technical specifications VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 757 of 906

SUSPENSION - FRONT

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:51PM

NOTE: Wheel bearing is destroyed when pressed out of housing. When

either wheel hub or bearing has been removed from housing, a

new bearing must be installed.

Removal

1) Remove axle shaft nut. Raise and support vehicle with

safety stands. Allow suspension to hang free. Remove wheel assembly.

Remove brake caliper attaching bolts. Remove caliper and hang out of

work area. Remove brake disc retaining screw and remove disc.

2) Remove tie rod ball joint from wheel bearing housing.

Remove nut and clamp bolt from control arm ball joint. Remove control

arm ball joint from wheel bearing housing and remove housing.

3) Remove 2 circlips retaining bearing in hub. Using Hub

Remover (VW 295a), press wheel hub from bearing housing. Using a

bearing puller, remove wheel bearing inner race from hub assembly.

Using Bearing Remover (VW 433), press wheel bearing from outboard end

of bearing housing.

Installation

1) Press new bearing race onto hub. Using Bearing & Hub

Installer (VW 472/1), press new bearing into bearing housing from

outboard side. Using same adapter, press wheel hub into bearing

housing. Apply a small bead of locking compound to axle splines before

installing into hub.

2) To complete installation, reverse removal procedure.

Always replace self-locking axle shaft nut. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS TABLE at end of article.

Check wheel alignment. See SPECIFICATIONS & PROCEDURES article in the

WHEEL ALIGNMENT Section.

NOTE: When installing hub, ensure press adapter contacts inner

bearing race only.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ft. Lbs. (N.m)

Axle Nut ............................................ 170 (230)

Axle Shaft-To-Transaxle Bolt .......................... 32 (43)

Ball Joint Clamp Bolt ................................. 37 (50)

Ball Joint-To-Control Arm Bolt ........................ 18 (24)

Caliper Pin Bolt ...................................... 18 (24)

Control Arm Pivot Bolt

Cabriolet ........................................... 50 (68)

All Others ......................................... 96 (130)

Control Arm-To-Subframe Rear Bushing Bolt ............ 96 (130)

Strut Piston Rod Nut

Cabriolet ........................................... 50 (68)

All Others .......................................... 44 (60)

Page 759 of 906

SUSPENSION - REAR

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:51PM

ARTICLE BEGINNING

1990-92 SUSPENSION

Volkswagen Rear

Cabriolet, Corrado, Fox,

Golf, GTI, Jetta, Passat

DESCRIPTION

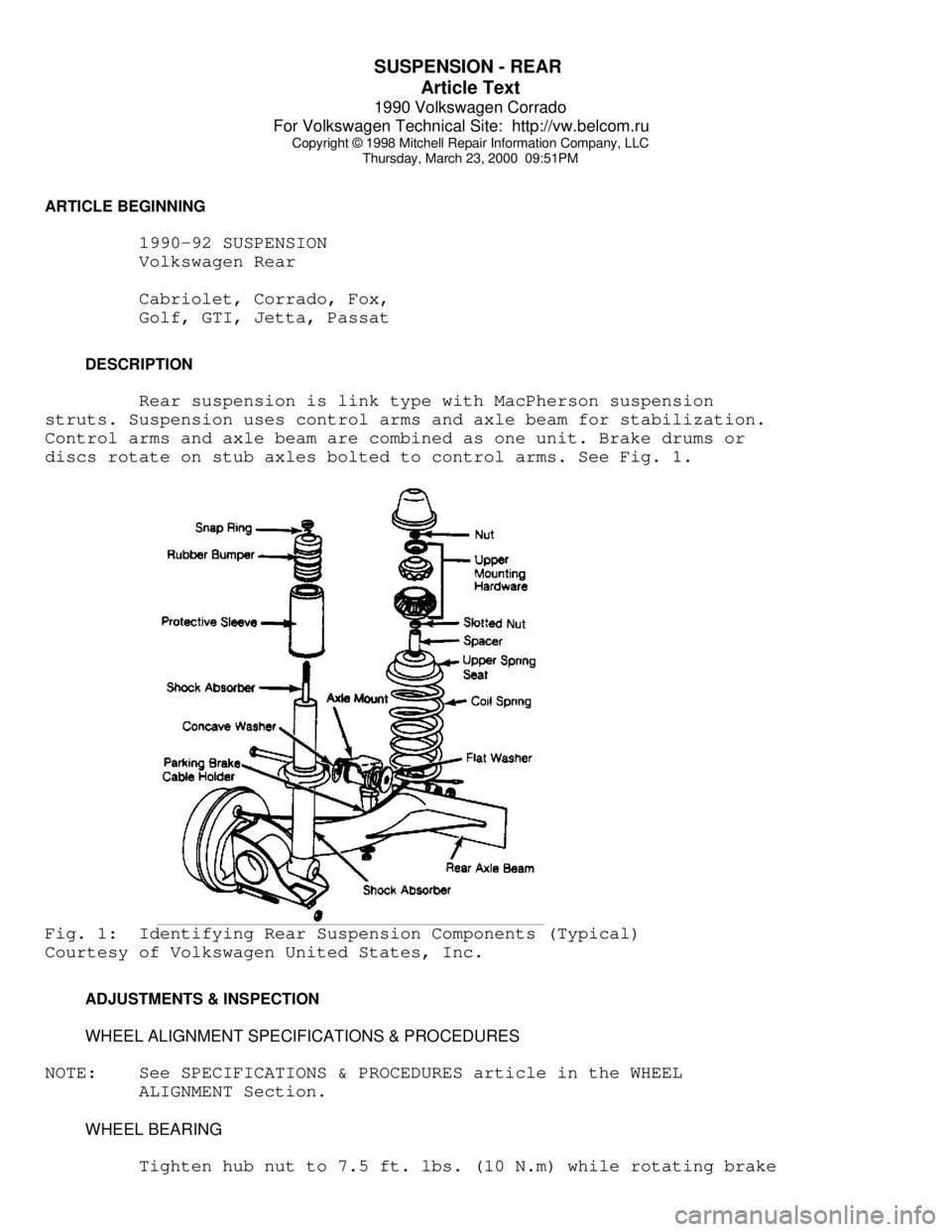

Rear suspension is link type with MacPherson suspension

struts. Suspension uses control arms and axle beam for stabilization.

Control arms and axle beam are combined as one unit. Brake drums or

discs rotate on stub axles bolted to control arms. See Fig. 1.Fig. 1: Identifying Rear Suspension Components (Typical)

Courtesy of Volkswagen United States, Inc.

ADJUSTMENTS & INSPECTION

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

NOTE: See SPECIFICATIONS & PROCEDURES article in the WHEEL

ALIGNMENT Section.

WHEEL BEARING

Tighten hub nut to 7.5 ft. lbs. (10 N.m) while rotating brake

Page 761 of 906

SUSPENSION - REAR

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:51PM

NOTE: DO NOT remove both suspension struts at same time, as this

would overload axle beam bushings.

Removal

1) With vehicle on floor, remove plastic cap which covers

upper strut retaining nuts. Remove strut retaining nuts. Slowly raise

vehicle until weight is off spring. Remove bolt which retains lower

end of strut shock absorber to axle beam mount. Raise vehicle until

strut can be removed. Place strut assembly in vise.

2) Hold piston rod. Remove strut retaining nut and related

components. See Fig. 1. Remove slotted nut (some models). Remove

spacer and coil spring. If coil spring is to be replaced, ensure paint

stripe color on replacement spring matches original spring color

stripe.

Installation

1) Install protective cap and tube onto shock absorber.

Install rubber buffer with small end downward. Install snap ring and

washer. Place spring into lower seat. Install upper retainer with

spacer sleeve.

2) Tighten slotted nut (some models) which retains piston

rod. Install upper mounting hardware. Tighten piston rod. To complete

installation, reverse removal procedure. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS TABLE at end of article.

SUSPENSION ASSEMBLY

CAUTION: When removing suspension assembly, add weight to rear of

vehicle to prevent tipping resulting from change in center

of gravity.

Removal

1) With vehicle on floor, disconnect upper strut mount. Raise

and support vehicle. Disconnect parking brake at bracket near axle

mount.

2) Disconnect and plug brake lines. Leave flex hose attached

to suspension. Separate brake pressure regulator spring from axle beam

(if equipped). Remove nuts which retain axle beam to body.

NOTE: DO NOT install bolts and nuts fouled with undercoating. With

waxy coating on threads, true tightening torque cannot be

measured. Clean or replace bolts and nuts.

Installation

1) If axle beam mounting has been removed, adjust mounting

pad. See Fig. 2. If pad is not correctly aligned, torsional preload of

mounting bushings will be incorrect.

2) Position rear suspension on body. Install nuts retaining

axle beam to body. Raise wheel. Guide upper end of strut into body

mount.

3) Connect parking brake cables. Connect brake lines. Lower

Page 762 of 906

SUSPENSION - REAR

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:51PM

vehicle. Tighten upper strut retaining nuts. Tighten all bolts and

nuts to specification. Bleed brake system.

WHEEL BEARING

Removal (Disc Brakes)

Raise and support vehicle. Remove wheel assembly. Remove

caliper assembly and support it out of work area. Remove dust cap,

cotter pin, hub nut, and thrust washer. Remove brake disc. Using a

long drift, tap bearings, races, and grease seal from disc hub.

Installation

1) Clean hub cavity thoroughly. Using Bearing Race Installer

(VW 432 and VW 411), press inner and outer bearing races into bore.

Lubricate and install inner bearing. Using Seal Installer (VW 295 and

3074), tap grease seal into bore.

2) Install brake disc, outer bearing, thrust washer, and hub

nut. Reverse removal procedure to complete installation. Adjust wheel

bearing. See WHEEL BEARING under ADJUSTMENTS & INSPECTION. Install NEW

cotter pin.

Removal (Drum Brakes)

Raise and support vehicle. Remove wheel assembly. Remove dust

cap, cotter pin, hub nut, and thrust washer. Remove brake drum. Using

a long drift, tap bearings, races, and grease seal from hub.

Installation

1) Clean hub cavity thoroughly. Using Outer Bearing Race

Installer (VW 431 and VW 411), press outer bearing race into bore.

Using Inner Bearing Race Installer (VW 432 and VW 411), press inner

bearing race into bore. Lubricate and install inner bearing. Using

Seal Installer (VW 295 and 3074), tap grease seal into bore.

2) Install brake drum, outer bearing, thrust washer, and hub

nut. Reverse removal procedure to complete installation. Adjust wheel

bearing. See WHEEL BEARING under ADJUSTMENTS & INSPECTION. Install NEW

cotter pin.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ft. Lbs. (N.m)

Brake Caliper Bolt .................................... 48 (65)

Coil Spring Retainer-To-Piston Rod Nut ................ 11 (15)

Rear Axle Beam Pivot Bushing Bolt ..................... 43 (58)

Rear Axle Mounting Pad-To-Body Bolt ................... 63 (85)

Shock Absorber Slot Nut ............................... 15 (20)

Shock Absorber-To-Axle Beam Nut ....................... 52 (70)

Shock Absorber-To-Body Bolt ........................... 26 (35)

Stub Axle-To-Control Arm Bolt ......................... 44 (60)

Wheel Lug Bolt ....................................... 81 (110)

Page 765 of 906

TRANSMISSION REMOVAL & INSTALLATION - A/T

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:51PM

bolts on front mount and remove mount. Place mating marks on drive

axle flanges and remove left and right axle shaft flange bolts.

4) Disconnect right strut-to-spindle bolts. Remove right side

axle. Reconnect strut. Remove protective plate from transaxle. Remove

torque converter-to-drive plate bolts.

5) Slightly lower engine assembly. Support transaxle with

jack. Remove lower transaxle-to-engine mounting bolts. Lower

transaxle. To install, reverse removal procedure. Adjust accelerator

and selector cables.

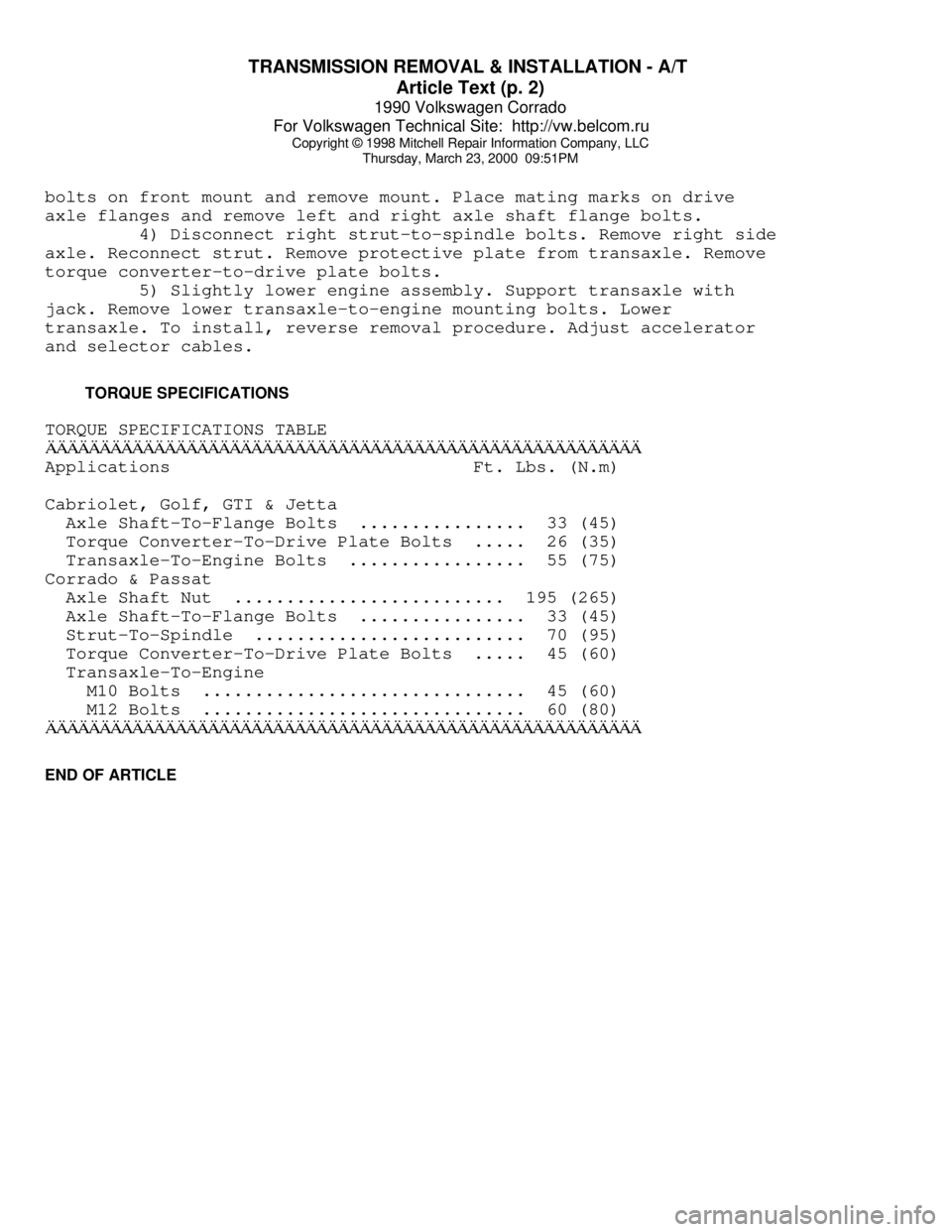

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplications Ft. Lbs. (N.m)

Cabriolet, Golf, GTI & Jetta

Axle Shaft-To-Flange Bolts ................ 33 (45)

Torque Converter-To-Drive Plate Bolts ..... 26 (35)

Transaxle-To-Engine Bolts ................. 55 (75)

Corrado & Passat

Axle Shaft Nut .......................... 195 (265)

Axle Shaft-To-Flange Bolts ................ 33 (45)

Strut-To-Spindle .......................... 70 (95)

Torque Converter-To-Drive Plate Bolts ..... 45 (60)

Transaxle-To-Engine

M10 Bolts ............................... 45 (60)

M12 Bolts ............................... 60 (80)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 779 of 906

TROUBLE SHOOTING - BASIC PROCEDURES

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:52PM

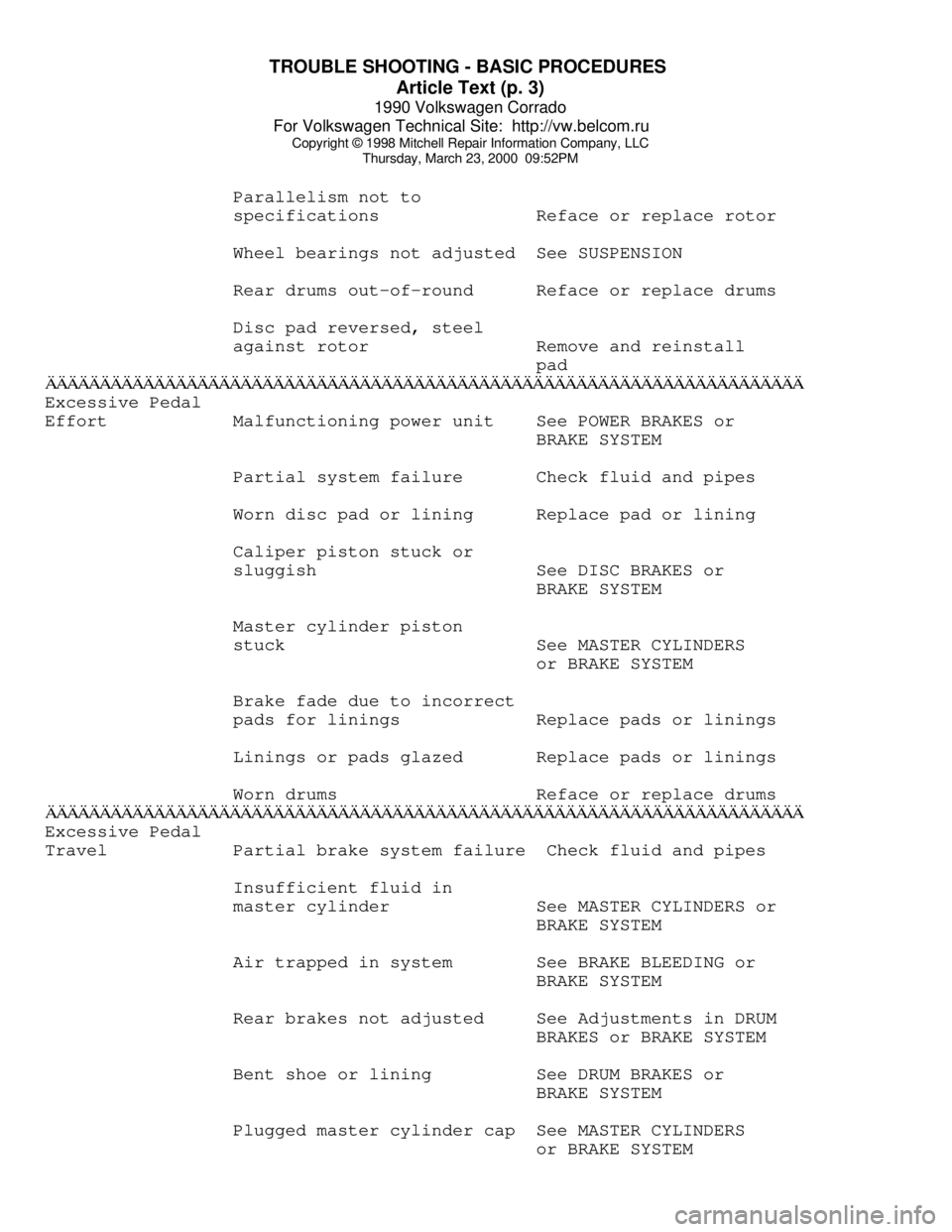

Parallelism not to

specifications Reface or replace rotor

Wheel bearings not adjusted See SUSPENSION

Rear drums out-of-round Reface or replace drums

Disc pad reversed, steel

against rotor Remove and reinstall

padÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄExcessive Pedal

Effort Malfunctioning power unit See POWER BRAKES or

BRAKE SYSTEM

Partial system failure Check fluid and pipes

Worn disc pad or lining Replace pad or lining

Caliper piston stuck or

sluggish See DISC BRAKES or

BRAKE SYSTEM

Master cylinder piston

stuck See MASTER CYLINDERS

or BRAKE SYSTEM

Brake fade due to incorrect

pads for linings Replace pads or linings

Linings or pads glazed Replace pads or linings

Worn drums Reface or replace drums

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄExcessive Pedal

Travel Partial brake system failure Check fluid and pipes

Insufficient fluid in

master cylinder See MASTER CYLINDERS or

BRAKE SYSTEM

Air trapped in system See BRAKE BLEEDING or

BRAKE SYSTEM

Rear brakes not adjusted See Adjustments in DRUM

BRAKES or BRAKE SYSTEM

Bent shoe or lining See DRUM BRAKES or

BRAKE SYSTEM

Plugged master cylinder cap See MASTER CYLINDERS

or BRAKE SYSTEM

Page 880 of 906

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

ARTICLE BEGINNING

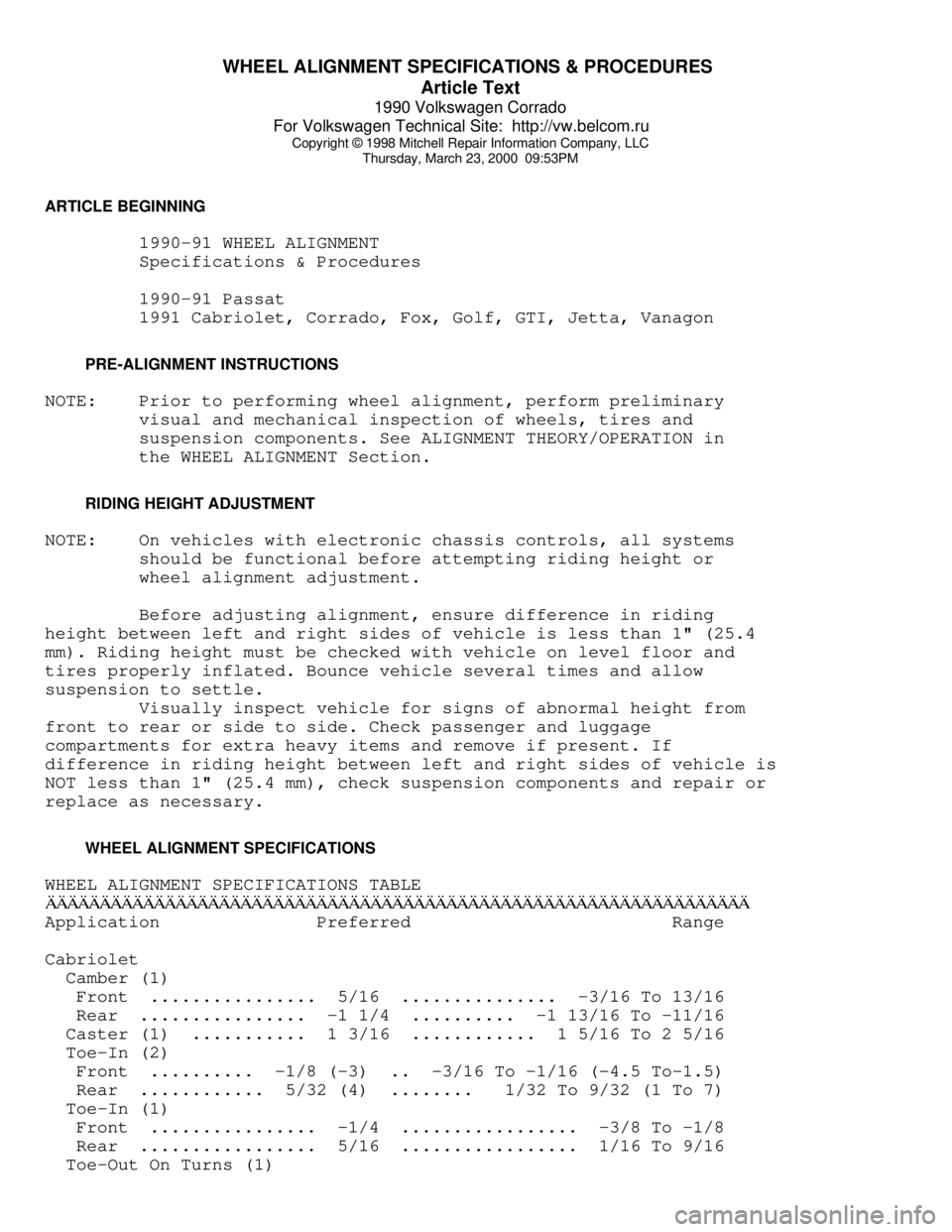

1990-91 WHEEL ALIGNMENT

Specifications & Procedures

1990-91 Passat

1991 Cabriolet, Corrado, Fox, Golf, GTI, Jetta, Vanagon

PRE-ALIGNMENT INSTRUCTIONS

NOTE: Prior to performing wheel alignment, perform preliminary

visual and mechanical inspection of wheels, tires and

suspension components. See ALIGNMENT THEORY/OPERATION in

the WHEEL ALIGNMENT Section.

RIDING HEIGHT ADJUSTMENT

NOTE: On vehicles with electronic chassis controls, all systems

should be functional before attempting riding height or

wheel alignment adjustment.

Before adjusting alignment, ensure difference in riding

height between left and right sides of vehicle is less than 1" (25.4

mm). Riding height must be checked with vehicle on level floor and

tires properly inflated. Bounce vehicle several times and allow

suspension to settle.

Visually inspect vehicle for signs of abnormal height from

front to rear or side to side. Check passenger and luggage

compartments for extra heavy items and remove if present. If

difference in riding height between left and right sides of vehicle is

NOT less than 1" (25.4 mm), check suspension components and repair or

replace as necessary.

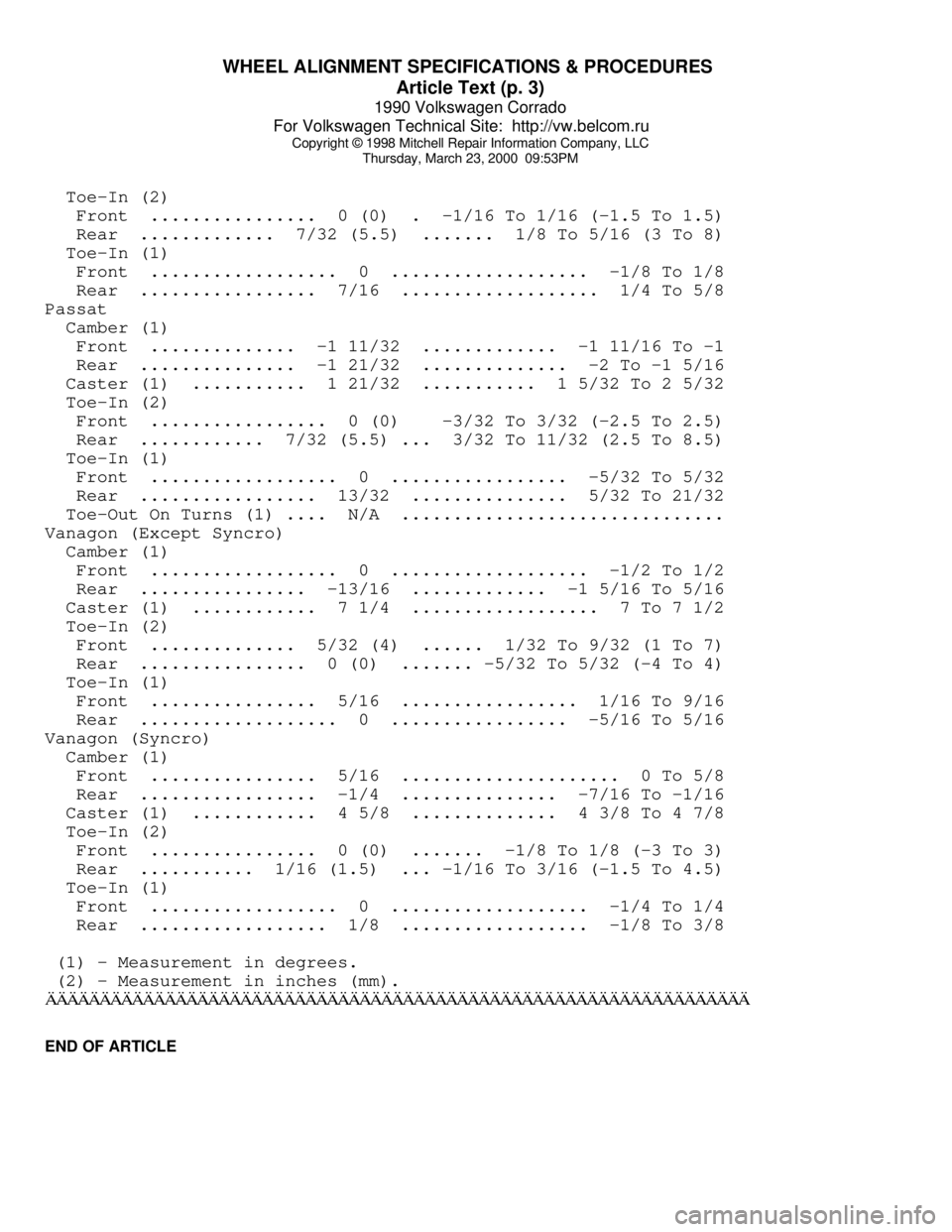

WHEEL ALIGNMENT SPECIFICATIONS

WHEEL ALIGNMENT SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Preferred Range

Cabriolet

Camber (1)

Front ................ 5/16 ............... -3/16 To 13/16

Rear ................ -1 1/4 .......... -1 13/16 To -11/16

Caster (1) ........... 1 3/16 ............ 1 5/16 To 2 5/16

Toe-In (2)

Front .......... -1/8 (-3) .. -3/16 To -1/16 (-4.5 To-1.5)

Rear ............ 5/32 (4) ........ 1/32 To 9/32 (1 To 7)

Toe-In (1)

Front ................ -1/4 ................. -3/8 To -1/8

Rear ................. 5/16 ................. 1/16 To 9/16

Toe-Out On Turns (1)

Page 881 of 906

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

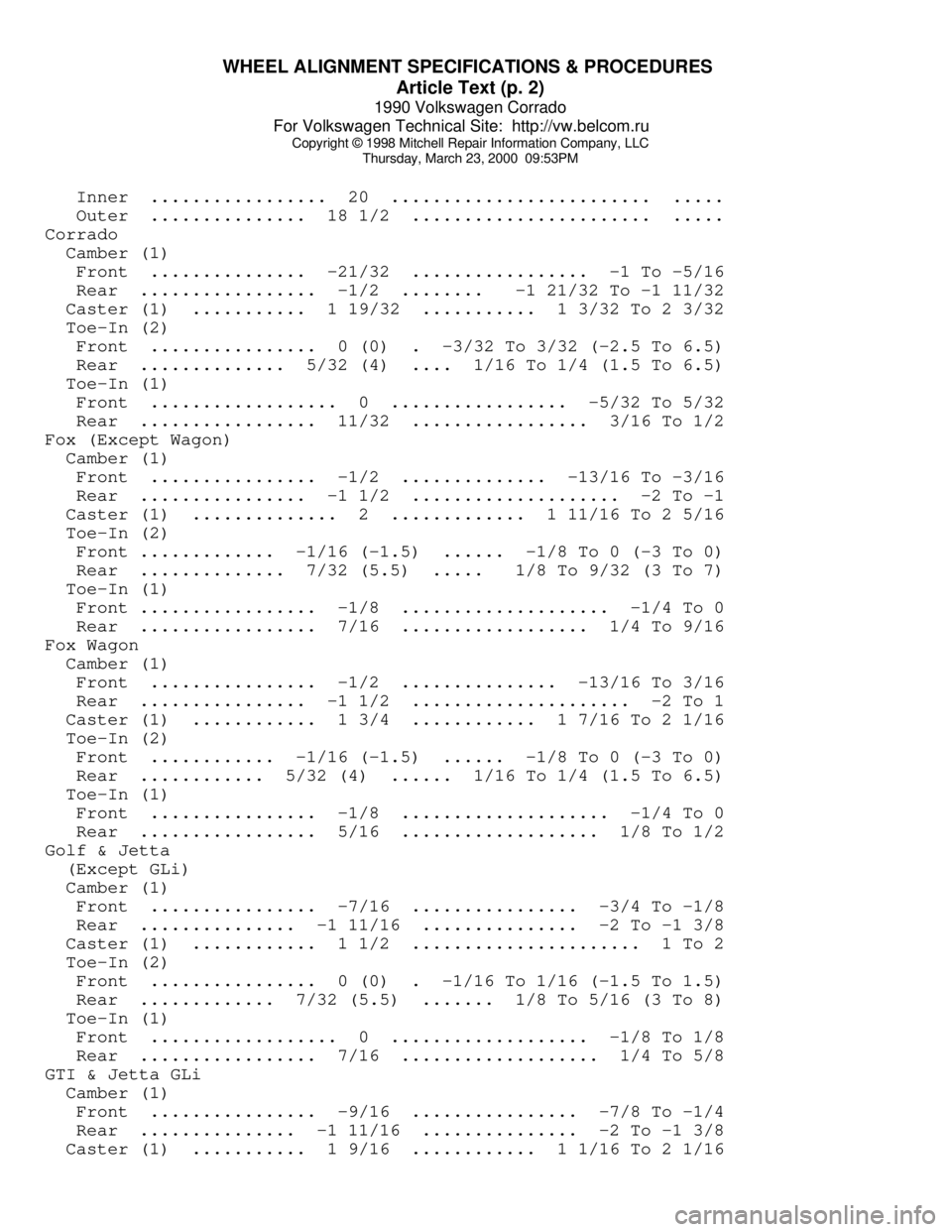

Inner ................. 20 ......................... .....

Outer ............... 18 1/2 ....................... .....

Corrado

Camber (1)

Front ............... -21/32 ................. -1 To -5/16

Rear ................. -1/2 ........ -1 21/32 To -1 11/32

Caster (1) ........... 1 19/32 ........... 1 3/32 To 2 3/32

Toe-In (2)

Front ................ 0 (0) . -3/32 To 3/32 (-2.5 To 6.5)

Rear .............. 5/32 (4) .... 1/16 To 1/4 (1.5 To 6.5)

Toe-In (1)

Front .................. 0 ................. -5/32 To 5/32

Rear ................. 11/32 ................. 3/16 To 1/2

Fox (Except Wagon)

Camber (1)

Front ................ -1/2 .............. -13/16 To -3/16

Rear ................ -1 1/2 .................... -2 To -1

Caster (1) .............. 2 ............. 1 11/16 To 2 5/16

Toe-In (2)

Front ............. -1/16 (-1.5) ...... -1/8 To 0 (-3 To 0)

Rear .............. 7/32 (5.5) ..... 1/8 To 9/32 (3 To 7)

Toe-In (1)

Front ................. -1/8 .................... -1/4 To 0

Rear ................. 7/16 .................. 1/4 To 9/16

Fox Wagon

Camber (1)

Front ................ -1/2 ............... -13/16 To 3/16

Rear ................ -1 1/2 ..................... -2 To 1

Caster (1) ............ 1 3/4 ............ 1 7/16 To 2 1/16

Toe-In (2)

Front ............ -1/16 (-1.5) ...... -1/8 To 0 (-3 To 0)

Rear ............ 5/32 (4) ...... 1/16 To 1/4 (1.5 To 6.5)

Toe-In (1)

Front ................ -1/8 .................... -1/4 To 0

Rear ................. 5/16 ................... 1/8 To 1/2

Golf & Jetta

(Except GLi)

Camber (1)

Front ................ -7/16 ................ -3/4 To -1/8

Rear ............... -1 11/16 ............... -2 To -1 3/8

Caster (1) ............ 1 1/2 ...................... 1 To 2

Toe-In (2)

Front ................ 0 (0) . -1/16 To 1/16 (-1.5 To 1.5)

Rear ............. 7/32 (5.5) ....... 1/8 To 5/16 (3 To 8)

Toe-In (1)

Front .................. 0 ................... -1/8 To 1/8

Rear ................. 7/16 ................... 1/4 To 5/8

GTI & Jetta GLi

Camber (1)

Front ................ -9/16 ................ -7/8 To -1/4

Rear ............... -1 11/16 ............... -2 To -1 3/8

Caster (1) ........... 1 9/16 ............ 1 1/16 To 2 1/16

Page 882 of 906

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

Toe-In (2)

Front ................ 0 (0) . -1/16 To 1/16 (-1.5 To 1.5)

Rear ............. 7/32 (5.5) ....... 1/8 To 5/16 (3 To 8)

Toe-In (1)

Front .................. 0 ................... -1/8 To 1/8

Rear ................. 7/16 ................... 1/4 To 5/8

Passat

Camber (1)

Front .............. -1 11/32 ............. -1 11/16 To -1

Rear ............... -1 21/32 .............. -2 To -1 5/16

Caster (1) ........... 1 21/32 ........... 1 5/32 To 2 5/32

Toe-In (2)

Front ................. 0 (0) -3/32 To 3/32 (-2.5 To 2.5)

Rear ............ 7/32 (5.5) ... 3/32 To 11/32 (2.5 To 8.5)

Toe-In (1)

Front .................. 0 ................. -5/32 To 5/32

Rear ................. 13/32 ............... 5/32 To 21/32

Toe-Out On Turns (1) .... N/A ...............................

Vanagon (Except Syncro)

Camber (1)

Front .................. 0 ................... -1/2 To 1/2

Rear ................ -13/16 ............. -1 5/16 To 5/16

Caster (1) ............ 7 1/4 .................. 7 To 7 1/2

Toe-In (2)

Front .............. 5/32 (4) ...... 1/32 To 9/32 (1 To 7)

Rear ................ 0 (0) ....... -5/32 To 5/32 (-4 To 4)

Toe-In (1)

Front ................ 5/16 ................. 1/16 To 9/16

Rear ................... 0 ................. -5/16 To 5/16

Vanagon (Syncro)

Camber (1)

Front ................ 5/16 ..................... 0 To 5/8

Rear ................. -1/4 ............... -7/16 To -1/16

Caster (1) ............ 4 5/8 .............. 4 3/8 To 4 7/8

Toe-In (2)

Front ................ 0 (0) ....... -1/8 To 1/8 (-3 To 3)

Rear ........... 1/16 (1.5) ... -1/16 To 3/16 (-1.5 To 4.5)

Toe-In (1)

Front .................. 0 ................... -1/4 To 1/4

Rear .................. 1/8 .................. -1/8 To 3/8

(1) - Measurement in degrees.

(2) - Measurement in inches (mm).ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 883 of 906

WHEEL ALIGNMENT THEORY/OPERATION

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

ARTICLE BEGINNING

GENERAL INFORMATION

Wheel Alignment Theory & Operation

ALL MODELS

* PLEASE READ THIS FIRST *

NOTE: This article is intended for general information purposes

only. This information may not apply to all makes and models.

PRE-ALIGNMENT INSTRUCTIONS

GENERAL ALIGNMENT CHECKS

Before adjusting wheel alignment, check the following:

* Each axle uses tires of same construction and tread style,

equal in tread wear and overall diameter. Verify that radial

and axial runout is not excessive. Inflation should be at

manufacturer's specifications.

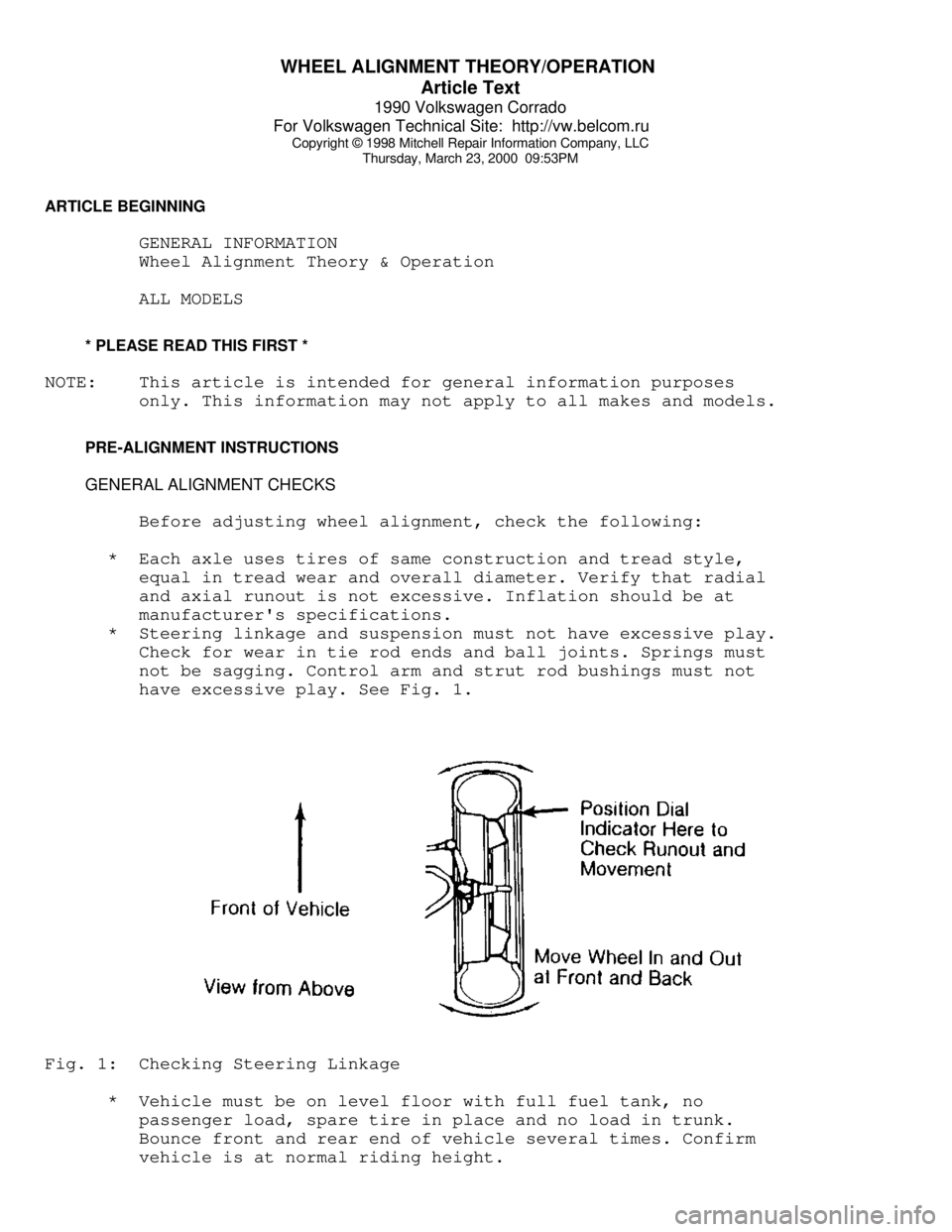

* Steering linkage and suspension must not have excessive play.

Check for wear in tie rod ends and ball joints. Springs must

not be sagging. Control arm and strut rod bushings must not

have excessive play. See Fig. 1.Fig. 1: Checking Steering Linkage

* Vehicle must be on level floor with full fuel tank, no

passenger load, spare tire in place and no load in trunk.

Bounce front and rear end of vehicle several times. Confirm

vehicle is at normal riding height.