stop start VAUXHALL ANTARA 2014 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: ANTARA, Model: VAUXHALL ANTARA 2014Pages: 217, PDF Size: 5.94 MB

Page 129 of 217

Driving and operating127Engine exhaust9Danger

Engine exhaust gases contain

poisonous carbon monoxide,

which is colourless and odourless and could be fatal if inhaled.

If exhaust gases enter the interior

of the vehicle, open the windows.

Have the cause of the fault

rectified by a workshop.

Avoid driving with an open load

compartment, otherwise exhaust

gases could enter the vehicle.

Malfunction indicator light 3 84.

Diesel particle filter

The diesel particle filter system filters

harmful soot particles out of the

exhaust gases. The system includes

a self-cleaning function that runs

automatically during driving without

any notification.

The filter is cleaned by periodically

burning off the soot particles at high

temperature. This process takes

place automatically under set driving

conditions and may take more than

15 minutes. Autostop is not available

and fuel consumption may be higher

during this period. The emission of

smells and smoke during this process is normal.

Under certain driving conditions, e.g.

short distances, the system cannot

clean itself automatically.

If cleaning of the filter is required and previous driving conditions did not

enable automatic cleaning, it will be

indicated by control indicator %

3 87.

% illuminates, accompanied by a

warning chime, when diesel particle

filter is full. Start cleaning process as

soon as possible.

% flashes when diesel particle filter

has reached the maximum filling level. Start cleaning process

immediately to avoid damage to the

engine. A warning chime sounds every 3 minutes until the cleaning

process is complete.

Cleaning process

To activate the cleaning process,

continue driving, keeping engine

speed above 2000 revolutions per

minute. Shift down if necessary.

Diesel particle filter cleaning is then

started.

If control indicator Z illuminates

additionally in the instrument cluster

when the engine is running, there

Page 132 of 217

![VAUXHALL ANTARA 2014 Owners Guide 130Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<=Shift to a higher gear.]=Shift to a lower gear.

Tip selector lever in the a VAUXHALL ANTARA 2014 Owners Guide 130Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<=Shift to a higher gear.]=Shift to a lower gear.

Tip selector lever in the a](/img/38/19316/w960_19316-131.png)

130Driving and operatingManual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<=Shift to a higher gear.]=Shift to a lower gear.

Tip selector lever in the appropriate

direction. It then returns to the centre

position.

Gearshifting in manual mode can be

achieved whilst accelerating. If the

engine speed is too low, the

transmission will automatically shift to a lower gear, even in manual mode,

to prevent the engine from stalling.

If a higher gear is selected when

vehicle speed is too low, or a lower

gear when vehicle speed is too high,

the shift is not executed.

In manual mode, no automatic

shifting to a higher gear takes place

at high engine revolutions.

Gears can be skipped by moving the selector lever repeatedly at short

intervals.

After stopping, 1st gear is

automatically selected. When starting

on slippery surfaces, tip selector lever forwards to engage 2nd gear.

To move back to position D, move

selector lever back to the right.

Electronic driving

programmes ■ Following a cold start, the operating

temperature programme increasesengine speed to quickly bring the

catalytic converter to the required

temperature.Kickdown

In both automatic and manual modes, if the accelerator pedal is pressed

down completely the transmission

shifts to a lower gear depending on

engine speed. Full engine power is

available for acceleration.

Fuel economy mode

Activate fuel economy mode to allow

the transmission to adapt gearshift

patterns, improving the vehicle's fuel

economy.

Page 139 of 217

Driving and operating137

Fault

Failure mode of electrical parking

brake is indicated by control indicator

j 3 85.

In the event of a fault, to apply

electrical parking brake: pull and hold the switch m for a few seconds. If

control indicator m illuminates,

electrical parking brake has been

applied successfully.

To release electrical parking brake:

push and hold the switch m for a few

seconds. If control indicator m

extinguishes, electrical parking brake has been released successfully.

If control indicator m flashes:

electrical parking brake is not fully

applied or released. When m is

continuously flashing, with ignition

switched on depress brake pedal,

release electrical parking brake and

retry applying.

If m continues to flash, do not drive

the vehicle. If necessary, place

wedge blocks or equivalent in front of and behind wheels to prevent vehiclemovement. Seek the assistance of a

workshop to have the cause of the

fault remedied.

Brake assist

If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the brake pedal for as long as full braking is required. Maximum brake force is

automatically reduced when the

brake pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the foot brake after

stopping on an incline, the brakes

remain on for a further 2 seconds. The brakes release automatically as soon

as the vehicle begins to accelerate.Ride control systems

Electronic Stability Control Electronic Stability Control (ESC)

improves driving stability when

necessary, regardless of the type of

road surface or tyre grip. It also

prevents the drive wheels from

spinning.

As soon as the vehicle starts to

swerve (understeer/oversteer),

engine output is reduced and the wheels are braked individually. This

considerably improves the driving

stability of the vehicle on slippery road

surfaces.

ESC is operational as soon as control indicators b and t extinguish in the

instrument cluster after switching on the ignition.

When ESC is active b flashes 3 86.

Page 148 of 217

146Driving and operatingTrailer hitch

General information

The coupling ball bar is kept in a bag,

fastened with a strap and is stowed

below the floor cover in the load

compartment.

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Control indicator á illuminates in the

instrument cluster when a trailer is

connected to the vehicle 3 90.

Driving characteristics and

towing tips In the case of trailers with brakes,

attach the break-away stopping cable

to the eye - not to the coupling ball

bar.If no eye is available, loop cable

around coupling ball bar. Ensure

cable is crossed under the vertical

coupling socket to ensure the trailer

nose cannot drop to the ground if it

becomes separated from the trailer

hitch. Do not allow the cable to drag

along the ground and always allow

enough slack to permit full turning.

Follow the instructions supplied with

the towing equipment.

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements. For trailers with

low driving stability, the use of a

friction-type stabiliser is strongly

recommended.

Do not drive faster than 50 mph, even

in countries where higher speeds are

permitted. When driving uphill, do not drive faster than 20 mph in 1st gear,

or 30 mph in 2nd gear.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 207.

Trailer towing Trailer loads

The permissible trailer loads are

vehicle-dependent and engine-

dependent maximum values which

must not be exceeded. The actual

trailer load is the difference between

the actual gross weight of the trailer

and the actual coupling socket load

with the trailer coupled.

When the trailer load is being

checked, therefore, only the trailer

wheels - and not the jockey wheel -

must be standing on the weighing

apparatus.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12 %.

Page 154 of 217

152Vehicle careBonnetOpening

Pull the release lever and return it to

its original position.

Locate the safety catch, found slightly left of centre on the underside of the

bonnet, push the catch upwards and

lift the bonnet gently.

The bonnet is held open

automatically.

If the bonnet is opened during an Autostop, the engine will be restarted automatically for safety reasons.

Air intake 3 120.

Closing

Lower the bonnet and let it fall into the latch from a low height (20-25 cm).

Check that the bonnet is engaged.

Caution

Do not press the bonnet into the

latch to avoid dents.

Engine oil

Check the engine oil level manually on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 195.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Pull out the dipstick, wipe it clean, insert it to the stop on the handle, pull

out and read the engine oil level.

Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Page 158 of 217

156Vehicle careCaution

Only use high-performance brake

fluid approved for the vehicle.

Brake fluid 3 195.

Brake fluid level control indicator R

3 84.

Clutch fluid

9 Warning

Clutch fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

If the fluid in the reservoir falls below

the MIN mark, seek the assistance of

a workshop.

Clutch fluid 3 195.

Vehicle battery Vehicles without stop-start system

will be equipped with a lead acid

battery. Vehicles with stop-start

system will be equipped with an

AGM vehicle battery which is not a

lead acid battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the vehicle battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

6 weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

The anti-theft alarm siren must be

deactivated as follows: Switch the ignition on then off, disconnect the

vehicle's battery within 15 seconds.

Page 159 of 217

Vehicle care157

Retrofitted electrical or electronic

accessories can place an additional load on the vehicle battery or

discharge the battery. Seek the

assistance of a workshop regarding technical possibilities, such as fitting

a more powerful battery.

Ensure the ignition is switched off

before reconnecting the vehicle

battery. Then perform the following actions:

1. Set date and time in the information display 3 76.

2. If necessary, activate the power windows and sun roof 3 29, 3 31.

In order to prevent the vehicle battery

from discharging, some consumers

such as the courtesy lights

automatically switch off after a delay.

Charge a disconnected vehicle

battery every 6 weeks.

Vehicle battery discharge protection

3 113.Replacing the vehicle battery

Notice

Any deviation from the instructions

given in this paragraph may lead to

a temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap, and the ventilation in the vicinity of the

negative terminal must be opened.

Only use batteries that allow the fuse

box to be mounted above the vehicle

battery.

In vehicles with stop-start system,

ensure to have the AGM (Absorptive

Glass Mat) vehicle battery replaced

with an AGM battery again.

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Vauxhall battery.

Notice

Using an AGM vehicle battery

different from the original Vauxhall

vehicle battery may result in a lower performance of the stop-start

system.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 124.

Page 160 of 217

158Vehicle care

Charging the vehicle battery9Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 187.

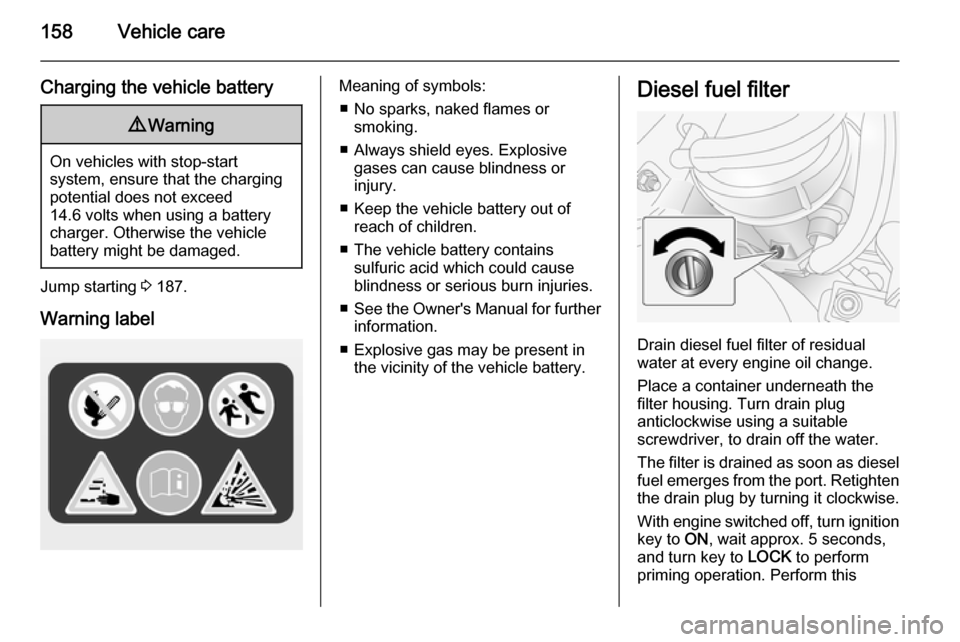

Warning label

Meaning of symbols: ■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulfuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

■ Explosive gas may be present in the vicinity of the vehicle battery.Diesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Turn drain plug

anticlockwise using a suitable

screwdriver, to drain off the water.

The filter is drained as soon as diesel fuel emerges from the port. Retighten

the drain plug by turning it clockwise.

With engine switched off, turn ignition

key to ON, wait approx. 5 seconds,

and turn key to LOCK to perform

priming operation. Perform this

Page 171 of 217

Vehicle care169

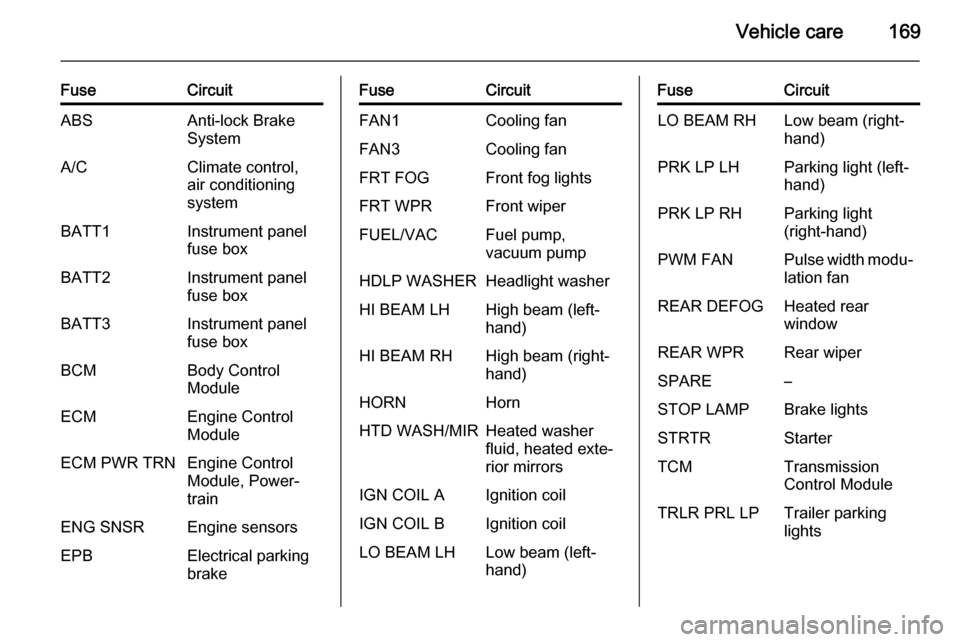

FuseCircuitABSAnti-lock Brake

SystemA/CClimate control,

air conditioning

systemBATT1Instrument panel

fuse boxBATT2Instrument panel

fuse boxBATT3Instrument panel

fuse boxBCMBody Control

ModuleECMEngine Control

ModuleECM PWR TRNEngine Control

Module, Power‐

trainENG SNSREngine sensorsEPBElectrical parking

brakeFuseCircuitFAN1Cooling fanFAN3Cooling fanFRT FOGFront fog lightsFRT WPRFront wiperFUEL/VACFuel pump,

vacuum pumpHDLP WASHERHeadlight washerHI BEAM LHHigh beam (left-

hand)HI BEAM RHHigh beam (right-

hand)HORNHornHTD WASH/MIRHeated washer

fluid, heated exte‐

rior mirrorsIGN COIL AIgnition coilIGN COIL BIgnition coilLO BEAM LHLow beam (left-

hand)FuseCircuitLO BEAM RHLow beam (right-

hand)PRK LP LHParking light (left-

hand)PRK LP RHParking light

(right-hand)PWM FANPulse width modu‐ lation fanREAR DEFOGHeated rear

windowREAR WPRRear wiperSPARE–STOP LAMPBrake lightsSTRTRStarterTCMTransmission

Control ModuleTRLR PRL LPTrailer parking

lights

Page 183 of 217

Vehicle care181

6. Press the on/off button to turn the

tyre repair kit on. The tyre is filled

with sealant.

The pressure gauge briefly shows a high pressure while the sealant

canister is emptying. Then the

pressure starts to drop.

All of the sealant is pumped into

the tyre. Then the tyre is inflated.

7. Inflate the tyre to the recommended inflation pressure

using the pressure gauge. The

prescribed tyre pressure should

be obtained within 10 minutes

3 207 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for 10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button next to the pressure

gauge.

Do not run the compressor for

longer than 10 minutes.

8. Detach the tyre repair kit and replace the tyre valve cap.

9. Remove any excess sealant using a cloth.

10. Take the label indicating maximum permitted speed from

the sealant canister and affix in

the driver's field of view.

11. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

6 miles (but no more than 10 minutes) stop and check tyre

pressure.

If the tyre pressure has fallen

slightly, set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen by

more than 10 psi, the vehicle must