lock VAUXHALL ADAM 2014.5 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: ADAM, Model: VAUXHALL ADAM 2014.5Pages: 217, PDF Size: 6.68 MB

Page 150 of 217

148Driving and operating

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

Page 153 of 217

Vehicle care151

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are

not functional, e.g. anti-theft alarm

system.

Putting back into operation

When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website. Only entrust this work to an

authorised recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 160 of 217

158Vehicle care

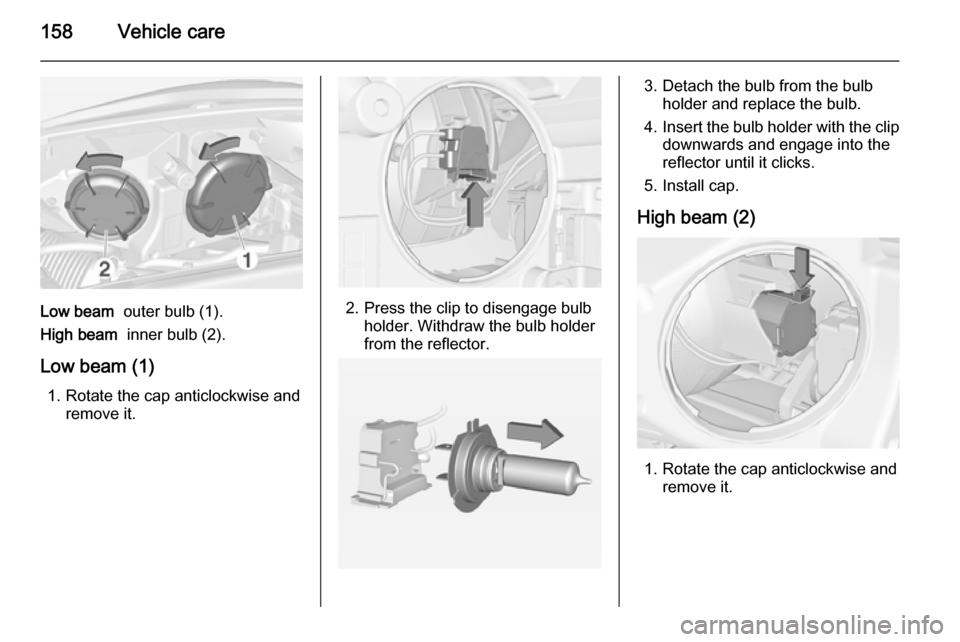

Low beam outer bulb (1).

High beam inner bulb (2).

Low beam (1) 1. Rotate the cap anticlockwise and remove it.2. Press the clip to disengage bulbholder. Withdraw the bulb holder

from the reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder with the clip

downwards and engage into the

reflector until it clicks.

5. Install cap.

High beam (2)

1. Rotate the cap anticlockwise and remove it.

Page 161 of 217

Vehicle care159

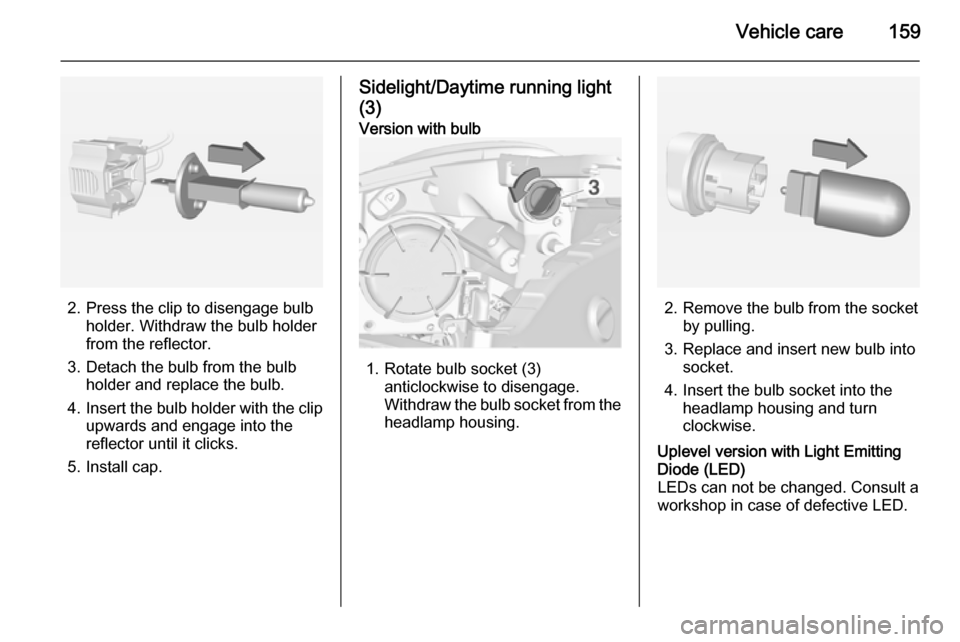

2. Press the clip to disengage bulbholder. Withdraw the bulb holder

from the reflector.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder with the clip

upwards and engage into the

reflector until it clicks.

5. Install cap.

Sidelight/Daytime running light

(3)Version with bulb

1. Rotate bulb socket (3) anticlockwise to disengage.

Withdraw the bulb socket from the

headlamp housing.2. Remove the bulb from the socket by pulling.

3. Replace and insert new bulb into socket.

4. Insert the bulb socket into the headlamp housing and turn

clockwise.

Uplevel version with Light Emitting

Diode (LED)

LEDs can not be changed. Consult a

workshop in case of defective LED.

Page 162 of 217

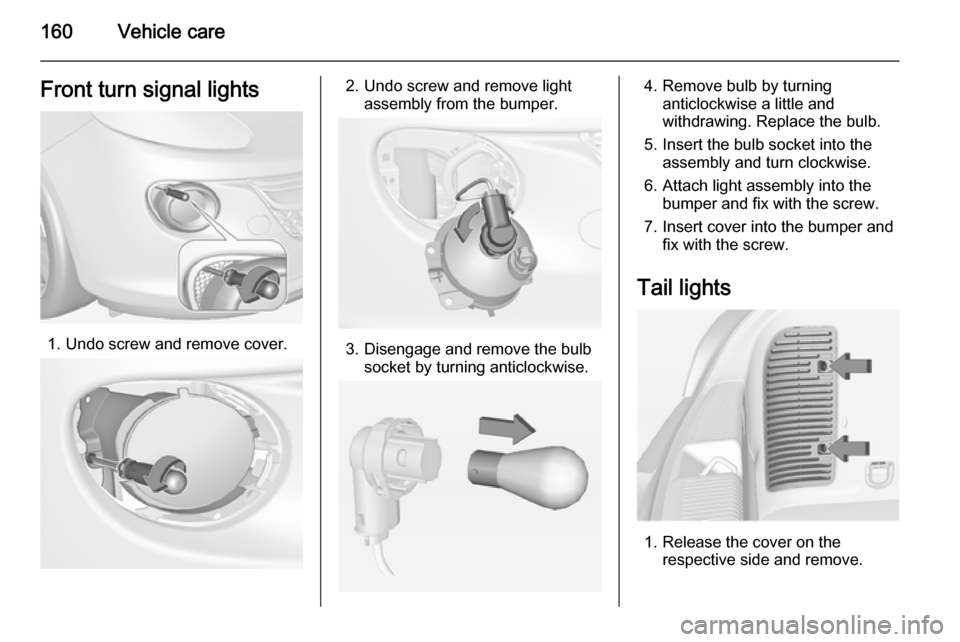

160Vehicle careFront turn signal lights

1. Undo screw and remove cover.

2. Undo screw and remove lightassembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

4. Remove bulb by turninganticlockwise a little and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Attach light assembly into the bumper and fix with the screw.

7. Insert cover into the bumper and fix with the screw.

Tail lights

1. Release the cover on the respective side and remove.

Page 163 of 217

Vehicle care161

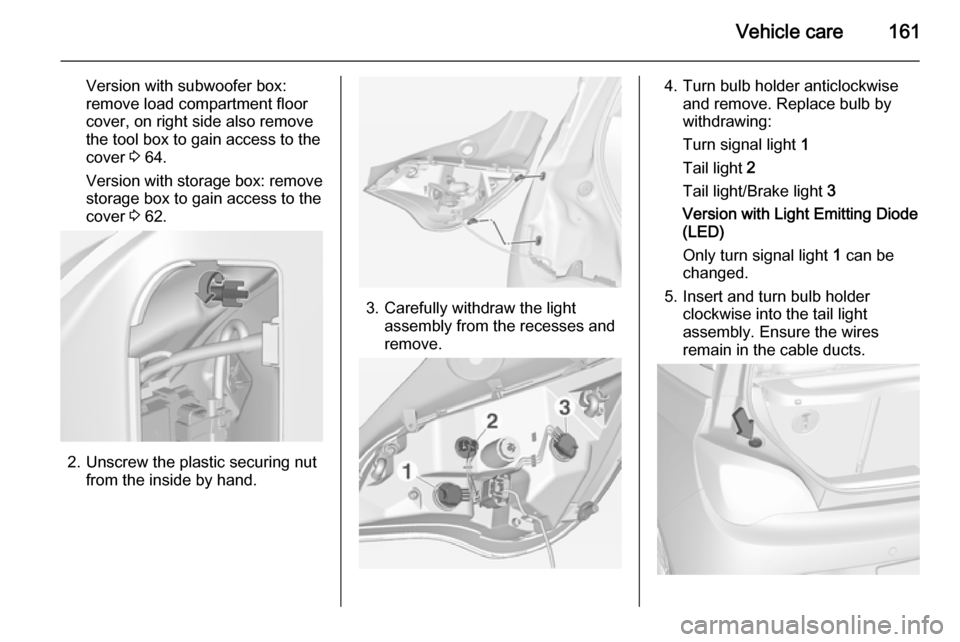

Version with subwoofer box:remove load compartment floor

cover, on right side also remove

the tool box to gain access to the

cover 3 64.

Version with storage box: remove

storage box to gain access to the

cover 3 62.

2. Unscrew the plastic securing nut

from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Turn bulb holder anticlockwise and remove. Replace bulb by

withdrawing:

Turn signal light 1

Tail light 2

Tail light/Brake light 3

Version with Light Emitting Diode (LED)

Only turn signal light 1 can be

changed.

5. Insert and turn bulb holder clockwise into the tail light

assembly. Ensure the wires

remain in the cable ducts.

Page 164 of 217

162Vehicle care

Fit light assembly with the

retaining pins into the recesses of

the vehicle body and tighten the

securing nut from inside the load

compartment. Pull the circular

gasket over the recess in the lamp housing.

Close cover and engage.

Reversing light/rear fog light

Reversing light is located on the right

side of the bumper, and the rear fog

light is located on the left side of the

bumper for left-hand drive vehicles,

and vice versa for right hand drive

models.

The description of bulb replacement

is the same for both.

1. Undo screw and remove cover.

2. Undo screw and remove light assembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

Page 165 of 217

Vehicle care163

4. Remove bulb by turninganticlockwise slightly and

withdrawing. Replace the bulb.

5. Insert the bulb socket into the assembly and turn clockwise.

6. Replace light assembly in the bumper and fix with the screw.

7. Insert cover into the bumper and fix with the screw.

Side turn signal lights To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

Page 166 of 217

164Vehicle care

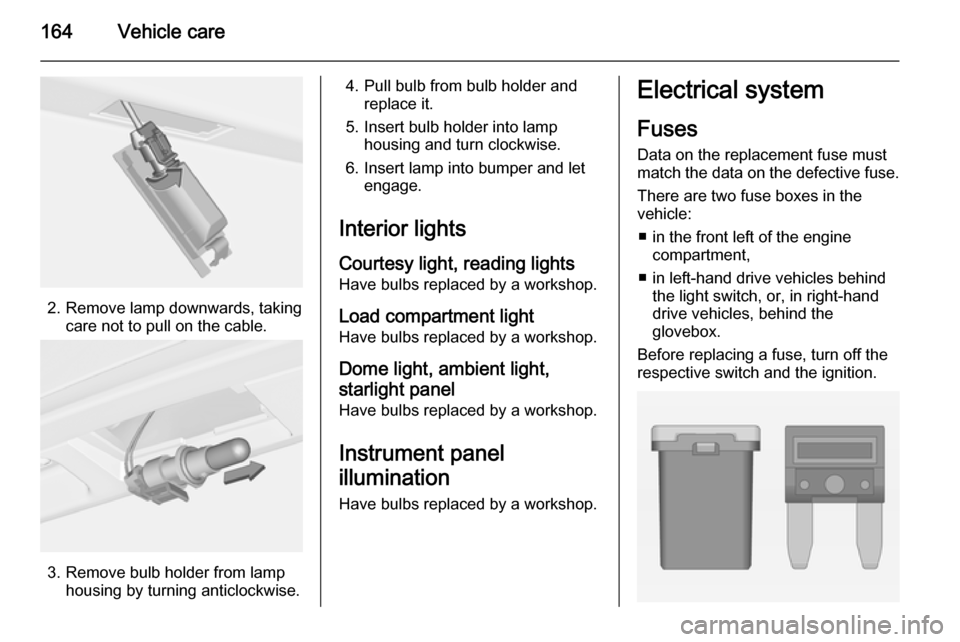

2. Remove lamp downwards, takingcare not to pull on the cable.

3. Remove bulb holder from lamphousing by turning anticlockwise.

4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light Have bulbs replaced by a workshop.

Dome light, ambient light,starlight panel

Have bulbs replaced by a workshop.

Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

■ in the front left of the engine compartment,

■ in left-hand drive vehicles behind the light switch, or, in right-handdrive vehicles, behind the

glovebox.

Before replacing a fuse, turn off the

respective switch and the ignition.

Page 178 of 217

176Vehicle care

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 175/70 R 14,

185/70 R 14, 185/60 R 15,

185/65 R 15 and 195/55 R 16.

Tyre chains are not permitted on tyres of size 215/45 R 17 and 225/35 R 18 .

The use of tyre chains is not permitted

on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear.