lock VAUXHALL CORSA 2016 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: CORSA, Model: VAUXHALL CORSA 2016Pages: 267, PDF Size: 7.79 MB

Page 149 of 267

Driving and operating147Manual transmission

To engage reverse, depress the

clutch pedal and then press the

release button on the selector lever

and engage the gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not slip the clutch unnecessarily.

When operating, depress the clutch

pedal completely. Do not use the

pedal as a foot rest.

Caution

It is not advisable to drive with the hand resting on the selector lever.

Gear shift indication 3 92.

Stop-start system 3 138.

Manual transmission

automated

The automated manual transmission permits manual gearshifting (manual

mode) or automatic gearshifting

(automatic mode), both with

automatic clutch control.

Manual shifting is possible by tapping the selector lever in manual mode.

Notice

When unlocking or opening a

vehicle door, a sound may be

audible caused by the hydraulic

system.

Page 153 of 267

Driving and operating151Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing the journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 92.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting-off the system performs

a self-test which may be audible.

Control indicator u 3 92.

Adaptive brake light

During full braking, all three brake

lights flash for the duration of ABS

control.Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

Page 158 of 267

156Driving and operatingoff. In this case, switch on ignition andturn steering wheel once from lock to

lock.

If control indicators c and b do not

extinguish after calibration, seek the

assistance of a workshop.Driver assistance

systems9 Warning

Driver assistance systems are

developed to support the driver

and not to replace the driver's

attention.

The driver accepts full

responsibility when driving the

vehicle.

When using driver assistance

systems, always take care

regarding the current traffic

situation.

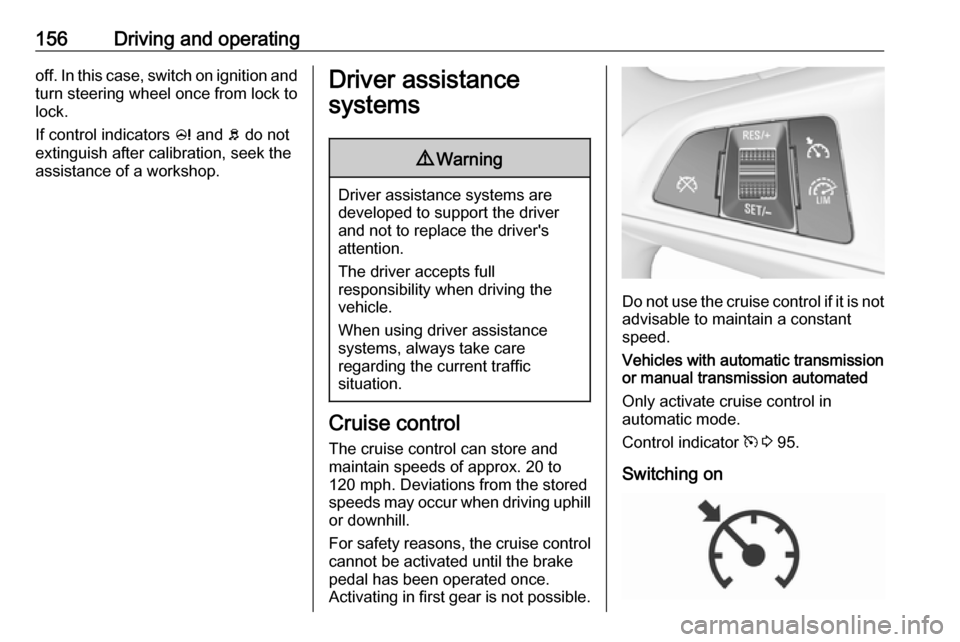

Cruise control

The cruise control can store and

maintain speeds of approx. 20 to

120 mph. Deviations from the stored

speeds may occur when driving uphill or downhill.

For safety reasons, the cruise control cannot be activated until the brake

pedal has been operated once.

Activating in first gear is not possible.

Do not use the cruise control if it is not advisable to maintain a constant

speed.

Vehicles with automatic transmission

or manual transmission automated

Only activate cruise control in

automatic mode.

Control indicator m 3 95.

Switching on

Page 163 of 267

Driving and operating161The complete attention of the

driver is always required while

driving. The driver must always be

ready to take action and apply the

brakes.

System limitations

The system is designed to warn of vehicles only, but may react also to

other objects.

In the following cases, forward

collision alert may not detect a vehicle ahead or sensor performance is

limited:

● on winding roads

● when weather limits visibility, e.g.

fog, rain, or snow

● when the sensor is blocked by snow, ice, slush, mud, dirt, or

windscreen damage

Following distance

indication

The following distance indication

displays the distance to a preceding

moving vehicle. The front camera in

the windscreen is used to detect the

distance of a vehicle directly ahead in

the vehicle's path. It is active at

speeds above 25 mph.

When a preceding vehicle is detected

ahead, the distance is indicated in

seconds, displayed on a page in the

Driver Information Centre 3 96 . Press

MENU on the turn signal lever to

select Vehicle Information

Menu ? and turn the adjuster

wheel to choose following distance

indication page.

The minimum indicated distance is

0.5 seconds.

If there is no vehicle ahead or the vehicle ahead is out of range, two

dashes will be displayed: -.- sec.

Parking assist Rear parking assist9 Warning

It is the driver who bears full

responsibility for the parking

manoeuvre.

Always check the surrounding

area while reversing and using the rear parking assist system.

The rear parking assist makes

parking easier by measuring the

distance between the vehicle and

rear obstacles. It informs and warns

the driver by giving acoustic signals

and display indication.

Page 183 of 267

Driving and operating1819Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

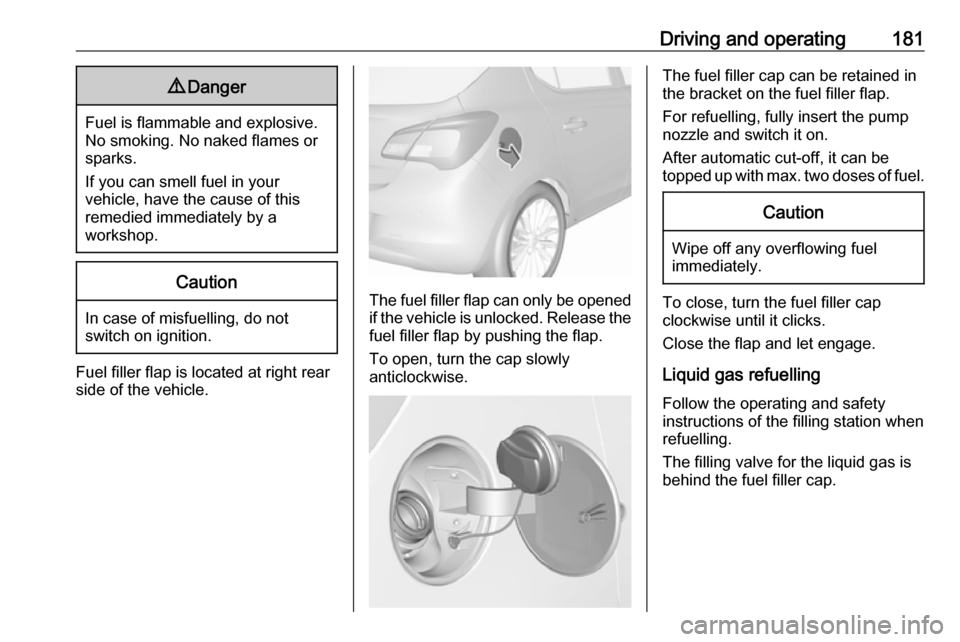

Fuel filler flap is located at right rear

side of the vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

To open, turn the cap slowly

anticlockwise.

The fuel filler cap can be retained in

the bracket on the fuel filler flap.

For refuelling, fully insert the pump

nozzle and switch it on.

After automatic cut-off, it can be

topped up with max. two doses of fuel.Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and let engage.

Liquid gas refuelling

Follow the operating and safety

instructions of the filling station when

refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

Page 184 of 267

182Driving and operating

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle. Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

Page 188 of 267

186Driving and operatingGeneral

If the permitted rear axle load is

exceeded a maximum speed of

60 mph applies. If lower national

maximum speeds are specified for

trailer operation, they must be

complied with.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The coupling ball bar is stowed in a

bag in the spare wheel well and

secured to the lashing eyes in the

load compartment.

When inserting, fit protective cap over rotary knob with key.

Fitting the coupling ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

● The rotary knob rests on the

coupling ball bar.

● Green marking on the rotary knob is not visible.

● Locking pin at the top of the coupling ball bar is set inwards.

● The key is in the lock.

Page 189 of 267

Driving and operating187Otherwise, the coupling ball bar must

be tensioned before it is inserted into

the coupling housing:

● Place the key in the lock and unlock the coupling ball bar.

● Push the rotary knob onto the coupling ball bar and rotate right

while pressed down until it

engages. The key remains in the

lock.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary knob snaps back into its

original position resting against the

coupling ball bar without a gap.

9 Warning

Do not touch rotary knob during

insertion.

Green marking on the rotary knob is

visible.

Lock coupling ball bar and remove key.

Page 190 of 267

188Driving and operatingEye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob is visible.

● There must be no gap between the rotary knob and the coupling

ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.

9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Insert the key in the lock and unlock

the coupling ball bar.

Push the rotary knob onto the

coupling ball bar and rotate right while pressed down until it engages. Pull

out the ball bar downwards.

Insert sealing plug in opening for

coupling ball bar. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 154.

Page 192 of 267

190Vehicle careGeneral Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps may be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website. Only entrust this work to an

authorised recycling centre.