INSPECT LOW OIL PRESSURE WARNING LIGHT

(a) Disconnect the connector from the warning switch and

ground terminal on the wire harness side connector.

(b) Turn the ignition switch ON, and check that the warning

light lights up.

If the warning light does not light up, test the bulb.

10. INSPECT LOW OIL PRESSURE SWITCH CONTINUITY

(a) Disconnect the connector from the switch.

(b) Check that there is continuity between terminal and

ground with the engine stopped.

(c) Check that there is no continuity between terminal and

ground with the engine running.

HINT:

Oil pressure should be over 49 kPa (0.5 kgf/cm

2, 7.1 psi).

If operation is not as specified, replace the switch.

11. INSPECT BRAKE SYSTEM WARNING LIGHT

(a) Disconnect the connectors from the level warning switch

and parking brake switch.

(b) Connect terminals on the wire harness side connector of

the level warning switch connector.

(c) Turn the ignition switch ON, and check that the warning

light lights up.

If the warning light does not light up, test the bulb.

12. INSPECT BRAKE FLUID LEVEL WARNING SWITCH

CONTINUITY

(a) Check that there is no continuity between terminals with

the switch OFF (float up).

(b) Check that there is continuity between terminals with the

switch ON (float down).

If operation is not as specified, replace the switch.

Page 1043 of 1202

Z11183

BE0044

Ignition

Switch

BatteryWarning Light

BE1428

ON

OFF

Z17684

Ignition

Switch

BatteryWarning Light

Wire Harness Side

N20834

OFF

ON BE-42

- BODY ELECTRICALCOMBINATION METER

1996 TERCEL (RM440U)

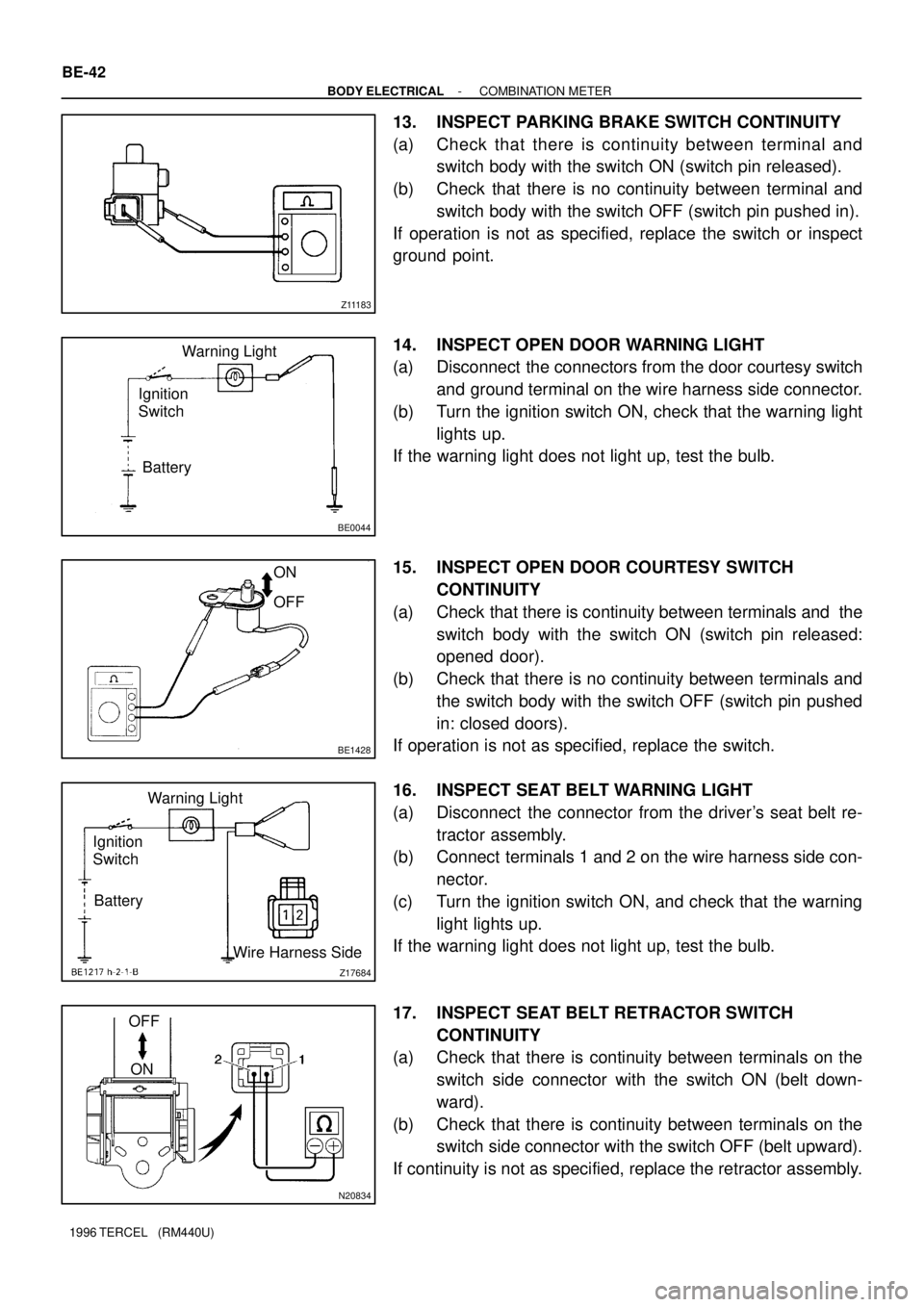

13. INSPECT PARKING BRAKE SWITCH CONTINUITY

(a) Check that there is continuity between terminal and

switch body with the switch ON (switch pin released).

(b) Check that there is no continuity between terminal and

switch body with the switch OFF (switch pin pushed in).

If operation is not as specified, replace the switch or inspect

ground point.

14. INSPECT OPEN DOOR WARNING LIGHT

(a) Disconnect the connectors from the door courtesy switch

and ground terminal on the wire harness side connector.

(b) Turn the ignition switch ON, check that the warning light

lights up.

If the warning light does not light up, test the bulb.

15. INSPECT OPEN DOOR COURTESY SWITCH

CONTINUITY

(a) Check that there is continuity between terminals and the

switch body with the switch ON (switch pin released:

opened door).

(b) Check that there is no continuity between terminals and

the switch body with the switch OFF (switch pin pushed

in: closed doors).

If operation is not as specified, replace the switch.

16. INSPECT SEAT BELT WARNING LIGHT

(a) Disconnect the connector from the driver's seat belt re-

tractor assembly.

(b) Connect terminals 1 and 2 on the wire harness side con-

nector.

(c) Turn the ignition switch ON, and check that the warning

light lights up.

If the warning light does not light up, test the bulb.

17. INSPECT SEAT BELT RETRACTOR SWITCH

CONTINUITY

(a) Check that there is continuity between terminals on the

switch side connector with the switch ON (belt down-

ward).

(b) Check that there is continuity between terminals on the

switch side connector with the switch OFF (belt upward).

If continuity is not as specified, replace the retractor assembly.