lock VAUXHALL MOVANO_B 2015.5 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2015.5Pages: 215, PDF Size: 5.11 MB

Page 150 of 215

148Vehicle care

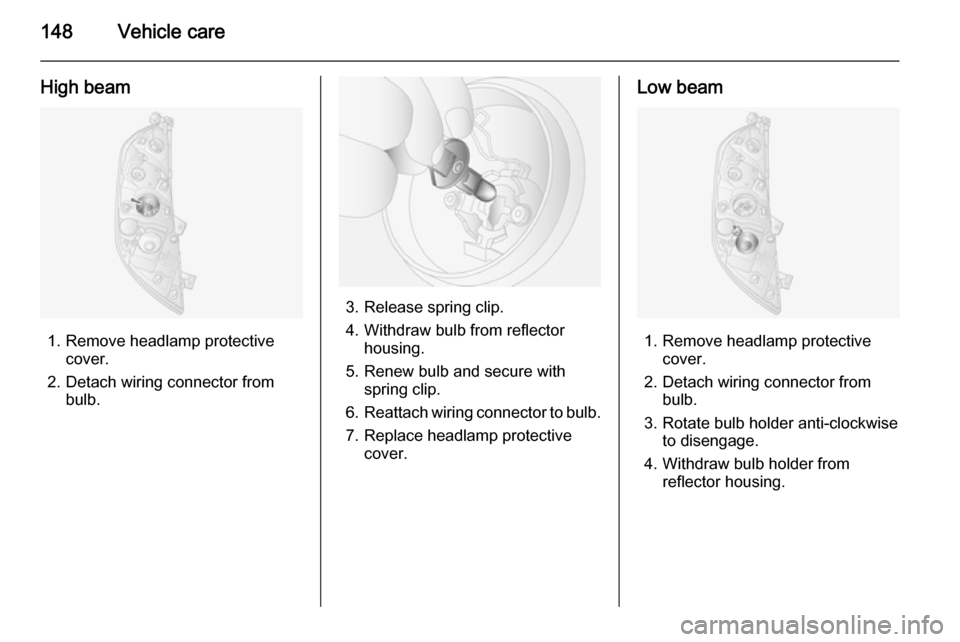

High beam

1. Remove headlamp protectivecover.

2. Detach wiring connector from bulb.

3. Release spring clip.

4. Withdraw bulb from reflector housing.

5. Renew bulb and secure with spring clip.

6. Reattach wiring connector to bulb.

7. Replace headlamp protective cover.

Low beam

1. Remove headlamp protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 151 of 215

Vehicle care149

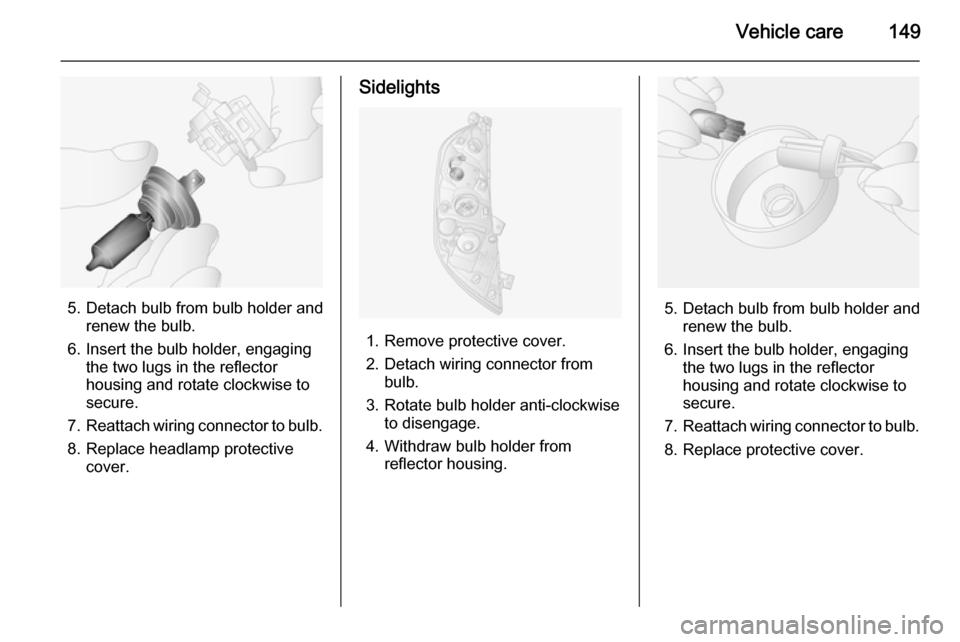

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace headlamp protective cover.

Sidelights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Page 152 of 215

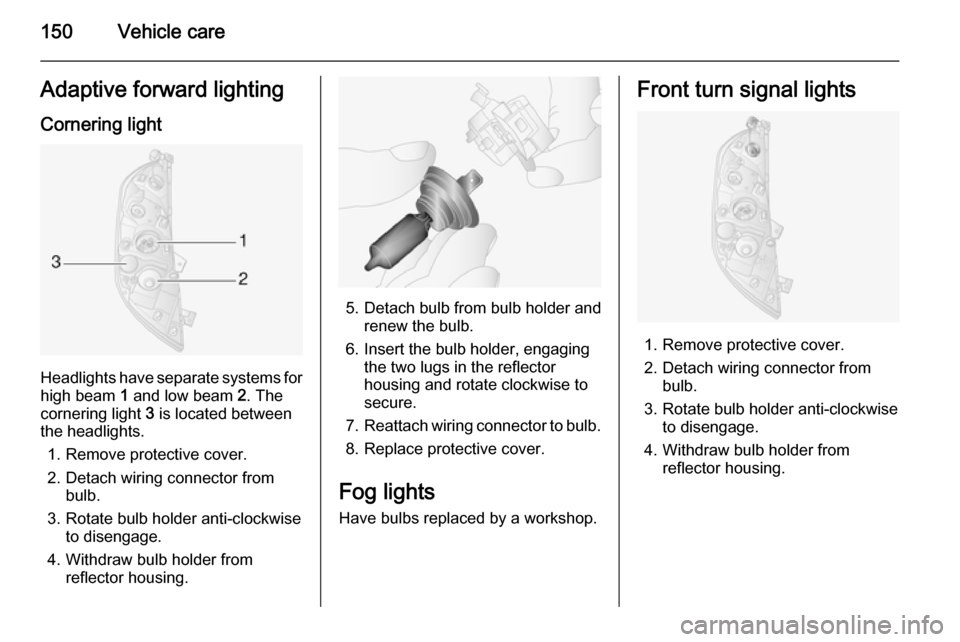

150Vehicle careAdaptive forward lightingCornering light

Headlights have separate systems forhigh beam 1 and low beam 2. The

cornering light 3 is located between

the headlights.

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Fog lights

Have bulbs replaced by a workshop.

Front turn signal lights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 153 of 215

Vehicle care151

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

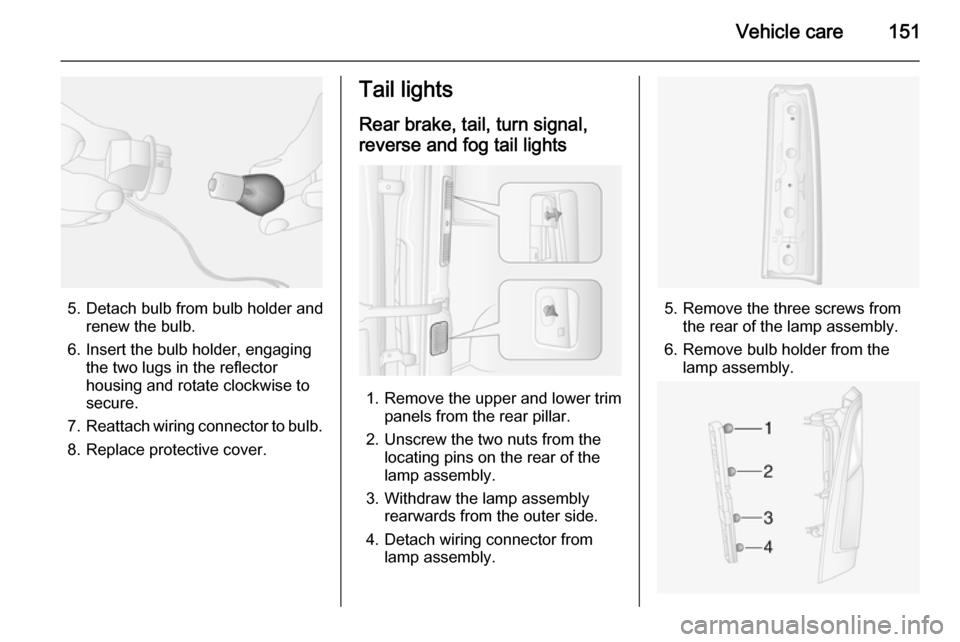

Tail lights

Rear brake, tail, turn signal,

reverse and fog tail lights

1. Remove the upper and lower trim panels from the rear pillar.

2. Unscrew the two nuts from the locating pins on the rear of the

lamp assembly.

3. Withdraw the lamp assembly rearwards from the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove the three screws from the rear of the lamp assembly.

6. Remove bulb holder from the lamp assembly.

Page 154 of 215

152Vehicle care

7. Push bulb into socket slightly,rotate anti-clockwise, remove andrenew bulb.

Turn signal light ( 1)

Tail and brake light ( 2)

Reverse light ( 3)

Rear fog light, may be on one side

only ( 4)

8. Replace bulb holder in lamp assembly.

9. Replace the three screws on the rear of the lamp assembly.

10. Reattach wiring connector to lamp

assembly.

11. Replace lamp assembly from the outer side into original position,

ensuring that it is seated correctly.

12. Replace the two nuts onto the locating pins on the rear of the

lamp assembly.

13. Install the upper and lower trim panels to the rear pillar.Side turn signal lights

1. Push the lamp assembly to the right and pull at the left-hand sideof the lamp assembly to release

from the aperture.

2. Detach wiring connector from lamp assembly.

3. Remove bulb holder from lamp assembly by rotating 90° and

renew bulb.

4. Install bulb holder in lamp assembly.

5. Reattach wiring connector.

6. Install lamp assembly into aperture and push to the left to

secure.

Mirror turn signal lights 1. Move the lower mirror assembly from the front to access the screw.

2. Remove the screw using a torx screwdriver.

3. Remove bulb holder from the rear

of the lower mirror assembly.

4. Renew bulb.

5. Replace bulb holder.

6. Replace the screw.

Page 159 of 215

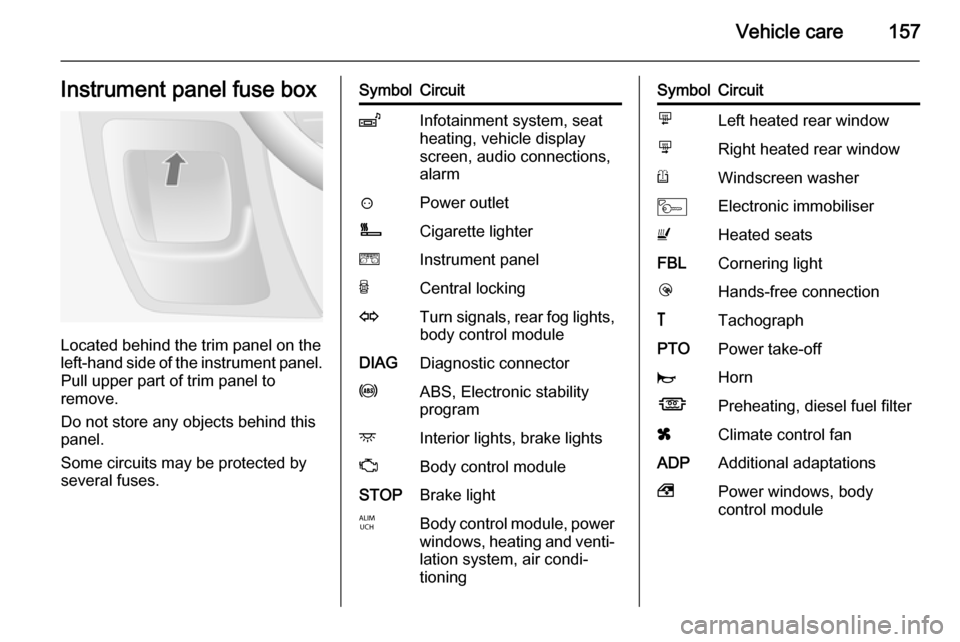

Vehicle care157Instrument panel fuse box

Located behind the trim panel on the

left-hand side of the instrument panel. Pull upper part of trim panel to

remove.

Do not store any objects behind this

panel.

Some circuits may be protected by

several fuses.

SymbolCircuitZInfotainment system, seat

heating, vehicle display

screen, audio connections,

alarm?Power outletÌCigarette lightereInstrument panelUCentral lockingOTurn signals, rear fog lights,

body control moduleDIAGDiagnostic connectoruABS, Electronic stability

programdInterior lights, brake lightsZBody control moduleSTOPBrake lightIBody control module, power windows, heating and venti‐

lation system, air condi‐

tioningSymbolCircuitmLeft heated rear windownRight heated rear windowRWindscreen washerMElectronic immobiliserUHeated seatsFBLCornering lightlHands-free connection&TachographPTOPower take-offjHornÍPreheating, diesel fuel filterxClimate control fanADPAdditional adaptations,Power windows, body

control module

Page 165 of 215

Vehicle care163

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

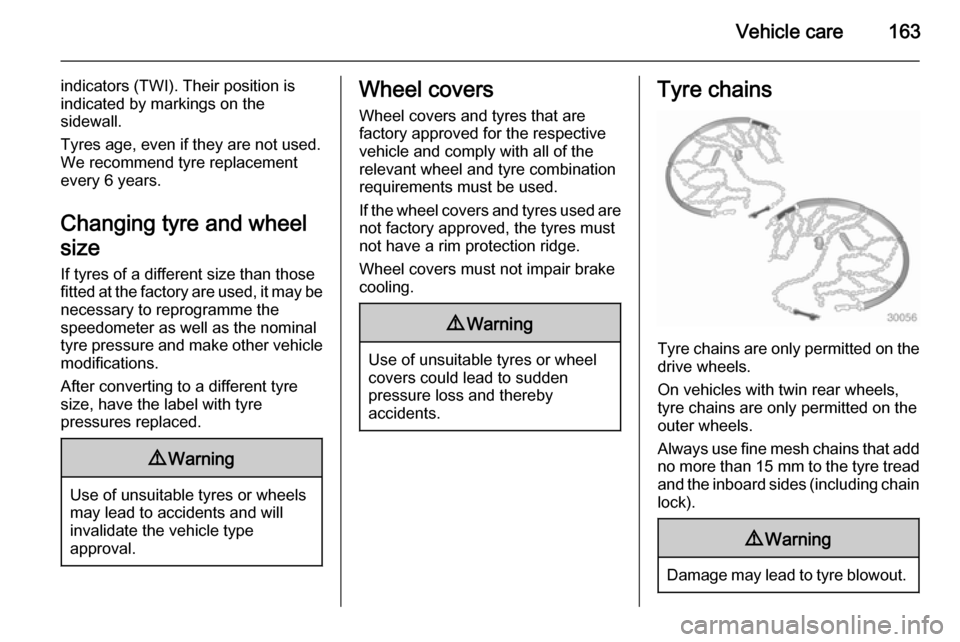

Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Page 167 of 215

Vehicle care165

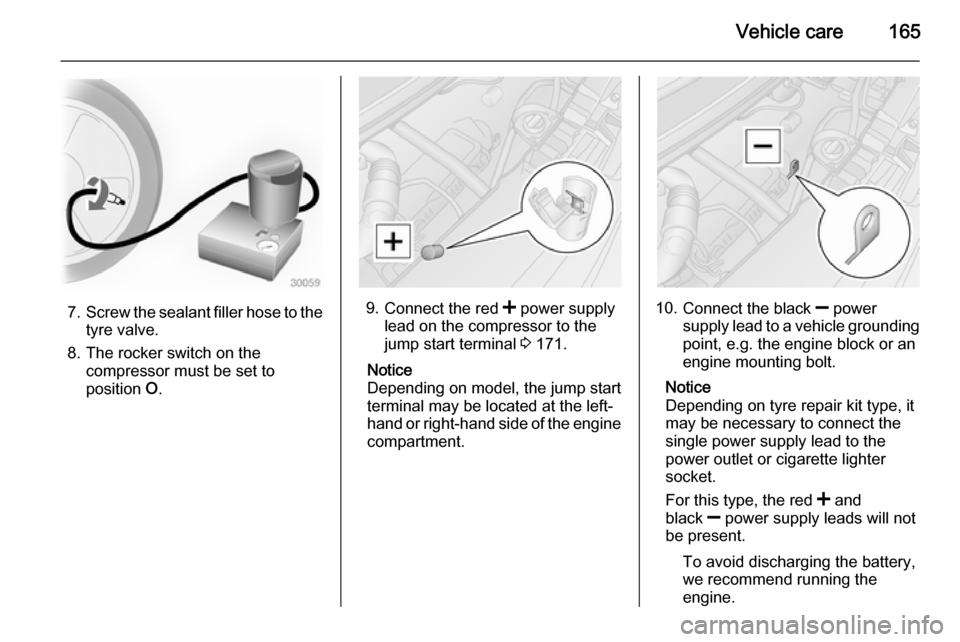

7.Screw the sealant filler hose to the

tyre valve.

8. The rocker switch on the compressor must be set to

position O.9.

Connect the red < power supply

lead on the compressor to the

jump start terminal 3 171.

Notice

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.10. Connect the black ] power

supply lead to a vehicle grounding point, e.g. the engine block or an

engine mounting bolt.

Notice

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

Page 175 of 215

Vehicle care173

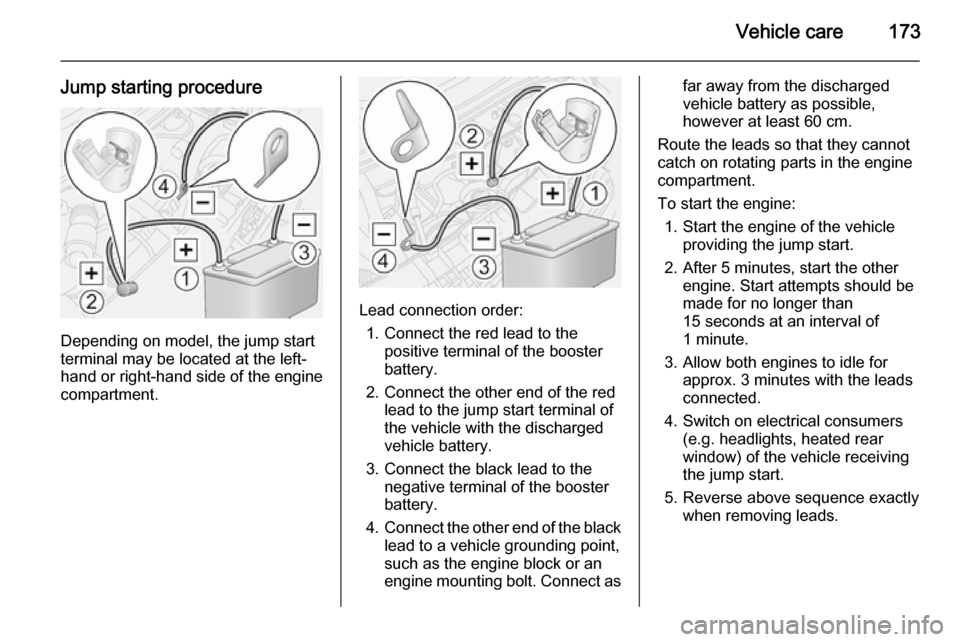

Jump starting procedure

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the jump start terminal of

the vehicle with the discharged

vehicle battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 176 of 215

174Vehicle careTowing

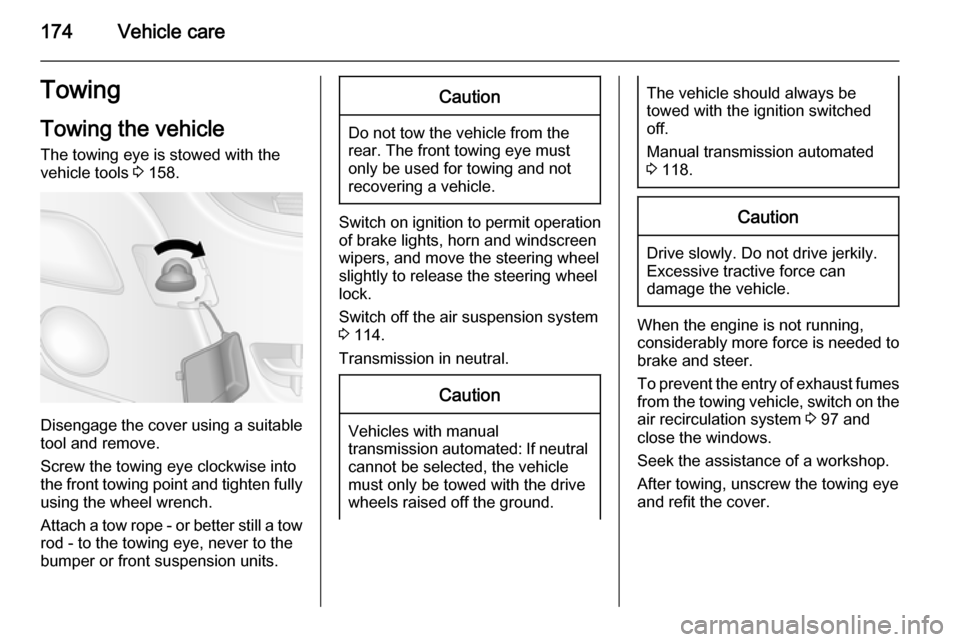

Towing the vehicle The towing eye is stowed with the

vehicle tools 3 158.

Disengage the cover using a suitable

tool and remove.

Screw the towing eye clockwise into

the front towing point and tighten fully using the wheel wrench.

Attach a tow rope - or better still a tow

rod - to the towing eye, never to the

bumper or front suspension units.

Caution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Switch off the air suspension system 3 114.

Transmission in neutral.

Caution

Vehicles with manual

transmission automated: If neutral cannot be selected, the vehiclemust only be towed with the drive

wheels raised off the ground.

The vehicle should always be

towed with the ignition switched

off.

Manual transmission automated

3 118.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system 3 97 and

close the windows.

Seek the assistance of a workshop.

After towing, unscrew the towing eye

and refit the cover.