parking brake VAUXHALL ZAFIRA TOURER 2015 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2015Pages: 297, PDF Size: 8.99 MB

Page 165 of 297

Driving and operating163

8. Unscrew the hose from the fillerneck.

9. Mount the protective cap and turn

clockwise until it engages.

Notice

Dispose of AdBlue canister and

hose according to environmental requirements.

Exchanging AdBlue

If less than 5 litres of AdBlue have

been refilled during the last 2 years,

the remaining fluid should be

exchanged since AdBlue has a

limited durability.Caution

Disregard could lead to damage to

the selective catalytic reduction

system.

Automatic transmission

The automatic transmission permits

automatic gearshifting (automatic

mode) or manual gearshifting

(manual mode).

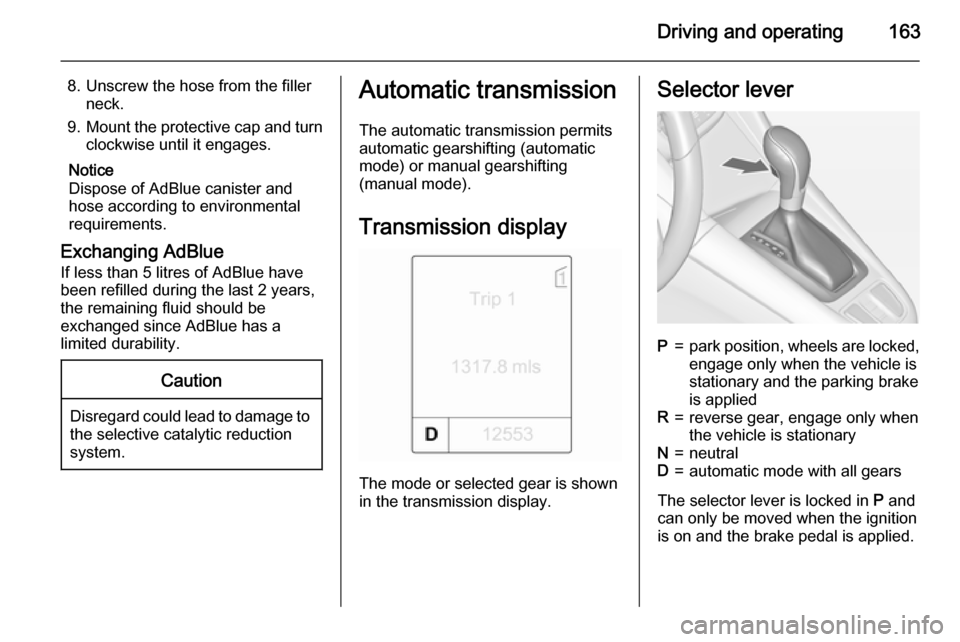

Transmission display

The mode or selected gear is shown

in the transmission display.

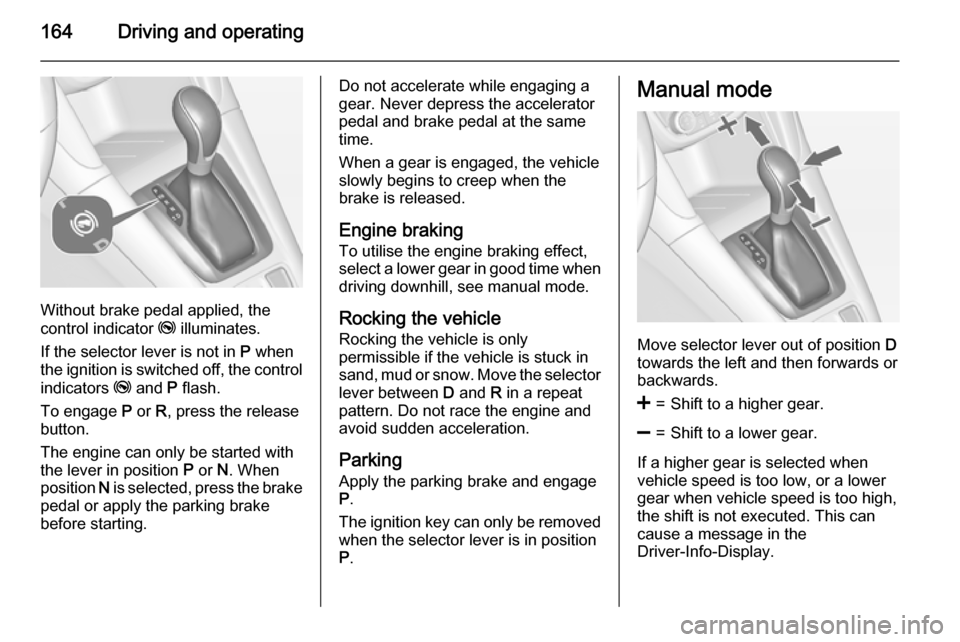

Selector leverP=park position, wheels are locked, engage only when the vehicle is

stationary and the parking brake

is appliedR=reverse gear, engage only when

the vehicle is stationaryN=neutralD=automatic mode with all gears

The selector lever is locked in P and

can only be moved when the ignition is on and the brake pedal is applied.

Page 166 of 297

164Driving and operating

Without brake pedal applied, the

control indicator j illuminates.

If the selector lever is not in P when

the ignition is switched off, the control

indicators j and P flash.

To engage P or R, press the release

button.

The engine can only be started with the lever in position P or N. When

position N is selected, press the brake

pedal or apply the parking brake

before starting.

Do not accelerate while engaging a

gear. Never depress the accelerator

pedal and brake pedal at the same

time.

When a gear is engaged, the vehicle

slowly begins to creep when the

brake is released.

Engine braking To utilise the engine braking effect,select a lower gear in good time when

driving downhill, see manual mode.

Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

sand, mud or snow. Move the selector

lever between D and R in a repeat

pattern. Do not race the engine and

avoid sudden acceleration.

Parking

Apply the parking brake and engage P .

The ignition key can only be removed

when the selector lever is in position

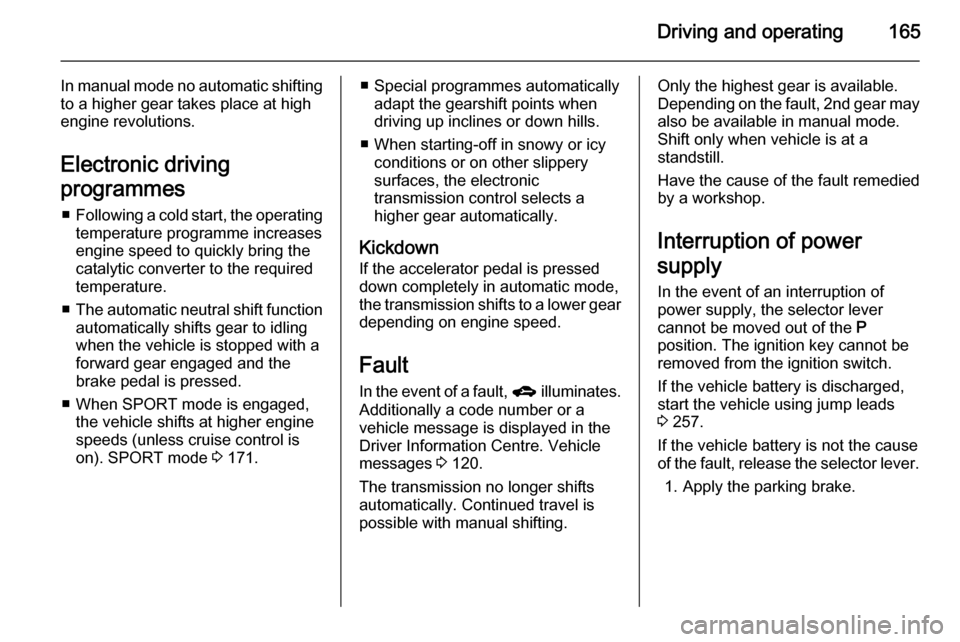

P .Manual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<=Shift to a higher gear.]=Shift to a lower gear.

If a higher gear is selected when

vehicle speed is too low, or a lower

gear when vehicle speed is too high,

the shift is not executed. This can

cause a message in the

Driver-Info-Display.

Page 167 of 297

Driving and operating165

In manual mode no automatic shiftingto a higher gear takes place at high

engine revolutions.

Electronic driving

programmes ■ Following a cold start, the operating

temperature programme increasesengine speed to quickly bring the

catalytic converter to the required

temperature.

■ The automatic neutral shift function

automatically shifts gear to idling

when the vehicle is stopped with a

forward gear engaged and the

brake pedal is pressed.

■ When SPORT mode is engaged, the vehicle shifts at higher engine

speeds (unless cruise control is

on). SPORT mode 3 171.■ Special programmes automatically

adapt the gearshift points when

driving up inclines or down hills.

■ When starting-off in snowy or icy conditions or on other slippery

surfaces, the electronic

transmission control selects a

higher gear automatically.

Kickdown If the accelerator pedal is pressed

down completely in automatic mode, the transmission shifts to a lower gear depending on engine speed.

Fault In the event of a fault, g illuminates.

Additionally a code number or a

vehicle message is displayed in the

Driver Information Centre. Vehicle

messages 3 120.

The transmission no longer shifts

automatically. Continued travel is

possible with manual shifting.Only the highest gear is available.

Depending on the fault, 2nd gear may also be available in manual mode.

Shift only when vehicle is at a

standstill.

Have the cause of the fault remedied by a workshop.

Interruption of power

supply In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position. The ignition key cannot be

removed from the ignition switch.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 257.

If the vehicle battery is not the cause

of the fault, release the selector lever.

1. Apply the parking brake.

Page 170 of 297

168Driving and operating

Fault9Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can no longer be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

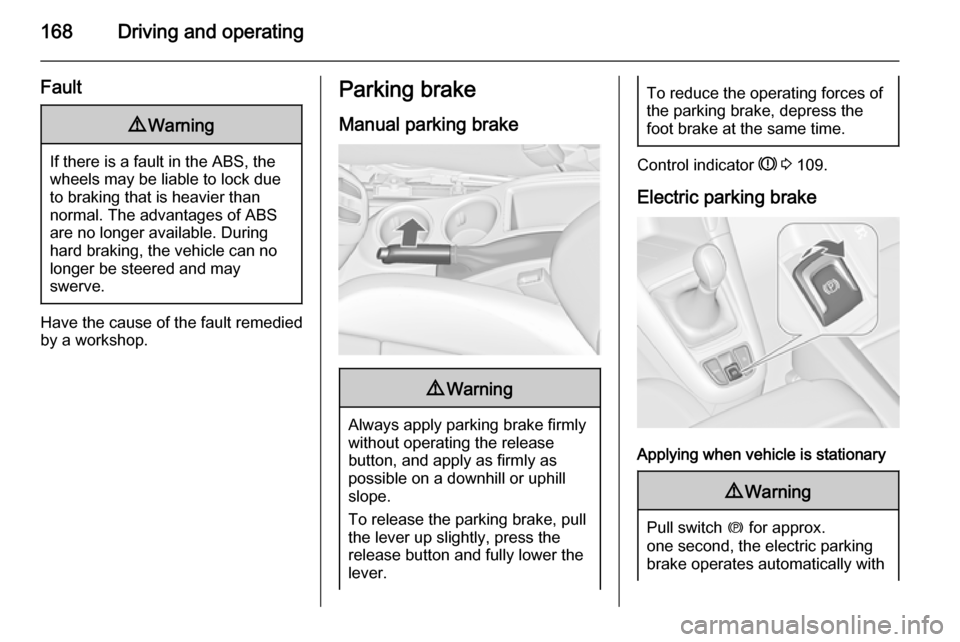

Parking brake

Manual parking brake9 Warning

Always apply parking brake firmly

without operating the release

button, and apply as firmly as

possible on a downhill or uphill

slope.

To release the parking brake, pull

the lever up slightly, press the

release button and fully lower the

lever.

To reduce the operating forces of

the parking brake, depress the

foot brake at the same time.

Control indicator R 3 109.

Electric parking brake

Applying when vehicle is stationary

9 Warning

Pull switch m for approx.

one second, the electric parking

brake operates automatically with

Page 171 of 297

Driving and operating169adequate force. For maximum

force, e.g. parking with trailer or on

inclines, pull switch m twice.

The electric parking brake is

applied when control indicator m

illuminates 3 109.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often with engine not

running, as this will discharge the

vehicle battery.

Before leaving the vehicle, check the electric parking brake status. Control

indicator m 3 109.

Releasing

Switch on ignition. Keep brake pedal

depressed and then press switch m.

Drive away function

Depressing clutch pedal (manual

transmission) or engaging drive gear

(automatic transmission) and then

depressing the accelerator pedal

releases the electric parking brake

automatically. This is not possible

when the switch is pulled at the same

time.

This function also helps driving away

on inclines.

Aggressive drive-away may reduce

lifetime of wear parts.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Fault

Failure mode of electric parking brake

is indicated by control indicator j and

by a code number or a vehicle

message which is displayed in the

Driver Information Centre (DIC).

Vehicle messages 3 120.Apply electric parking brake: pull and

hold switch m for more than

5 seconds. If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: press and hold switch m for more than

2 seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or released. When continuously

flashing, release electric parking

brake and retry applying.

Brake assist

If the brake pedal is depressed

quickly and forcefully, maximum

brake force is automatically applied

(full braking).

Maintain steady pressure on the

brake pedal for as long as full braking is required. Maximum brake force isautomatically reduced when the

brake pedal is released.

Page 219 of 297

Vehicle care217Vehicle careGeneral Information...................217

Vehicle checks ........................... 218

Bulb replacement .......................226

Electrical system ........................234

Vehicle tools .............................. 241

Wheels and tyres .......................241

Jump starting ............................. 257

Towing ....................................... 258

Appearance care .......................260General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Fill up fuel tank completely.

■ Change the engine oil.

■ Drain the washer fluid reservoir.

■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear or set selector lever to P . Prevent the vehicle from rolling.

■ Do not apply the parking brake.

Page 239 of 297

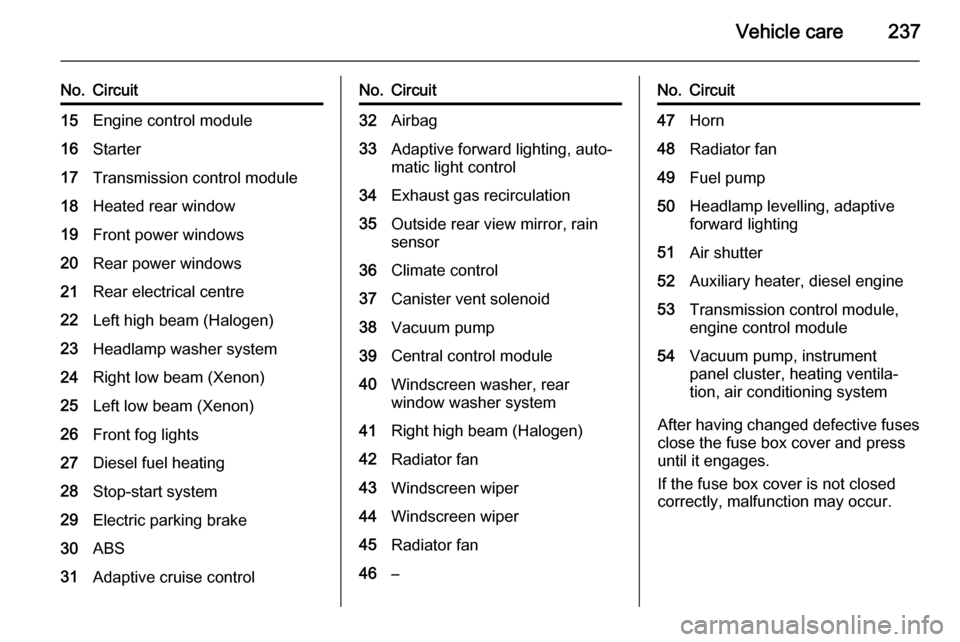

Vehicle care237

No.Circuit15Engine control module16Starter17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear electrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27Diesel fuel heating28Stop-start system29Electric parking brake30ABS31Adaptive cruise controlNo.Circuit32Airbag33Adaptive forward lighting, auto‐

matic light control34Exhaust gas recirculation35Outside rear view mirror, rain

sensor36Climate control37Canister vent solenoid38Vacuum pump39Central control module40Windscreen washer, rear

window washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44Windscreen wiper45Radiator fan46–No.Circuit47Horn48Radiator fan49Fuel pump50Headlamp levelling, adaptive

forward lighting51Air shutter52Auxiliary heater, diesel engine53Transmission control module,

engine control module54Vacuum pump, instrument

panel cluster, heating ventila‐

tion, air conditioning system

After having changed defective fuses

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 247 of 297

Vehicle care245

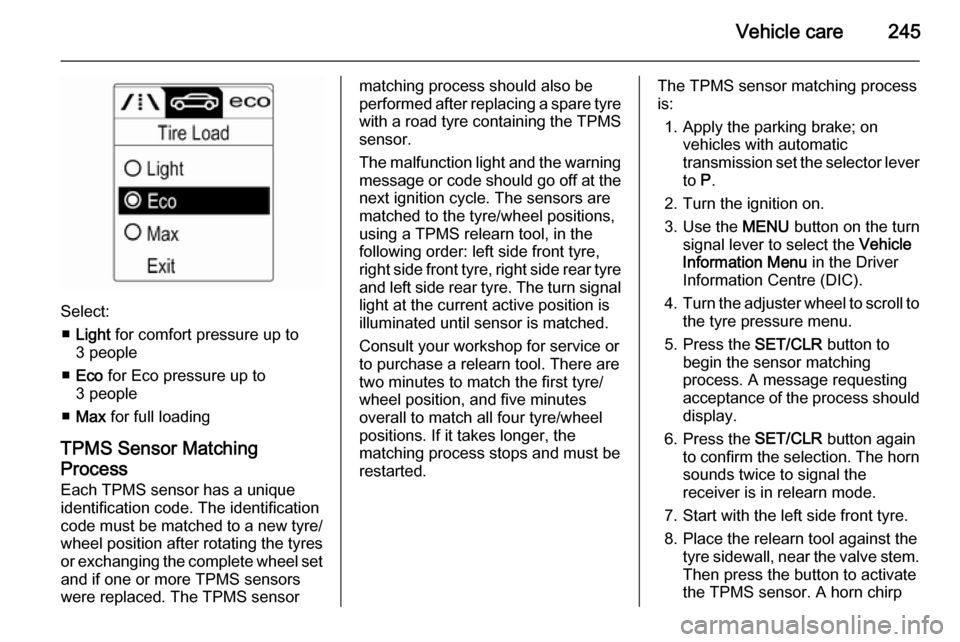

Select:■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: left side front tyre,

right side front tyre, right side rear tyre and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

Page 250 of 297

248Vehicle care

The use of tyre chains is not permittedon the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

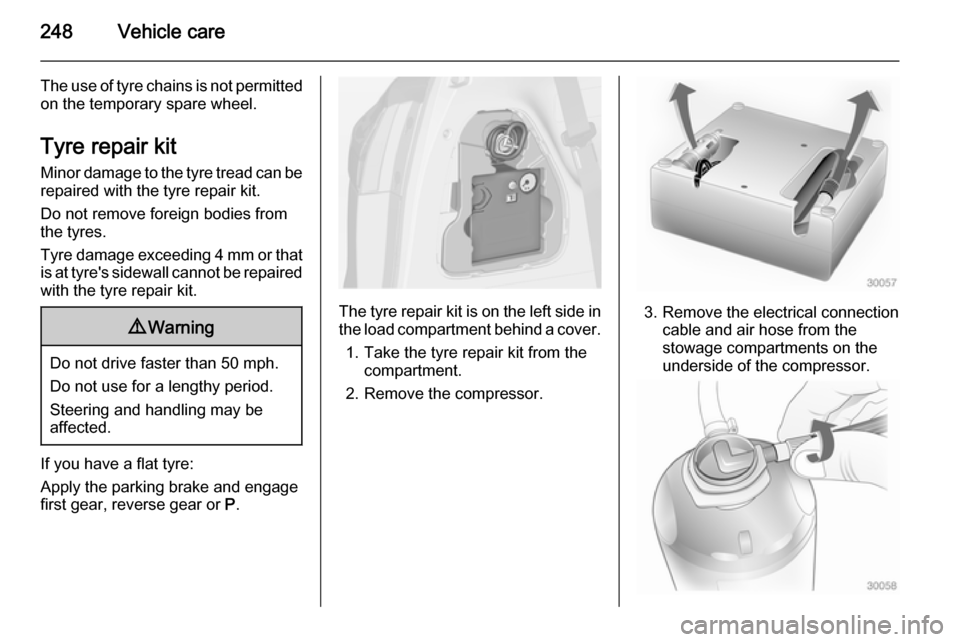

The tyre repair kit is on the left side in

the load compartment behind a cover.

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 253 of 297

Vehicle care251

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 253.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Clean wheel nuts and thread with a

clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

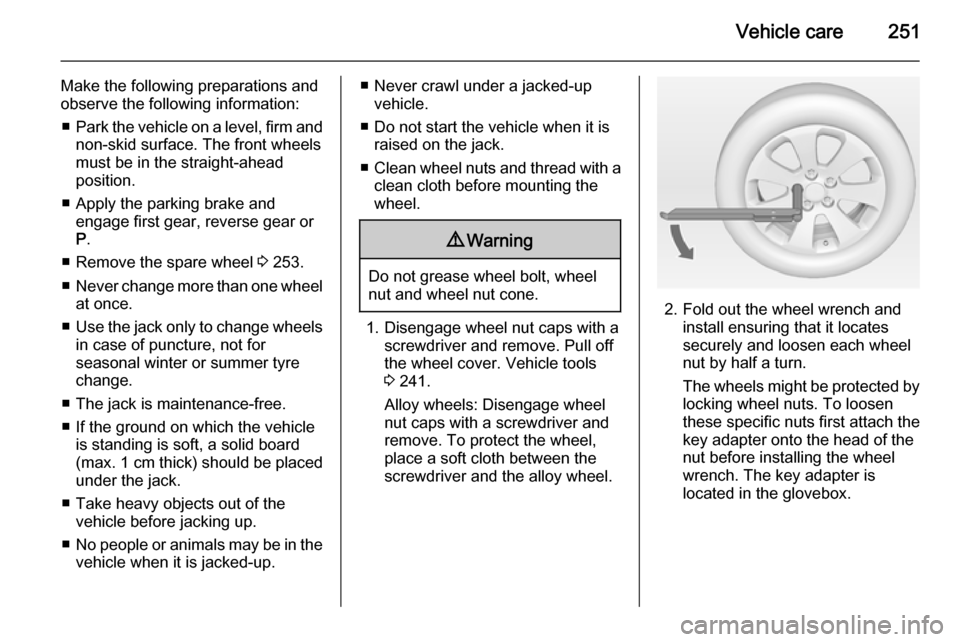

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 241.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

key adapter onto the head of the

nut before installing the wheel

wrench. The key adapter is

located in the glovebox.