clock VOLKSWAGEN CORRADO 1990 User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 356 of 906

A/C SYSTEM PRECAUTIONS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

refrigerant into the system.

On 2-piece can taps, be certain tap handle is turned fully

inward to the closed position. Check that locking base is turned to

its outer limit. Securely engage locking lugs over the can flange.

Turn entire tap assembly (without disturbing the closed setting)

downward into the locking base to pierce the can. DO NOT open tap

until ready to dispense into system.

SCREW TYPE SEAL CANS

Ensure can tap is fully closed. Screw refrigerant can into

can tap fitting until tight. This will pierce the can. Connect tap to

center hose on manifold gauge set. DO NOT open tap until ready to

dispense R-12 into system.

WARNING: DO NOT open high side hand valve while air conditioning

system is in operation. This high pressure could rupture can

or fitting at safety can valve, resulting in damage and

personal injury.

CONNECTING LINES & FITTINGS

A new "O" ring should be used in all instances when

connecting lines and fittings (dip "O" ring in clean refrigeration oil

and make certain it is not twisted during installation). Always use

two wrenches to avoid twisting or distorting lines and fittings,

tighten coupling nuts securely.

PLACING SYSTEM IN OPERATION

After component replacement and/or system servicing has been

completed and all connections have been made, proceed as follows:

1) Evacuate the system using a vacuum pump.

2) Charge the system with new R-12 (refrigerant) according to

each individual vehicle as outlined in the GENERAL SERVICING article.

Also see Refrigerant Capacity in this Section.

3) Leak test the system, with particular attention to all new

connections and components.

4) Make a performance test of the system. Never assume that a

recharging has automatically corrected a problem.

COMPRESSOR REMOVAL INFORMATION - ISOLATION METHOD

On systems which have compressors equipped with stem-type

service valves (Tecumseh), it is possible to isolate the compressor

for removal.

Isolating

Turn both high and low pressure manual valves to extreme

clockwise (front seat) position. Loosen cap on high pressure manual

Page 358 of 906

A/C-HEATER SYSTEM - MANUAL

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 MANUAL A/C-HEATER SYSTEMS

Volkswagen

Cabriolet, Corrado, Fox, Golf GL, GTI,

Jetta, Jetta GLi, Vanagon

* PLEASE READ THIS FIRST *

CAUTION: When discharging air conditioning system, use only approved

refrigerant recovery/recycling equipment. Make every attempt

to avoid discharging refrigerant into the atmosphere.

AIR BAG WARNING

WARNING: To avoid accidental air bag deployment on Cabriolet, see AIR

BAG DEACTIVATION under SERVICING PRECAUTIONS in this article.

DESCRIPTION

The Volkswagen air conditioning system is a cycling clutch

type. The compressor is cycled on and off by a thermostatic switch to

maintain constant cooling rate.

Other components include an evaporator, expansion valve,

receiver-drier, control panel, condenser, high-pressure switch and a

low-pressure switch. On Vanagon, the A/C thermostat can be found on

left rear pillar, above relay panel assembly (behind trim panel).

The control panel includes a pair of levers and a fan control

switch. The upper lever operates air distribution flap. The lower

lever controls temperature selection. The rotary fan control switch

controls fan speed selection.

OPERATION

SYSTEM CONTROLS

Air Distribution Lever

When in A/C position, cool air is routed to registers and

side air vents. In BI-LEVEL position, cool air is routed to floor

vents as well as registers and side air vents. In HEAT position, warm

air is routed to windshield vents, side window nozzles and floor and

center registers. In DEFOG position, warm air is routed to windshield

vents, side window nozzles and side registers.

Fan Control Knob

The fan control knob controls airflow. As knob is turned

clockwise, air intake opens and fan operates, increasing speed as knob

is moved to extreme right position.

Page 362 of 906

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

MICROSWITCH

Loosen microswitch mounting screw. Move microswitch so switch

is on when lever is at maximum A/C, NORM (normal), BI-LEVEL or extreme

right position, and off when lever is at VENT or HEAT position.

Tighten microswitch mounting screw. Recheck operation.

TEMPERATURE SWITCH

Move temperature lever to full cool position. Loosen

temperature switch mounting screw. Move temperature switch

counterclockwise to full stop position. Tighten temperature switch

mounting screw.

TROUBLE SHOOTING

NO COOLING

1) Ensure fan motor operates in all 4 speeds, air duct closes

off outside air and heater water valve is closed. Adjust belt tension.

2) Inspect receiver-drier pressure seal. If seal is good, go

to step 5). If seal is broken, evacuate and recharge system. If system

cools properly, testing is complete. If system does not cool, connect

pressure gauges.

3) Set engine speed at 2500 RPM. Insert thermometer in left

register and close all others. Place controls on high blower and

maximum cooling. With vehicle out of direct sunlight, close all

windows. Radiator fan should come on with system pressure at 200 psi

(14 kg/cmý).

NOTE: If system doors allow air leaks, evaporator will freeze up

and testing will not be possible.

4) If fan does not operate, replace pressure switch. Ensure

system is okay. If fan does come on, turn engine off and check for

condenser obstructions and blocked airflow.

5) Turn air conditioner on and off with temperature control

lever. Ensure compressor clutch engages. Push lever to extreme right

position and back again. A click should be heard from compressor

clutch. If a click is not heard, check for voltage at clutch coil wire

with switch on. If voltage is present, replace clutch coil. If voltage

is not present, check wiring or replace thermostatic switch.

6) If compressor clutch operates, check gauge readings. If

both are low, locate leak and recharge system. If both are high,

replace expansion valve. If low side is too high and high side reads

too low, replace or rebuild compressor.

INSUFFICIENT COOLING

1) Ensure fan motor operates at all 4 speeds, air duct closes

off outside air intake and heater water valve is closed. Adjust

compressor belt tension and clean condenser.

Page 380 of 906

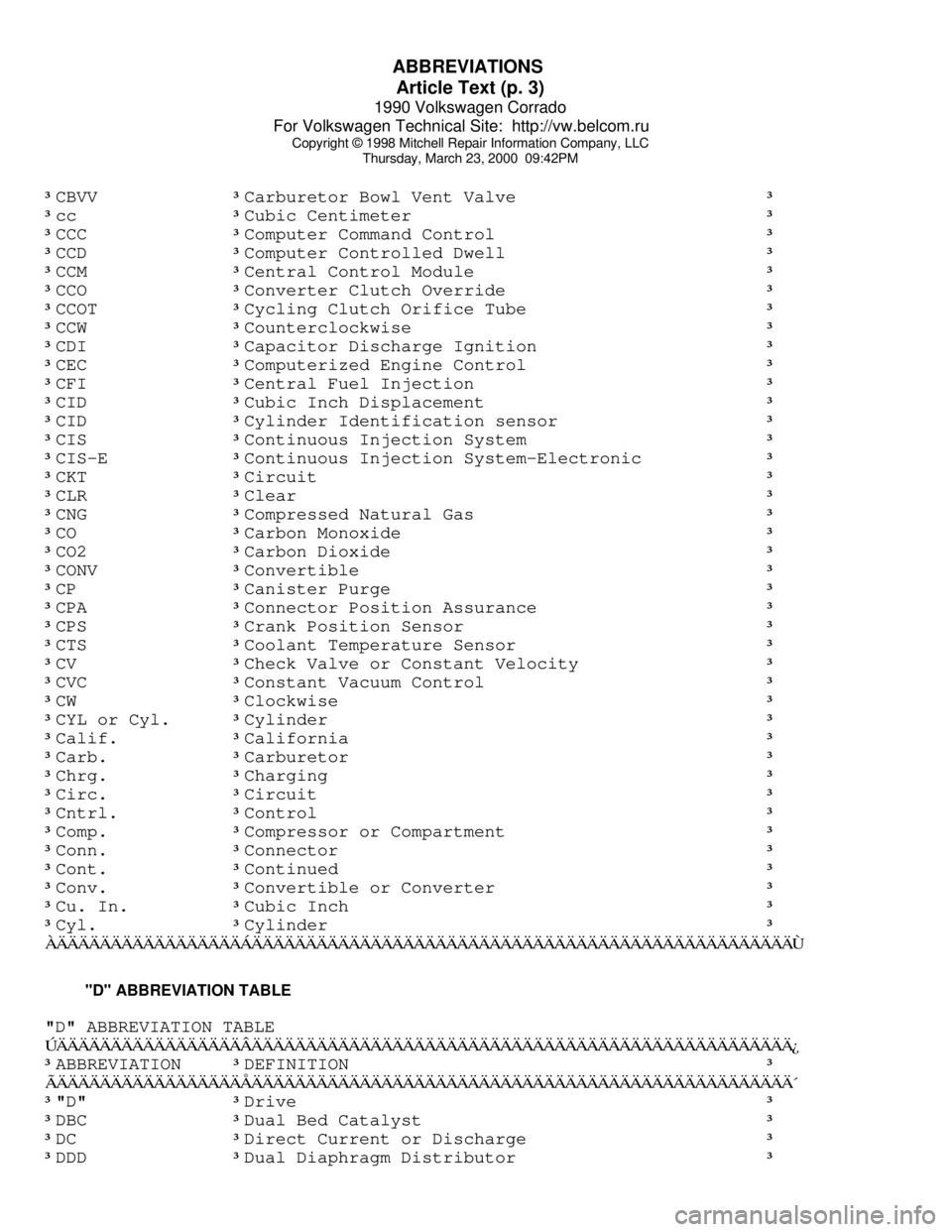

ABBREVIATIONS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PM³CBVV ³Carburetor Bowl Vent Valve ³

³cc

³Cubic Centimeter ³

³CCC

³Computer Command Control ³

³CCD

³Computer Controlled Dwell ³

³CCM

³Central Control Module ³

³CCO

³Converter Clutch Override ³

³CCOT

³Cycling Clutch Orifice Tube ³

³CCW

³Counterclockwise ³

³CDI

³Capacitor Discharge Ignition ³

³CEC

³Computerized Engine Control ³

³CFI

³Central Fuel Injection ³

³CID

³Cubic Inch Displacement ³

³CID

³Cylinder Identification sensor ³

³CIS

³Continuous Injection System ³

³CIS-E

³Continuous Injection System-Electronic ³

³CKT

³Circuit ³

³CLR

³Clear ³

³CNG

³Compressed Natural Gas ³

³CO

³Carbon Monoxide ³

³CO2

³Carbon Dioxide ³

³CONV

³Convertible ³

³CP

³Canister Purge ³

³CPA

³Connector Position Assurance ³

³CPS

³Crank Position Sensor ³

³CTS

³Coolant Temperature Sensor ³

³CV

³Check Valve or Constant Velocity ³

³CVC

³Constant Vacuum Control ³

³CW

³Clockwise ³

³CYL or Cyl.

³Cylinder ³

³Calif.

³California ³

³Carb.

³Carburetor ³

³Chrg.

³Charging ³

³Circ.

³Circuit ³

³Cntrl.

³Control ³

³Comp.

³Compressor or Compartment ³

³Conn.

³Connector ³

³Cont.

³Continued ³

³Conv.

³Convertible or Converter ³

³Cu. In.

³Cubic Inch ³

³Cyl.

³Cylinder ³

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ "D" ABBREVIATION TABLE

"D" ABBREVIATION TABLE

ÚÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

³ABBREVIATION

³DEFINITION ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³"D"

³Drive ³

³DBC

³Dual Bed Catalyst ³

³DC

³Direct Current or Discharge ³

³DDD

³Dual Diaphragm Distributor ³

Page 392 of 906

ABBREVIATIONS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PM³CBD ³Closed Bowl Distributor ³

³CBVV

³Carburetor Bowl Vent Valve ³

³cc

³Cubic Centimeter ³

³CCC

³Computer Command Control ³

³CCD

³Computer Controlled Dwell ³

³CCM

³Central Control Module ³

³CCO

³Converter Clutch Override ³

³CCOT

³Cycling Clutch Orifice Tube ³

³CCW

³Counterclockwise ³

³CDI

³Capacitor Discharge Ignition ³

³CEC

³Computerized Engine Control ³

³CFI

³Central Fuel Injection ³

³CID

³Cubic Inch Displacement ³

³CID

³Cylinder Identification sensor ³

³CIS

³Continuous Injection System ³

³CIS-E

³Continuous Injection System-Electronic ³

³CKT

³Circuit ³

³CLR

³Clear ³

³CNG

³Compressed Natural Gas ³

³CO

³Carbon Monoxide ³

³CO2

³Carbon Dioxide ³

³CONV

³Convertible ³

³CP

³Canister Purge ³

³CPA

³Connector Position Assurance ³

³CPS

³Crank Position Sensor ³

³CTS

³Coolant Temperature Sensor ³

³CV

³Check Valve or Constant Velocity ³

³CVC

³Constant Vacuum Control ³

³CW

³Clockwise ³

³CYL or Cyl.

³Cylinder ³

³Calif.

³California ³

³Carb.

³Carburetor ³

³Chrg.

³Charging ³

³Circ.

³Circuit ³

³Cntrl.

³Control ³

³Comp.

³Compressor or Compartment ³

³Conn.

³Connector ³

³Cont.

³Continued ³

³Conv.

³Convertible or Converter ³

³Cu. In.

³Cubic Inch ³

³Cyl.

³Cylinder ³

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ "D" ABBREVIATION TABLE

"D" ABBREVIATION TABLE

ÚÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

³ABBREVIATION

³DEFINITION ³

ÃÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´

³"D"

³Drive ³

³DBC

³Dual Bed Catalyst ³

³DC

³Direct Current or Discharge ³

Page 442 of 906

D - ADJUSTMENTS

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

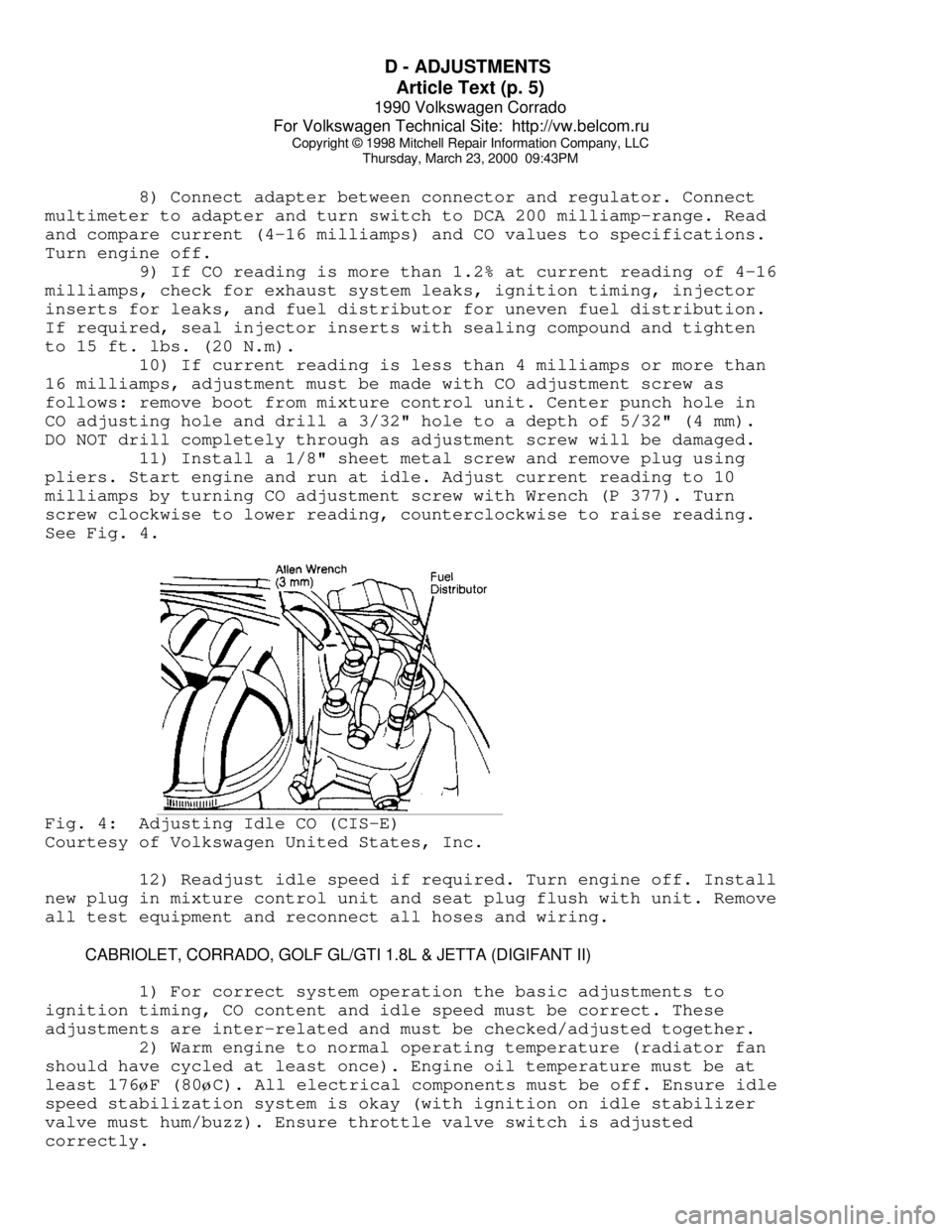

8) Connect adapter between connector and regulator. Connect

multimeter to adapter and turn switch to DCA 200 milliamp-range. Read

and compare current (4-16 milliamps) and CO values to specifications.

Turn engine off.

9) If CO reading is more than 1.2% at current reading of 4-16

milliamps, check for exhaust system leaks, ignition timing, injector

inserts for leaks, and fuel distributor for uneven fuel distribution.

If required, seal injector inserts with sealing compound and tighten

to 15 ft. lbs. (20 N.m).

10) If current reading is less than 4 milliamps or more than

16 milliamps, adjustment must be made with CO adjustment screw as

follows: remove boot from mixture control unit. Center punch hole in

CO adjusting hole and drill a 3/32" hole to a depth of 5/32" (4 mm).

DO NOT drill completely through as adjustment screw will be damaged.

11) Install a 1/8" sheet metal screw and remove plug using

pliers. Start engine and run at idle. Adjust current reading to 10

milliamps by turning CO adjustment screw with Wrench (P 377). Turn

screw clockwise to lower reading, counterclockwise to raise reading.

See Fig. 4.Fig. 4: Adjusting Idle CO (CIS-E)

Courtesy of Volkswagen United States, Inc.

12) Readjust idle speed if required. Turn engine off. Install

new plug in mixture control unit and seat plug flush with unit. Remove

all test equipment and reconnect all hoses and wiring.

CABRIOLET, CORRADO, GOLF GL/GTI 1.8L & JETTA (DIGIFANT II)

1) For correct system operation the basic adjustments to

ignition timing, CO content and idle speed must be correct. These

adjustments are inter-related and must be checked/adjusted together.

2) Warm engine to normal operating temperature (radiator fan

should have cycled at least once). Engine oil temperature must be at

least 176øF (80øC). All electrical components must be off. Ensure idle

speed stabilization system is okay (with ignition on idle stabilizer

valve must hum/buzz). Ensure throttle valve switch is adjusted

correctly.

Page 443 of 906

D - ADJUSTMENTS

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

NOTE: Before checking engine timing, raise engine speed above 2100

RPM at least 4 times. This must be done each time ignition

is turned off and restarted to clear ECU memory and by-pass

hot-start, fast-idle function.

3) Connect an inductive tachometer or Tester (VW 1367) to

alternator, Test Lead (VW 1473) to ignition coil, and timing light

lead to No. 1 spark plug wire. See Fig. 2. Start engine and ensure

engine speed and timing are correct. If not, adjust to specification.

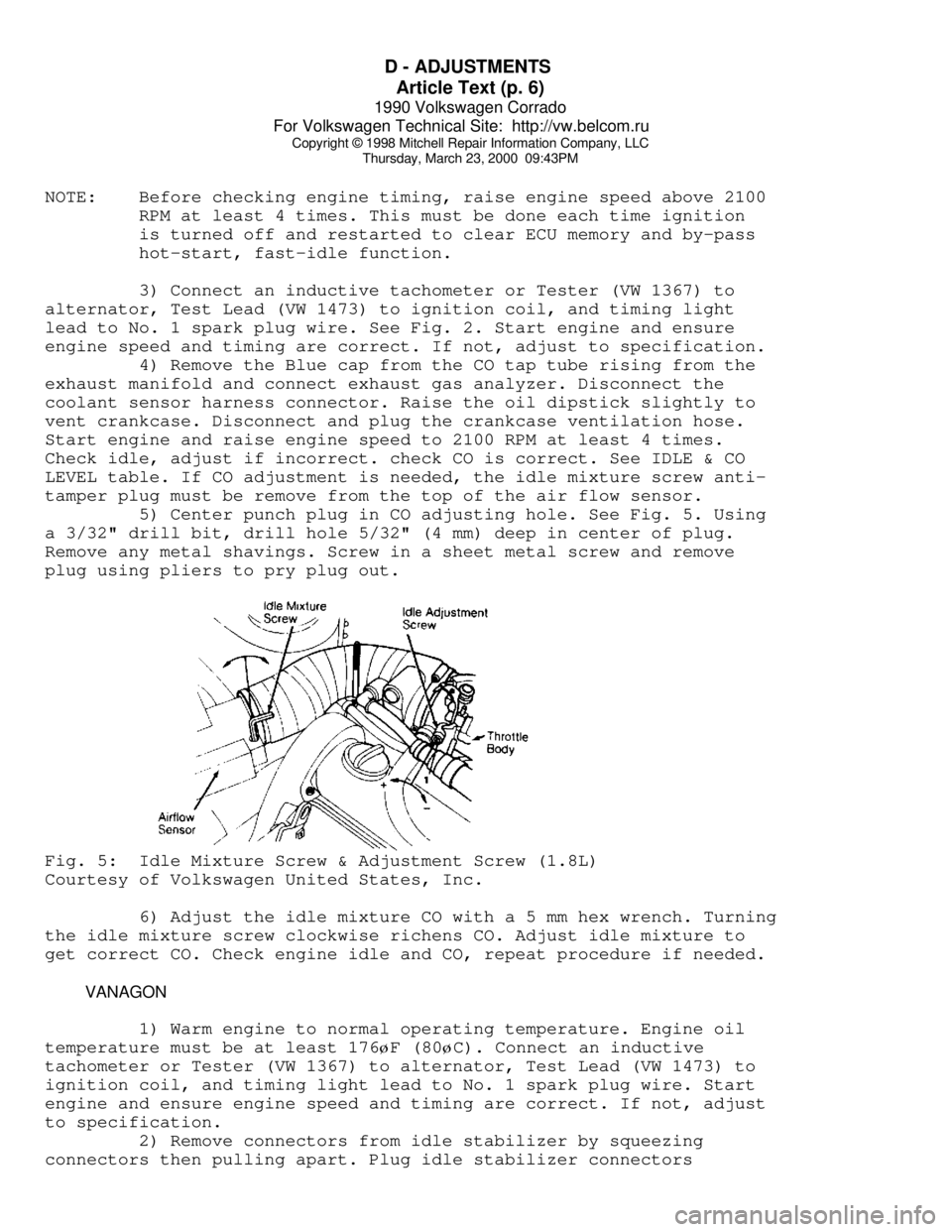

4) Remove the Blue cap from the CO tap tube rising from the

exhaust manifold and connect exhaust gas analyzer. Disconnect the

coolant sensor harness connector. Raise the oil dipstick slightly to

vent crankcase. Disconnect and plug the crankcase ventilation hose.

Start engine and raise engine speed to 2100 RPM at least 4 times.

Check idle, adjust if incorrect. check CO is correct. See IDLE & CO

LEVEL table. If CO adjustment is needed, the idle mixture screw anti-

tamper plug must be remove from the top of the air flow sensor.

5) Center punch plug in CO adjusting hole. See Fig. 5. Using

a 3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.Fig. 5: Idle Mixture Screw & Adjustment Screw (1.8L)

Courtesy of Volkswagen United States, Inc.

6) Adjust the idle mixture CO with a 5 mm hex wrench. Turning

the idle mixture screw clockwise richens CO. Adjust idle mixture to

get correct CO. Check engine idle and CO, repeat procedure if needed.

VANAGON

1) Warm engine to normal operating temperature. Engine oil

temperature must be at least 176øF (80øC). Connect an inductive

tachometer or Tester (VW 1367) to alternator, Test Lead (VW 1473) to

ignition coil, and timing light lead to No. 1 spark plug wire. Start

engine and ensure engine speed and timing are correct. If not, adjust

to specification.

2) Remove connectors from idle stabilizer by squeezing

connectors then pulling apart. Plug idle stabilizer connectors

Page 444 of 906

D - ADJUSTMENTS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

together. Turn idle speed screw until idle speed is correct. To adjust

timing, see CHECKING & ADJUSTING under IGNITION TIMING in this

article.

3) Ensure all vehicle electrical equipment is off. Place

exhaust gas analyzer in exhaust pipe. See IDLE SPEED & CO LEVEL table.

If adjustment is needed, go to next step.

4) If adjustment is needed in step 2). Remove intake air

sensor from engine. Center punch plug in CO adjusting hole. Using a

3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.

5) Disconnect oxygen sensor connector on left side of engine

compartment (Green wire). Start engine. Set idle speed and CO reading

by alternately turning mixture and idle speed adjustment screws.

Reconnect oxygen sensor and idle stabilizer connectors. Let engine

idle for 2 minutes.

6) Check CO value. If incorrect, repeat adjusting procedure.

If correct turn ignition off. Drive in new adjusting hole plug flush

with air intake sensor. Remove all test equipment and reconnect all

hoses and wiring.

NOTE: Do not push down on adjustment screw and do not accelerate

engine with wrench in plate. Remove wrench after each

adjustment and accelerate engine briefly before measuring

current reading. Always adjust from a high to a low reading.

IDLE SPEED & CO LEVELÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level

Cabriolet .................. 850-1000 ................... 0.3-1.2%

Fox ........................ 800-1000 ................... 0.3-1.2%

Golf ....................... 800-1000 ................... 0.3-1.2%

Golf GT ..................... 800-900 ................... 0.3-1.2%

GTI ........................ 800-1000 ................... 0.3-1.2%

Jetta ...................... 800-1000 ................... 0.3-1.2%

Vanagon ..................... 830-930 ................... 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THROTTLE STOP SCREW

NOTE: Stop screw is set by manufacturer and should not be moved.

If basic factory setting has been changed, turn throttle stop

screw counterclockwise until there is a gap between stop and screw.

Turn screw in until it just touches stop. Turn screw 1/2 turn (180

degrees) further. Check and adjust idle speed and CO.

IDLE & FULL THROTTLE SWITCH ADJUSTMENTS

IDLE SWITCH ADJUSTMENT DIGIFANT II (EXCEPT VANAGON)

Page 603 of 906

INSTRUMENT PANEL

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

ARTICLE BEGINNING

1989-90 ACCESSORIES & EQUIPMENT

Volkswagen Instrument Panels

Cabriolet, Fox, Golt, GTI, Jetta, Jetta GLI, Vanagon

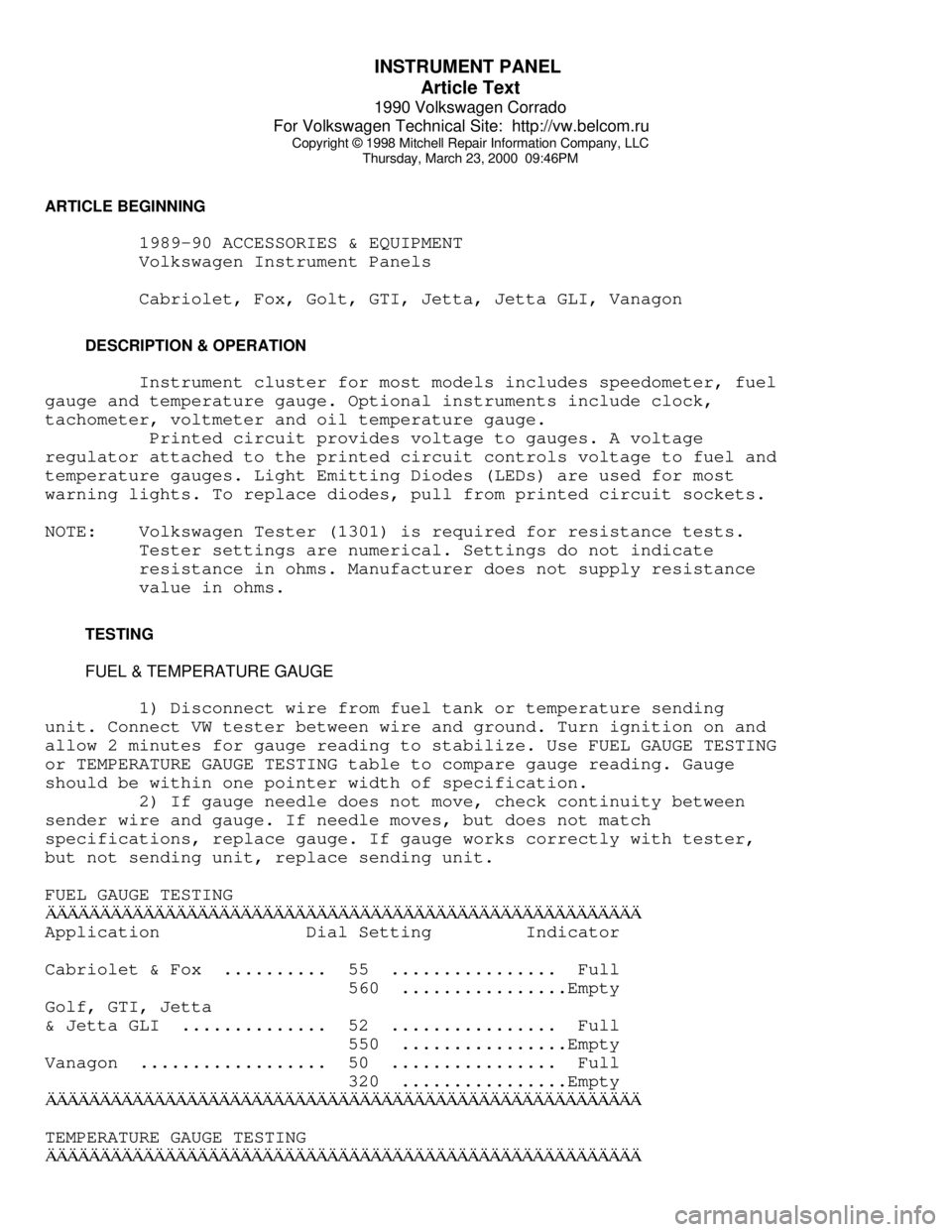

DESCRIPTION & OPERATION

Instrument cluster for most models includes speedometer, fuel

gauge and temperature gauge. Optional instruments include clock,

tachometer, voltmeter and oil temperature gauge.

Printed circuit provides voltage to gauges. A voltage

regulator attached to the printed circuit controls voltage to fuel and

temperature gauges. Light Emitting Diodes (LEDs) are used for most

warning lights. To replace diodes, pull from printed circuit sockets.

NOTE: Volkswagen Tester (1301) is required for resistance tests.

Tester settings are numerical. Settings do not indicate

resistance in ohms. Manufacturer does not supply resistance

value in ohms.

TESTING

FUEL & TEMPERATURE GAUGE

1) Disconnect wire from fuel tank or temperature sending

unit. Connect VW tester between wire and ground. Turn ignition on and

allow 2 minutes for gauge reading to stabilize. Use FUEL GAUGE TESTING

or TEMPERATURE GAUGE TESTING table to compare gauge reading. Gauge

should be within one pointer width of specification.

2) If gauge needle does not move, check continuity between

sender wire and gauge. If needle moves, but does not match

specifications, replace gauge. If gauge works correctly with tester,

but not sending unit, replace sending unit.

FUEL GAUGE TESTINGÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Dial Setting Indicator

Cabriolet & Fox .......... 55 ................ Full

560 ................Empty

Golf, GTI, Jetta

& Jetta GLI .............. 52 ................ Full

550 ................Empty

Vanagon .................. 50 ................ Full

320 ................Empty

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTEMPERATURE GAUGE TESTING

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 649 of 906

MAINTENANCE INFORMATION

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:48PM

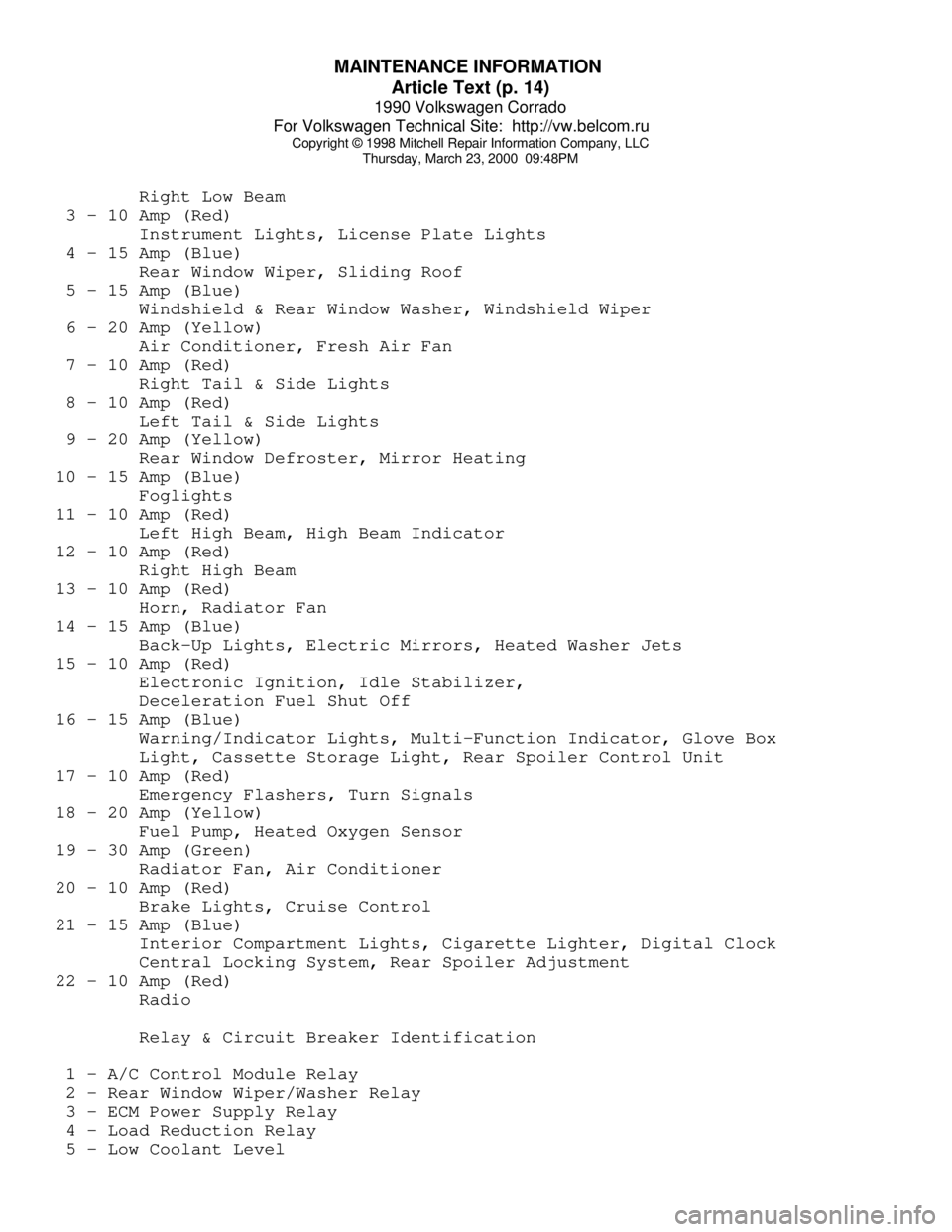

Right Low Beam

3 - 10 Amp (Red)

Instrument Lights, License Plate Lights

4 - 15 Amp (Blue)

Rear Window Wiper, Sliding Roof

5 - 15 Amp (Blue)

Windshield & Rear Window Washer, Windshield Wiper

6 - 20 Amp (Yellow)

Air Conditioner, Fresh Air Fan

7 - 10 Amp (Red)

Right Tail & Side Lights

8 - 10 Amp (Red)

Left Tail & Side Lights

9 - 20 Amp (Yellow)

Rear Window Defroster, Mirror Heating

10 - 15 Amp (Blue)

Foglights

11 - 10 Amp (Red)

Left High Beam, High Beam Indicator

12 - 10 Amp (Red)

Right High Beam

13 - 10 Amp (Red)

Horn, Radiator Fan

14 - 15 Amp (Blue)

Back-Up Lights, Electric Mirrors, Heated Washer Jets

15 - 10 Amp (Red)

Electronic Ignition, Idle Stabilizer,

Deceleration Fuel Shut Off

16 - 15 Amp (Blue)

Warning/Indicator Lights, Multi-Function Indicator, Glove Box

Light, Cassette Storage Light, Rear Spoiler Control Unit

17 - 10 Amp (Red)

Emergency Flashers, Turn Signals

18 - 20 Amp (Yellow)

Fuel Pump, Heated Oxygen Sensor

19 - 30 Amp (Green)

Radiator Fan, Air Conditioner

20 - 10 Amp (Red)

Brake Lights, Cruise Control

21 - 15 Amp (Blue)

Interior Compartment Lights, Cigarette Lighter, Digital Clock

Central Locking System, Rear Spoiler Adjustment

22 - 10 Amp (Red)

Radio

Relay & Circuit Breaker Identification

1 - A/C Control Module Relay

2 - Rear Window Wiper/Washer Relay

3 - ECM Power Supply Relay

4 - Load Reduction Relay

5 - Low Coolant Level