brake VAUXHALL CROSSLAND X 2020 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: CROSSLAND X, Model: VAUXHALL CROSSLAND X 2020Pages: 245, PDF Size: 21.85 MB

Page 195 of 245

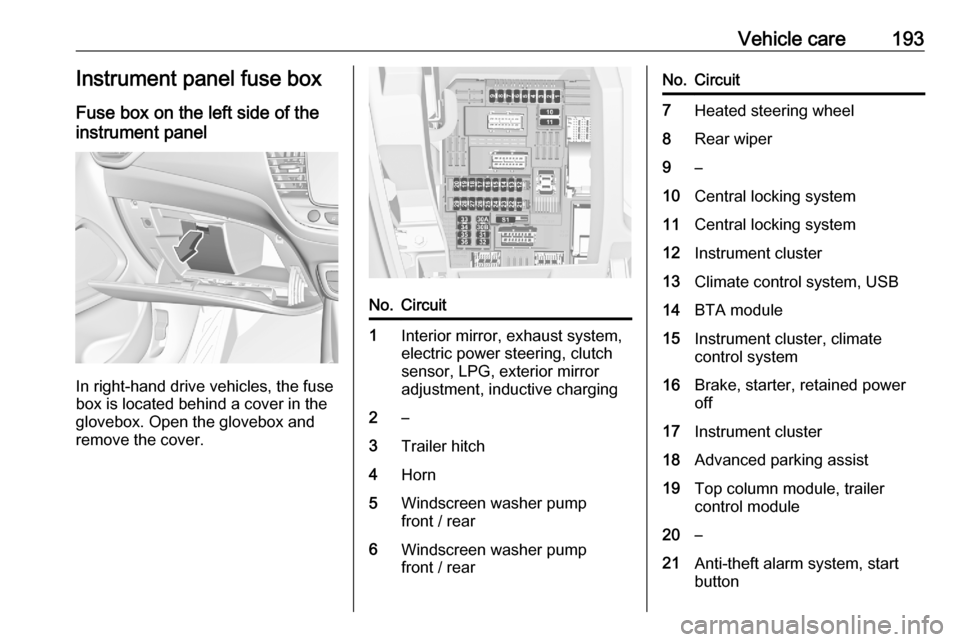

Vehicle care193Instrument panel fuse boxFuse box on the left side of the

instrument panel

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

No.Circuit1Interior mirror, exhaust system,

electric power steering, clutch

sensor, LPG, exterior mirror

adjustment, inductive charging2–3Trailer hitch4Horn5Windscreen washer pump

front / rear6Windscreen washer pump

front / rearNo.Circuit7Heated steering wheel8Rear wiper9–10Central locking system11Central locking system12Instrument cluster13Climate control system, USB14BTA module15Instrument cluster, climate

control system16Brake, starter, retained power

off17Instrument cluster18Advanced parking assist19Top column module, trailer

control module20–21Anti-theft alarm system, start

button

Page 200 of 245

198Vehicle careCaution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction.

Once the road tyre has been refitted,

check the tyre pressure with cold

tyres and initialise the system.

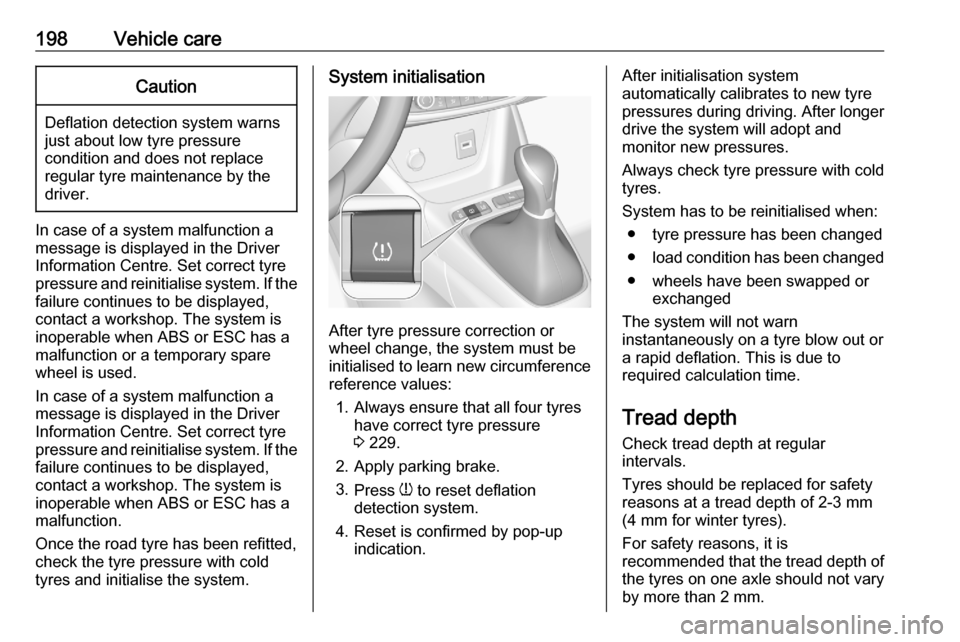

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

1. Always ensure that all four tyres have correct tyre pressure3 229.

2. Apply parking brake. 3. Press w to reset deflation

detection system.

4. Reset is confirmed by pop-up indication.

After initialisation system

automatically calibrates to new tyre

pressures during driving. After longer

drive the system will adopt and

monitor new pressures.

Always check tyre pressure with cold

tyres.

System has to be reinitialised when: ● tyre pressure has been changed

● load condition has been changed

● wheels have been swapped or exchanged

The system will not warn

instantaneously on a tyre blow out or

a rapid deflation. This is due to

required calculation time.

Tread depthCheck tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of the tyres on one axle should not vary

by more than 2 mm.

Page 201 of 245

Vehicle care199

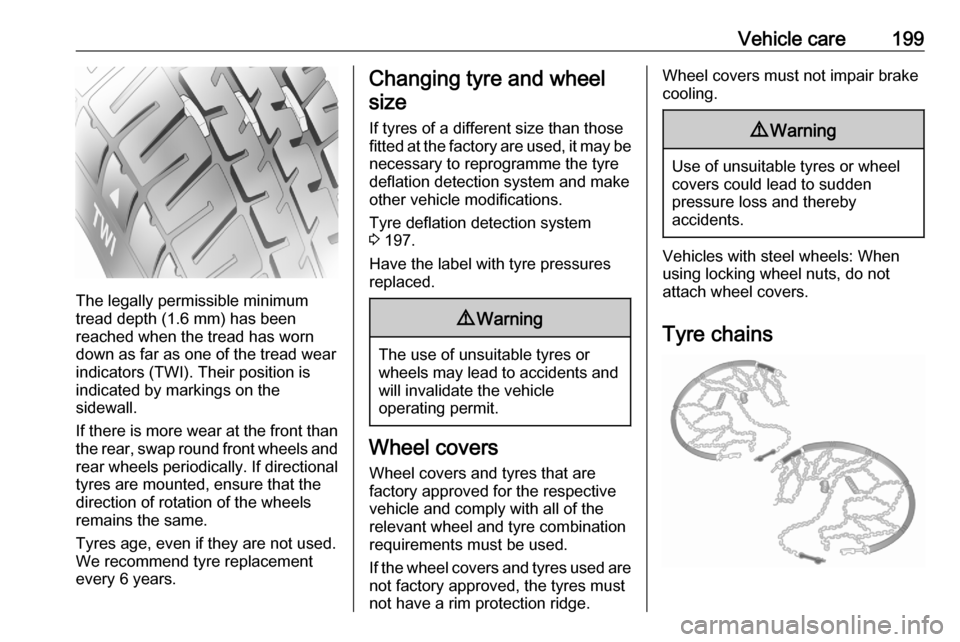

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. If directional

tyres are mounted, ensure that the

direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the tyre

deflation detection system and make other vehicle modifications.

Tyre deflation detection system

3 197.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Page 202 of 245

200Vehicle careTyre chains are only permitted on thefront wheels.

Always use fine mesh chains that add

no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 195/65 R15 91 and

195/60 R16 89

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

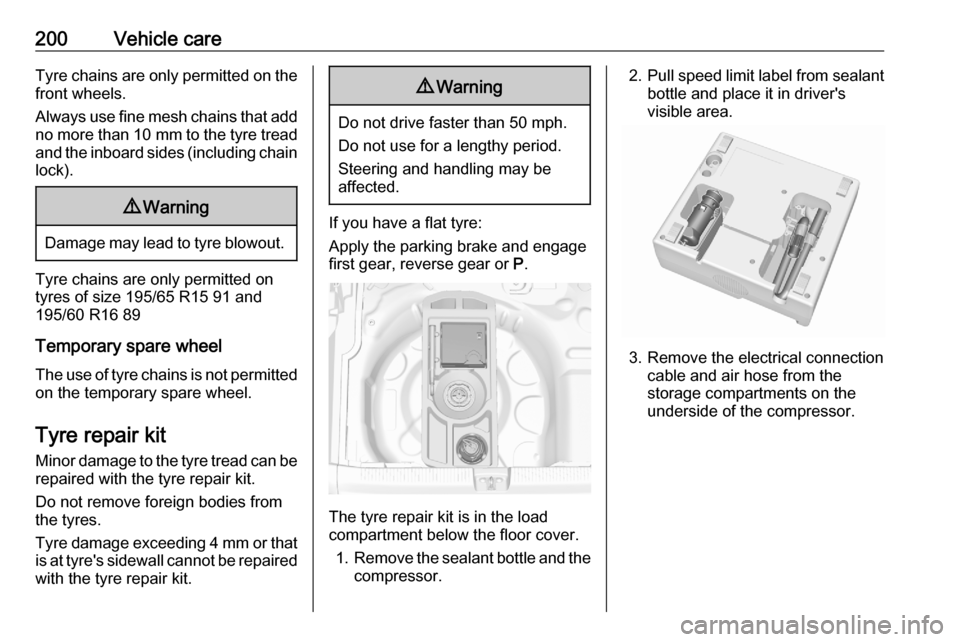

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.

9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in the load

compartment below the floor cover.

1. Remove the sealant bottle and the

compressor.

2. Pull speed limit label from sealant

bottle and place it in driver's

visible area.

3. Remove the electrical connection cable and air hose from the

storage compartments on the

underside of the compressor.

Page 205 of 245

Vehicle care203The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Wheel changing Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

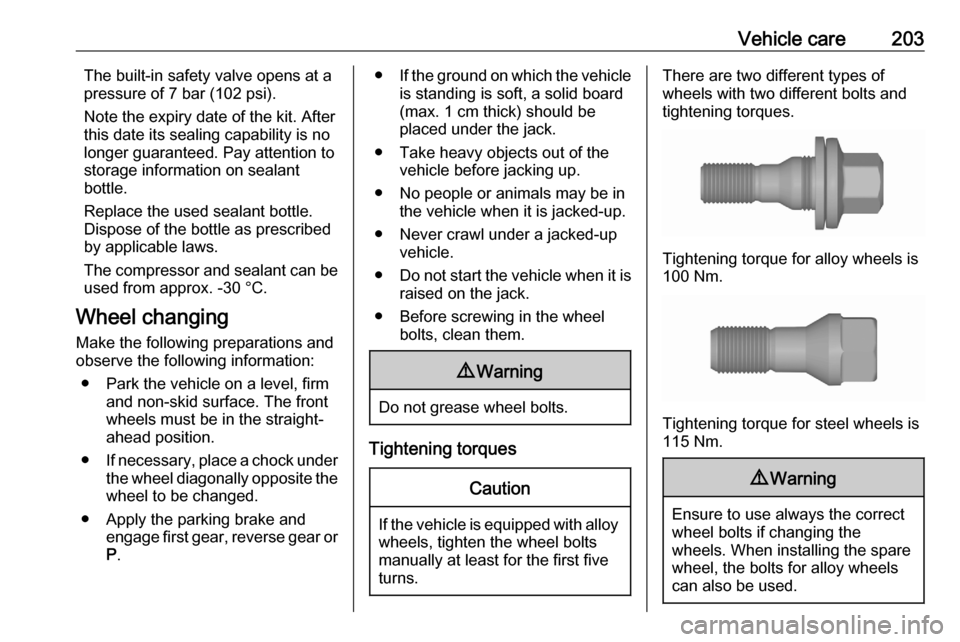

There are two different types of

wheels with two different bolts and tightening torques.

Tightening torque for alloy wheels is

100 Nm.

Tightening torque for steel wheels is

115 Nm.

9 Warning

Ensure to use always the correct

wheel bolts if changing the

wheels. When installing the spare

wheel, the bolts for alloy wheels can also be used.

Page 211 of 245

Vehicle care209● The vehicles must not come intocontact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage.

Insert a screwdriver in the slot at the

bottom of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the vehicle tools 3 195.

Page 212 of 245

210Vehicle care

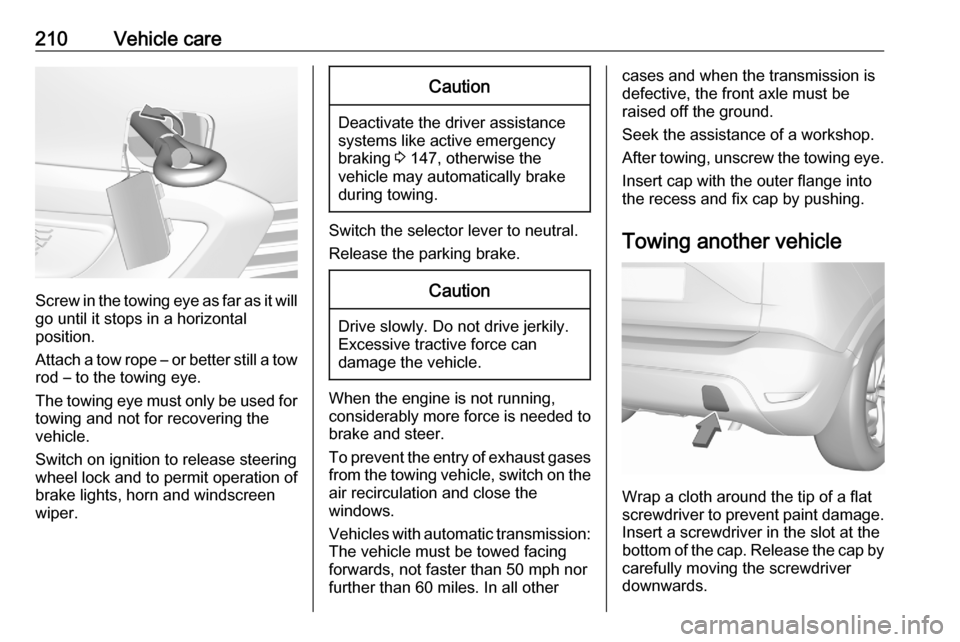

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 147, otherwise the

vehicle may automatically brake during towing.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap with the outer flange into

the recess and fix cap by pushing.

Towing another vehicle

Wrap a cloth around the tip of a flat

screwdriver to prevent paint damage.

Insert a screwdriver in the slot at the

bottom of the cap. Release the cap by carefully moving the screwdriver

downwards.

Page 216 of 245

214Vehicle carePlastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior

cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Floor mats9 Warning

If a floor mat has the wrong size or

is not properly installed, it can

interfere with the accelerator pedal

and/or brake pedal, what can

cause unintended acceleration

and/or increased stopping

distance which can cause a crash and injury.

Use the following guidelines for

proper floor mat usage.

● The original equipped floor mats were designed for your vehicle.

Have damaged floor mats only

replaced by certified floor mats.

Always check that the floor mats

do not interfere with the pedals.

● Use the floor mat with the correct

side up. Do not turn it over.

● Do not place anything on top of the driver's side floor mat.

● Use only a single floor mat on the

driver's side.

Installing and removing the floor

mats

The driver's side floor mat and the

passenger's side floor mat are each

held in place by two retainers.

To install the floor mat: 1. Move the seat backwards as far as possible.

2. Align slots in the mat with the retainers, as shown.

3. Push the mat to the floor.

To remove the floor mat: 1. Move the seat backwards as far as possible.

2. Pull the floor mat upwards to remove.

Page 222 of 245

220Service and maintenanceadditional coolant additives that

intend to give additional corrosion

protection or seal against minor leaks

can cause function problems. Liability

for consequences resulting from the

use of additional coolant additives will be rejected.

Washer fluid Use only washer fluid approved for

the vehicle to prevent damage of

wiper blades, paintwork, plastic and

rubber parts. Consult a workshop.

Brake fluid Over time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should

therefore be replaced at the specified

interval.

AdBlue

Only use AdBlue to reduce the

nitrogen oxides in the exhaust

emission 3 130.

Page 236 of 245

234Customer informationVehicle data recording

and privacy

Event data recorders

Electronic control units are installed in

your vehicle. Control units process

data which is received e.g. by vehicle sensors, or which they generate

themselves or exchange amongst

themselves. Some control units are

necessary for the safe functioning of

your vehicle, others assist you while

you drive (driver assistance systems),

while others provide comfort or

infotainment functions.

The following contains general

information about data processing in

the vehicle. You will find additional

information as to which specific data

is uploaded, stored and passed on to third parties and for what purpose in

your vehicle under the key word Data Protection closely linked to the

references for the affected functional

characteristics in the relevant

Owner's Manual or in the general

terms of sale. These are also

available online.Operating data in the vehicle

Control units process data for

operation of the vehicle.

This data may include: ● vehicle status information (e.g. speed, movement delay, lateral

acceleration, wheel rotation rate,

"seat belts fastened" display)

● ambient conditions (e.g. temperature, rain sensor,

distance sensor)

As a rule such data is transient and is

not stored for longer than an

operational cycle, and only processed

on board the vehicle itself. Often

control units include data storage

(including the vehicle key). This is

used to allow information to be

documented temporarily or

permanently on vehicle condition,

component stress, maintenance

requirements and technical events

and errors.Depending on technical equipment

levels, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggeringof an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used where necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.