engine VAUXHALL VIVARO 2016 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: VIVARO, Model: VAUXHALL VIVARO 2016Pages: 209, PDF Size: 4.86 MB

Page 153 of 209

Vehicle care151

Drain filter of residual water at every

engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screw on the lower part of the filter by approx. one turn, to drain off the

water.

The filter is drained as soon as water-

free diesel fuel emerges. Retighten

the screw.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

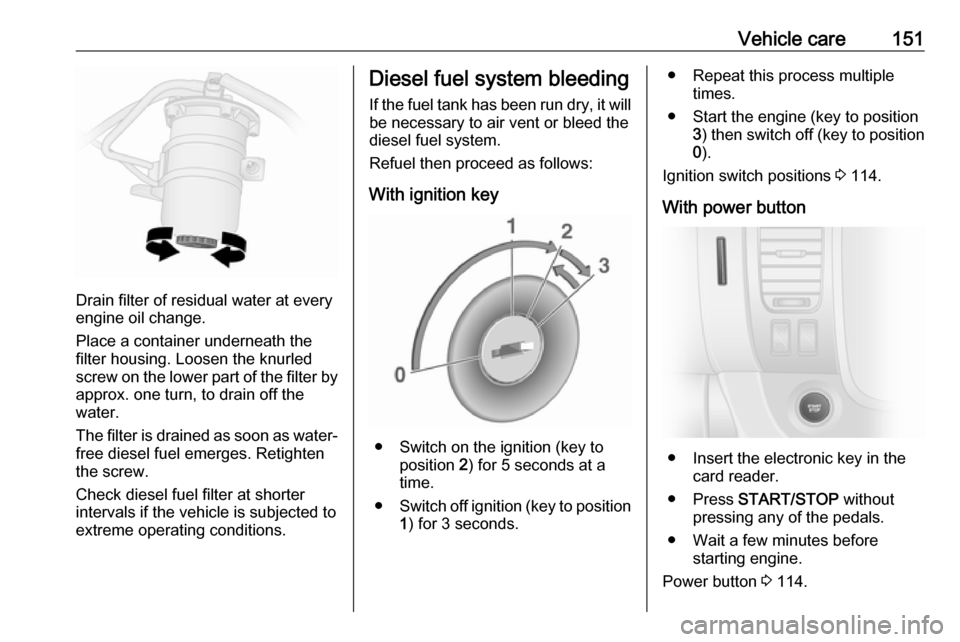

Diesel fuel system bleeding

If the fuel tank has been run dry, it will be necessary to air vent or bleed the

diesel fuel system.

Refuel then proceed as follows:

With ignition key

● Switch on the ignition (key to position 2) for 5 seconds at a

time.

● Switch off ignition (key to position

1 ) for 3 seconds.

● Repeat this process multiple

times.

● Start the engine (key to position 3) then switch off (key to position

0 ).

Ignition switch positions 3 114.

With power button

● Insert the electronic key in the card reader.

● Press START/STOP without

pressing any of the pedals.

● Wait a few minutes before starting engine.

Power button 3 114.

Page 154 of 209

152Vehicle careIf the engine fails to start, seek the

assistance of a workshop.

Starting the engine 3 116.

Wiper blade replacement

Wiper blades on the windscreen

Lift the wiper arm, press button to

disengage the wiper blade and

remove.

Attach new wiper blade slightly

angled to the wiper arm and push until

it engages.

Lower wiper arm carefully.

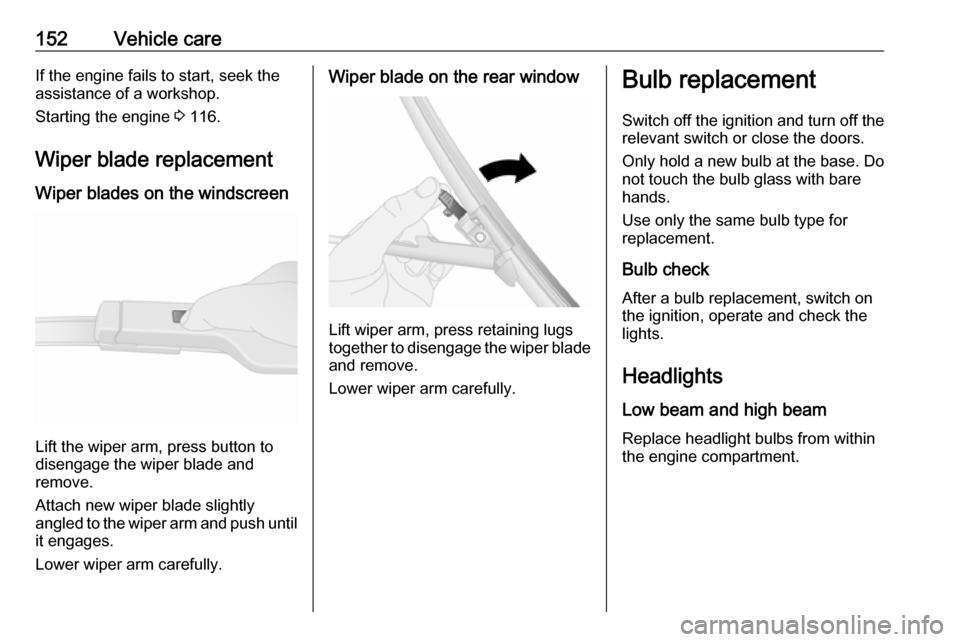

Wiper blade on the rear window

Lift wiper arm, press retaining lugs

together to disengage the wiper blade

and remove.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and turn off the relevant switch or close the doors.

Only hold a new bulb at the base. Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Bulb check After a bulb replacement, switch on

the ignition, operate and check the

lights.

Headlights

Low beam and high beam

Replace headlight bulbs from within

the engine compartment.

Page 166 of 209

164Vehicle careThe tyre pressure information labelon the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

Always inflate tyres to the pressures

shown on the label.

Tyre pressures 3 196.

The tyre pressure data refers to cold tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 186.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 196.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The TPMS sensors monitor the air

pressure in the tyres and transmit tyre pressure readings to a receiver

located in the vehicle.

Tyre pressure chart 3 196.

Tyre pressures in display

The current tyre pressures can be

shown in the Driver Information

Centre (DIC) 3 89.

Page 168 of 209

166Vehicle carePuncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 85 and a corresponding message

appears in the DIC. Stop vehicle and

switch off engine.

Tyre pressure 3 196, Tyre repair kit

3 168, Spare wheel 3 172, Wheel

changing 3 171.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the tyre information label and tyre

pressure chart are valid for cold tyres,

which means at 20 °C. The pressure

increases by nearly 1.5 psi for a

10 °C temperature increase. This

must be considered when warm tyres

are checked.The tyre pressure value displayed in

the DIC shows the actual tyre

pressure. A cooled down tyre will show a decreased value, which does

not indicate an air leak.

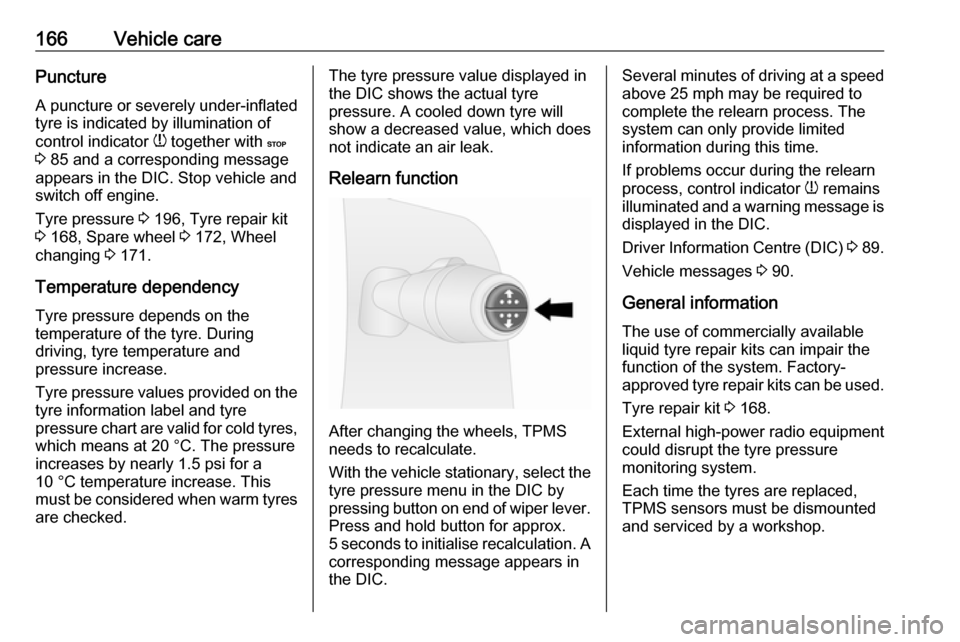

Relearn function

After changing the wheels, TPMS

needs to recalculate.

With the vehicle stationary, select the tyre pressure menu in the DIC by

pressing button on end of wiper lever.

Press and hold button for approx.5 seconds to initialise recalculation. A

corresponding message appears in

the DIC.

Several minutes of driving at a speed above 25 mph may be required to

complete the relearn process. The

system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is

displayed in the DIC.

Driver Information Centre (DIC) 3 89.

Vehicle messages 3 90.

General information The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 168.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, TPMS sensors must be dismounted

and serviced by a workshop.

Page 171 of 209

Vehicle care169

3. Screw the air hose to theconnection on the sealant bottle.

4. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

5. Unscrew valve cap from defective

tyre.6. Screw the filler hose to the tyre valve.

7. The switch on the compressor must be set to O.

8. Connect the electrical connection cable to the power outlet or

cigarette lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.9. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

10. The compressor pressure gauge briefly indicates up to 6 bar(600 kPa/87 psi). Then the

pressure starts to drop.

11. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 173 of 209

Vehicle care171Notice

The driving characteristics of the

repaired tyre is severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Pay attention to storage information

and expiry date on sealant bottle. Its

sealing capability is not guaranteed

after this time.

Replace the used sealant bottle. Dispose of the sealant bottle as

prescribed by applicable laws.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 168.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear.● Remove the spare wheel 3 172.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for a seasonal winter or summer

tyre change.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts/nuts and thread with a clean cloth before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover (using the hook supplied). Vehicle tools

3 162.

2. Loosen each of the wheel bolts by

half a turn using the wheel

wrench. Ensure the wrench

locates securely. The wrench

should turn anticlockwise to

loosen the bolts. Invert the wrench if necessary.

Page 176 of 209

174Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and the vehicle battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral.

● Open the positive terminal protection caps of both batteries.

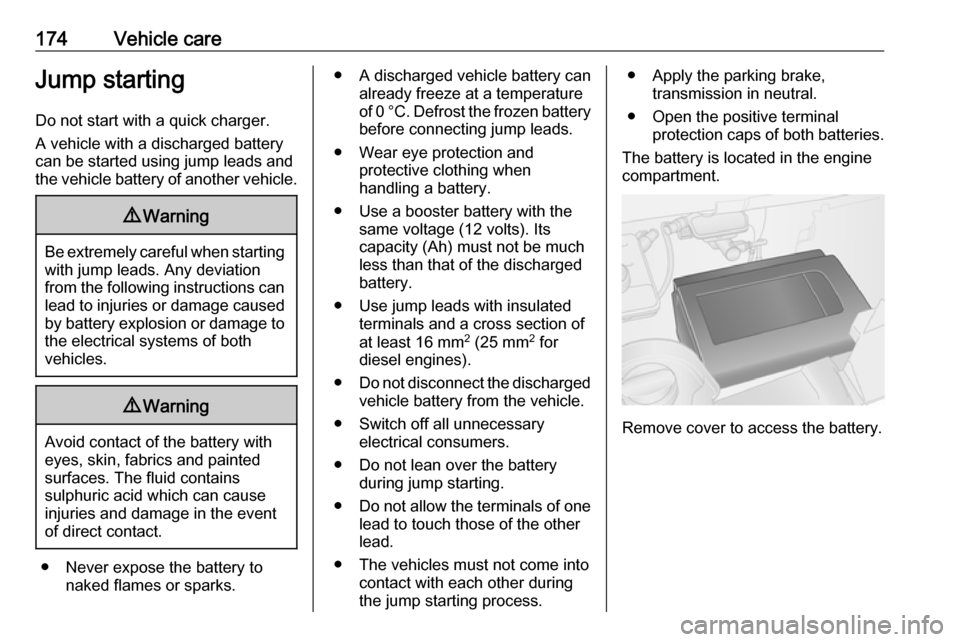

The battery is located in the engine

compartment.

Remove cover to access the battery.

Page 177 of 209

Vehicle care175

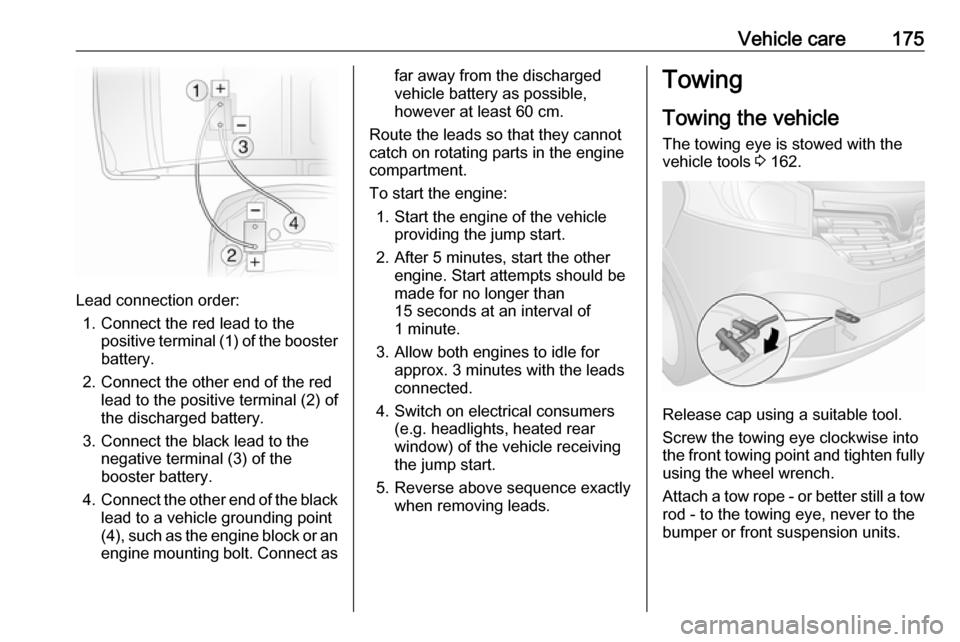

Lead connection order:1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the positive terminal (2) of

the discharged battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

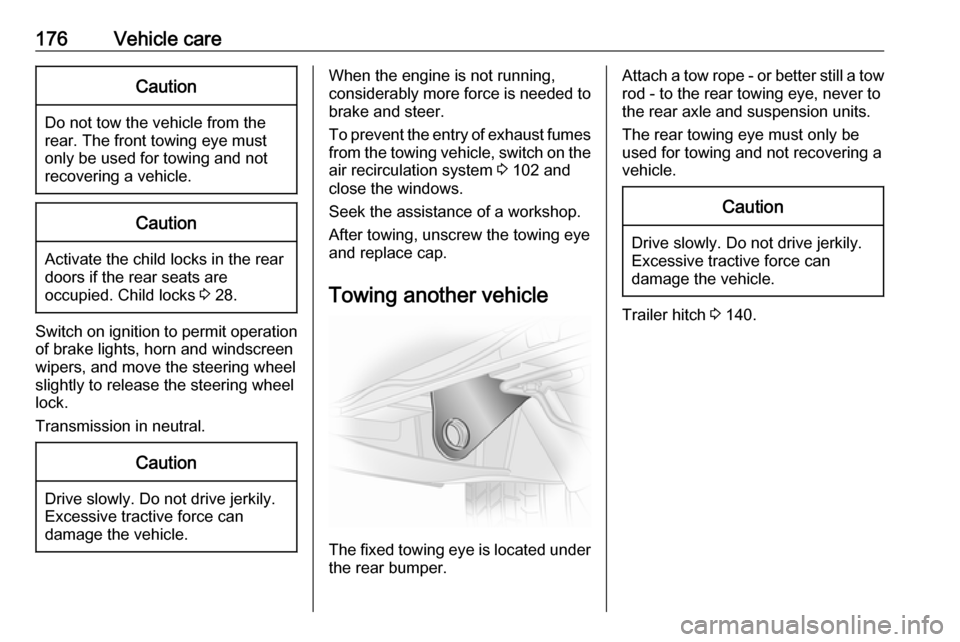

Towing the vehicle The towing eye is stowed with thevehicle tools 3 162.

Release cap using a suitable tool.

Screw the towing eye clockwise into

the front towing point and tighten fully

using the wheel wrench.

Attach a tow rope - or better still a tow rod - to the towing eye, never to the

bumper or front suspension units.

Page 178 of 209

176Vehicle careCaution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Caution

Activate the child locks in the rear

doors if the rear seats are

occupied. Child locks 3 28.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system 3 102 and

close the windows.

Seek the assistance of a workshop.

After towing, unscrew the towing eye

and replace cap.

Towing another vehicle

The fixed towing eye is located under the rear bumper.

Attach a tow rope - or better still a tow

rod - to the rear towing eye, never to

the rear axle and suspension units.

The rear towing eye must only be

used for towing and not recovering a

vehicle.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

Trailer hitch 3 140.

Page 179 of 209

Vehicle care177Appearance care

Exterior care LocksThe locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use de-icing agent only when

absolutely necessary, as this has a

degreasing effect and impairs lock

function. After using a de-icing agent,

have the locks regreased by a

workshop.

WashingThe paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly.

When using automatic vehicle

washes, select a programme that

includes waxing. Restrictions for

filmed or matt painted body parts or decor tapes, see "Polishing and

waxing".

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can cause paint damage.If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wipers

and rear window wiper must be

switched off and the exterior mirrors

must be folded in. Remove antenna

and external accessories such as roof racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.Caution

Always use a cleaning agent with

a pH value of 4 to 9.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a protective film, making waxing

unnecessary.

Unpainted plastic body parts must not

be treated with wax or polishing

agents.