change wheel VAUXHALL ASTRA J GTC 2018.5 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018.5, Model line: ASTRA J GTC, Model: VAUXHALL ASTRA J GTC 2018.5Pages: 293, PDF Size: 8.28 MB

Page 167 of 293

Driving and operating165● There is no traffic and nothingdetected on the road sides for

several minutes. In this case,

there are no radar echoes and

the sensor may report that it is

blocked.

● The collision imminent braking system is applying the brakes.

● The radar sensor is blocked by an ice or water film.

● A fault is detected in the radar, engine or brake system.

When adaptive cruise control is

deactivated automatically, the control

indicator m illuminates white and a

warning symbol is displayed as a pop- up in the Driver Information Centre.

The stored speed is maintained.

9 Warning

When adaptive cruise control is

deactivated, the driver must take

over full brake and engine control.

Switching off

Press C to switch off adaptive cruise

control. The control indicator m

extinguishes. The stored speed is

deleted.

Switching off the ignition also

switches off adaptive cruise control

and deletes the stored speed.

Driver's attention

● Use adaptive cruise control carefully on bends or mountain

roads, as it can lose the vehicle

ahead and need time to detect it

again.

● Do not use the system on slippery roads as it can create

rapid changes in tyre traction

(wheel spinning), so that you

could lose control.

● Do not use adaptive cruise control during rain, snow or

heavy dirt, as the radar sensor

can be covered by a water film,

dust, ice or snow. This reduces or suppresses completely the

visibility. In case of sensor

blockage, clean the sensor

cover.

System limits ● The system's automatic brake force does not permit hard

braking and the braking level

may not be sufficient to avoid a

collision.

Page 240 of 293

238Vehicle careMake the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 241.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a

screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 226.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

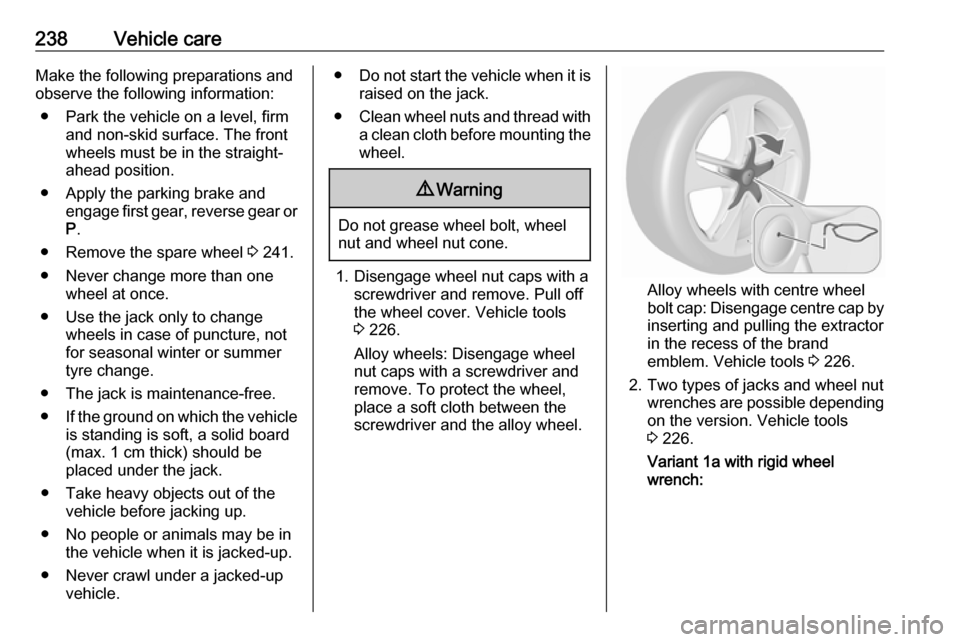

screwdriver and the alloy wheel.Alloy wheels with centre wheel

bolt cap: Disengage centre cap by

inserting and pulling the extractor

in the recess of the brand

emblem. Vehicle tools 3 226.

2. Two types of jacks and wheel nut wrenches are possible dependingon the version. Vehicle tools

3 226.

Variant 1a with rigid wheel

wrench:

Page 242 of 293

240Vehicle care

Set the jack to the necessary

height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate

handle until wheel is clear of the ground.

5. Unscrew the wheel nuts.

6. Change the wheel. Spare wheel 3 241.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Install vehicle jacking point cover on versions with sill panelling.

12. Stow the replaced wheel 3 241,

the vehicle tools 3 226 and the

adapter for the locking wheel nuts 3 59.

13. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.Have the defective tyre renewed or repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Page 243 of 293

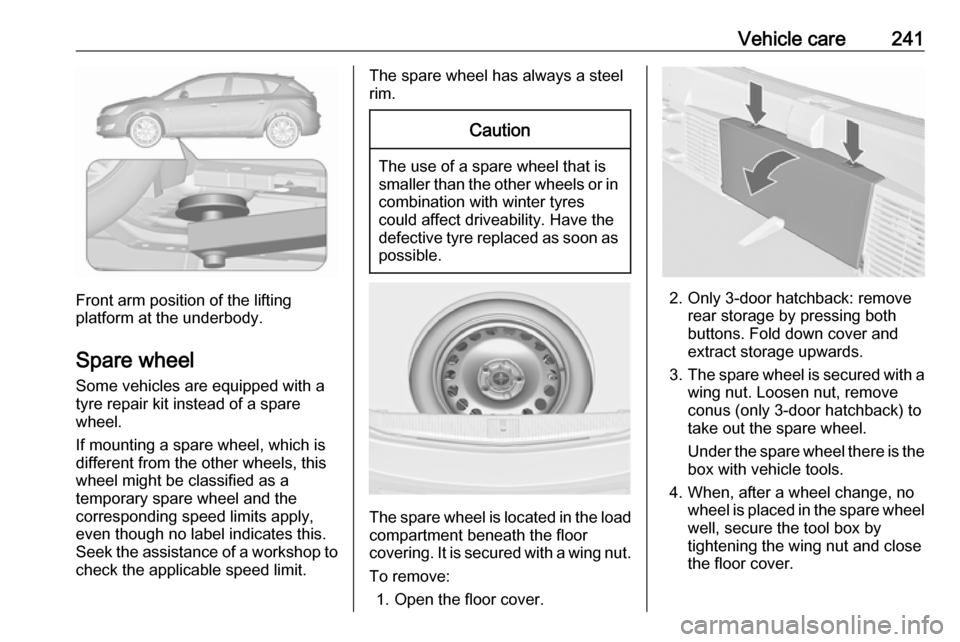

Vehicle care241

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has always a steel

rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

To remove: 1. Open the floor cover.

2. Only 3-door hatchback: remove rear storage by pressing both

buttons. Fold down cover and

extract storage upwards.

3. The spare wheel is secured with a

wing nut. Loosen nut, remove

conus (only 3-door hatchback) to

take out the spare wheel.

Under the spare wheel there is the box with vehicle tools.

4. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut and close

the floor cover.

Page 284 of 293

282Customer informationThis data includes, for example:● Vehicle status information (e.g. wheel rotation rate, speed,

movement delay, lateral

acceleration, "seatbelts

fastened" display),

● Ambient conditions (e.g. temperature, rain sensor,

distance sensor).

Most of this data is volatile and is

processed only in the vehicle itself, and not beyond the operating time.

Moreover, many control units include

data storage device (amongst others the vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle condition, component stress,

maintenance requirements and

technical events and errors.

The following information, for

example, is stored:

● System component operating states (e.g. fill level, tyre

pressure, battery status),

● State of charge of the high voltage battery, estimated range

(in the case of electric vehicles),● Faults and defects in important system components (e.g. lights,

brakes),

● System reactions in special driving situations (e.g. triggeringof an airbag, actuation of the

stability control systems),

● Information on events damaging the vehicle.

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services, the operating

data saved can be read together with the vehicle identification number andused if necessary. Staff working for

the service net-work (e.g. garages, manufacturers) or third parties (e.g.

breakdown services) can read the

data from the vehicle. Services

include repair services, maintenance

processes, warranty cases and

quality assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which has been read

out documents the technical conditionof the vehicle or individual

components and assists with fault

diagnosis, compliance with warranty

obligations and quality improvement.

This data, in particular information on component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also needs operating data

from vehicles for product recalls.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs.

Comfort and infotainment

functions

Comfort settings and custom settings

can be stored in the vehicle and

changed at any time.