lock VAUXHALL MERIVA 2015 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: MERIVA, Model: VAUXHALL MERIVA 2015Pages: 245, PDF Size: 7.76 MB

Page 144 of 245

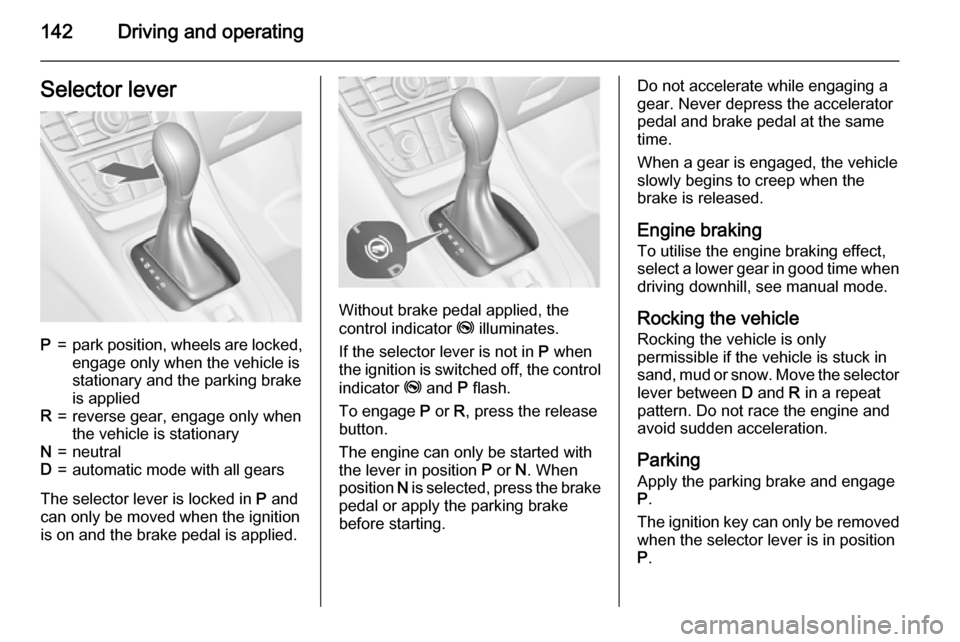

142Driving and operatingSelector leverP=park position, wheels are locked,engage only when the vehicle is

stationary and the parking brake

is appliedR=reverse gear, engage only when

the vehicle is stationaryN=neutralD=automatic mode with all gears

The selector lever is locked in P and

can only be moved when the ignition is on and the brake pedal is applied.

Without brake pedal applied, the

control indicator j illuminates.

If the selector lever is not in P when

the ignition is switched off, the control

indicator j and P flash.

To engage P or R, press the release

button.

The engine can only be started with the lever in position P or N. When

position N is selected, press the brake

pedal or apply the parking brake

before starting.

Do not accelerate while engaging a

gear. Never depress the accelerator

pedal and brake pedal at the same

time.

When a gear is engaged, the vehicle

slowly begins to creep when the

brake is released.

Engine braking

To utilise the engine braking effect,

select a lower gear in good time when driving downhill, see manual mode.

Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud or snow. Move the selector

lever between D and R in a repeat

pattern. Do not race the engine and

avoid sudden acceleration.

Parking

Apply the parking brake and engage P .

The ignition key can only be removed

when the selector lever is in position

P .

Page 146 of 245

144Driving and operating

If the vehicle battery is discharged,

start the vehicle using jump leads

3 209.

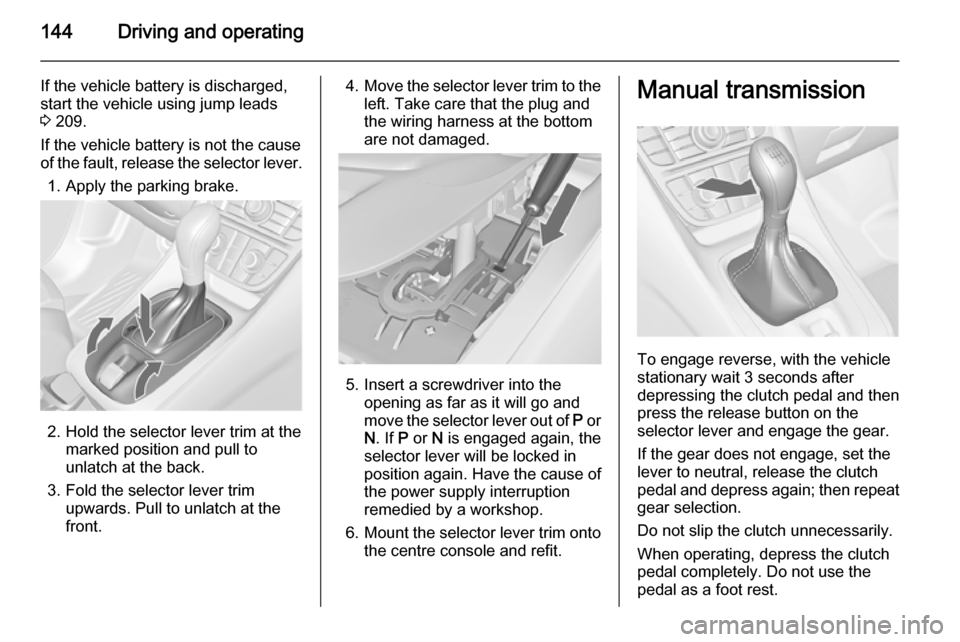

If the vehicle battery is not the cause

of the fault, release the selector lever.

1. Apply the parking brake.

2. Hold the selector lever trim at the marked position and pull tounlatch at the back.

3. Fold the selector lever trim upwards. Pull to unlatch at the

front.

4. Move the selector lever trim to the

left. Take care that the plug and

the wiring harness at the bottom are not damaged.

5. Insert a screwdriver into the opening as far as it will go and

move the selector lever out of P or

N . If P or N is engaged again, the

selector lever will be locked in

position again. Have the cause of

the power supply interruption

remedied by a workshop.

6. Mount the selector lever trim onto

the centre console and refit.

Manual transmission

To engage reverse, with the vehicle

stationary wait 3 seconds after

depressing the clutch pedal and then

press the release button on the

selector lever and engage the gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not slip the clutch unnecessarily.

When operating, depress the clutch

pedal completely. Do not use the

pedal as a foot rest.

Page 147 of 245

Driving and operating145Caution

It is not advisable to drive with thehand resting on the selector lever.

Brakes

The brake system comprises two independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear

this in mind when being towed.

Control indicator R 3 95.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off, the system performs

a self-test which may be audible.

Control indicator u 3 95.

Adaptive brake light During full braking, all three brakelights flash for the duration of ABS

control.

Page 148 of 245

146Driving and operating

Fault9Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

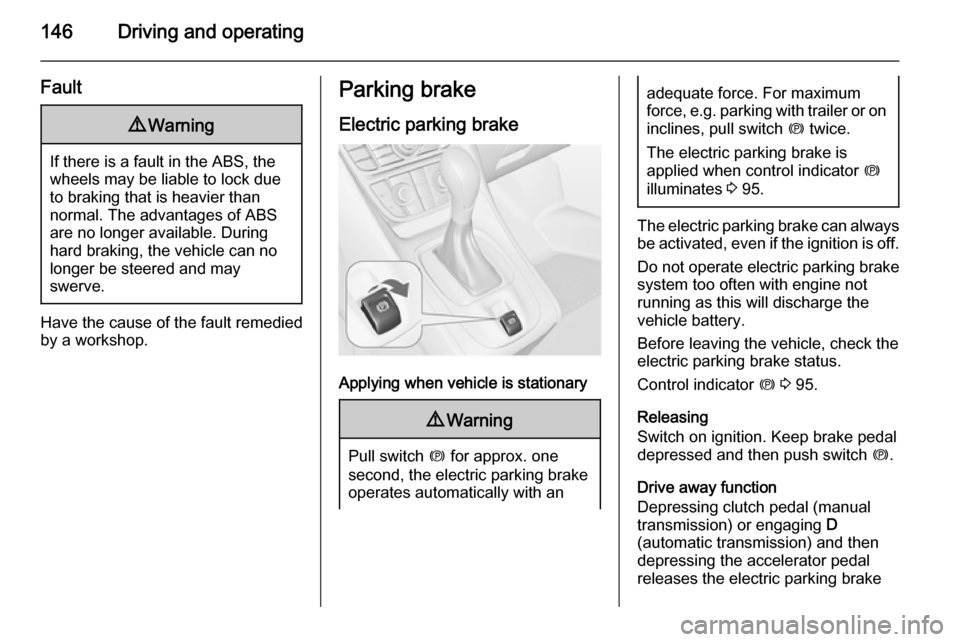

Parking brake

Electric parking brake

Applying when vehicle is stationary

9 Warning

Pull switch m for approx. one

second, the electric parking brake

operates automatically with an

adequate force. For maximum

force, e.g. parking with trailer or on

inclines, pull switch m twice.

The electric parking brake is

applied when control indicator m

illuminates 3 95.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often with engine not

running as this will discharge the

vehicle battery.

Before leaving the vehicle, check the electric parking brake status.

Control indicator m 3 95.

Releasing

Switch on ignition. Keep brake pedal

depressed and then push switch m.

Drive away function

Depressing clutch pedal (manual

transmission) or engaging D

(automatic transmission) and then

depressing the accelerator pedal

releases the electric parking brake

Page 159 of 245

Driving and operating157

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

■ Is there enough liquid gas present?

■ Is there enough petrol present for starting?

Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to liquid gas mode.

In extreme situations, the system may

also switch back to petrol mode if the

minimum requirements are not

fulfilled.

Seek the assistance of a workshop in the event of all other faults.Caution

Repairs and adjustments may onlybe made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

9 Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If possible, close the manual shut-off

valve on the multivalve. The

multivalve is located on the liquid gas

tank in the load compartment,

underneath the rear floor cover.

Turn the thumb wheel clockwise.

If no further gas odour is perceptible

when the manual shut-off valve is

closed, the vehicle can be used in

petrol mode. If the gas odour persists, do not start the engine. Have the

cause of the fault remedied by a

workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Notice

In the event of an accident, switch off

the ignition and lights. Close the

manual shut-off valve on multivalve.

Page 160 of 245

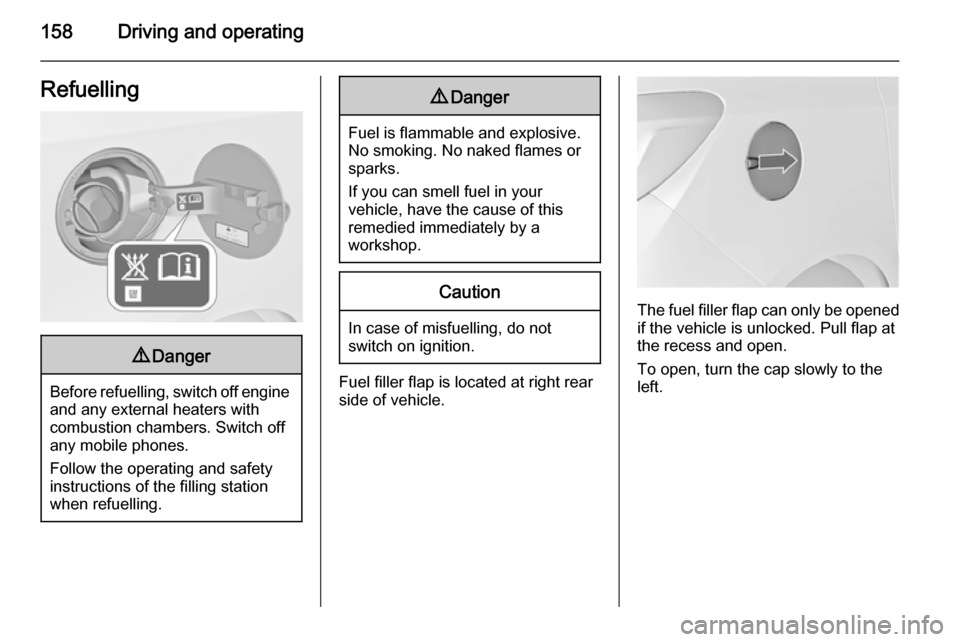

158Driving and operatingRefuelling9Danger

Before refuelling, switch off engine

and any external heaters with

combustion chambers. Switch off

any mobile phones.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

Fuel filler flap is located at right rear

side of vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Pull flap at

the recess and open.

To open, turn the cap slowly to the

left.

Page 162 of 245

160Driving and operating

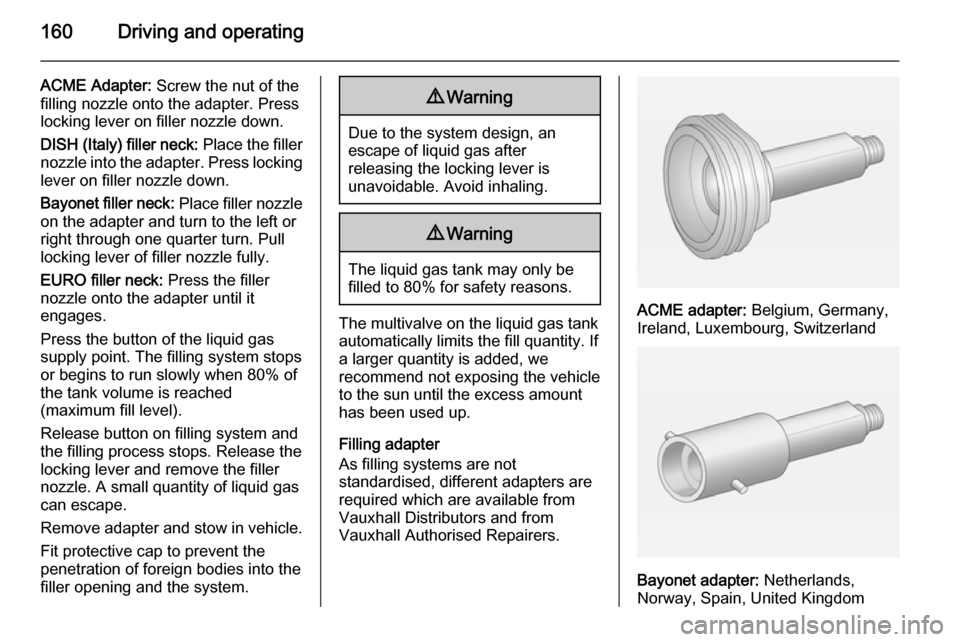

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

Page 166 of 245

164Driving and operating

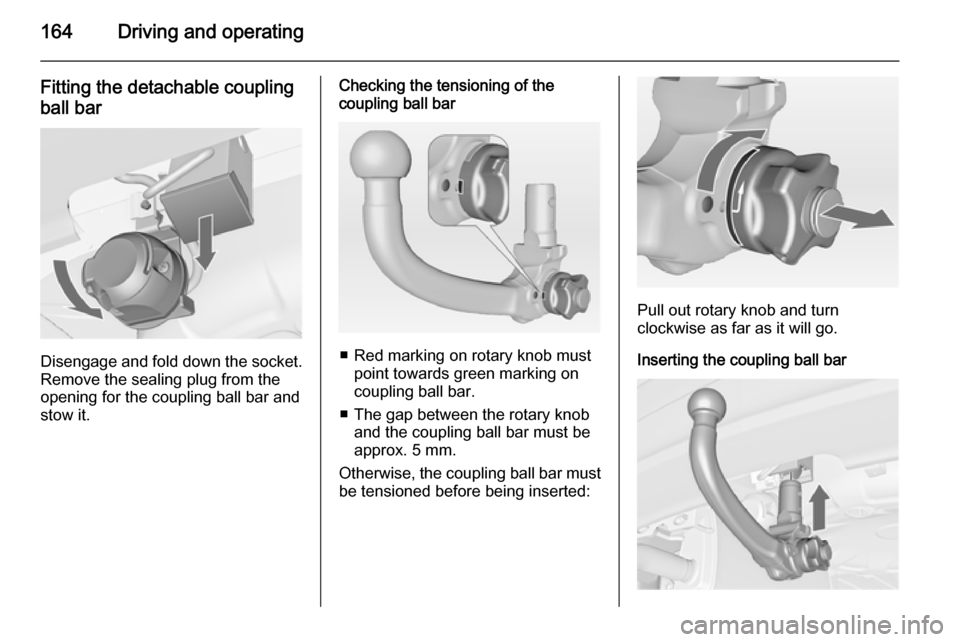

Fitting the detachable coupling

ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

■ Red marking on rotary knob must

point towards green marking on

coupling ball bar.

■ The gap between the rotary knob and the coupling ball bar must beapprox. 5 mm.

Otherwise, the coupling ball bar must be tensioned before being inserted:

Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Page 167 of 245

Driving and operating165

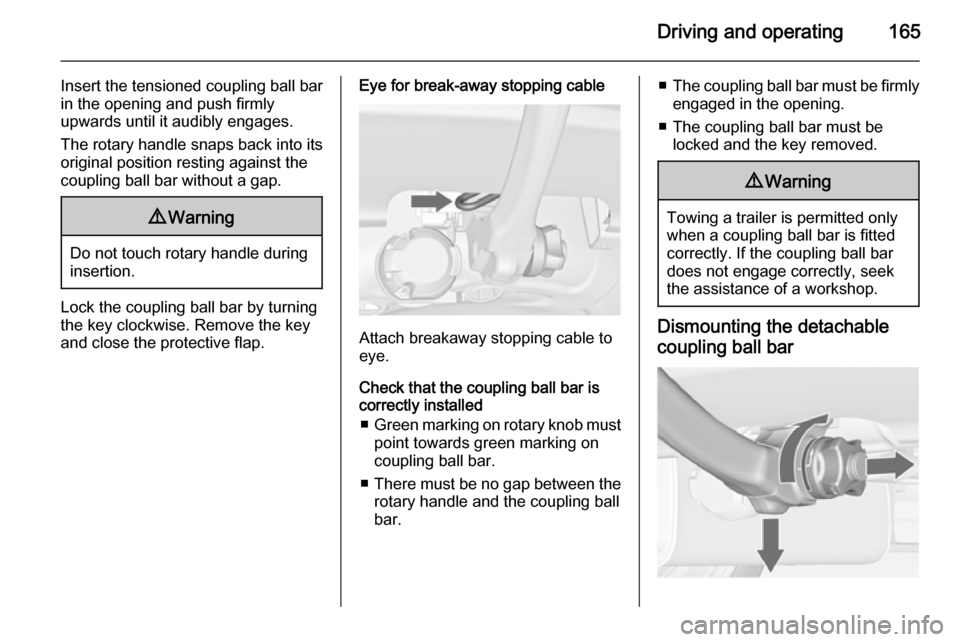

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning the key clockwise. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

■ Green marking on rotary knob must

point towards green marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the detachable

coupling ball bar

Page 168 of 245

166Driving and operating

Open the protective flap and turn the

key clockwise to unlock the coupling

ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.