run flat VAUXHALL ASTRA K 2019.5 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019.5, Model line: ASTRA K, Model: VAUXHALL ASTRA K 2019.5Pages: 311, PDF Size: 9.6 MB

Page 161 of 311

Driving and operating159preheating. Control indicators

illuminate and most electrical

functions are operable.Engine start

Press Engine Start/Stop briefly while:

● manual transmission: operating clutch pedal,

● automatic transmission: operating brake pedal with

selector lever in P or N.

Starting the engine 3 160.Ignition off

Press Engine Start/Stop briefly when

Autostop is activated or when engine is running and vehicle is stationary.

Automatic transmission: apply the

parking brake and engage P.

Press Engine Start/Stop briefly

without operating clutch or brake pedal when in ignition on power

mode.

Some functions remain active until

driver's door is opened, provided the

ignition was on previously.Emergency shut off during driving

Press Engine Start/Stop for longer

than 2 seconds or press twice briefly

within 5 seconds 3 160.

Steering wheel lock The steering wheel lock activates

automatically when:

● The vehicle is stationary.

● The ignition has been switched off.

● The driver's door is opened.

To release steering wheel lock, open

and close driver's door and switch on accessory mode or start the engine

directly.9 Warning

If the vehicle battery is discharged,

the vehicle must not be towed,

tow-started or jump-started as the

steering wheel lock cannot be

disengaged.

Operation on vehicles with

electronic key system in case of

failure

If either the electronic key fails or the

battery of the electronic key is weak,

the Driver Information Centre may

display No Remote Detected or

Replace Battery in Remote Key when

you try to start the vehicle.

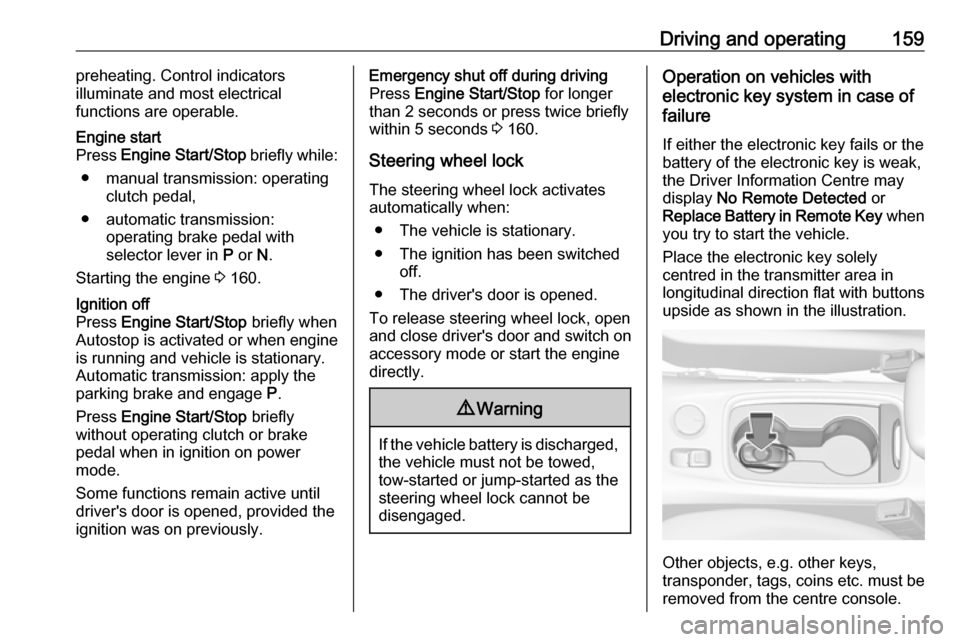

Place the electronic key solely

centred in the transmitter area in

longitudinal direction flat with buttons

upside as shown in the illustration.

Other objects, e.g. other keys,

transponder, tags, coins etc. must be removed from the centre console.

Page 255 of 311

Vehicle care253Tyre designations

E.g. 215/50 R 16 95 H215:Tyre width, mm50:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat16:Wheel diameter, inches95:Load index e.g. 95 is

equivalent to 690 kgH:Speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer

to the EEC Certificate of Conformity

provided with the vehicle or other national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Tyre pressure 3 289.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Make sure tyre loading setting

matches the current tyre pressure.

Tyre loading 3 254.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code.

Page 264 of 311

262Vehicle care

10. Set the rocker switch on thecompressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes.

Tyre pressure 3 289.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Depending on version the button

can be located on the air hose.

Do not run the compressor longer

than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.