lock VAUXHALL INSIGNIA 2015.5 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: INSIGNIA, Model: VAUXHALL INSIGNIA 2015.5Pages: 331, PDF Size: 9.08 MB

Page 194 of 331

192Driving and operating

Emergency automatic brakingAfter the brake preparation and just

before the imminent collision, this

function automatically applies limited

braking to reduce the impact speed of the collision.

Below a speed of 11 mph the system

can apply full braking.

Forward looking brake assist

In addition to the brake preparation

system and emergency automatic

braking, the forward looking brake

assist function makes the brake assist more sensitive. Therefore,

depressing the brake pedal less

strongly results in immediate hard

braking. This function helps the driver brake quicker and harder before the

imminent collision.9 Warning

Active emergency braking is not

designed to apply hard

autonomous braking or to

automatically avoid a collision. It is designed to reduce the vehicle

speed before a collision. It may not

react for stopped vehicles,

pedestrians or animals. After a

sudden lane change, the system

needs a certain time to detect the

next preceding vehicle.

The complete attention of the

driver is always required while

driving. The driver shall always be ready to take action and apply the

brakes and steer to avoid

collisions. The system is designed to work with all occupants wearingtheir seat belts.

System limitations

The active emergency braking has

limited or no function during rain,

snow or heavy dirt, as the radar

sensor can be covered by a water

film, dust, ice or snow. In case of

sensor blockage, clean the sensor

cover.

In some cases, the active emergency braking system may provide an

automatic braking in situations that

seem to be unnecessary, for instance

in parking garages, due to traffic signs

in a curve or due to vehicles in

another lane. This is normal

operation, the vehicle does not need

service. Firmly apply the accelerator

pedal to override the automatic

braking.

Settings Settings can be changed in the

vehicle personalisation menu in the

Colour-Info-Display.

Select the relevant setting in Settings,

I Vehicle in the Colour-Info-Display.

Colour-Info-Display 3 118.

Vehicle personalisation 3 122.

Fault In the event of a system service

requirement, a message is displayed

in the Driver Information Centre.

Page 215 of 331

Driving and operating213

Turn the thumb wheel clockwise.

If no further gas odour is perceptible

when the manual shut-off valve is

closed, the vehicle can be used in

petrol mode. If the gas odour persists, do not start the engine. Have the

cause of the fault remedied by a workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Notice

In the event of an accident, switch off

the ignition and lights. Close the

manual shut-off valve on multivalve.

Refuelling9 Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

Fuel filler flap is located at right rear

side of vehicle.

Page 216 of 331

214Driving and operating

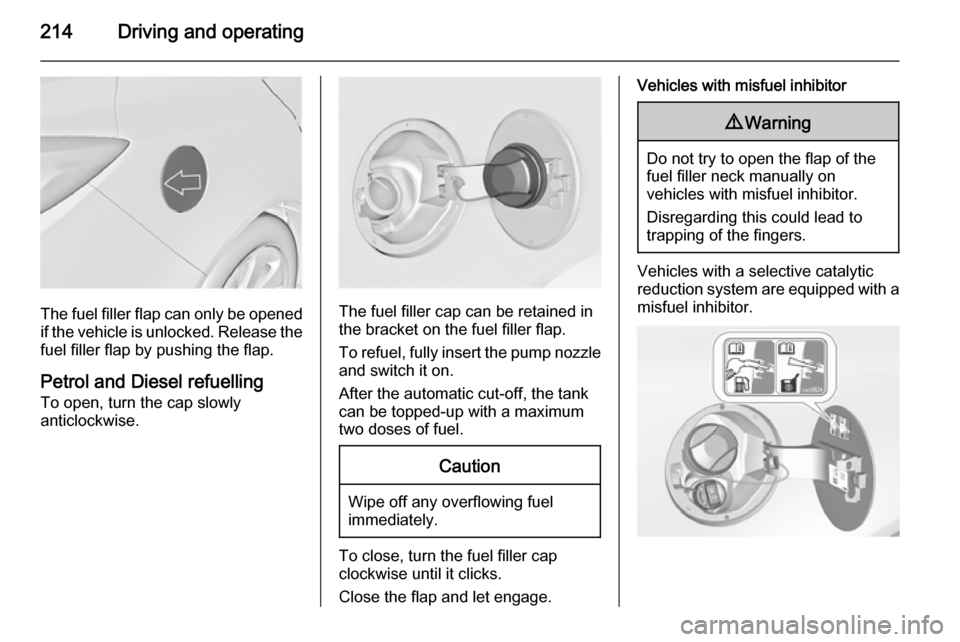

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

Petrol and Diesel refuelling

To open, turn the cap slowly

anticlockwise.The fuel filler cap can be retained in

the bracket on the fuel filler flap.

To refuel, fully insert the pump nozzle

and switch it on.

After the automatic cut-off, the tank can be topped-up with a maximum

two doses of fuel.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and let engage.

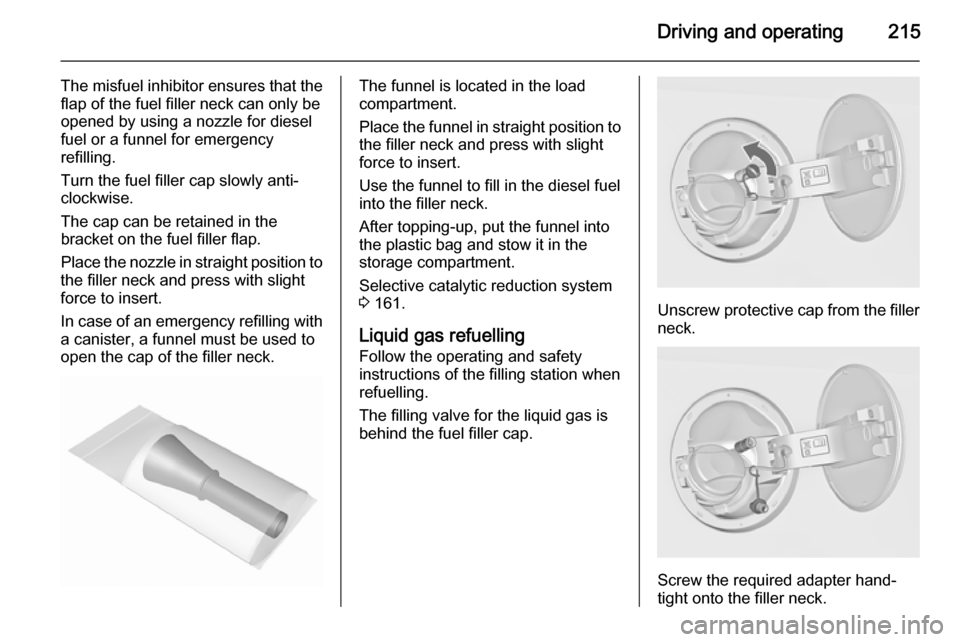

Vehicles with misfuel inhibitor9 Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

Vehicles with a selective catalytic

reduction system are equipped with a

misfuel inhibitor.

Page 217 of 331

Driving and operating215

The misfuel inhibitor ensures that theflap of the fuel filler neck can only be

opened by using a nozzle for diesel

fuel or a funnel for emergency

refilling.

Turn the fuel filler cap slowly anti-

clockwise.

The cap can be retained in the

bracket on the fuel filler flap.

Place the nozzle in straight position to

the filler neck and press with slight

force to insert.

In case of an emergency refilling with a canister, a funnel must be used to

open the cap of the filler neck.The funnel is located in the load

compartment.

Place the funnel in straight position to the filler neck and press with slight

force to insert.

Use the funnel to fill in the diesel fuel

into the filler neck.

After topping-up, put the funnel into

the plastic bag and stow it in the storage compartment.

Selective catalytic reduction system

3 161.

Liquid gas refuelling Follow the operating and safety

instructions of the filling station when refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

Page 218 of 331

216Driving and operating

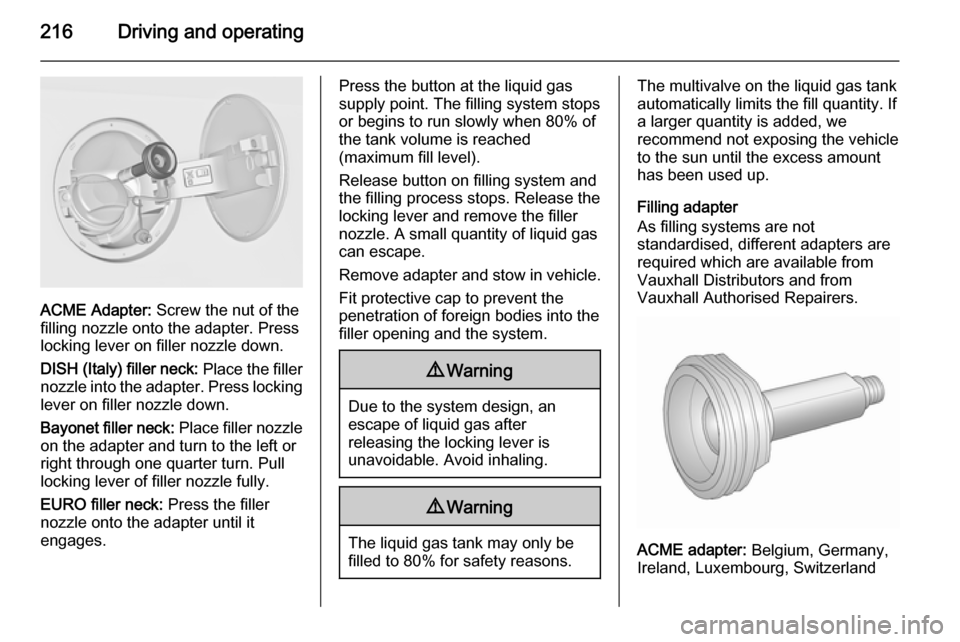

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button at the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 225 of 331

Vehicle care223

■ Open bonnet, close all doors andlock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are

not functional, e.g. anti-theft alarm

system.

Putting back into operation

When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.

End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on ourwebsite, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 235 of 331

Vehicle care233

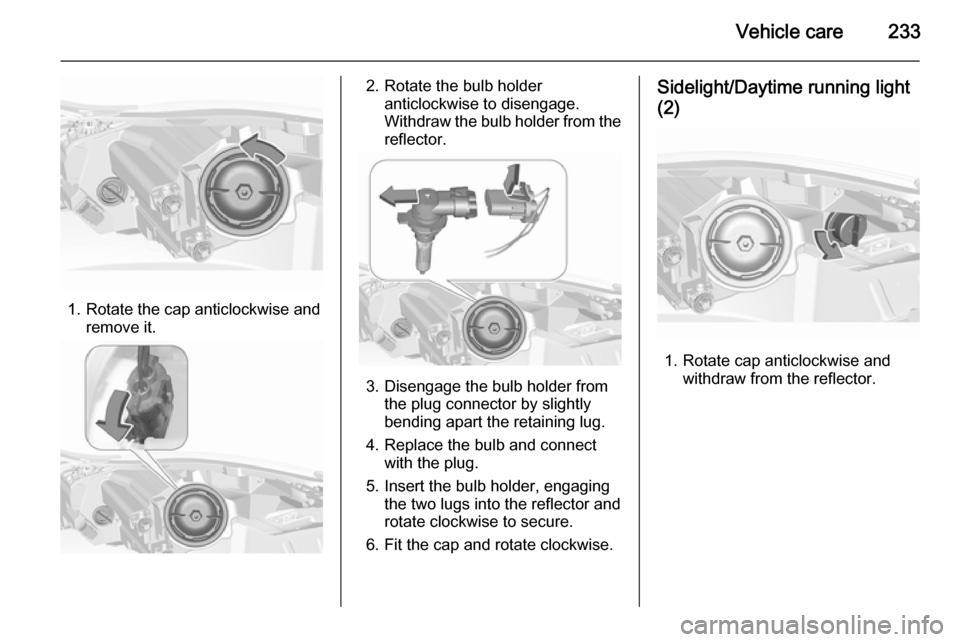

1. Rotate the cap anticlockwise andremove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by slightly

bending apart the retaining lug.

4. Replace the bulb and connect with the plug.

5. Insert the bulb holder, engaging the two lugs into the reflector androtate clockwise to secure.

6. Fit the cap and rotate clockwise.

Sidelight/Daytime running light

(2)

1. Rotate cap anticlockwise and withdraw from the reflector.

Page 236 of 331

234Vehicle care

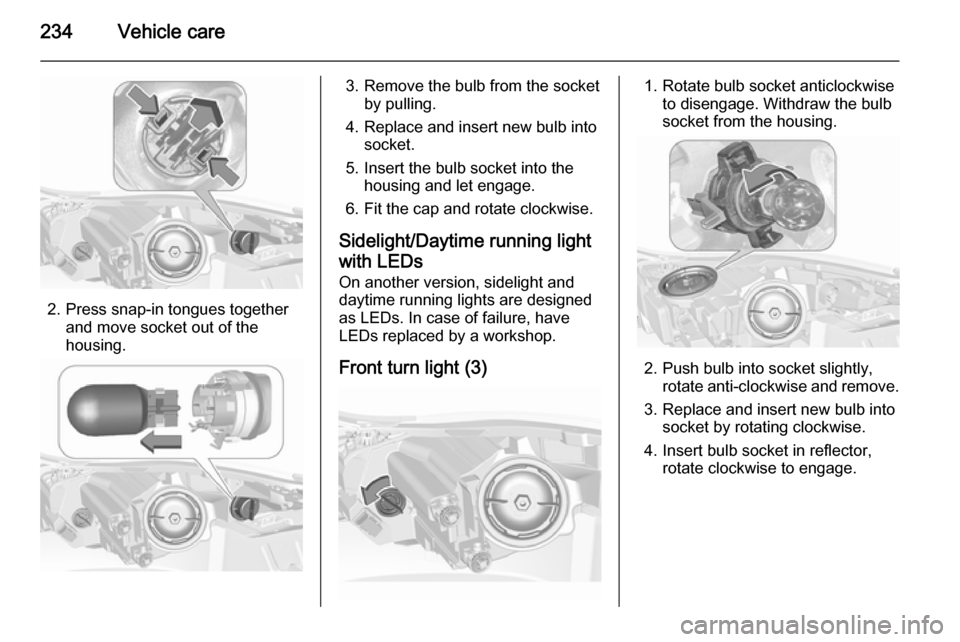

2. Press snap-in tongues togetherand move socket out of the

housing.

3. Remove the bulb from the socket by pulling.

4. Replace and insert new bulb into socket.

5. Insert the bulb socket into the housing and let engage.

6. Fit the cap and rotate clockwise.

Sidelight/Daytime running light with LEDs

On another version, sidelight and

daytime running lights are designed

as LEDs. In case of failure, have

LEDs replaced by a workshop.

Front turn light (3)1. Rotate bulb socket anticlockwise to disengage. Withdraw the bulb

socket from the housing.

2. Push bulb into socket slightly, rotate anti-clockwise and remove.

3. Replace and insert new bulb into socket by rotating clockwise.

4. Insert bulb socket in reflector, rotate clockwise to engage.

Page 237 of 331

Vehicle care235Xenon headlights9Danger

Adaptive forward lighting system

uses Xenon headlights.

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Bulbs for front turn signal and

corner lighting can be changed.

Sidelight/Daytime running lights are

designed as Light Emitting Diodes

(LEDs) and cannot be replaced.

Corner lighting

1. Rotate the cap anticlockwise and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb from the plug connector by unlatching and

pulling.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Page 238 of 331

236Vehicle care

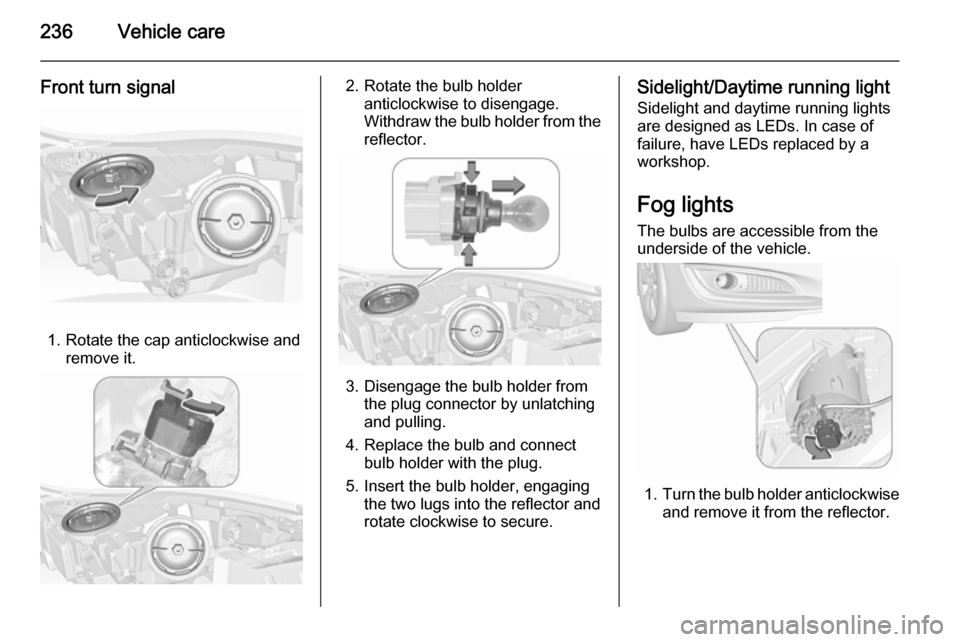

Front turn signal

1. Rotate the cap anticlockwise andremove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by unlatching

and pulling.

4. Replace the bulb and connect bulb holder with the plug.

5. Insert the bulb holder, engaging the two lugs into the reflector androtate clockwise to secure.

Sidelight/Daytime running light

Sidelight and daytime running lights

are designed as LEDs. In case of

failure, have LEDs replaced by a

workshop.

Fog lights

The bulbs are accessible from the

underside of the vehicle.

1. Turn the bulb holder anticlockwise

and remove it from the reflector.