clock VAUXHALL VIVARO C 2020 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: VIVARO C, Model: VAUXHALL VIVARO C 2020Pages: 289, PDF Size: 10.16 MB

Page 226 of 289

224Vehicle care3. Detach the bulb from the bulbsocket and replace the bulb.

4. Insert the bulb socket into the reflector housing.

5. Fit the cover.

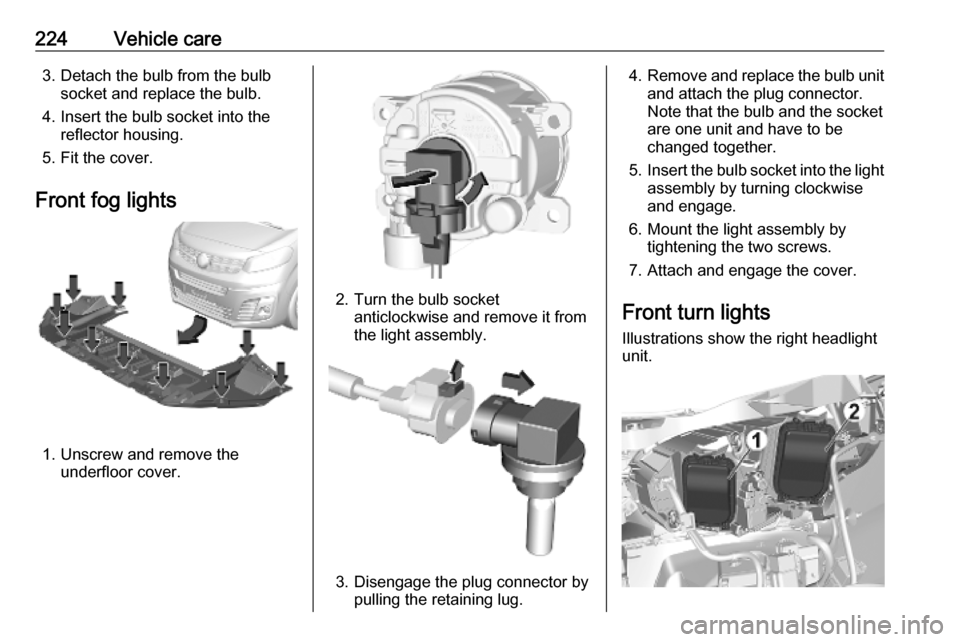

Front fog lights

1. Unscrew and remove the underfloor cover.

2. Turn the bulb socketanticlockwise and remove it from

the light assembly.

3. Disengage the plug connector by pulling the retaining lug.

4.Remove and replace the bulb unit

and attach the plug connector.

Note that the bulb and the socket

are one unit and have to be

changed together.

5. Insert the bulb socket into the light

assembly by turning clockwise

and engage.

6. Mount the light assembly by tightening the two screws.

7. Attach and engage the cover.

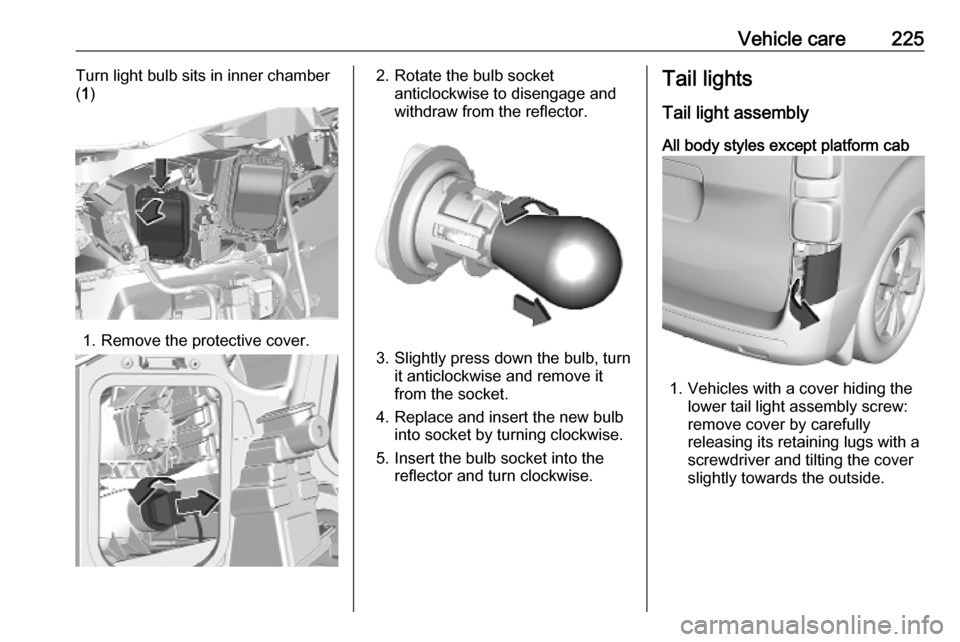

Front turn lights Illustrations show the right headlight

unit.

Page 227 of 289

Vehicle care225Turn light bulb sits in inner chamber

( 1 )

1. Remove the protective cover.

2. Rotate the bulb socket

anticlockwise to disengage and

withdraw from the reflector.

3. Slightly press down the bulb, turn it anticlockwise and remove it

from the socket.

4. Replace and insert the new bulb into socket by turning clockwise.

5. Insert the bulb socket into the reflector and turn clockwise.

Tail lights

Tail light assembly All body styles except platform cab

1. Vehicles with a cover hiding the lower tail light assembly screw:

remove cover by carefully

releasing its retaining lugs with a

screwdriver and tilting the cover

slightly towards the outside.

Page 229 of 289

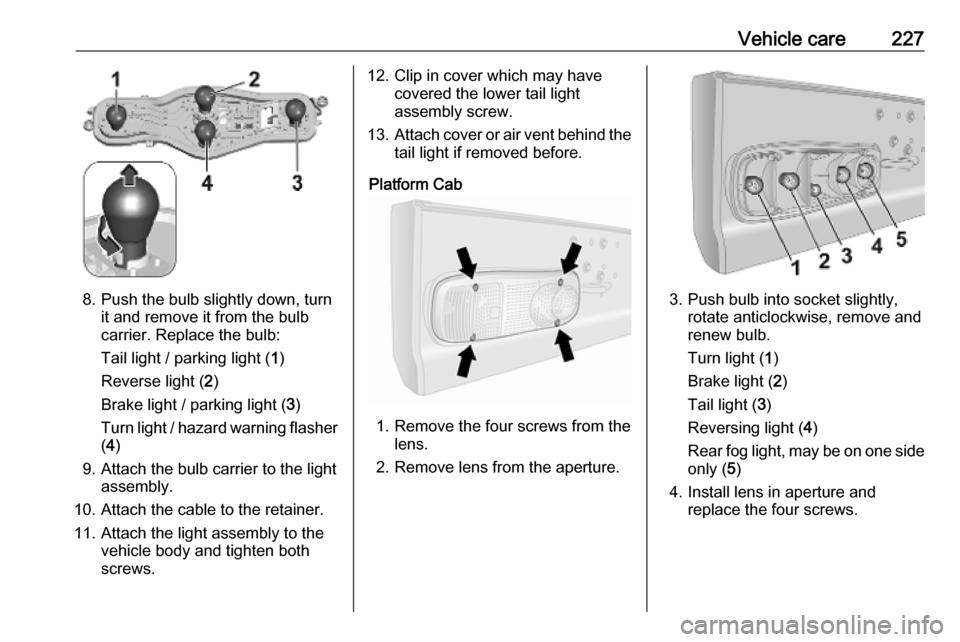

Vehicle care227

8. Push the bulb slightly down, turnit and remove it from the bulb

carrier. Replace the bulb:

Tail light / parking light ( 1)

Reverse light ( 2)

Brake light / parking light ( 3)

Turn light / hazard warning flasher

( 4 )

9. Attach the bulb carrier to the light assembly.

10. Attach the cable to the retainer.

11. Attach the light assembly to the vehicle body and tighten both

screws.

12. Clip in cover which may have covered the lower tail light

assembly screw.

13. Attach cover or air vent behind the

tail light if removed before.

Platform Cab

1. Remove the four screws from the lens.

2. Remove lens from the aperture.

3. Push bulb into socket slightly, rotate anticlockwise, remove and

renew bulb.

Turn light ( 1)

Brake light ( 2)

Tail light ( 3)

Reversing light ( 4)

Rear fog light, may be on one side

only ( 5)

4. Install lens in aperture and replace the four screws.

Page 231 of 289

Vehicle care229Wrap a cloth around the tip of a

slot screwdriver to prevent paint

damage. Remove the inner cover

or air vent with the screwdriver.

3. Push the brake light assembly carefully out through the recess.

4. Detach the cable from the retainer

in the light assembly.

5. Remove the socket of the defect bulb by turning it a quarter turn

anti-clockwise.

6. Renew bulb.

7. Install brake light assembly like explained above, in reversed

order.

Number plate light

1. a) vehicles with tailgate:

Insert a thin screwdriver, e.g., in

one of the recesses of the cover and push it outwards to unclip it.

Remove the cover.

b) vehicles with hinged doors:

Insert a screwdriver in one of the

recesses of the cover and lever it

out. Remove the cover.

Page 245 of 289

Vehicle care243Repeat the checking procedure

once more after driving further

three miles but no more than ten

minutes to check that there is no

more loss of pressure.

If the tyre pressure has fallen

below 150 kPa (1.5 bar), the

vehicle must not be used. Seek

the assistance of a workshop.

13. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant cartridge. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

Removing the pipe and cartridge

1. Turn pipe assembly to the left until

it contacts the unit.

2. Disconnect the connector from the cartridge by turning it a quarter

turn anti-clockwise.

Page 246 of 289

244Vehicle care3. Pull pipe assembly out slightly,then disconnect connector from

the air hose by turning it a quarter

turn anticlockwise.

4. Remove air hose.

Keep the kit vertical and unscrew

the cartridge from the bottom.

5. To fit the new cartridge and new pipe, carry out these operations in

reverse order.

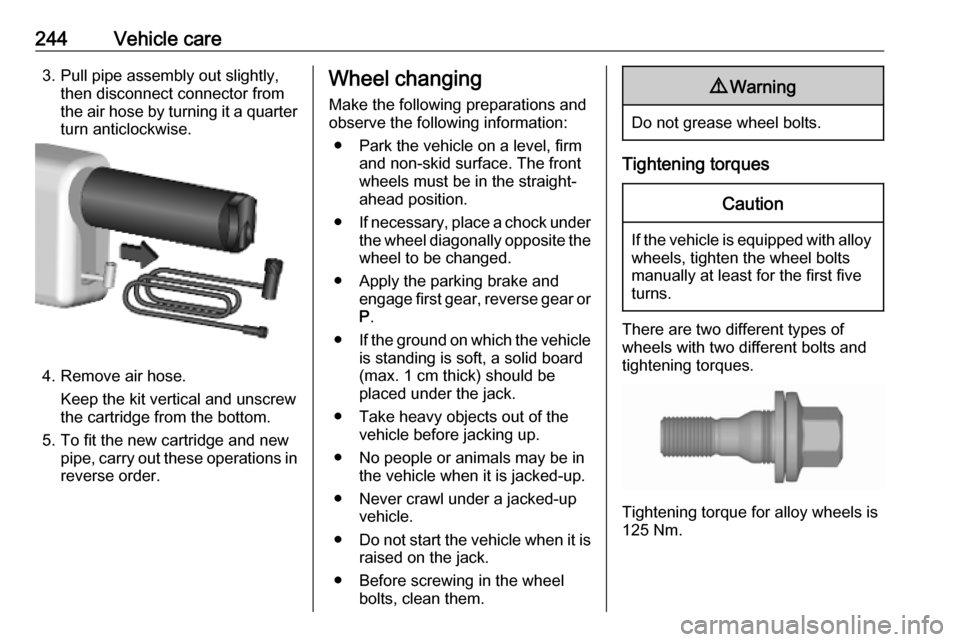

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

Tightening torques

Caution

If the vehicle is equipped with alloy

wheels, tighten the wheel bolts

manually at least for the first five

turns.

There are two different types of

wheels with two different bolts and tightening torques.

Tightening torque for alloy wheels is

125 Nm.

Page 248 of 289

246Vehicle care

2. Remove the cover of the carrierbolt, located on the rear door sill

3. Fit the wheel wrench on thehexagon bolt. Turn it

anticlockwise until the spare wheel holder is low enough to

allow the catch to be unhooked.

4. Lift the spare wheel holder and unhook the catch.

Lower the spare wheel holder.

5. Remove the spare wheel.

6. Change the wheel.

7. Position the damaged wheel with the outside down in the spare

wheel holder.

8. Lift the spare wheel holder and engage in the catch. The open

side of the catch must point in the

direction of travel.

9. Close the spare wheel holder by turning the hexagon bolt

clockwise using the wheel

wrench.

10. Stow wheel wrench in the storage.

11. Close the tailgate or the rear doors.

Page 253 of 289

Vehicle care251Towing

Towing the vehicle

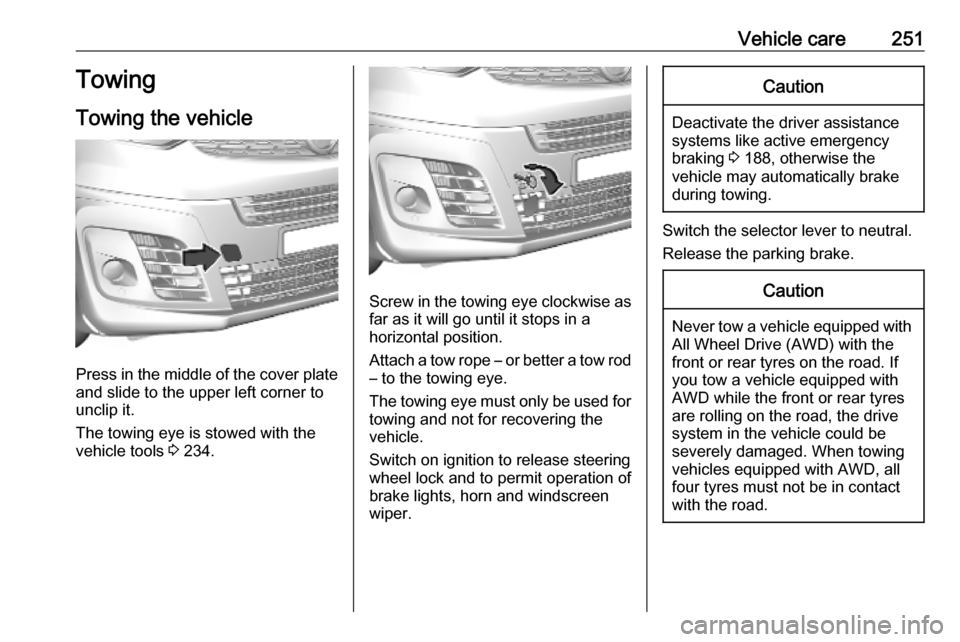

Press in the middle of the cover plate

and slide to the upper left corner to

unclip it.

The towing eye is stowed with the vehicle tools 3 234.

Screw in the towing eye clockwise as

far as it will go until it stops in a

horizontal position.

Attach a tow rope – or better a tow rod

– to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 188, otherwise the

vehicle may automatically brake during towing.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Never tow a vehicle equipped with All Wheel Drive (AWD) with the

front or rear tyres on the road. If

you tow a vehicle equipped with

AWD while the front or rear tyres

are rolling on the road, the drive

system in the vehicle could be

severely damaged. When towing

vehicles equipped with AWD, all

four tyres must not be in contact

with the road.

Page 254 of 289

252Vehicle careCaution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap with the flange into the

recess and fix cap by pushing.

Towing another vehicle

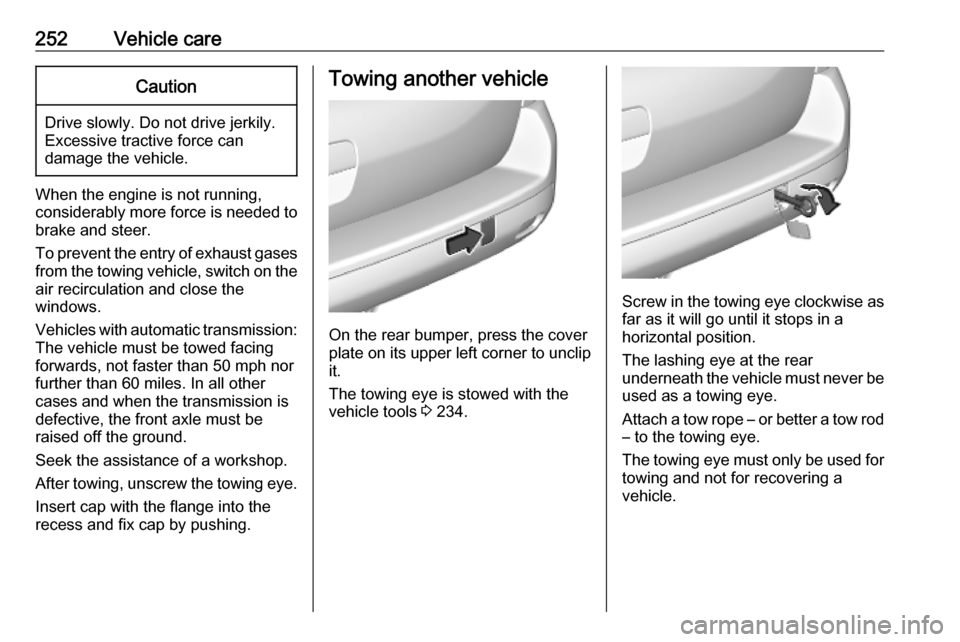

On the rear bumper, press the cover

plate on its upper left corner to unclip it.

The towing eye is stowed with the

vehicle tools 3 234.

Screw in the towing eye clockwise as

far as it will go until it stops in a

horizontal position.

The lashing eye at the rear

underneath the vehicle must never be used as a towing eye.

Attach a tow rope – or better a tow rod

– to the towing eye.

The towing eye must only be used for towing and not for recovering a

vehicle.

Page 258 of 289

256Vehicle carePlastic and rubber parts

Plastic and rubber parts can be

cleaned with the same cleaner as

used to clean the body. Use interior

cleaner if necessary. Do not use any

other agent. Avoid solvents and petrol in particular. Do not use high-

pressure jet cleaners.

Floor mats9 Warning

If a floor mat has the wrong size or

is not properly installed, it can

interfere with the accelerator pedal

and/or brake pedal, what can

cause unintended acceleration

and/or increased stopping

distance which can cause a crash and injury.

Use the following guidelines for

proper floor mat usage.

● The original equipment floor mats

were designed for your vehicle. If the floor mats need replacing, it

is recommended that certified

floor mats be purchased. Always

check that the floor mats do not

interfere with the pedals.

● Use the floor mat with the correct

side up. Do not turn it over.

● Do not place anything on top of the driver side floor mat.

● Use only a single floor mat on the

driver side.

● Do not place one floor mat on top

of another.

Inserting and removing the floor

mats

The driver side floor mat is held in

place by two retainers.

To install the driver's side floor mat: 1. Move the driver's seat backwards

as far as possible.

2. Align slots in the mat with the retainers, as shown.

3. Turn retainers clockwise for aquarter turn.