spare wheel VAUXHALL MOVANO_B 2016.5 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.5, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2016.5Pages: 239, PDF Size: 5.64 MB

Page 92 of 239

90Instruments and controlsIlluminates briefly when the ignition is

switched on.

Illuminates

Tyre pressure loss. Stop immediately

and check tyre pressure.

Control indicator w illuminates

together with C 3 88 and a

corresponding message appears in the Driver Information Centre (DIC)

when a puncture or severely under-

inflated tyre is detected.

Flashes

Fault in system. After a delay the

control indicator illuminates

continuously. Consult a workshop.

Control indicator w illuminates

together with A 3 87 and a

corresponding message appears in

the DIC when a tyre without a

pressure sensor is mounted (e.g.

spare wheel).

Tyre pressure monitoring system

3 182.

Engine oil pressure

I illuminates red.Illuminates briefly when the ignition is

switched on.

Illuminates when the engine is

runningCaution

Engine lubrication may be

interrupted. This may result in

damage to the engine and/or

locking of the drive wheels.

1. Depress clutch.

2. Select neutral gear, set selector lever to N.

3. Move out of the flow of traffic as quickly as possible without

impeding other vehicles.

4. Switch off ignition.

9 Warning

When the engine is off,

considerably more force is needed

to brake and steer. During an

Autostop the brake servo unit will still be operational.

Do not remove key until vehicle isstationary, otherwise the steeringwheel lock could engage

unexpectedly.

Check oil level before seeking

assistance of a workshop 3 160.

Low fuel

Y illuminates yellow.

Illuminates when the ignition is

switched on and extinguishes shortly

after the engine starts.

Illuminates when the engine is

running

Fuel level in the tank is too low. Refuel

immediately.

Never run the tank dry.

Refuelling 3 152.

Catalytic converter 3 127.

Bleeding the diesel fuel system

3 166.

Stop-start system

\

Page 159 of 239

Vehicle care157Vehicle careGeneral Information...................158

Accessories and vehicle modifications .......................... 158

Vehicle storage ........................158

End-of-life vehicle recovery .....159

Vehicle checks ........................... 159

Performing work ......................159

Bonnet ..................................... 159

Engine oil ................................. 160

Engine coolant ......................... 161

Power steering fluid .................162

Washer fluid ............................ 163

Brakes ..................................... 163

Brake fluid ............................... 163

Vehicle battery ......................... 163

Diesel fuel filter ........................165

Diesel fuel system bleeding .....166

Wiper blade replacement ........166

Bulb replacement .......................167

Headlights ............................... 167

Adaptive forward lighting .........169

Fog lights ................................. 169

Front turn signal lights .............170

Tail lights ................................. 170

Side turn signal lights ..............171Centre high-mounted brake

light ......................................... 172

Number plate light ...................173

Interior lights ............................ 173

Instrument panel illumination ...174

Electrical system ........................174

Fuses ....................................... 174

Engine compartment fuse box . 176

Instrument panel fuse box .......176

Load compartment fuse box ....177

Vehicle tools .............................. 179

Tools ........................................ 179

Wheels and tyres .......................180

Tyres ....................................... 180

Winter tyres ............................. 180

Tyre designations ....................180

Tyre pressure .......................... 181

Tyre pressure monitoring system .................................... 182

Tread depth ............................. 184

Changing tyre and wheel size . 184 Wheel covers ........................... 184

Tyre chains .............................. 185

Tyre repair kit .......................... 185

Wheel changing .......................188

Spare wheel ............................ 190

Jump starting ............................. 193Towing....................................... 195

Towing the vehicle ...................195

Towing another vehicle ...........196

Appearance care .......................197

Exterior care ............................ 197

Interior care ............................. 198

Page 181 of 239

Vehicle care179Some circuits may be protected by

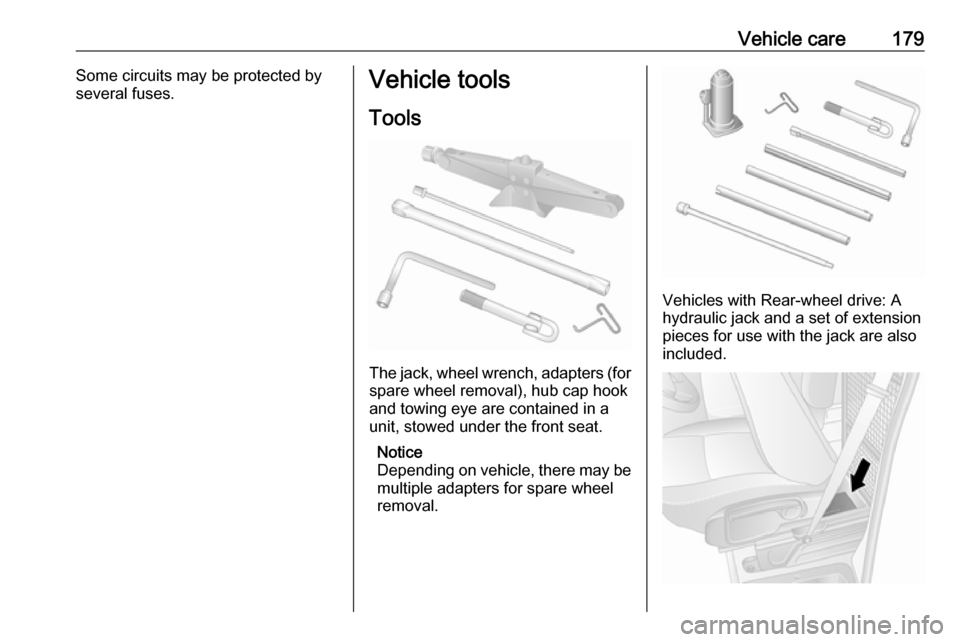

several fuses.Vehicle tools

Tools

The jack, wheel wrench, adapters (for

spare wheel removal), hub cap hook

and towing eye are contained in a

unit, stowed under the front seat.

Notice

Depending on vehicle, there may be multiple adapters for spare wheel

removal.

Vehicles with Rear-wheel drive: A hydraulic jack and a set of extension

pieces for use with the jack are also

included.

Page 182 of 239

180Vehicle careTo access this unit, slide the seat fullyforwards and fold down the backrest.

Tyre repair kit 3 185.

Wheel changing 3 188.

Spare wheel 3 190.Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb

when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehiclestability. Always use less worn tyres

on the rear axle.

Tyres

Factory-fitted tyres are matched to the chassis and offer optimum driving comfort and safety.Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the maximum speed

sticker in the driver's field of view.

Tyre designations

E.g. 215/65 R 16 C 109 R215:tyre width, mm65:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat16:wheel diameter, inchesC:cargo or commercial use88:load index e.g. 109 is

equivalent to approx. 1030 kgR:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Page 183 of 239

Vehicle care181Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

Always inflate tyres to the pressures

shown on the label.

Tyre pressures 3 225.The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 206.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 225.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the

tyre information label and tyre

pressure chart are valid for cold tyres, which means at 20 °C. The pressure

increases by nearly 1.5 psi for a

Page 185 of 239

Vehicle care183A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. TPMS is not operational for

these wheels. For the further three wheels, TPMS remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.

Driver Information Centre (DIC) 3 92.

Vehicle messages 3 92.

Puncture A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 88 and a corresponding message

appears in the DIC. Stop vehicle and

switch off engine.

Tyre pressure 3 225, Tyre repair kit

3 185, Spare wheel 3 190, Wheel

changing 3 188.Relearn function

After a puncture has been repaired

and the driver has inflated the tyres to

the correct tyre pressure, TPMS

needs to recalculate.

Tyre pressure 3 225, Tyre repair kit

3 185.

During driving, select the tyre

pressure menu in the DIC by pressing button on end of wiper lever. Press

and hold button for approx.

5 seconds to initialise recalculation. A

corresponding message appears in

the DIC.

Several minutes of driving at a speed above 25 mph may be required tocomplete the relearn process. The

system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is

displayed in the DIC.

Driver Information Centre (DIC) 3 92.

Vehicle messages 3 92.

General information The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 185, Tyre chains

3 185.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.

Page 187 of 239

Vehicle care185Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 30 mph and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

neutral (manual transmission) or N

(manual transmission automated).

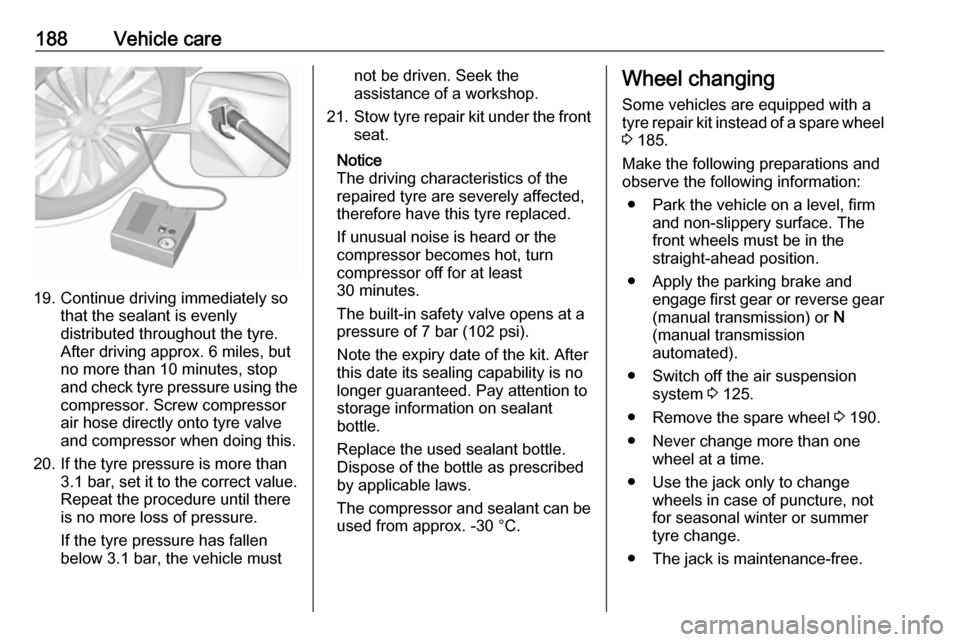

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

3. Remove the power supply lead(s)

and air hose from the stowage

compartments on the underside

of the compressor.

Page 190 of 239

188Vehicle care

19. Continue driving immediately sothat the sealant is evenlydistributed throughout the tyre.

After driving approx. 6 miles, but

no more than 10 minutes, stop

and check tyre pressure using the

compressor. Screw compressor

air hose directly onto tyre valve

and compressor when doing this.

20. If the tyre pressure is more than 3.1 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 3.1 bar, the vehicle must

not be driven. Seek the

assistance of a workshop.

21. Stow tyre repair kit under the front

seat.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 185.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear

(manual transmission) or N

(manual transmission

automated).

● Switch off the air suspension system 3 125.

● Remove the spare wheel 3 190.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

Page 192 of 239

190Vehicle careEnsure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench, to position the base plate

correctly.

Raise the vehicle by pressing the

wheel wrench until the wheel is

clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench ensuring that it locates securely and tighten

each wheel bolt/nut in a crosswise sequence. Tightening torque is:

172 Nm (Front-wheel drive),

235 Nm (Rear-wheel drive with

twin rear wheels), 264 Nm (Rear-

wheel drive with single rear

wheels).9. Refit wheel cover.

Notice

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel cover).

10. Stow the replaced wheel 3 190

and the vehicle tools 3 179.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 225 and also the wheel bolt/nut

torque as soon as possible.

Have the defective tyre renewed or

repaired.

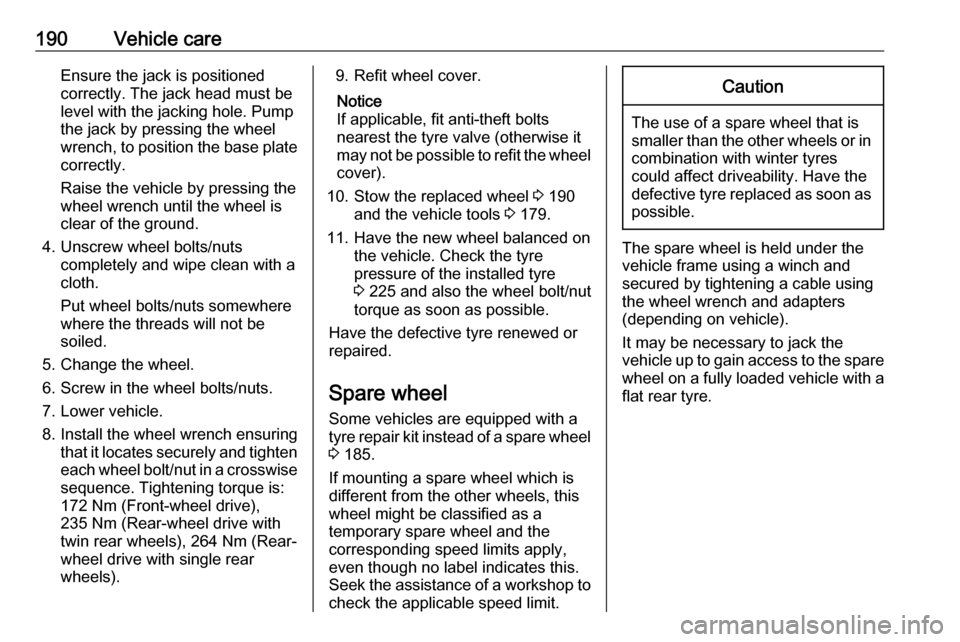

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 185.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapters

(depending on vehicle).

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

Page 193 of 239

Vehicle care191

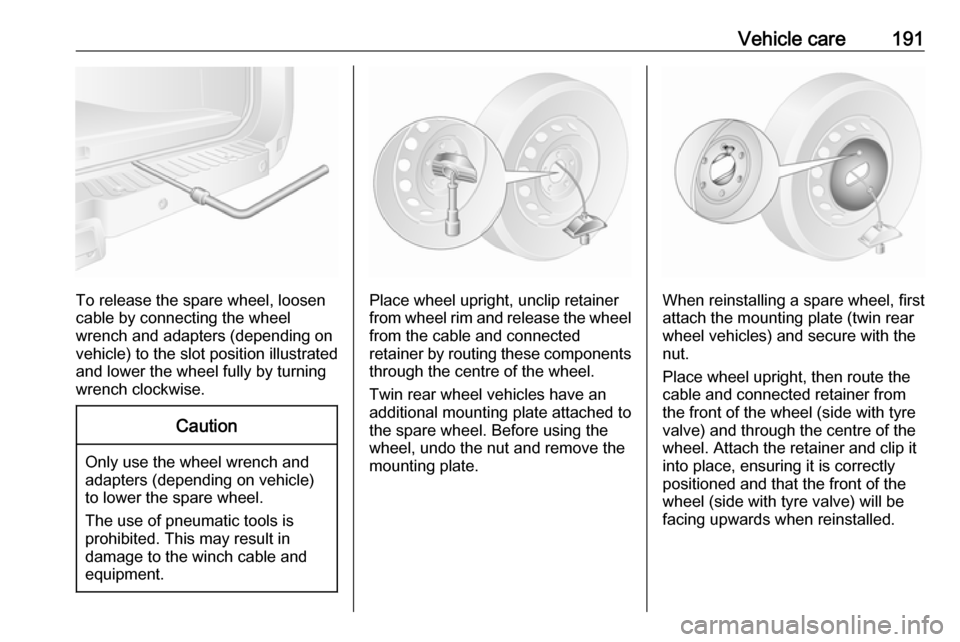

To release the spare wheel, loosen

cable by connecting the wheel

wrench and adapters (depending on

vehicle) to the slot position illustrated

and lower the wheel fully by turning

wrench clockwise.

Caution

Only use the wheel wrench and

adapters (depending on vehicle)

to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Place wheel upright, unclip retainer

from wheel rim and release the wheel

from the cable and connected

retainer by routing these components through the centre of the wheel.

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.When reinstalling a spare wheel, first

attach the mounting plate (twin rear

wheel vehicles) and secure with the

nut.

Place wheel upright, then route the

cable and connected retainer from

the front of the wheel (side with tyre

valve) and through the centre of the

wheel. Attach the retainer and clip it

into place, ensuring it is correctly

positioned and that the front of the

wheel (side with tyre valve) will be

facing upwards when reinstalled.