brake VAUXHALL COMBO E 2020 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: COMBO E, Model: VAUXHALL COMBO E 2020Pages: 279, PDF Size: 28.6 MB

Page 219 of 279

Vehicle care217

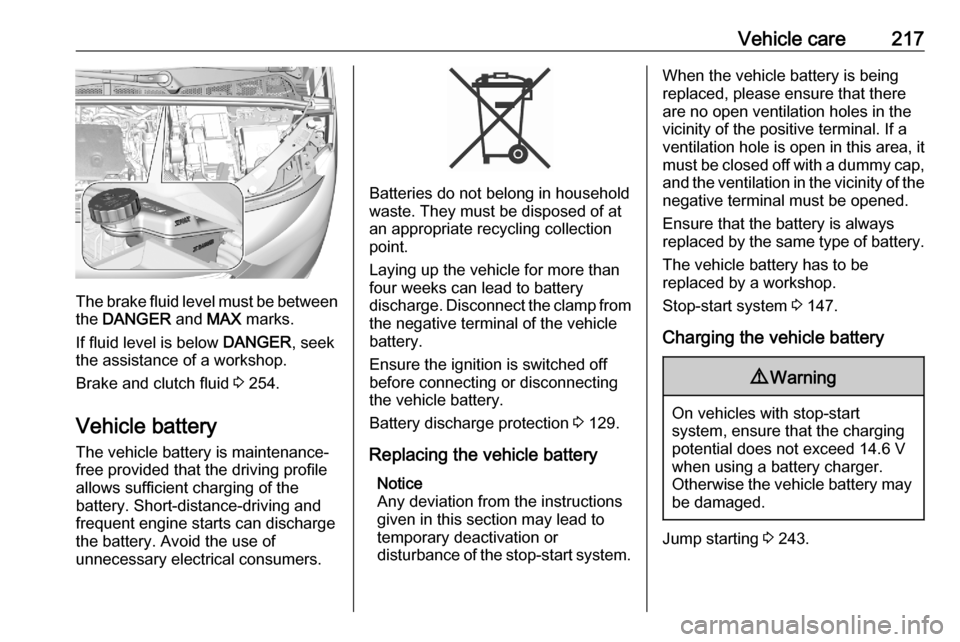

The brake fluid level must be betweenthe DANGER and MAX marks.

If fluid level is below DANGER, seek

the assistance of a workshop.

Brake and clutch fluid 3 254.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Battery discharge protection 3 129.

Replacing the vehicle battery Notice

Any deviation from the instructions

given in this section may lead to

temporary deactivation or

disturbance of the stop-start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap,

and the ventilation in the vicinity of the negative terminal must be opened.

Ensure that the battery is always

replaced by the same type of battery.

The vehicle battery has to be

replaced by a workshop.

Stop-start system 3 147.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed 14.6 V

when using a battery charger.

Otherwise the vehicle battery may be damaged.

Jump starting 3 243.

Page 227 of 279

Vehicle care2255. Push the bulb slightly down, turnit and remove it from the bulb

carrier. Replace the bulb:

Rear fog light ( 1)

Reversing light ( 2)

Turn light / hazard warning flasher ( 3 )

Tail light / brake light ( 4)

6. Attach the bulb carrier to the light assembly.

7. Attach the cable to the retainer.

8. Attach the light assembly to the vehicle body and tighten both

screws.

Vehicle with rear doors1. Unscrew and remove the two screws.

2. Carefully withdraw the tail lightassembly from recess and

remove. Take care that the cable

duct remains in position.

3. Detach the cable from the retainer.

4. Disengage the retaining lugs toremove the bulb carrier.

5. Push the bulb slightly down, turnit and remove it from the bulb

carrier. Replace the bulb:

Page 228 of 279

226Vehicle careTail light / brake light (1)

Turn light / hazard warning flasher ( 2 ) outer bulb

Reversing light ( 3) inner bulb

Rear fog light ( 4)

6. Attach the bulb carrier to the light assembly.

7. Attach the cable to the retainer. 8. Attach the light assembly to the vehicle body and tighten both

screws.

3rd-brake light The 3rd-brake light is designed as

LED and can not be changed.

Have lights repaired by a workshop in case of failure.

Bulb check

Switch on the ignition, operate and

check all lights.Side turn lights

To replace the bulb, remove the lamp

housing:

1. Slide the lamp housing forward and remove it at the back.

2. Press the retaining lug upwardsand remove the bulb socket from

the plug connector.

3. Replace the complete unit.

4. Insert left end of the lamp, slide to

the left and insert right end.

Page 235 of 279

Vehicle care233information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Tyre deflation detectionsystem

The tyre deflation detection system

continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values and further

signals.

If a tyre loses pressure the control

indicator w illuminates, a warning

chime is given and a warning

message is displayed in the Driver

Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 105.After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.Caution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used. Once the road tyre has

been refitted, check the tyre pressure with cold tyres and initialise the

system.

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

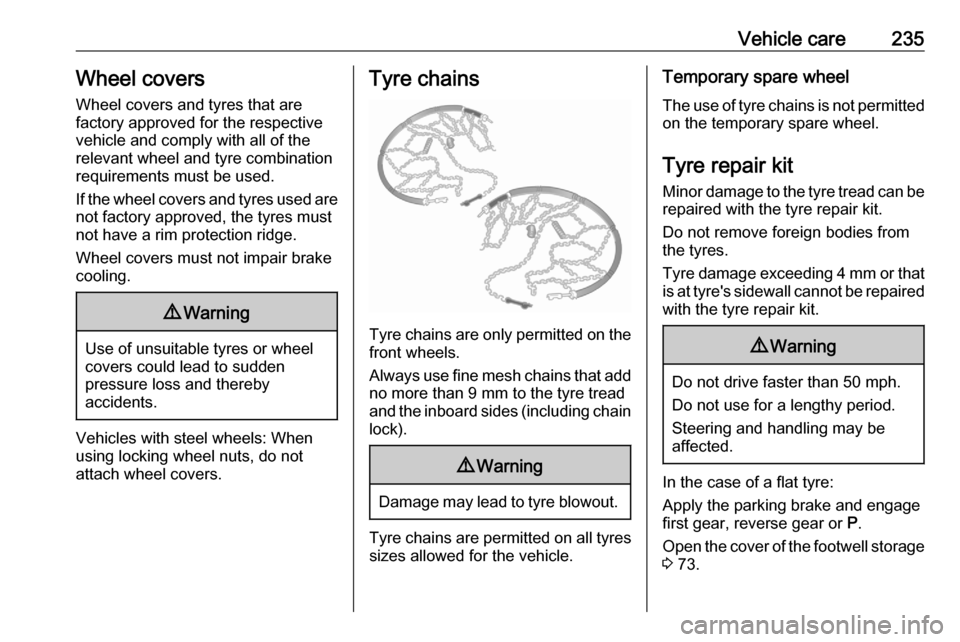

1. Always ensure that all four tyres have correct tyre pressure

3 263.

2. Apply parking brake.

3. Initialise the deflation detection system: If the vehicle has a

graphic info display, press F for

three seconds. If the vehicle has a

colour info display, the

initialisation is done in the vehicle

personalisation 3 115.

4. Reset is confirmed by pop-up indication.

Page 237 of 279

Vehicle care235Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on all tyres

sizes allowed for the vehicle.

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

In the case of a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

Open the cover of the footwell storage

3 73.

Page 240 of 279

238Vehicle care

16. Continue driving immediately sothat sealant is evenly distributed

in the tyre. After driving approx.

three miles but no more than ten

minutes, stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve when

doing this. Fill tyre as described

before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 150 kPa (1.5 bar), set it to

the correct value. Otherwise the

vehicle must not be used. Seek

assistance of a workshop. 3 263

Repeat the checking procedure

once more after driving further

three miles but no more than ten

minutes to check that there is no

more loss of pressure.

If the tyre pressure has fallen

below 150 kPa (1.5 bar), the

vehicle must not be used. Seek

the assistance of a workshop.

17. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of seven bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear orP .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

Page 243 of 279

Vehicle care2415. Change the wheel.

6. Position the damaged wheel with the outside down in the spare

wheel holder.

7. Lift the spare wheel holder and engage in the catch. The open

side of the catch must point in the direction of travel.

8. Close the spare wheel holder by turning the hexagon bolt

clockwise using the wheel

wrench.

9. Stow wheel wrench in the storage.

10. Close the tailgate or the rear doors.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 240.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

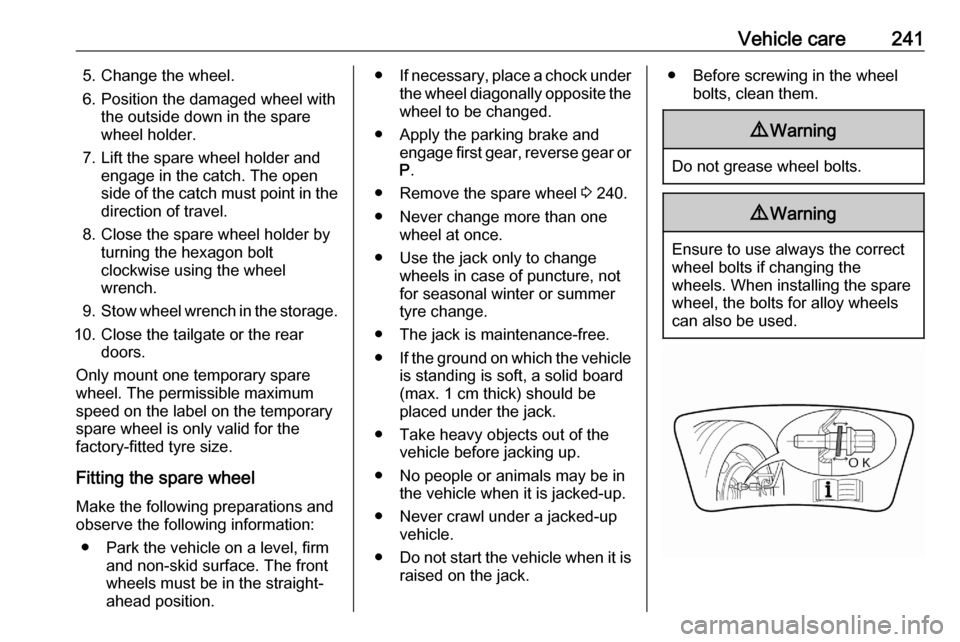

raised on the jack.● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

9Warning

Ensure to use always the correct

wheel bolts if changing the

wheels. When installing the spare

wheel, the bolts for alloy wheels can also be used.

Page 246 of 279

244Vehicle care● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than 15 s at an interval of 1 min.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers e.g. headlights, heated rear

window of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 247 of 279

Vehicle care245Towing

Towing the vehicle

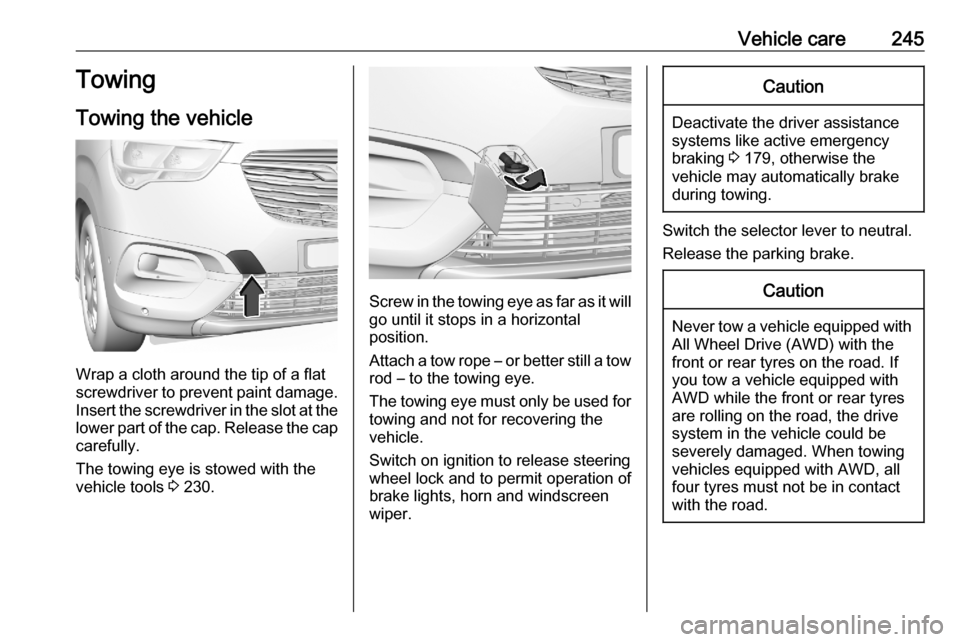

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

lower part of the cap. Release the cap carefully.

The towing eye is stowed with the

vehicle tools 3 230.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 179, otherwise the

vehicle may automatically brake during towing.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Never tow a vehicle equipped with All Wheel Drive (AWD) with the

front or rear tyres on the road. If

you tow a vehicle equipped with

AWD while the front or rear tyres

are rolling on the road, the drive

system in the vehicle could be

severely damaged. When towing

vehicles equipped with AWD, all

four tyres must not be in contact

with the road.

Page 248 of 279

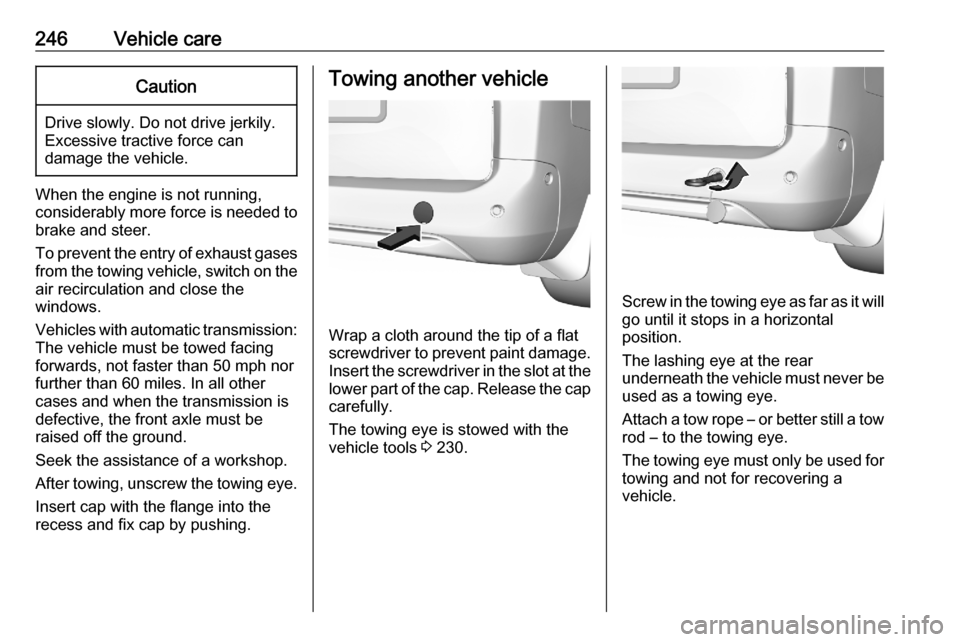

246Vehicle careCaution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap with the flange into the

recess and fix cap by pushing.

Towing another vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

lower part of the cap. Release the cap carefully.

The towing eye is stowed with the

vehicle tools 3 230.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

The lashing eye at the rear

underneath the vehicle must never be used as a towing eye.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering a

vehicle.