ESP VAUXHALL ADAM 2014.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: ADAM, Model: VAUXHALL ADAM 2014.5Pages: 217, PDF Size: 6.68 MB

Page 138 of 217

136Driving and operating

In the Driver Information Centre, the

distance to a front and rear obstacle

is displayed by changing distance

lines.

In the Colour-Info-Display, distance is displayed by coloured zones in front

of or behind the vehicle.

The distance indication in the Driver

Information Centre can be inhibited

by vehicle messages with a higher

priority. After approving the message

by pressing the SET/CLR button on

the turn signal lever, distance

indication appears again.

Fault

In the event of a fault or if the system

does not work temporarily, e.g.

because of high external noise level

or other interference factors, the LED in the button flashes for 3 seconds

and then extinguishes. Control

indicator r illuminates in the

instrument cluster 3 85 and a

message pops-up in the Driver

Information Centre.

Vehicle messages 3 93.Advanced parking assist9 Warning

It is the driver who bears full

responsibility for accepting the

parking slot suggested by the

system and the parking

manoeuvre.

Always check the sourrounding

area in all directions when using

advanced parking assist.

The advanced parking assist

measures a suitable parking slot

while passing, calculates the

trajectory and automatically steers

the vehicle into a parallel or

perpendicular parking slot.

Instructions are given by the Driver

Information Centre or the Colour-Info-

Display supported by acoustic

signals. The driver must control

acceleration, braking and gear

shifting, while steering is done

automatically.

Advanced parking assist can only be

activated when driving forwards.

Page 144 of 217

142Driving and operating

Basic notes on parking assistsystems9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention has to be paid to

low obstacles which can damage

the lower part of the bumper.

Caution

Performance of the system can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and

correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Notice

It is possible that the sensor detects a non-existing object caused by

echo disturbance from external

acoustic noise or mechanical

misalignments (sporadic false

warnings might happen).

Make sure that the front license plate

is properly mounted (not bent and no gaps to the bumper on the left or

right side) and the sensors are well

in place.

Advanced parking assist system

may not respond to changes in the

available parking space after

initiating a parking manoeuvre. The

system may recognize an entry, a

gateway, a courtyard or even a

crossing as parking slot. After

selecting reverse gear the system

would start a parking manoeuvre.

Take care of the availability of the

suggested parking slot.

Surface irregularities, e.g. on

construction zones, are not detected

by the system. The driver accepts

responsibility.

Notice

If engaging a forward gear and

exceeding a certain speed, the rear

parking assist will be deactivated

when the rear carrier system is

extended.

If engaging reverse at first, the

parking assist will detect the rear

carrier system and provide a buzzing

sound. Press r or D briefly to

deactivate the parking assist.

Notice

After production, the system

requires a calibration. For optimal

parking guidance, a driving distance

of at least 6 miles, including a

number of bends, is required.

Page 155 of 217

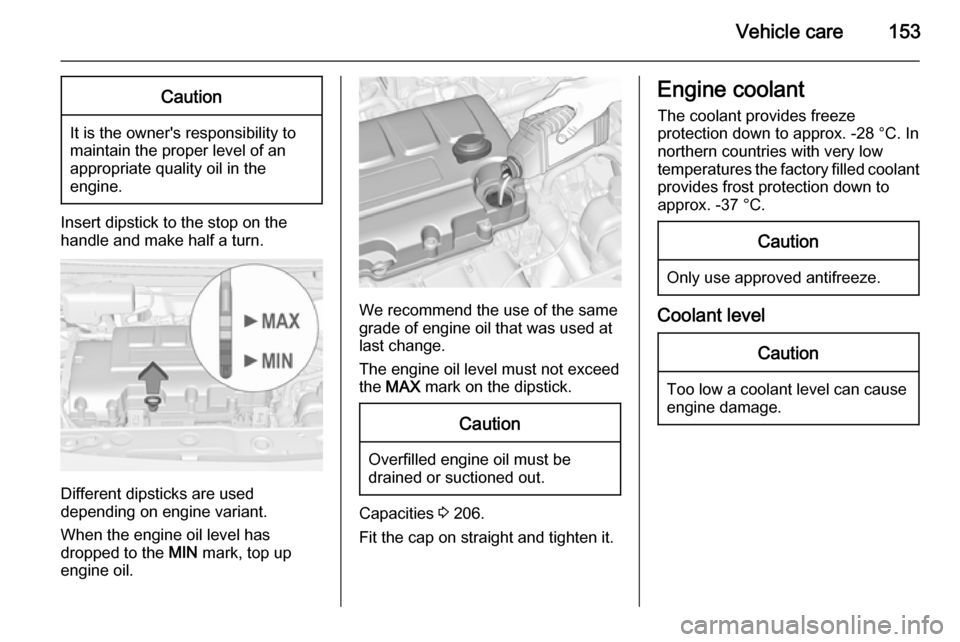

Vehicle care153Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

When the engine oil level has

dropped to the MIN mark, top up

engine oil.

We recommend the use of the same

grade of engine oil that was used at

last change.

The engine oil level must not exceed

the MAX mark on the dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

Capacities 3 206.

Fit the cap on straight and tighten it.

Engine coolant

The coolant provides freeze

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

Page 162 of 217

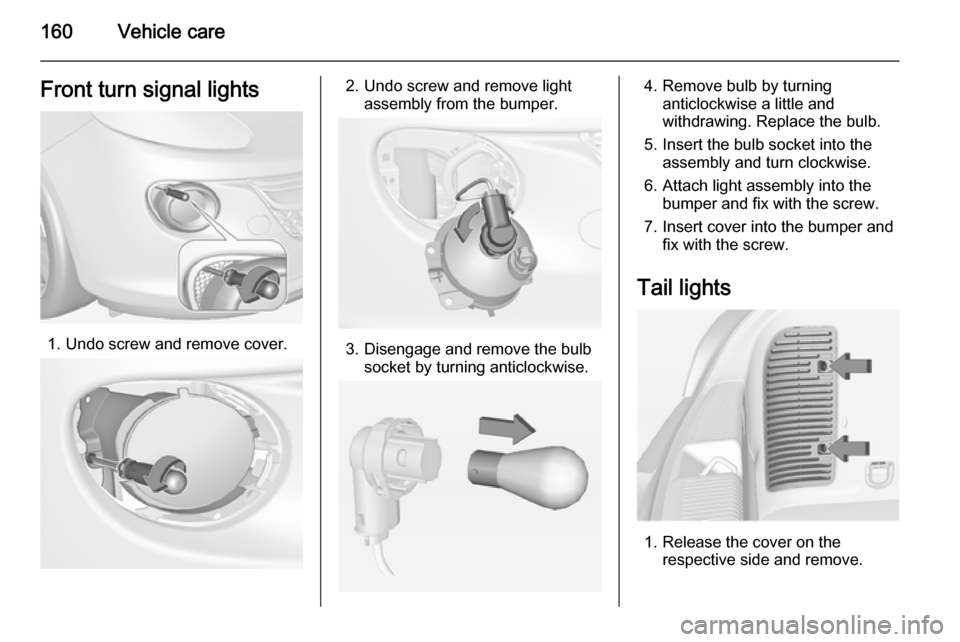

160Vehicle careFront turn signal lights

1. Undo screw and remove cover.

2. Undo screw and remove lightassembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

4. Remove bulb by turninganticlockwise a little and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Attach light assembly into the bumper and fix with the screw.

7. Insert cover into the bumper and fix with the screw.

Tail lights

1. Release the cover on the respective side and remove.

Page 166 of 217

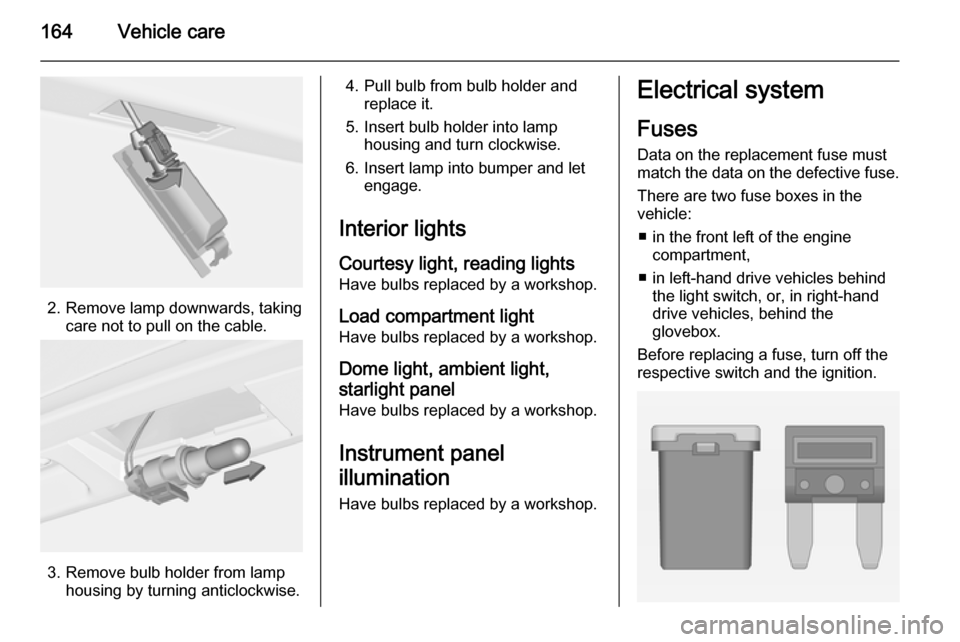

164Vehicle care

2. Remove lamp downwards, takingcare not to pull on the cable.

3. Remove bulb holder from lamphousing by turning anticlockwise.

4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light Have bulbs replaced by a workshop.

Dome light, ambient light,starlight panel

Have bulbs replaced by a workshop.

Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

■ in the front left of the engine compartment,

■ in left-hand drive vehicles behind the light switch, or, in right-handdrive vehicles, behind the

glovebox.

Before replacing a fuse, turn off the

respective switch and the ignition.

Page 174 of 217

172Vehicle care

Tyre pressure 3 207.

The tyre and loading information label on the right door frame indicates theoriginal equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter

tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre pressure value, follow the procedure

below:

1. Identify drive axle and body style.

2. Identify the engine identifier code.

Engine data 3 202.

3. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 207.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition. After adjusting tyre

pressure switch on ignition and select the relevant setting on the page Tyre

load in the Driver Information Centre,

3 87.

Tyre pressure monitoring

system The tyre pressure monitoring system

checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Page 175 of 217

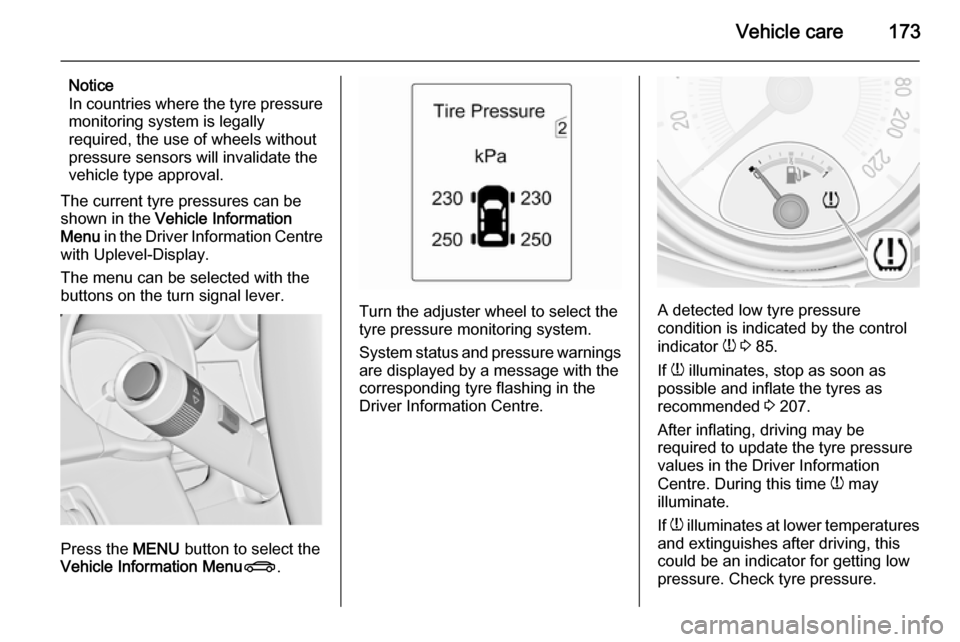

Vehicle care173

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

with Uplevel-Display.

The menu can be selected with the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X.

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.A detected low tyre pressure

condition is indicated by the control

indicator w 3 85.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 207.

After inflating, driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for getting low

pressure. Check tyre pressure.

Page 177 of 217

Vehicle care175

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 183 of 217

Vehicle care181

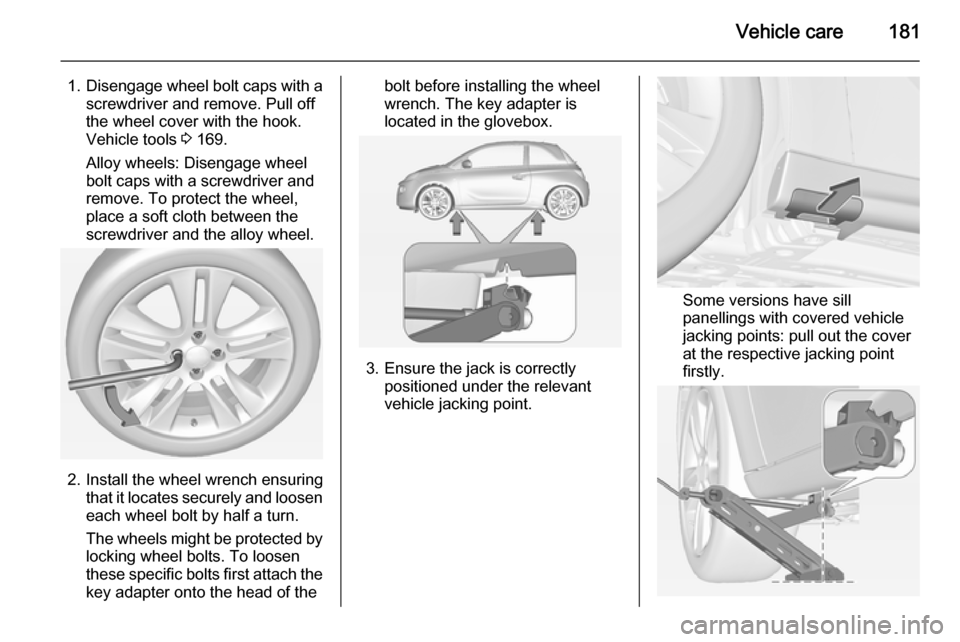

1.Disengage wheel bolt caps with a

screwdriver and remove. Pull off

the wheel cover with the hook.

Vehicle tools 3 169.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts first attach the key adapter onto the head of the

bolt before installing the wheel

wrench. The key adapter is

located in the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Some versions have sill

panellings with covered vehicle

jacking points: pull out the cover

at the respective jacking point

firstly.

Page 185 of 217

Vehicle care183

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Open the load compartment floor 3 64.

Remove storage box if equipped

3 62.

2. Remove the wheel wrench from the tool box.

3. Fit the wheel wrench on the hexagon bolt near the tool box

and turn it anti-clockwise until a

resistance is noticeable.