clock VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 87 of 906

* ELECTRICAL SYSTEM UNIFORM INSPECTION GUIDELINES *

Article Text (p. 22)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:30PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CLOCK

CLOCK

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing, damaged mounting hardware

³ Require repair or replacement

³ of mounting hardware.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged (e.g., melted, burned,

³ Suggest repair or replacement.

cracked, etc.)

³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CIGARETTE LIGHTER/SOCKET/ELEMENT

CIGARETTE LIGHTER/SOCKET/ELEMENT

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing

³ Suggest replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing, damaged mounting hardware

³ Require repair or replacement

³ of mounting hardware.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CRUISE CONTROL/LINKAGE/CABLES

CRUISE CONTROL/LINKAGE/CABLES

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure ³ Note

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing

³ Require replacement. ³

Page 299 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

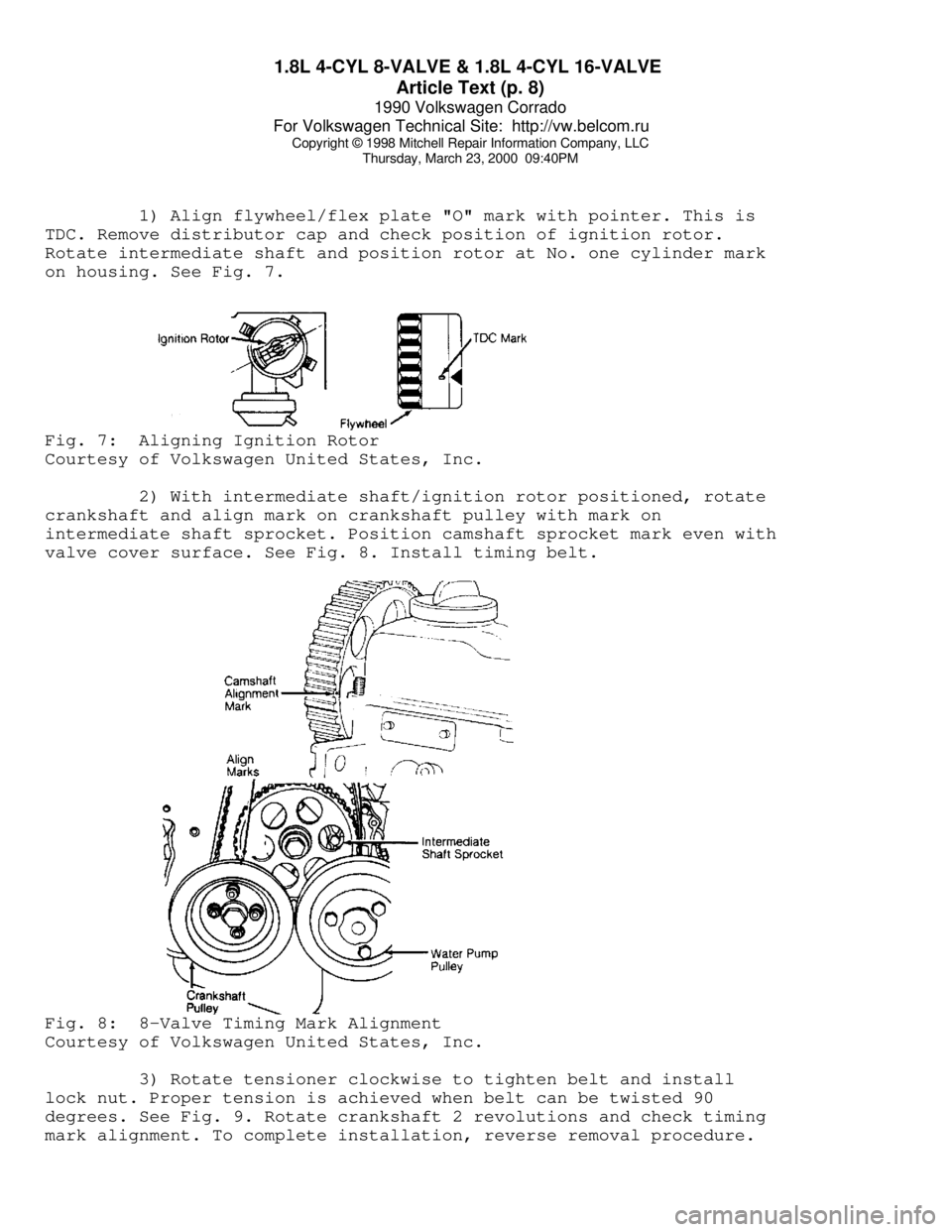

1) Align flywheel/flex plate "O" mark with pointer. This is

TDC. Remove distributor cap and check position of ignition rotor.

Rotate intermediate shaft and position rotor at No. one cylinder mark

on housing. See Fig. 7.Fig. 7: Aligning Ignition Rotor

Courtesy of Volkswagen United States, Inc.

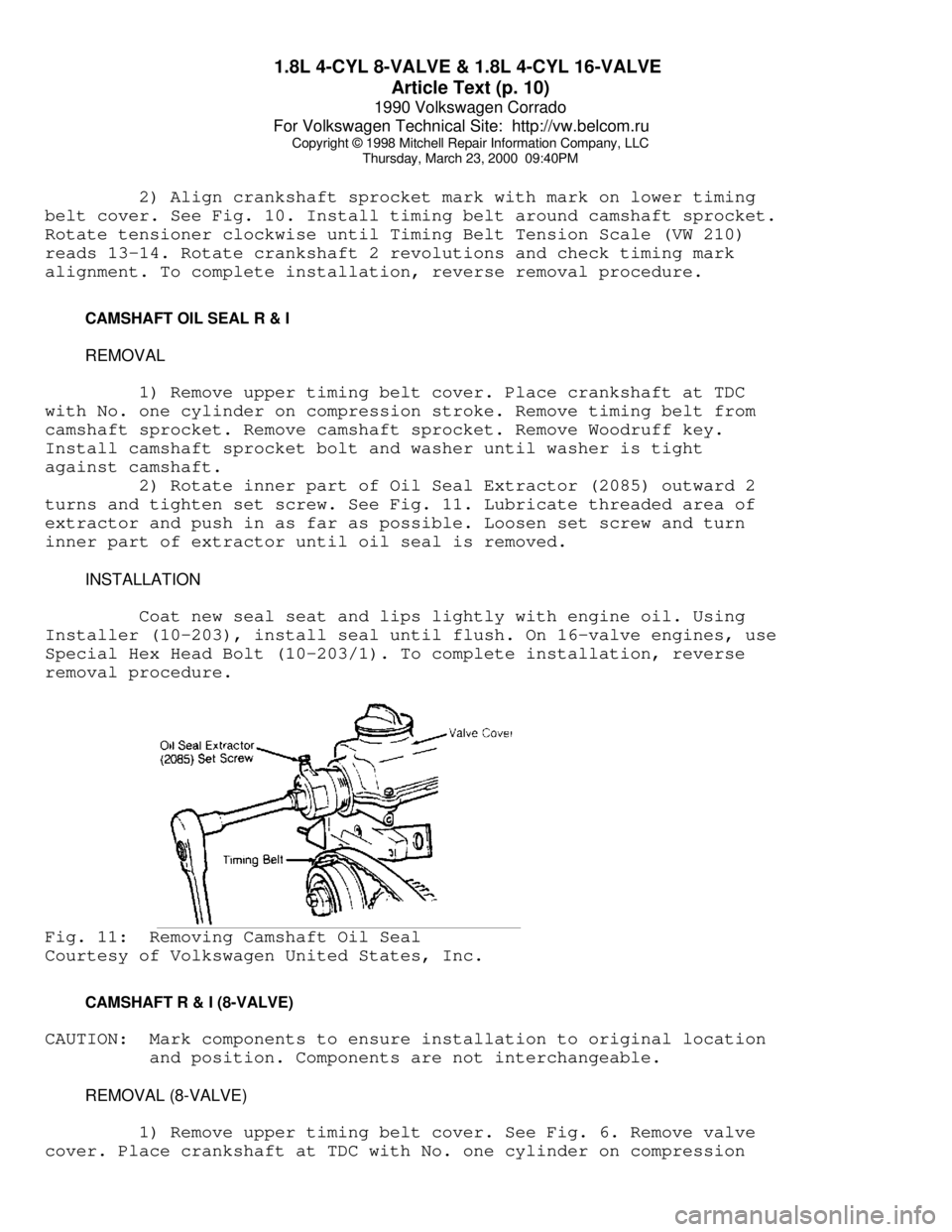

2) With intermediate shaft/ignition rotor positioned, rotate

crankshaft and align mark on crankshaft pulley with mark on

intermediate shaft sprocket. Position camshaft sprocket mark even with

valve cover surface. See Fig. 8. Install timing belt.Fig. 8: 8-Valve Timing Mark Alignment

Courtesy of Volkswagen United States, Inc.

3) Rotate tensioner clockwise to tighten belt and install

lock nut. Proper tension is achieved when belt can be twisted 90

degrees. See Fig. 9. Rotate crankshaft 2 revolutions and check timing

mark alignment. To complete installation, reverse removal procedure.

Page 301 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 10)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

2) Align crankshaft sprocket mark with mark on lower timing

belt cover. See Fig. 10. Install timing belt around camshaft sprocket.

Rotate tensioner clockwise until Timing Belt Tension Scale (VW 210)

reads 13-14. Rotate crankshaft 2 revolutions and check timing mark

alignment. To complete installation, reverse removal procedure.

CAMSHAFT OIL SEAL R & I

REMOVAL

1) Remove upper timing belt cover. Place crankshaft at TDC

with No. one cylinder on compression stroke. Remove timing belt from

camshaft sprocket. Remove camshaft sprocket. Remove Woodruff key.

Install camshaft sprocket bolt and washer until washer is tight

against camshaft.

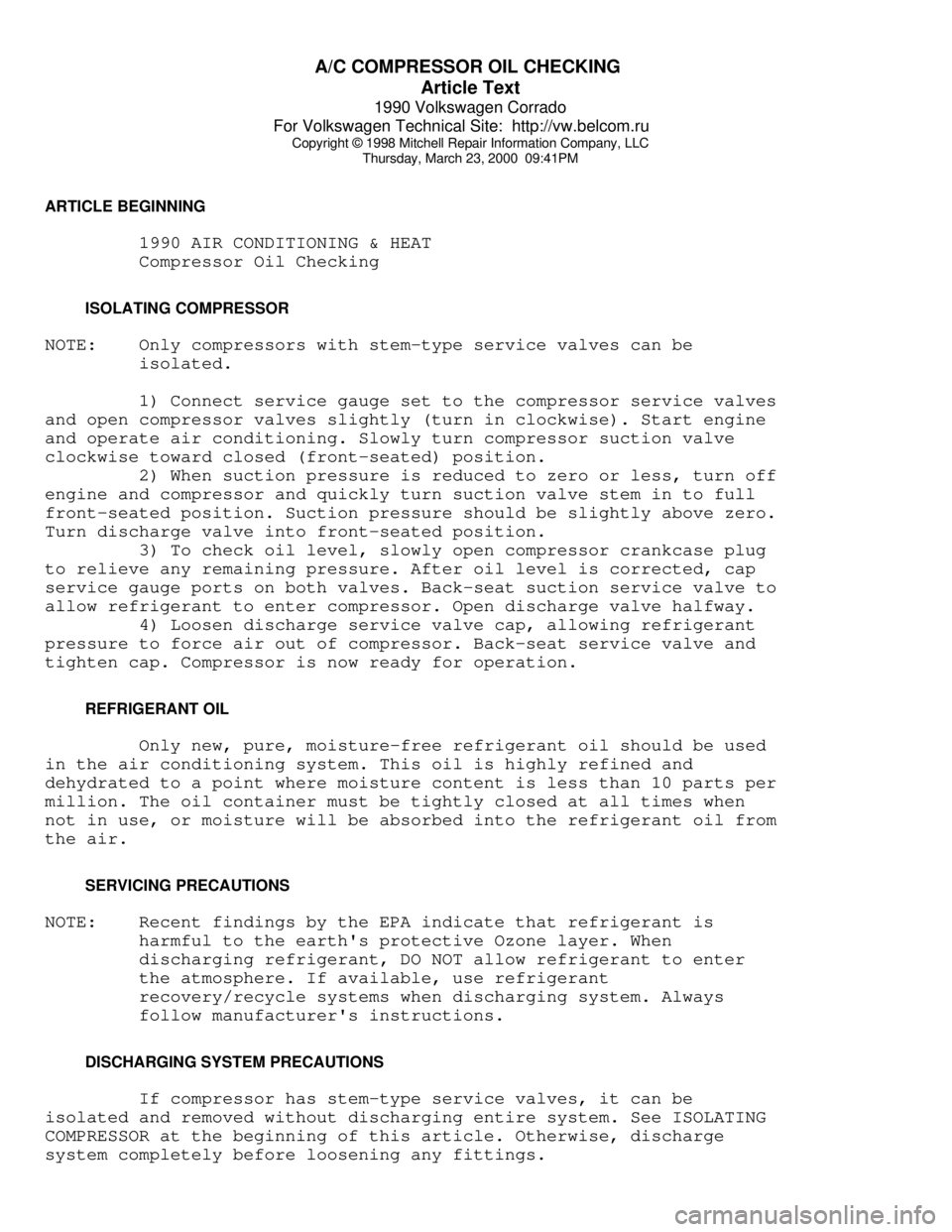

2) Rotate inner part of Oil Seal Extractor (2085) outward 2

turns and tighten set screw. See Fig. 11. Lubricate threaded area of

extractor and push in as far as possible. Loosen set screw and turn

inner part of extractor until oil seal is removed.

INSTALLATION

Coat new seal seat and lips lightly with engine oil. Using

Installer (10-203), install seal until flush. On 16-valve engines, use

Special Hex Head Bolt (10-203/1). To complete installation, reverse

removal procedure.Fig. 11: Removing Camshaft Oil Seal

Courtesy of Volkswagen United States, Inc.

CAMSHAFT R & I (8-VALVE)

CAUTION: Mark components to ensure installation to original location

and position. Components are not interchangeable.

REMOVAL (8-VALVE)

1) Remove upper timing belt cover. See Fig. 6. Remove valve

cover. Place crankshaft at TDC with No. one cylinder on compression

Page 319 of 906

A/C COMPRESSOR OIL CHECKING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 AIR CONDITIONING & HEAT

Compressor Oil Checking

ISOLATING COMPRESSOR

NOTE: Only compressors with stem-type service valves can be

isolated.

1) Connect service gauge set to the compressor service valves

and open compressor valves slightly (turn in clockwise). Start engine

and operate air conditioning. Slowly turn compressor suction valve

clockwise toward closed (front-seated) position.

2) When suction pressure is reduced to zero or less, turn off

engine and compressor and quickly turn suction valve stem in to full

front-seated position. Suction pressure should be slightly above zero.

Turn discharge valve into front-seated position.

3) To check oil level, slowly open compressor crankcase plug

to relieve any remaining pressure. After oil level is corrected, cap

service gauge ports on both valves. Back-seat suction service valve to

allow refrigerant to enter compressor. Open discharge valve halfway.

4) Loosen discharge service valve cap, allowing refrigerant

pressure to force air out of compressor. Back-seat service valve and

tighten cap. Compressor is now ready for operation.

REFRIGERANT OIL

Only new, pure, moisture-free refrigerant oil should be used

in the air conditioning system. This oil is highly refined and

dehydrated to a point where moisture content is less than 10 parts per

million. The oil container must be tightly closed at all times when

not in use, or moisture will be absorbed into the refrigerant oil from

the air.

SERVICING PRECAUTIONS

NOTE: Recent findings by the EPA indicate that refrigerant is

harmful to the earth's protective Ozone layer. When

discharging refrigerant, DO NOT allow refrigerant to enter

the atmosphere. If available, use refrigerant

recovery/recycle systems when discharging system. Always

follow manufacturer's instructions.

DISCHARGING SYSTEM PRECAUTIONS

If compressor has stem-type service valves, it can be

isolated and removed without discharging entire system. See ISOLATING

COMPRESSOR at the beginning of this article. Otherwise, discharge

system completely before loosening any fittings.

Page 327 of 906

A/C COMPRESSOR SERVICING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 AIR CONDITIONING & HEAT

Compressor Service

* PLEASE READ THIS FIRST *

CAUTION: When discharging air conditioning system, use only approved

refrigerant recovery/recycling equipment. Make every attempt

to avoid discharging refrigerant into the atmosphere.

ISOLATING COMPRESSOR

NOTE: Only compressors with stem-type service valves can be

isolated.

1) Connect service gauge set to the compressor service valves

and open compressor valves slightly (turn in clockwise). Start engine

and operate air conditioning. Slowly turn compressor suction valve

clockwise toward closed (front-seated) position.

2) When suction pressure is reduced to zero or less, turn off

engine and compressor and quickly turn suction valve stem in to full

front-seated position. Suction pressure should be slightly above zero.

Turn discharge valve into front-seated position.

3) To check oil level, slowly open compressor crankcase plug

to relieve any remaining pressure. After oil level is corrected, cap

service gauge ports on both valves. Back-seat suction service valve to

allow refrigerant to enter compressor. Open discharge valve halfway.

4) Loosen discharge service valve cap, allowing refrigerant

pressure to force air out of compressor. Back-seat service valve and

tighten cap. Compressor is now ready for operation.

REFRIGERANT OIL

Only new, pure, moisture-free refrigerant oil should be used

in the air conditioning system. This oil is highly refined and

dehydrated to a point where moisture content is less than 10 parts per

million. The oil container must be tightly closed at all times when

not in use, or moisture will be absorbed into the refrigerant oil from

the air.

DISCHARGING SYSTEM PRECAUTIONS

CAUTION: When discharging air conditioning system, use only approved

refrigerant recovery/recycling equipment. Make every attempt

to avoid discharging refrigerant into the atmosphere.

If compressor has stem-type service valves, it can be

isolated and removed without discharging entire system. Otherwise,

discharge system completely using approved refrigerant

Page 330 of 906

A/C COMPRESSOR SERVICING

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

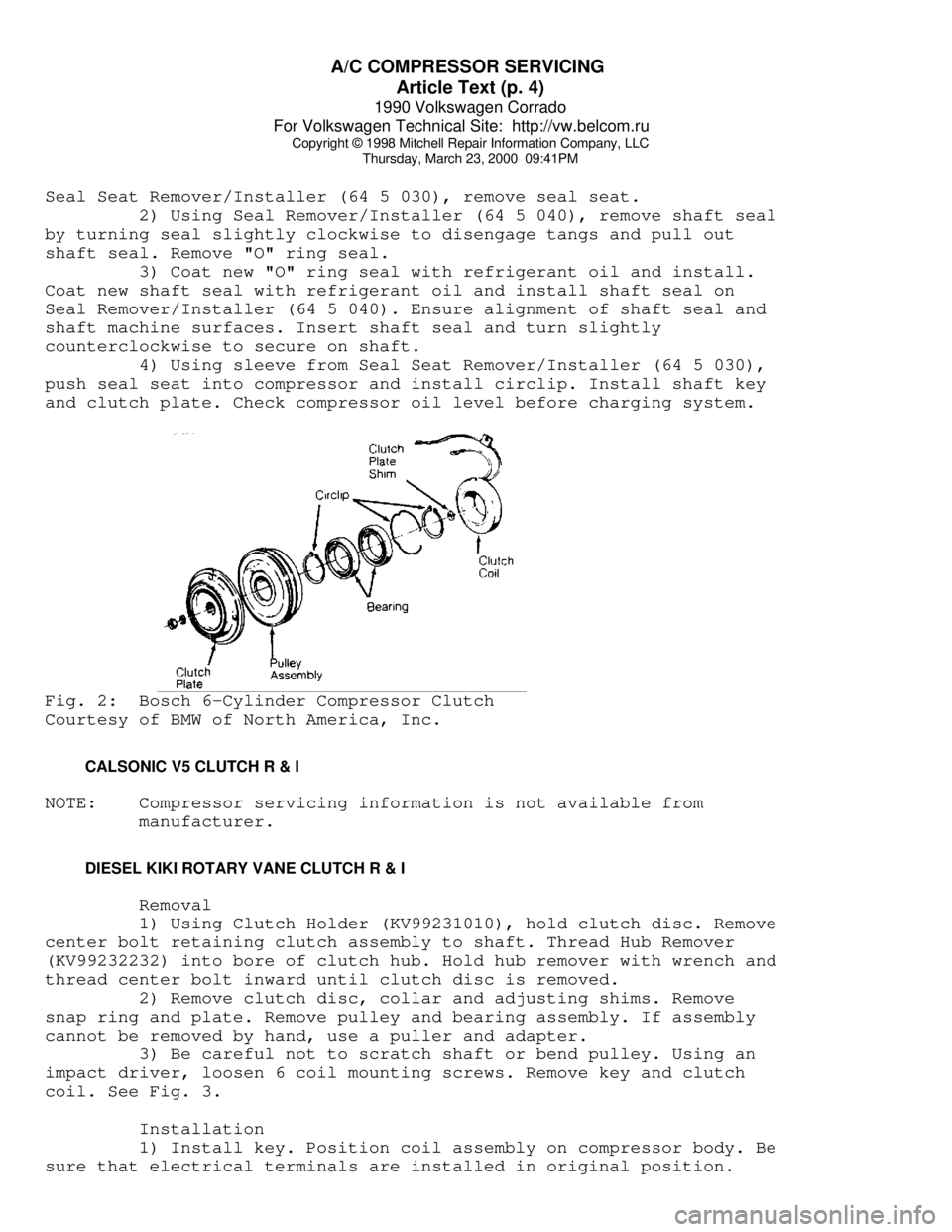

Seal Seat Remover/Installer (64 5 030), remove seal seat.

2) Using Seal Remover/Installer (64 5 040), remove shaft seal

by turning seal slightly clockwise to disengage tangs and pull out

shaft seal. Remove "O" ring seal.

3) Coat new "O" ring seal with refrigerant oil and install.

Coat new shaft seal with refrigerant oil and install shaft seal on

Seal Remover/Installer (64 5 040). Ensure alignment of shaft seal and

shaft machine surfaces. Insert shaft seal and turn slightly

counterclockwise to secure on shaft.

4) Using sleeve from Seal Seat Remover/Installer (64 5 030),

push seal seat into compressor and install circlip. Install shaft key

and clutch plate. Check compressor oil level before charging system.Fig. 2: Bosch 6-Cylinder Compressor Clutch

Courtesy of BMW of North America, Inc.

CALSONIC V5 CLUTCH R & I

NOTE: Compressor servicing information is not available from

manufacturer.

DIESEL KIKI ROTARY VANE CLUTCH R & I

Removal

1) Using Clutch Holder (KV99231010), hold clutch disc. Remove

center bolt retaining clutch assembly to shaft. Thread Hub Remover

(KV99232232) into bore of clutch hub. Hold hub remover with wrench and

thread center bolt inward until clutch disc is removed.

2) Remove clutch disc, collar and adjusting shims. Remove

snap ring and plate. Remove pulley and bearing assembly. If assembly

cannot be removed by hand, use a puller and adapter.

3) Be careful not to scratch shaft or bend pulley. Using an

impact driver, loosen 6 coil mounting screws. Remove key and clutch

coil. See Fig. 3.

Installation

1) Install key. Position coil assembly on compressor body. Be

sure that electrical terminals are installed in original position.

Page 332 of 906

A/C COMPRESSOR SERVICING

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

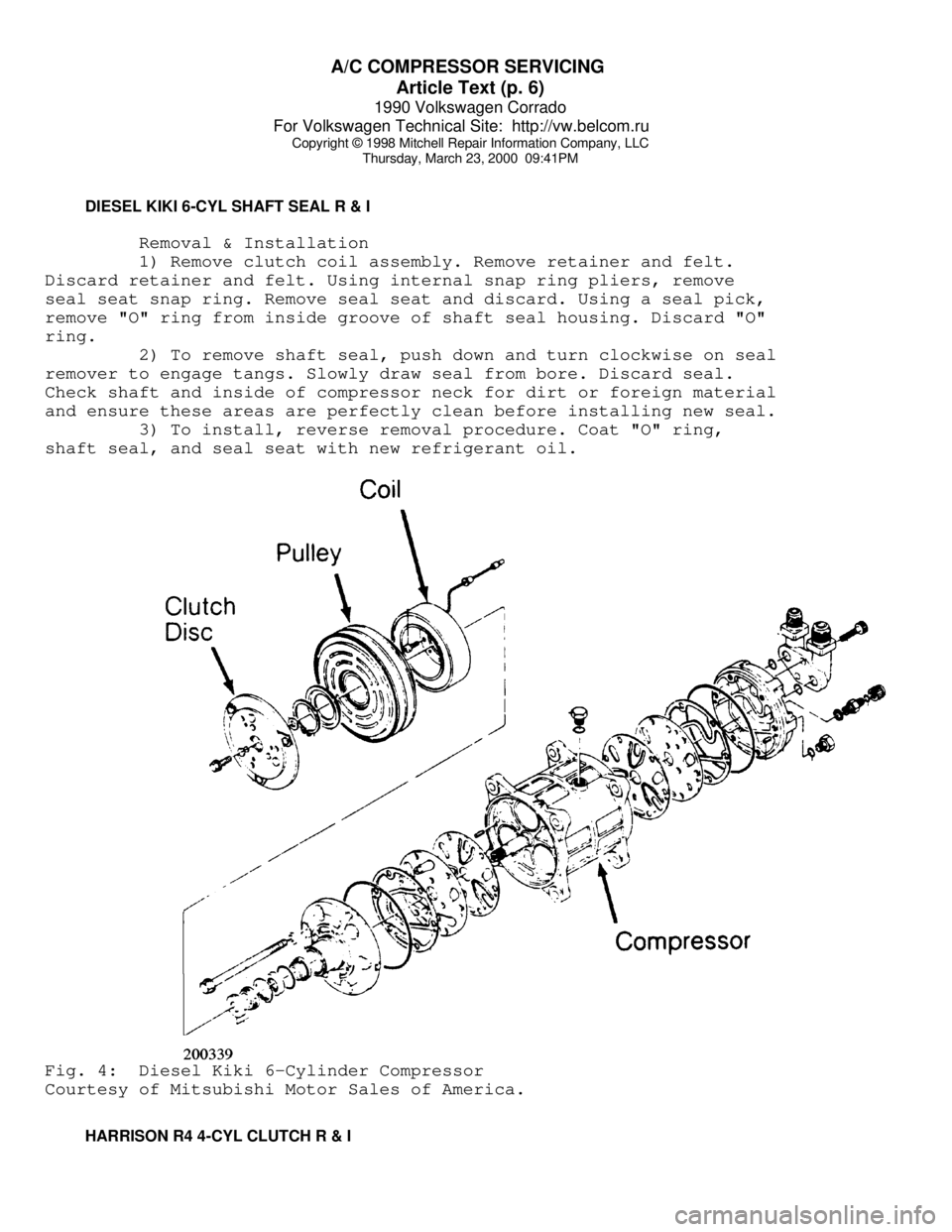

DIESEL KIKI 6-CYL SHAFT SEAL R & I

Removal & Installation

1) Remove clutch coil assembly. Remove retainer and felt.

Discard retainer and felt. Using internal snap ring pliers, remove

seal seat snap ring. Remove seal seat and discard. Using a seal pick,

remove "O" ring from inside groove of shaft seal housing. Discard "O"

ring.

2) To remove shaft seal, push down and turn clockwise on seal

remover to engage tangs. Slowly draw seal from bore. Discard seal.

Check shaft and inside of compressor neck for dirt or foreign material

and ensure these areas are perfectly clean before installing new seal.

3) To install, reverse removal procedure. Coat "O" ring,

shaft seal, and seal seat with new refrigerant oil.Fig. 4: Diesel Kiki 6-Cylinder Compressor

Courtesy of Mitsubishi Motor Sales of America.

HARRISON R4 4-CYL CLUTCH R & I

Page 333 of 906

A/C COMPRESSOR SERVICING

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

Removal

1) Clamp Holding Fixture (J-25008-A) in a vise and attach

compressor to holding fixture with thumb screws. Use Clutch Hub Holder

(J-33027) to hold clutch. Remove shaft nut using Shaft Nut Socket (J-

9399).

2) Thread Clutch Plate and Hub Assembly Remover (J-33013-B)

into hub. Hold body of remover with a wrench and turn center screw

into remover body to remove clutch plate and hub assembly. Remove

shaft key and retain for assembly. See Fig. 5.

NOTE: DO NOT drive or pound on clutch hub or shaft.

Installation

1) Install shaft key into hub key groove. Allow key to

project approximately 1/8" out of key way. Shaft key is curved

slightly to provide an interference fit in hub key groove.

2) Ensure frictional surface of clutch plate and clutch rotor

are clean before installing clutch plate and hub assembly. Align shaft

key with shaft key way and place clutch plate and hub assembly onto

compressor shaft.

3) Hold hex portion of Installer (J-9480-B) with a wrench.

Tighten center screw to press hub into shaft until there is .020-.040"

(.5-1.0 mm) air gap between frictional plate and clutch rotor.

4) Install new shaft nut with small diameter boss of nut

against crankshaft shoulder. Use Thin Wall Socket (J-9399) and Clutch

Hub Holder (J-25030). Tighten shaft nut to 10 ft. lbs. (14 N.m). Spin

pulley rotor by hand to ensure rotor is not rubbing on clutch drive

plate.

HARRISON R4 4-CYL SHAFT SEAL R & I

Removal

1) Clamp Holding Fixture (J-25008-A) in a vise and attach

compressor to holding fixture with thumb screws. Use Clutch Hub Holder

(J-33027) to hold clutch. Remove shaft nut using Shaft Nut Socket (J-

9399).

2) Thread Clutch Plate and Hub Assembly Remover (J-33013-B)

into hub. Hold body of remover with a wrench and turn center screw

into remover body to remove clutch plate and hub assembly. Remove

clutch plate and shaft key. Pry out dust seal (if equipped). Remove

seal seat snap ring. Thoroughly clean compressor neck area and "O"

ring groove surrounding shaft. Any dirt or foreign material may cause

compressor damage.

3) Use Seal Remover/Installer (J23128-A), remove seal with a

twisting motion. Use "O" Ring Remover (J-9553-01) to remove "O" ring.

Installation

1) Coat new shaft seal with refrigerant oil and install shaft

seal on remover/installer. Align compressor shaft machined surface

with shaft seal and install. Turn remover/installer slightly

counterclockwise to secure shaft seal tangs.

2) Using Seal Installer (J-33011), install "O" ring and coat

Page 340 of 906

A/C COMPRESSOR SERVICING

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ring and carbon seal contact surface of shaft seal seat for damage.

Make sure that "O" ring contact surface on front cover is not damaged.

Make sure refrigerant oil is applied to oil seal in shaft seal seat.

Installation

1) To install, reverse removal procedure. Ensure shaft seal

contact surface is free of dirt. Lubricate with refrigerant oil. Cap

end of compressor shaft.

2) Using Guard (KV994C1143), insert shaft seal. Be sure shaft

seal case is aligned with shaft. Apply force to turn seal to left and

right. Ensure shaft seal seats properly in shaft cut-out.

3) Fit "O" ring to outside groove of shaft seal seat. Ensure

"O" ring seats properly. Apply refrigerant oil on contact surfaces and

around shaft seal seat. Lightly coat surface of shaft with refrigerant

oil.

4) Install key on compressor shaft. Using snap ring pliers,

compress retainer ring and fit retainer ring into front cover. Seat

retainer ring firmly in groove. Thoroughly wipe grease or oil from

shaft surface.

5) Connect Installer (KV99412329) to shaft of compressor, and

turn shaft 5 or 6 times in a clockwise direction to seat seal. See

REFRIGERANT OIL & R-12 SPECIFICATIONS chart in this section for system

capacities.

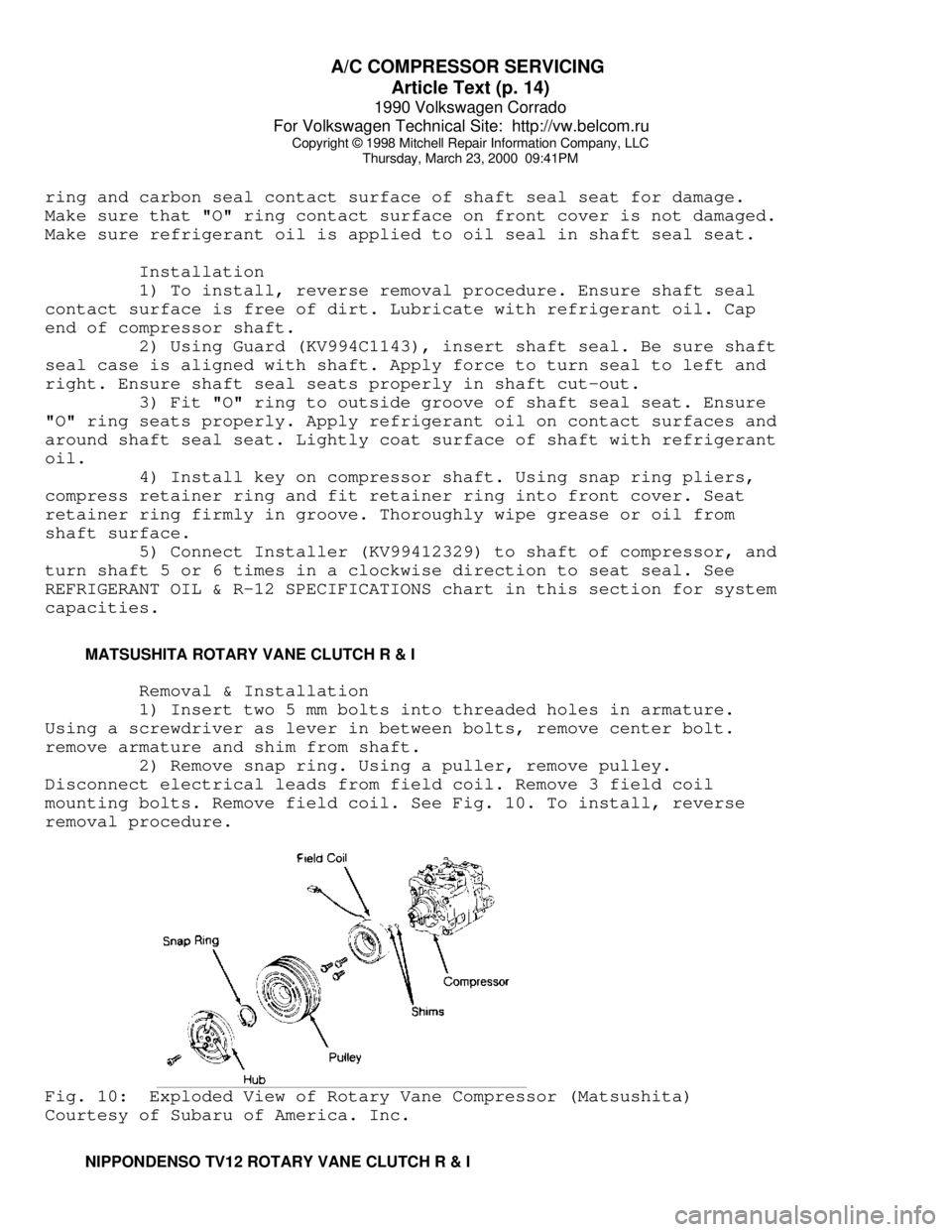

MATSUSHITA ROTARY VANE CLUTCH R & I

Removal & Installation

1) Insert two 5 mm bolts into threaded holes in armature.

Using a screwdriver as lever in between bolts, remove center bolt.

remove armature and shim from shaft.

2) Remove snap ring. Using a puller, remove pulley.

Disconnect electrical leads from field coil. Remove 3 field coil

mounting bolts. Remove field coil. See Fig. 10. To install, reverse

removal procedure.Fig. 10: Exploded View of Rotary Vane Compressor (Matsushita)

Courtesy of Subaru of America. Inc.

NIPPONDENSO TV12 ROTARY VANE CLUTCH R & I

Page 347 of 906

A/C COMPRESSOR SERVICING

Article Text (p. 21)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

clutch coil on compressor.

2) Support compressor on rear mounting ears. Align rotor on

front housing hub. Use adapter and press to install rotor (or drive

into place with soft mallet). After rotor is seated, install front

snap ring.

SANDEN 5-CYL SHAFT SEAL R & I

NOTE: Check compressor refrigerant oil level when replacing seals.

Removal

1) Hold clutch hub stationary and remove shaft nut with thin

wall socket. Use clutch plate puller to remove clutch plate. Tap key

out of slot in crankshaft.

2) Remove seal retainer with seal remover and 3/4" socket

wrench. Use seal seat remover tongs to pull seal seat off compressor

shaft. Insert seal remover into front housing and turn to engage tangs

on seal. Lift seal out. Remove seal "O" ring from front housing, being

careful not to scratch shaft.

Installation

1) Coat "O" ring with refrigerant oil and install into

groove. Load a new seal onto installer, being careful not to touch

carbon sealing surface with fingers. Install shaft protector. Dip seal

in refrigerant oil and install on shaft. Rotate seal clockwise until

seal fits into flats on shaft. Remove seal installer by turning

counterclockwise.

2) Coat seal seat with refrigerant oil and install with

tongs. Reinstall seal seat retainer (with flat side down). Install

shims and shaft key. Rotate shaft several times to help break in seal.

3) Use a press to install clutch plate. Make sure that air

gap is .016-.031" (.41-.79 mm). Hold plate stationary and install

shaft nut.