lights VAUXHALL COMBO D 2017.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017.5, Model line: COMBO D, Model: VAUXHALL COMBO D 2017.5Pages: 201, PDF Size: 4.7 MB

Page 150 of 201

148Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement, switch on

the ignition, operate and check the

lights.Halogen headlights

Headlights have separate systems for low beam/sidelight 1 (outer bulb),

high beam/daytime running light 2

(inner bulb).

To access bulbs, pull off protective

covers.

Low beam 1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove bulb from reflector.

4.Insert new bulb in reflector so that

the locating tab of the bulb aligns

with the reflector recess.

5. Attach connector to bulb.

6. Engage wire clip.

7. Install protective cover.

High beam 1. Remove protective cover.

2. Detach connector from bulb.

3. Disengage wire clip and remove bulb from reflector.

Page 152 of 201

150Vehicle care

2. Withdraw bulb holder fromreflector by turning anticlockwise.

3. Push bulb into holder slightly, rotate anticlockwise, remove and

renew bulb.

4. Insert bulb holder in reflector.

5. Rotate clockwise to engage.

6. Install protective cover.

Fog lights

Have bulbs replaced by a workshop.

Tail lights

1. Remove the three retaining screws.

2. Remove lamp assembly from vehicle.

3. Disengage connector plug from bulb holder.

4.Unscrew the four retaining screws

using a screwdriver. Turn bulb

holder for reverse light

anticlockwise and replace bulb.

5. Remove bulb holder and seal from lamp assembly.

6. Push bulb into socket slightly, rotate anticlockwise, remove and

renew bulb.

Page 153 of 201

Vehicle care151

Brake light (1)

Turn signal light ( 2)

Tail light ( 3)

Tail light/fog light ( 4)

7. Install seal on bulb holder ensuring it is fitted correctly.

Install bulb holder in lamp

assembly ensuring that it

engages correctly. Tighten the

four retaining screws using a

screwdriver.

8. Install reverse light bulb holder and turn clockwise to tighten.

9. Engage connector plug.

10. Insert lamp assembly in body, ensuring correct positioning.

Tighten the three retaining

screws.

11. Switch on ignition, operate and check all lights.

Side turn signal lights

Have bulbs replaced by a workshop.

Centre high-mounted brake light

Have bulbs replaced by a workshop.Number plate light

Tailgate

1. Insert screwdriver as indicated by

the arrows, press to the side and

release the bulb housing.

Page 154 of 201

152Vehicle care

2.Turn the bulb holder anticlockwise

to remove from the bulb housing.

Remove the bulb by pulling.

3. Replace the bulb.

4. Insert bulb holder in bulb housing and rotate clockwise

5. Install the bulb housing ensuring it

engages correctly.

Rear doors

1. Insert screwdriver as indicated by

the arrows, press to the left and

release the bulb housing.

2. Press bulb slightly towards spring

clip and remove.

3. Replace the bulb.

4. Install the bulb housing ensuring it

engages correctly.

Interior lights

Front and rear courtesy light

1. Remove lens using a flat blade screwdriver.

2. Open the rear cover. 3. Renew bulb.

4. Close rear cover.

5. Reinstall lens.

Page 155 of 201

Vehicle care153Front courtesy light, reading lights

1. Remove lens using a flat bladescrewdriver.

2. Open the rear cover. 3. Renew bulbs.

4. Close rear cover.

5. Reinstall lens.

Removable rear courtesy light

1. Press the button at the top of the lamp assembly to release it.

2.Prise the lamp assembly out at the

points illustrated.

3. Renew bulb, ensuring it engages correctly.

4. Reinstall lamp assembly.

Instrument panel illumination

Have bulbs replaced by a workshop.

Page 158 of 201

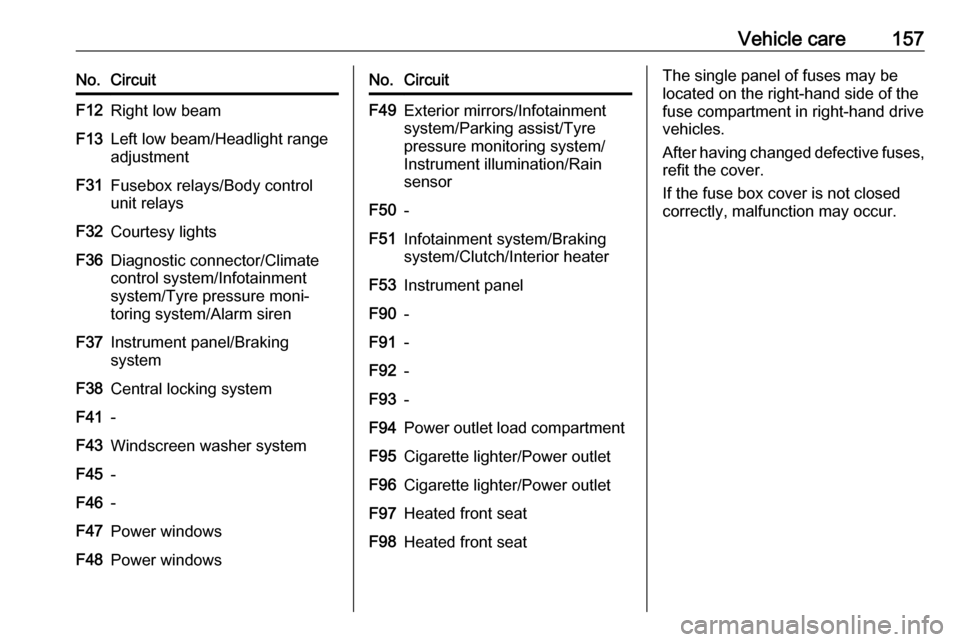

156Vehicle careNo.CircuitF09Rear door switchF10HornF14High beamF15PTCI additional heaterF19Air conditioning systemF20Heated rear windowF21Fuel pumpF30Fog lightsF84CNG systemF85Power outletsF86Cigarette lighter/Heated seatsF87Stop-start systemF88Mirror heating

After having changed defective fuses

refit the fuse box cover.

If the fuse box cover is not closed

correctly, malfunction may occur.

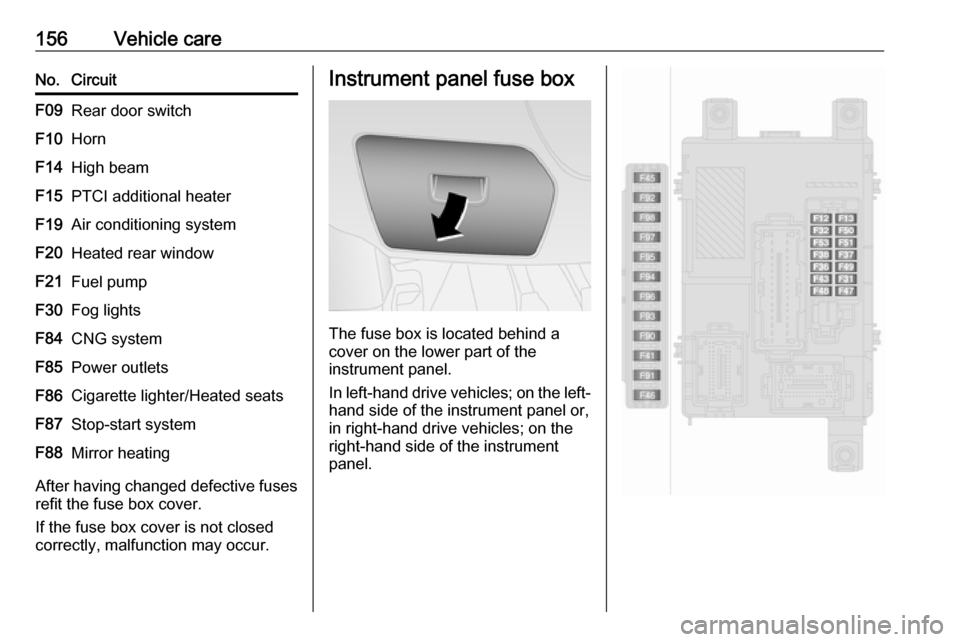

Instrument panel fuse box

The fuse box is located behind a

cover on the lower part of the

instrument panel.

In left-hand drive vehicles; on the left-

hand side of the instrument panel or,

in right-hand drive vehicles; on the

right-hand side of the instrument

panel.

Page 159 of 201

Vehicle care157No.CircuitF12Right low beamF13Left low beam/Headlight range

adjustmentF31Fusebox relays/Body control

unit relaysF32Courtesy lightsF36Diagnostic connector/Climate

control system/Infotainment

system/Tyre pressure moni‐

toring system/Alarm sirenF37Instrument panel/Braking

systemF38Central locking systemF41-F43Windscreen washer systemF45-F46-F47Power windowsF48Power windowsNo.CircuitF49Exterior mirrors/Infotainment

system/Parking assist/Tyre

pressure monitoring system/

Instrument illumination/Rain

sensorF50-F51Infotainment system/Braking

system/Clutch/Interior heaterF53Instrument panelF90-F91-F92-F93-F94Power outlet load compartmentF95Cigarette lighter/Power outletF96Cigarette lighter/Power outletF97Heated front seatF98Heated front seatThe single panel of fuses may be

located on the right-hand side of the

fuse compartment in right-hand drive

vehicles.

After having changed defective fuses,

refit the cover.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 172 of 201

170Vehicle care● The vehicles must not come intocontact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged vehicle battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

one minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 173 of 201

Vehicle care171Towing

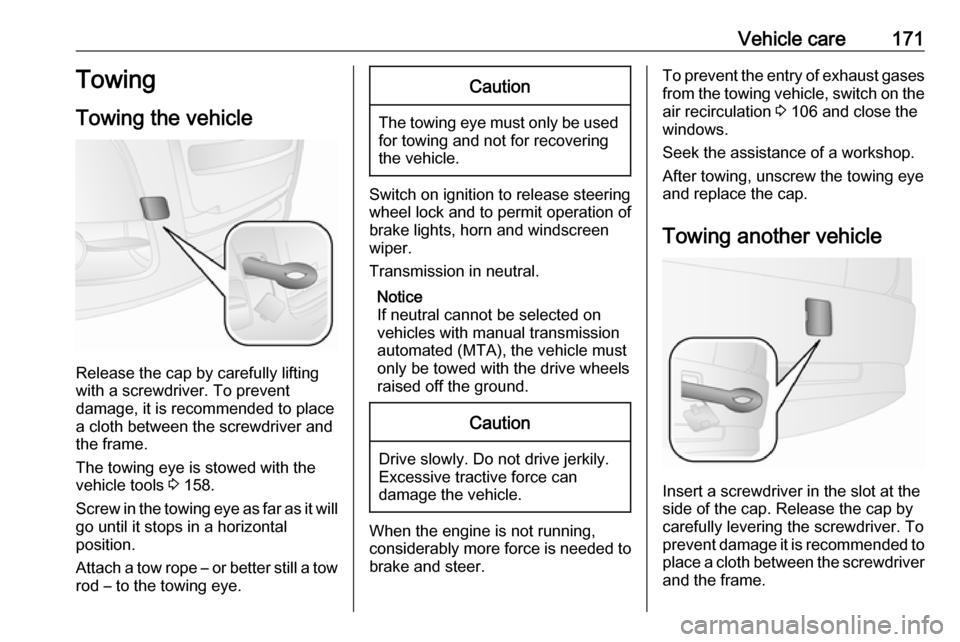

Towing the vehicle

Release the cap by carefully lifting

with a screwdriver. To prevent

damage, it is recommended to place

a cloth between the screwdriver and

the frame.

The towing eye is stowed with the vehicle tools 3 158.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

Caution

The towing eye must only be used for towing and not for recovering

the vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Notice

If neutral cannot be selected on

vehicles with manual transmission

automated (MTA), the vehicle must

only be towed with the drive wheels

raised off the ground.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation 3 106 and close the

windows.

Seek the assistance of a workshop. After towing, unscrew the towing eye

and replace the cap.

Towing another vehicle

Insert a screwdriver in the slot at the

side of the cap. Release the cap by

carefully levering the screwdriver. To

prevent damage it is recommended to place a cloth between the screwdriver

and the frame.

Page 175 of 201

Vehicle care173Do not clean the engine compartment

with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Unpainted plastic body parts must not be treated with wax or polishing

agents.

Matt filmed body parts or decor tapes must not be polished, to avoid

gleaming. Do not use hot wax

programmes in automatic car washes if the vehicle is equipped with these

parts.

Matt painted decor parts, e.g. mirror

housing cover, must not be polished. Otherwise these parts would become

agleam or the colour would be

dissolved.

Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and

window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous wiping on dry windows will damage or

even destroy the wiper blades.

Glass panel

Never clean with solvents or abrasive agents, fuels, aggressive media (e.g.

paint cleaner, acetone-containing

solutions etc.), acidic or highly

alkaline media or abrasive pads. Do

not apply wax or polishing agents to

the glass panel.

Wheels and tyres Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.