Button VAUXHALL ZAFIRA TOURER 2017 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2017Pages: 289, PDF Size: 8.91 MB

Page 190 of 289

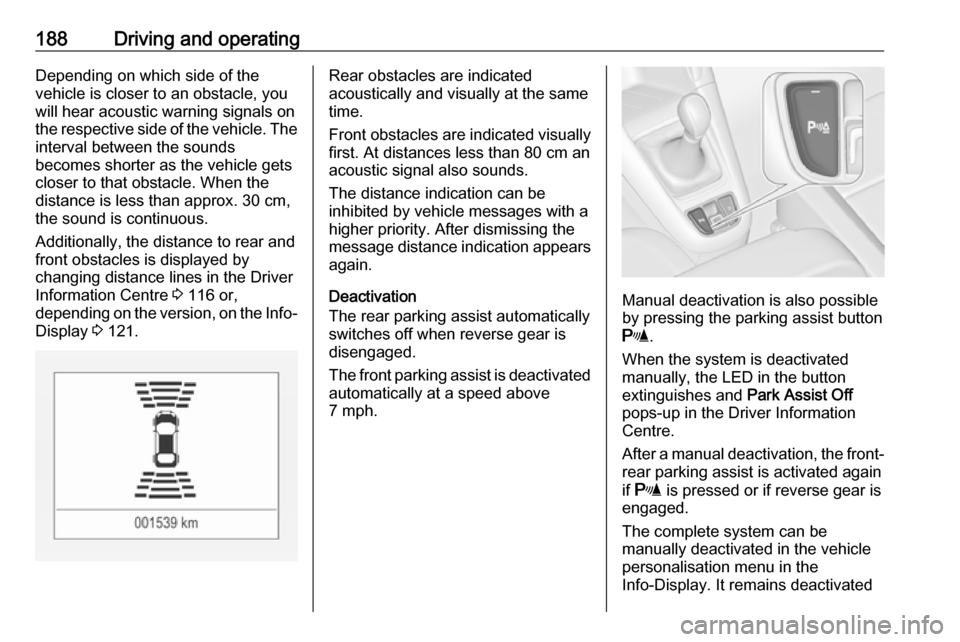

188Driving and operatingDepending on which side of the

vehicle is closer to an obstacle, you will hear acoustic warning signals on

the respective side of the vehicle. The

interval between the sounds

becomes shorter as the vehicle gets

closer to that obstacle. When the

distance is less than approx. 30 cm,

the sound is continuous.

Additionally, the distance to rear and

front obstacles is displayed by

changing distance lines in the Driver

Information Centre 3 116 or,

depending on the version, on the Info- Display 3 121.Rear obstacles are indicated

acoustically and visually at the same

time.

Front obstacles are indicated visually

first. At distances less than 80 cm an

acoustic signal also sounds.

The distance indication can be

inhibited by vehicle messages with a higher priority. After dismissing themessage distance indication appears again.

Deactivation

The rear parking assist automatically

switches off when reverse gear is

disengaged.

The front parking assist is deactivated

automatically at a speed above

7 mph.

Manual deactivation is also possible by pressing the parking assist button

r .

When the system is deactivated

manually, the LED in the button

extinguishes and Park Assist Off

pops-up in the Driver Information

Centre.

After a manual deactivation, the front- rear parking assist is activated again

if r is pressed or if reverse gear is

engaged.

The complete system can be

manually deactivated in the vehicle

personalisation menu in the

Info-Display. It remains deactivated

Page 194 of 289

192Driving and operatingDue to the high position of the

camera, the rear bumper can be seen on the display as a guide to position.

The area displayed by the camera is

limited. The distance of the image that

appears on the display differs from

the actual distance.

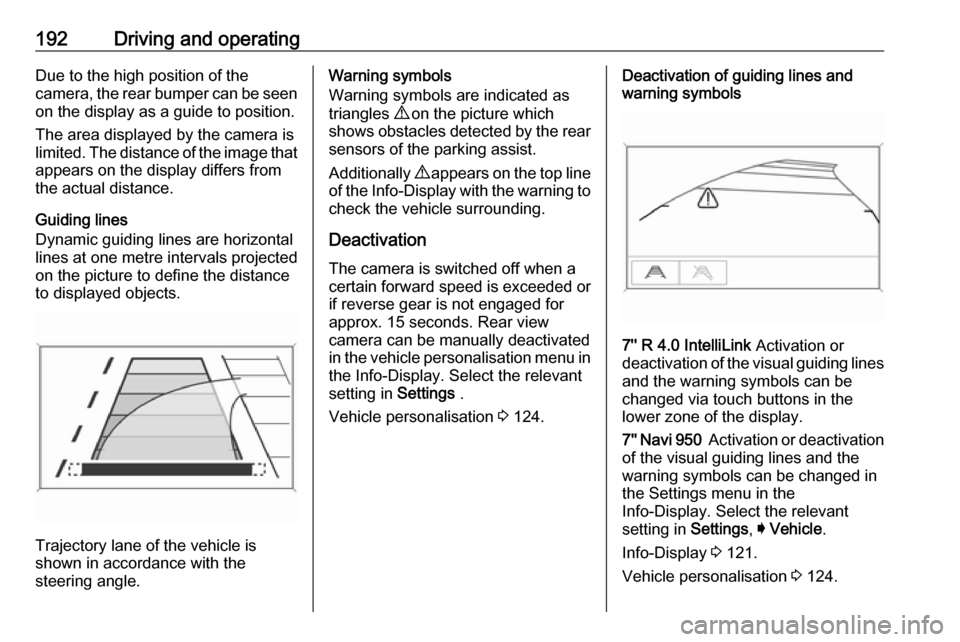

Guiding lines

Dynamic guiding lines are horizontal

lines at one metre intervals projected

on the picture to define the distance

to displayed objects.

Trajectory lane of the vehicle is

shown in accordance with the

steering angle.

Warning symbols

Warning symbols are indicated as

triangles 9 on the picture which

shows obstacles detected by the rear

sensors of the parking assist.

Additionally 9 appears on the top line

of the Info-Display with the warning to

check the vehicle surrounding.

Deactivation

The camera is switched off when a

certain forward speed is exceeded or

if reverse gear is not engaged for

approx. 15 seconds. Rear view

camera can be manually deactivated

in the vehicle personalisation menu in the Info-Display. Select the relevant

setting in Settings .

Vehicle personalisation 3 124.Deactivation of guiding lines and

warning symbols

7'' R 4.0 IntelliLink Activation or

deactivation of the visual guiding lines and the warning symbols can be

changed via touch buttons in the

lower zone of the display.

7'' Navi 950 Activation or deactivation

of the visual guiding lines and the

warning symbols can be changed in

the Settings menu in the

Info-Display. Select the relevant

setting in Settings, I Vehicle .

Info-Display 3 121.

Vehicle personalisation 3 124.

Page 199 of 289

Driving and operating197The lane departure warning system is

activated by pressing ). The

illuminated LED in the button

indicates that the system is switched

on. When the control indicator ) in

the instrument cluster illuminates

green, the system is ready to operate.

The system is only operable at

vehicle speeds above 35 mph and if

lane markings are available.

When the system recognises an

unintended lane change, the control

indicator ) changes to yellow and

flashes. Simultaneously a chime

sound is activated.

Deactivation

The system is deactivated by

pressing ), the LED in the button

extinguishes.

At speeds below 35 mph the system

is inoperable.

Fault

The lane departure warning system may not operate properly when:

● The windscreen is not clean.

● There are adverse environmental

conditions like heavy rain, snow,

direct sunlight or shadows.

The system can not operate when no

lane marking is detected.Fuel

Fuel for petrol engines Only use unleaded fuel that complies

with European standard EN 228 or

E DIN 51626-1 or equivalent.

The engine is capable of running with

fuel that contains up to 10% ethanol

(e.g. named E10).

Use fuel with the recommended

octane rating. A lower octane rating

can reduce engine power and torque

and slightly increases fuel

consumption.Caution

Do not use fuel or fuel additives

that contain metallic compounds

such as manganese-based

additives. This may cause engine

damage.

Page 207 of 289

Driving and operating205Press the button at the liquid gas

supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system to stop the filling process. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

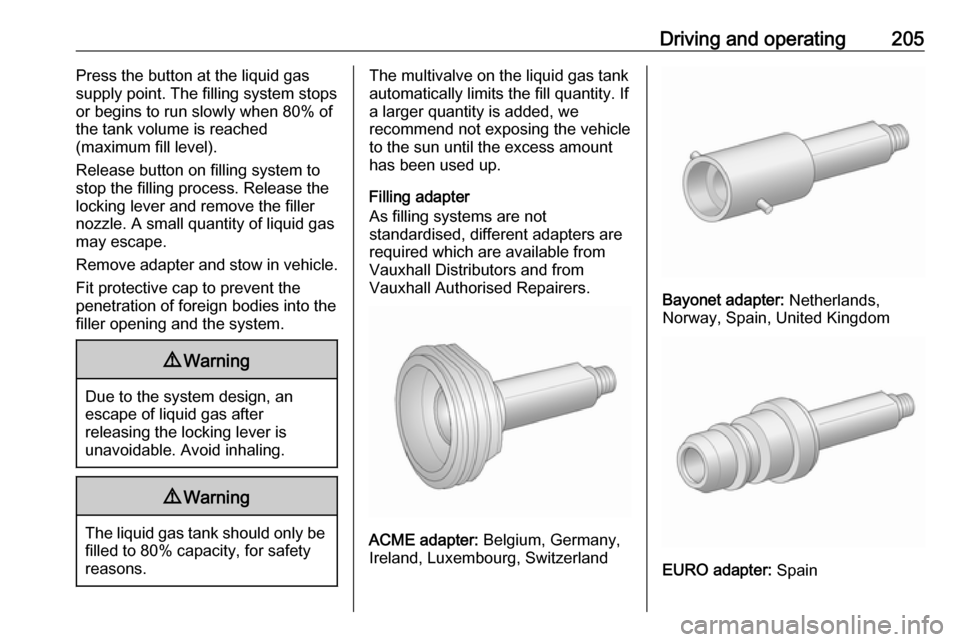

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

EURO adapter: Spain

Page 222 of 289

220Vehicle careMeaning of symbols:● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding

If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

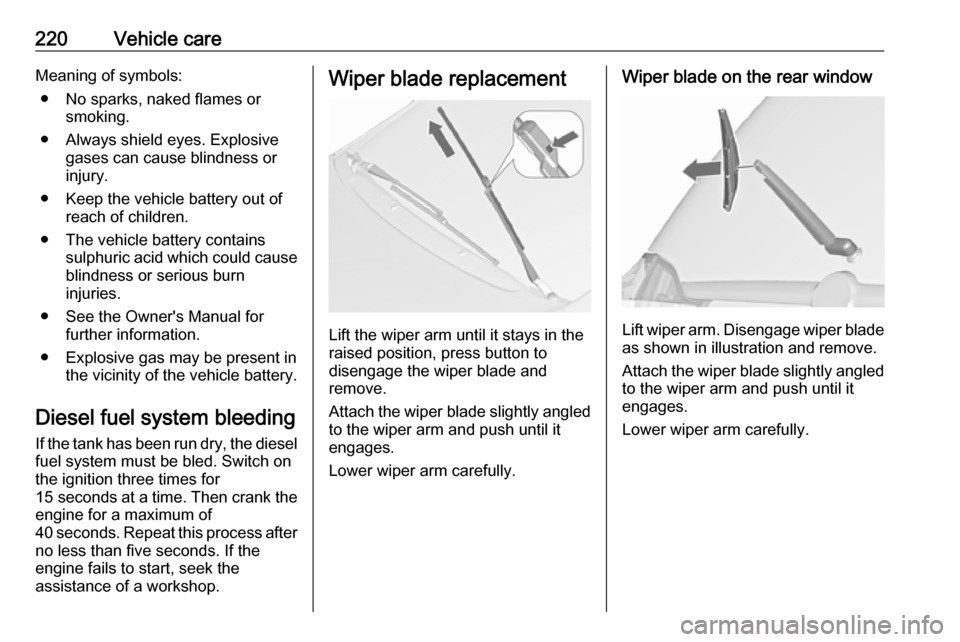

assistance of a workshop.Wiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 239 of 289

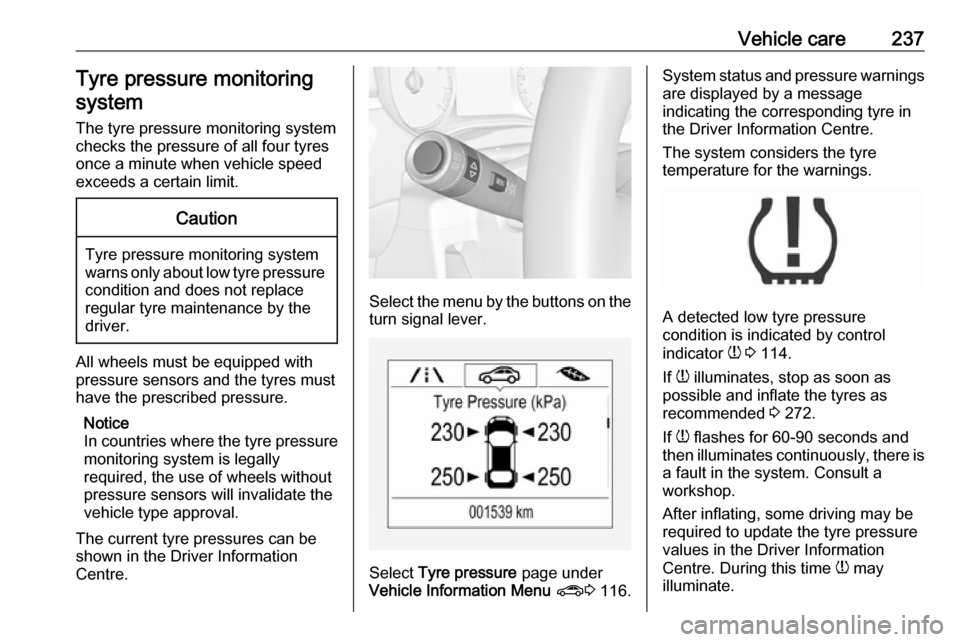

Vehicle care237Tyre pressure monitoringsystem

The tyre pressure monitoring system checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Driver Information

Centre.

Select the menu by the buttons on the turn signal lever.

Select Tyre pressure page under

Vehicle Information Menu ? 3 116.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

A detected low tyre pressure

condition is indicated by control

indicator w 3 114.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 272.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

Page 241 of 289

Vehicle care239the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle. The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service.

There are two minutes to match the

first wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the

Driver Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate the receiver is in

relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensor

identification code has been

Page 245 of 289

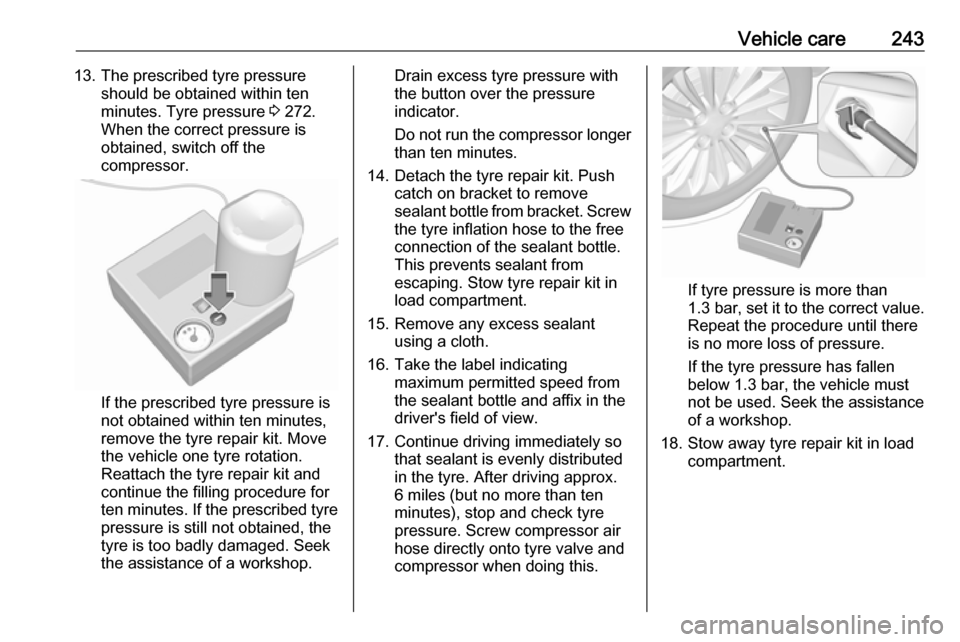

Vehicle care24313. The prescribed tyre pressureshould be obtained within ten

minutes. Tyre pressure 3 272.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

6 miles (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.