ECU VAUXHALL ADAM 2014.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: ADAM, Model: VAUXHALL ADAM 2014.5Pages: 217, PDF Size: 6.68 MB

Page 173 of 217

Vehicle care171

Vehicles with spare wheel

The jack, the wheel bolt wrench, the

tools and two straps for securing a

damaged wheel are in the tool box below the load compartment floor

cover 3 64.

On version with storage box, remove

box first 3 62.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety attemperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.Tyre designations

E.g. 195/55 R 16 95 H195=Tyre width, mm55=Cross-section ratio (tyre

height to tyre width), %R=Belt type: RadialRF=Type: RunFlat16=Wheel diameter, inches95=Load index e.g. 95 is

equivalent to 690 kgH=Speed code letter

Speed code letter:

Q=up to 100 mphS=up to 112 mphT=up to 118 mphH=up to 130 mphV=up to 150 mphW=up to 168 mph

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Page 183 of 217

Vehicle care181

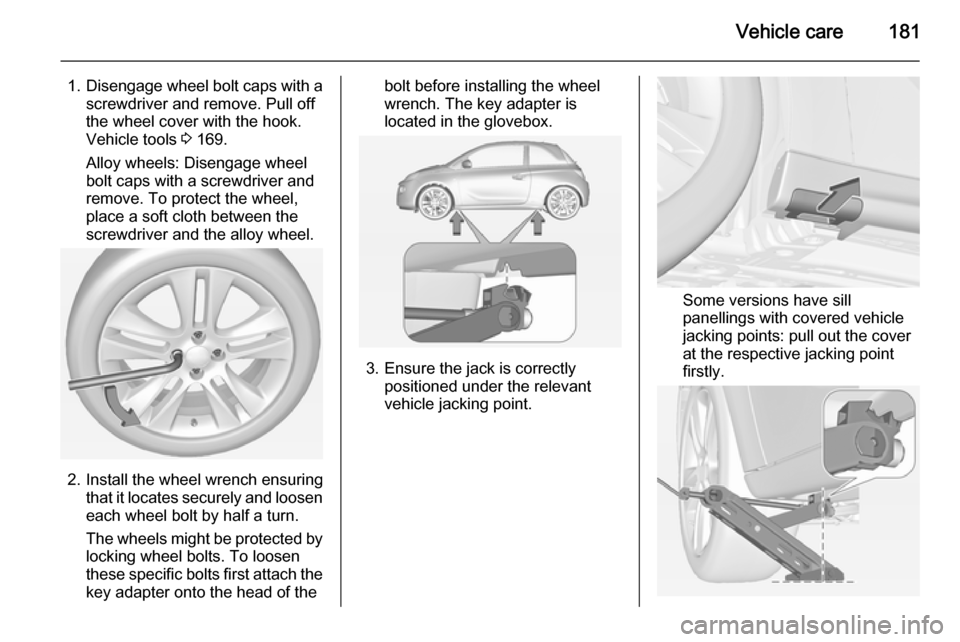

1.Disengage wheel bolt caps with a

screwdriver and remove. Pull off

the wheel cover with the hook.

Vehicle tools 3 169.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts first attach the key adapter onto the head of the

bolt before installing the wheel

wrench. The key adapter is

located in the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Some versions have sill

panellings with covered vehicle

jacking points: pull out the cover

at the respective jacking point

firstly.

Page 184 of 217

182Vehicle care

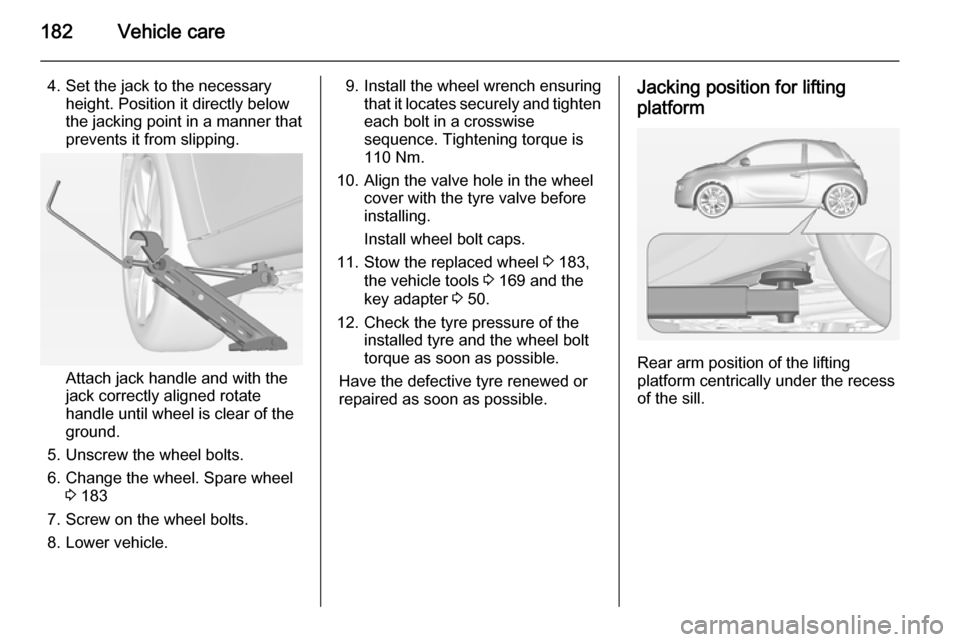

4. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel. Spare wheel 3 183

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.

11. Stow the replaced wheel 3 183,

the vehicle tools 3 169 and the

key adapter 3 50.

12. Check the tyre pressure of the installed tyre and the wheel bolttorque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.Jacking position for lifting

platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Page 186 of 217

184Vehicle care

4.Lift the spare wheel holder a bit by

hand and unhook the catch.

5. Lower the spare wheel holder.

6. Lift the spare wheel holder a bit by

hand and detach the safety cable.

7. Lower holder all the way and remove spare wheel.

8. Change the wheel 3 180.

The damaged wheel has to be

secured in the load compartment,

see below.

9. Lift the empty spare wheel holder and insert the safety cable.

10. Lift the spare wheel holder farther

and engage in catch. The open

side of the catch must point in the

direction of travel.

11. Close the empty spare wheel holder by turning the hexagon boltclockwise successively using the

wheel wrench.

12. Stow wheel wrench and the jack in the tool box in vehicle floor.

13. Close the load compartment floor.

Stowing a damaged wheel in the

load compartment The spare wheel holder is not

designed for other tyre sizes than the

spare wheel.

A damaged wheel wider than the

spare wheel has to be stowed in the

load compartment and secured with a strap. Vehicle tools 3 169.Wheels with tyre size up to

195/55R16 1. Remove load compartment cover and lift up load compartment floor.

Stow both behind the raised up

backrests of the rear seats.

Page 187 of 217

Vehicle care185

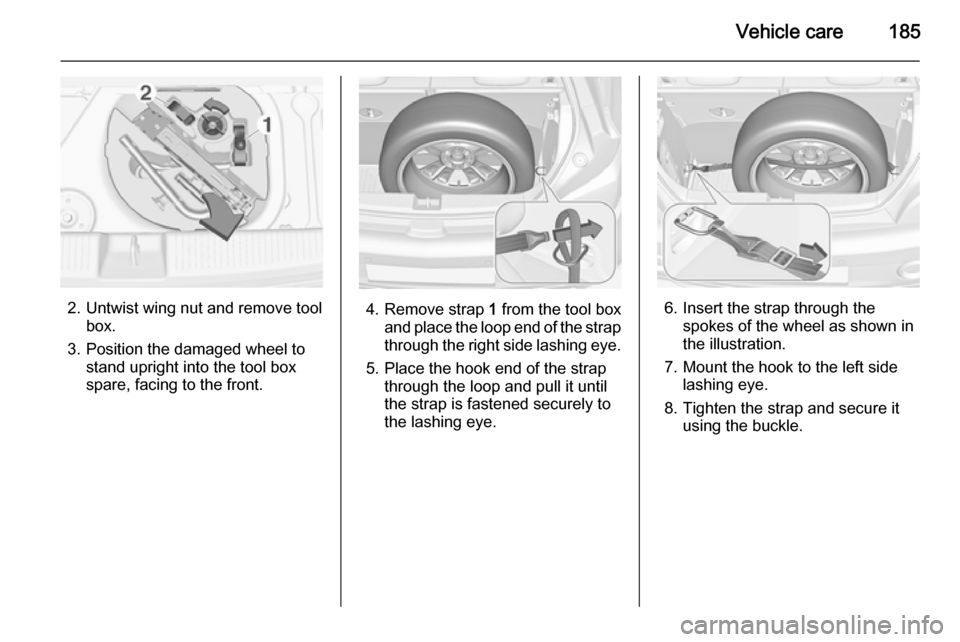

2. Untwist wing nut and remove toolbox.

3. Position the damaged wheel to stand upright into the tool box

spare, facing to the front.4. Remove strap 1 from the tool box

and place the loop end of the strap

through the right side lashing eye.

5. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.6. Insert the strap through the spokes of the wheel as shown in

the illustration.

7. Mount the hook to the left side lashing eye.

8. Tighten the strap and secure it using the buckle.

Page 188 of 217

186Vehicle care

9. Position the tool box in the insideof the wheel and secure it with

strap 2 inserted through two

spokes of the wheel.

Wheels with tyre size bigger than

195/55R16 1. Fold down backrests of the rear seats 3 61.

2. Remove strap 1 from the tool box.

3. Position the damaged wheel outside down in the load

compartment.

4. Take strap 1 and place the loop

end of the strap through the right

side lashing eye.

5. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

6. Insert the strap through the spokes of the wheel as shown in

the illustration.

7. Mount the hook to the left side lashing eye.

8. Tighten the strap and secure it using the buckle.

Page 189 of 217

Vehicle care1879Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Store jack and tools always in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured by the strap.

Temporary spare wheel

The use of the temporary spare wheel

could affect driveability. Have the

defective tyre renewed or repaired as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in the front and the full size tyre in the

rear.

Tyre chains 3 176.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

Page 211 of 217

Customer information209

■ Vehicle reactions in particulardriving situations (e.g. inflation of

an airbag, activation of the stability

regulation system)

■ Environmental conditions (e.g. temperature)

These data are exclusively technical

and help identifying and correcting

errors as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may be associated with a specific person -

possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular vehicle data from the vehicle.Radio Frequency

Identification (RFID) RFID technology is used in somevehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in

Vauxhall vehicles does not use or

record personal information or link with any other Vauxhall system

containing personal information.

Page 215 of 217

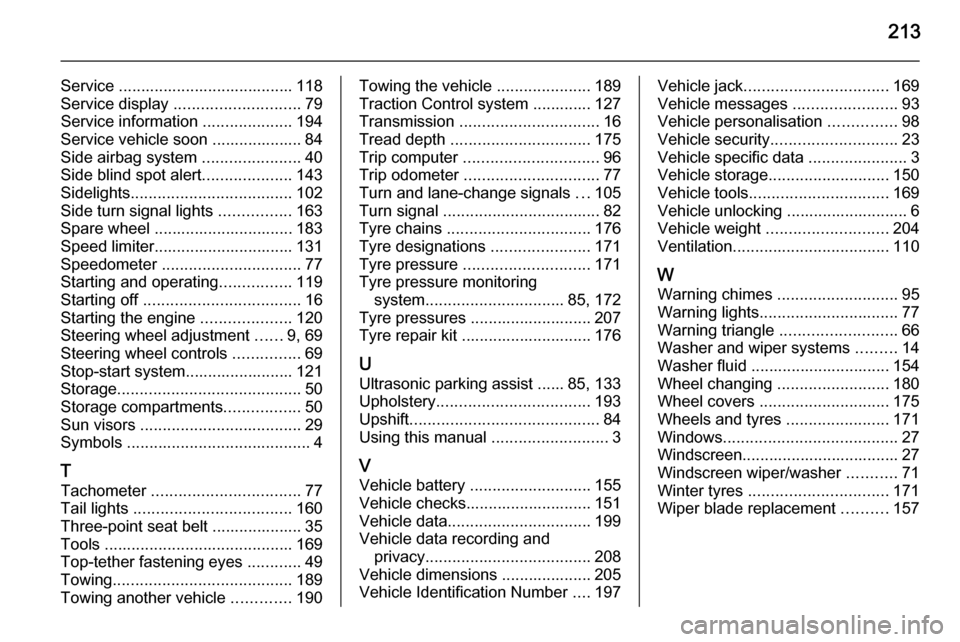

213

Service ....................................... 118

Service display ............................ 79

Service information ....................194

Service vehicle soon .................... 84

Side airbag system ......................40

Side blind spot alert ....................143

Sidelights .................................... 102

Side turn signal lights ................163

Spare wheel ............................... 183

Speed limiter............................... 131

Speedometer ............................... 77

Starting and operating ................119

Starting off ................................... 16

Starting the engine ....................120

Steering wheel adjustment ......9, 69

Steering wheel controls ...............69

Stop-start system........................ 121

Storage ......................................... 50

Storage compartments .................50

Sun visors .................................... 29

Symbols ......................................... 4

T Tachometer ................................. 77

Tail lights ................................... 160

Three-point seat belt .................... 35

Tools .......................................... 169

Top-tether fastening eyes ............49

Towing ........................................ 189

Towing another vehicle .............190Towing the vehicle .....................189

Traction Control system ............. 127

Transmission ............................... 16

Tread depth ............................... 175

Trip computer .............................. 96

Trip odometer .............................. 77

Turn and lane-change signals ...105

Turn signal ................................... 82

Tyre chains ................................ 176

Tyre designations ......................171

Tyre pressure ............................ 171

Tyre pressure monitoring system ............................... 85, 172

Tyre pressures ........................... 207

Tyre repair kit ............................. 176

U

Ultrasonic parking assist ...... 85, 133

Upholstery .................................. 193

Upshift .......................................... 84

Using this manual ..........................3

V Vehicle battery ........................... 155

Vehicle checks............................ 151

Vehicle data ................................ 199

Vehicle data recording and privacy ..................................... 208

Vehicle dimensions .................... 205

Vehicle Identification Number ....197Vehicle jack ................................ 169

Vehicle messages .......................93

Vehicle personalisation ...............98

Vehicle security ............................ 23

Vehicle specific data ......................3

Vehicle storage ........................... 150

Vehicle tools ............................... 169

Vehicle unlocking ........................... 6 Vehicle weight ........................... 204

Ventilation ................................... 110

W

Warning chimes ........................... 95

Warning lights ............................... 77

Warning triangle .......................... 66

Washer and wiper systems .........14

Washer fluid ............................... 154

Wheel changing .........................180

Wheel covers ............................. 175

Wheels and tyres .......................171

Windows ....................................... 27

Windscreen................................... 27 Windscreen wiper/washer ...........71

Winter tyres ............................... 171

Wiper blade replacement ..........157