engine VAUXHALL MOVANO_B 2015.5 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2015.5Pages: 215, PDF Size: 5.11 MB

Page 144 of 215

142Vehicle careEngine coolantThe coolant provides freeze

protection down to approx. -28 °C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be just above the

MINI mark.Top up if the level is low.9Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

Top up with antifreeze.If no antifreeze

is available, use clean tap water or

distilled water.Install the cap

tightly.Have the antifreeze

concentration checked and have the

cause of the coolant loss remedied by a workshop.

If a substantial amount of coolant is

required, it will be necessary to bleed

any trapped air from the cooling

system.Seek the assistance of a

workshop.

Power steering fluidCaution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap or from

entering the reservoir.

The fluid level normally does not need

to be checked. If an unusual noise is

heard during steering or if the power

steering reacts conspicuously, seek

the assistance of a workshop.

Depending on vehicle, the power

steering fluid reservoir may be

located in the engine compartment

(Type A) or below the front wheel

arch, behind a trim panel (Type B).

Page 146 of 215

144Vehicle careBrakesIn the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake linings replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

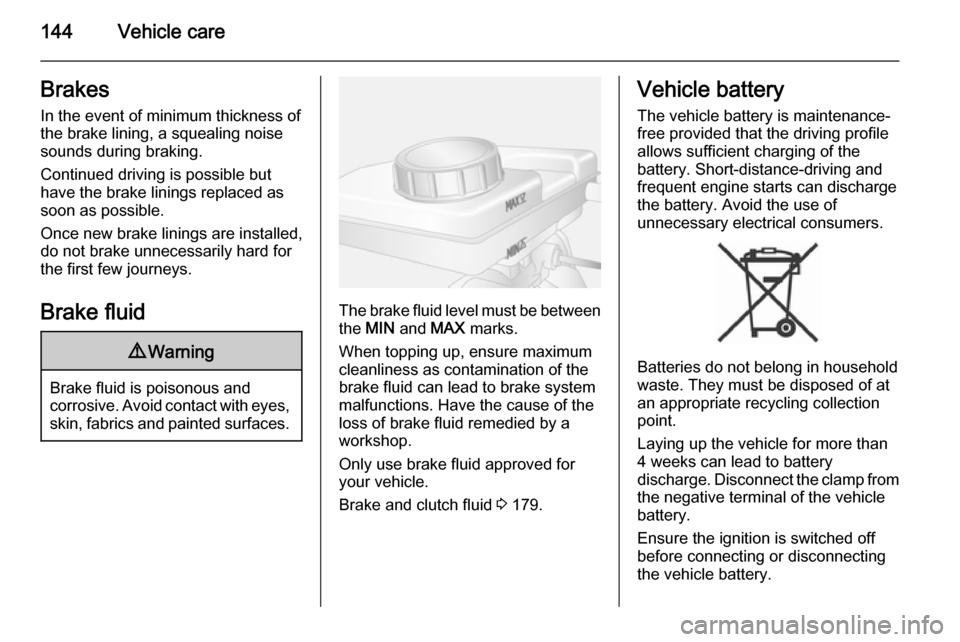

The brake fluid level must be betweenthe MIN and MAX marks.

When topping up, ensure maximum cleanliness as contamination of the

brake fluid can lead to brake system

malfunctions. Have the cause of the

loss of brake fluid remedied by a

workshop.

Only use brake fluid approved for

your vehicle.

Brake and clutch fluid 3 179.

Vehicle battery

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

4 weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Page 148 of 215

146Vehicle careDiesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screws on the filter cover and on the

lower part of the filter by approx. one

turn, to drain off the water.

The filter is drained as soon as diesel fuel emerges from the knurled screw

at the bottom. Retighten the two

screws.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system

bleeding

If the fuel tank has been run dry, it will be necessary to air vent or bleed the

diesel fuel system.

Fill the tank with fuel and proceed as

follows:

1. Place a suitable container underneath the fuel filter vent

screw to collect fuel.

2. Loosen the vent screw (arrowed) by one turn.

3. Manually operate the in-line supply pump slowly and steadily

until fuel discharging from the

loosened vent screw is free of air

bubbles.

4. Retighten the vent screw.

If the engine cannot be started after

several attempts to bleed the diesel

fuel system, seek the assistance of a

workshop.

Wiper blade replacement Wiper blades on the windscreen

Page 157 of 215

Vehicle care155Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

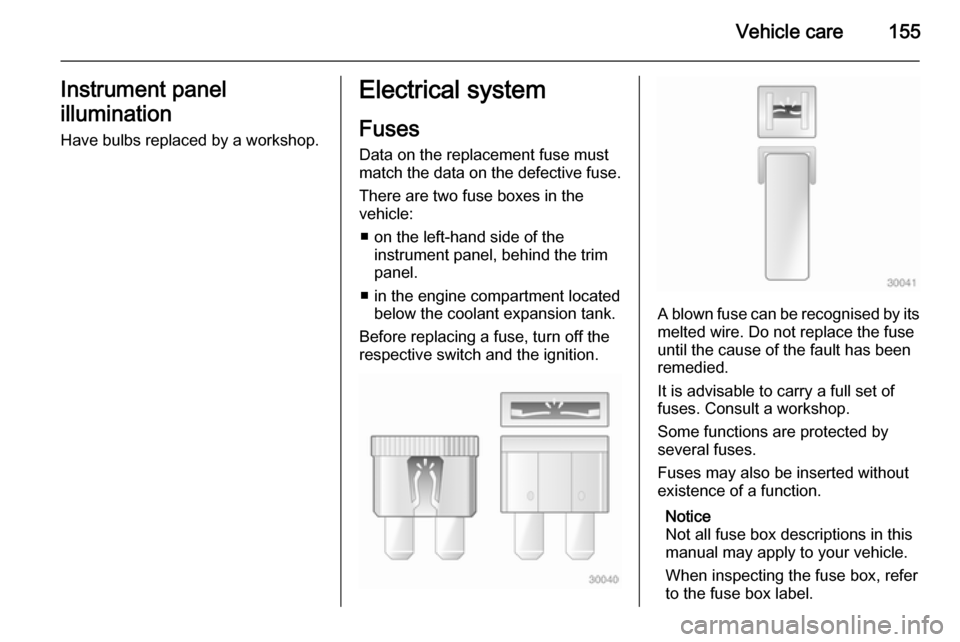

Fuses Data on the replacement fuse mustmatch the data on the defective fuse.

There are two fuse boxes in the

vehicle:

■ on the left-hand side of the instrument panel, behind the trim

panel.

■ in the engine compartment located below the coolant expansion tank.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

It is advisable to carry a full set of

fuses. Consult a workshop.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Notice

Not all fuse box descriptions in this

manual may apply to your vehicle.

When inspecting the fuse box, refer to the fuse box label.

Page 158 of 215

156Vehicle care

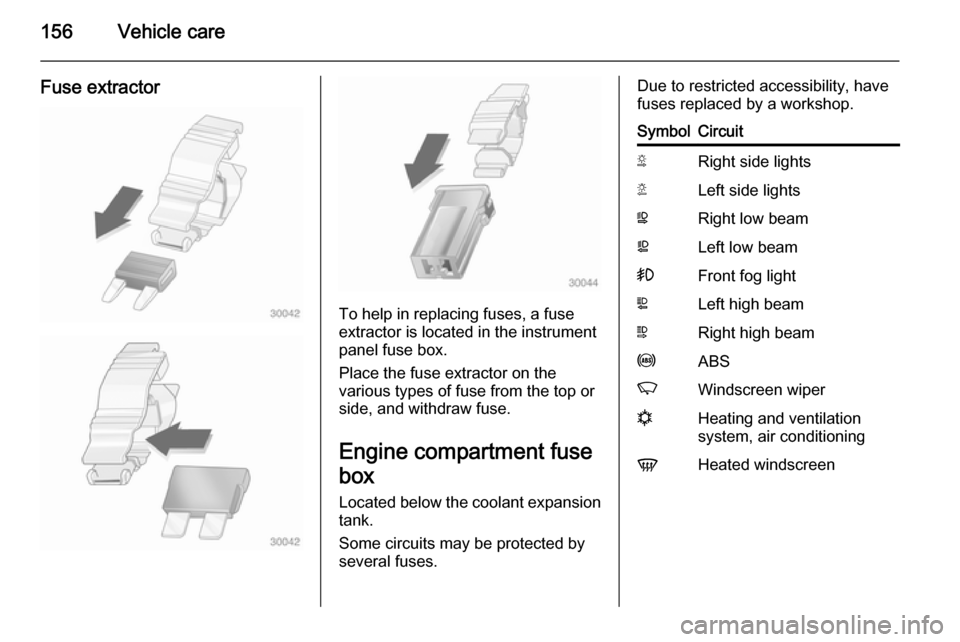

Fuse extractor

To help in replacing fuses, a fuse

extractor is located in the instrument

panel fuse box.

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

Engine compartment fusebox

Located below the coolant expansion tank.

Some circuits may be protected by

several fuses.

Due to restricted accessibility, have

fuses replaced by a workshop.SymbolCircuitSRight side lightsTLeft side lightsWRight low beamaLeft low beam>Front fog lightLLeft high beamNRight high beamuABSKWindscreen wipernHeating and ventilation

system, air conditioningVHeated windscreen

Page 162 of 215

160Vehicle care

Tyre pressures differ depending onvarious options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 185.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 201.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Rear-wheel drive, with twin rear

wheels When inflating the outer tyre, the

inflation tube should be passed

between the two wheels.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The TPMS sensors monitor the air

pressure in the tyres and transmit tyre pressure readings to a receiver

located in the vehicle.

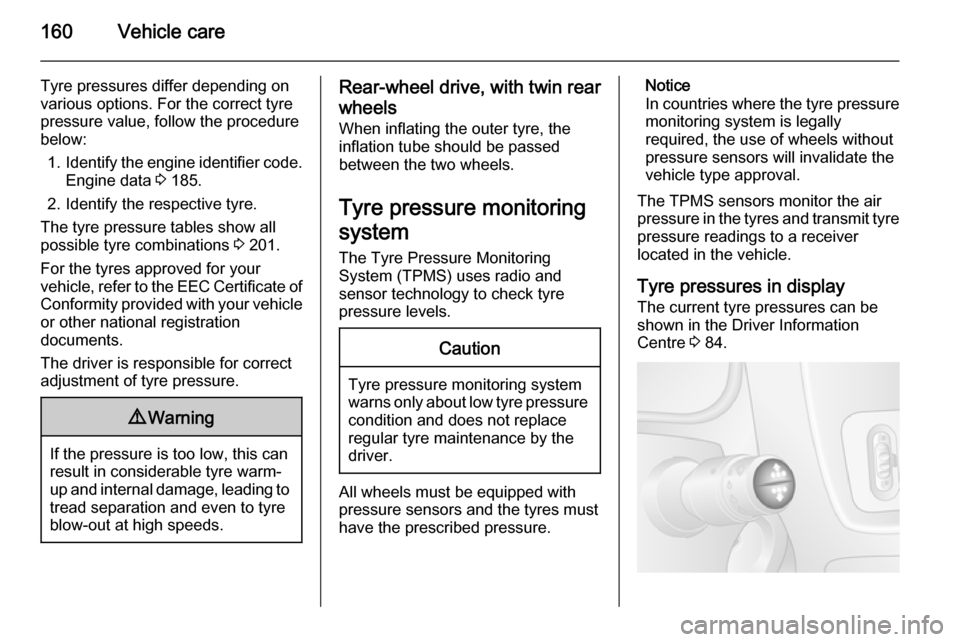

Tyre pressures in display The current tyre pressures can be

shown in the Driver Information

Centre 3 84.

Page 163 of 215

Vehicle care161

With the vehicle stationary, press

button on end of wiper lever

repeatedly until the tyre pressure

menu is displayed.

Low tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 82 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 201.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for getting low pressure. Check tyre pressure.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w flashes for

several seconds then illuminates continuously together with control

indicator A 3 80 and a

corresponding message appears in

the Driver Information Centre.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. TPMS is not operational for these wheels. For the further three

wheels, TPMS remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.Driver Information Centre 3 84.

Vehicle messages 3 85.

Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 80 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 201, Tyre repair kit

3 164, Spare wheel 3 169, Wheel

changing 3 167.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Page 167 of 215

Vehicle care165

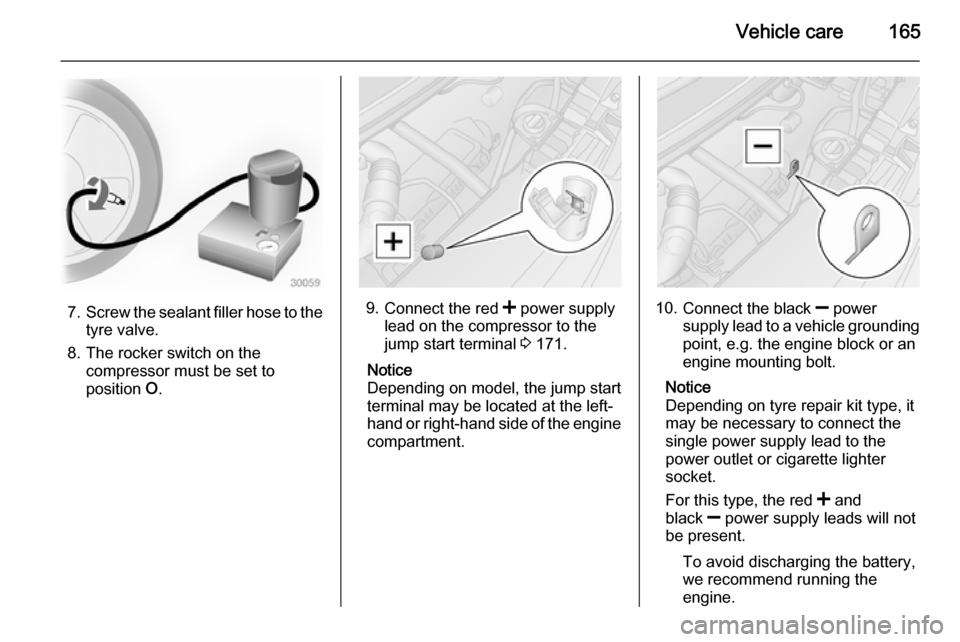

7.Screw the sealant filler hose to the

tyre valve.

8. The rocker switch on the compressor must be set to

position O.9.

Connect the red < power supply

lead on the compressor to the

jump start terminal 3 171.

Notice

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.10. Connect the black ] power

supply lead to a vehicle grounding point, e.g. the engine block or an

engine mounting bolt.

Notice

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

Page 170 of 215

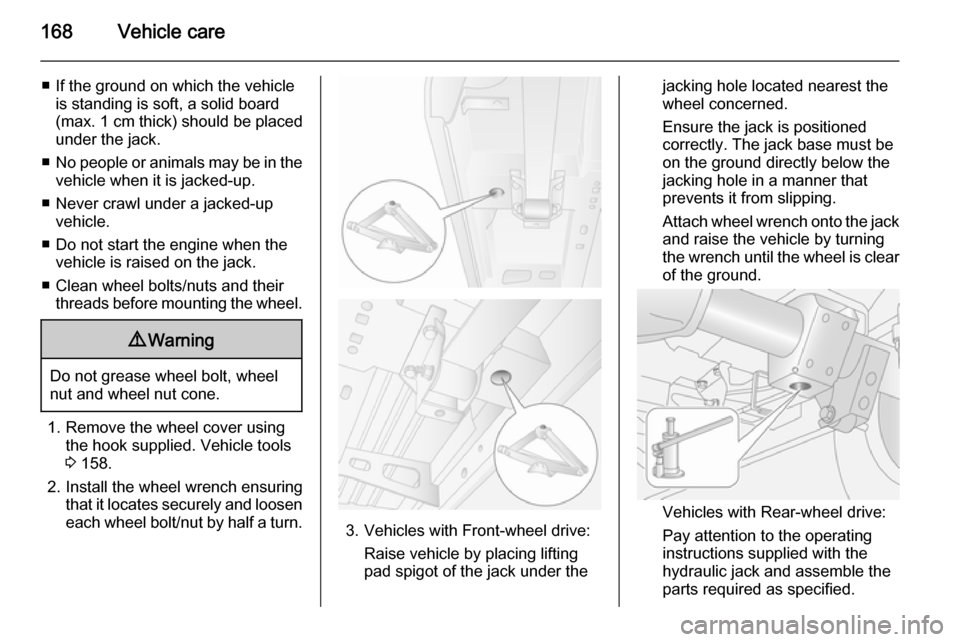

168Vehicle care

■ If the ground on which the vehicleis standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when the vehicle is raised on the jack.

■ Clean wheel bolts/nuts and their threads before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 158.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.

3. Vehicles with Front-wheel drive:

Raise vehicle by placing lifting

pad spigot of the jack under the

jacking hole located nearest the

wheel concerned.

Ensure the jack is positioned correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle by turning

the wrench until the wheel is clear of the ground.

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack and assemble the

parts required as specified.

Page 174 of 215

172Vehicle careCaution

The air suspension system must

be switched off prior to jump

starting.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

■ Never expose the vehicle battery to

naked flames or sparks.

■ A discharged vehicle battery can already freeze at a temperature of

0 °C. Defrost the frozen vehicle

battery before connecting jump

leads.

■ Wear eye protection and protective

clothing when handling a vehicle

battery.

■ Use a booster battery with the same voltage (12 volts). Its capacity(Ah) must not be much less than

that of the discharged vehicle

battery.

■ Use jump leads with insulated terminals and a cross section of at

least 25 mm 2

.

■ Do not disconnect the discharged battery from the vehicle.

■ Switch off all unnecessary electrical

consumers.

■ Switch off the air suspension system 3 114.

■ Do not lean over the vehicle battery

during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.

■ The vehicles must not come into contact with each other during the

jump starting process.

■ Apply the parking brake and engage neutral (manual

transmission) or N (manual

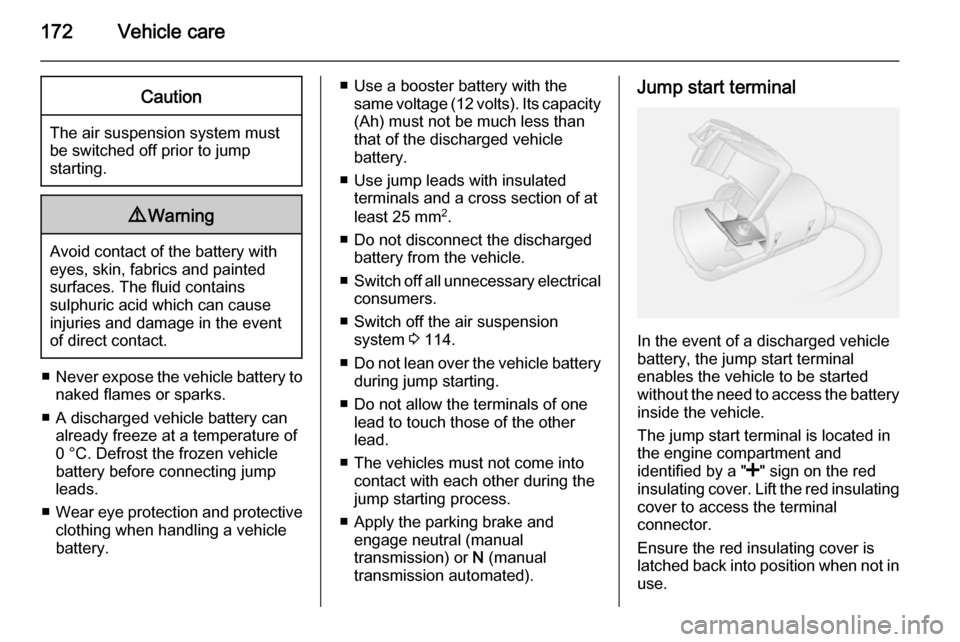

transmission automated).Jump start terminal

In the event of a discharged vehicle

battery, the jump start terminal

enables the vehicle to be started

without the need to access the battery inside the vehicle.

The jump start terminal is located in

the engine compartment and

identified by a " <" sign on the red

insulating cover. Lift the red insulating

cover to access the terminal

connector.

Ensure the red insulating cover is

latched back into position when not in

use.