technical specifications VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 636 of 906

MAINTENANCE INFORMATION

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:48PM

ARTICLE BEGINNING

1990-94 MAINTENANCE

Volkswagen Maintenance Information

Corrado G60 (1990-92)

SLC (1992-94 USA)

VR6 (1992-94 Canada)

* PLEASE READ THIS FIRST *

NOTE: For scheduled maintenance intervals and the related fluid

capacities, fluid specifications and labor times for major

service intervals, see SCHEDULED SERVICES article in this

section. Warranty information and specifications for fluid

capacities, lubrication specifications, wheel and tire size,

and battery type are covered in this article.

MODEL IDENTIFICATION

VIN LOCATION

The Vehicle Identification Number (VIN) is located on the

left side of the dash panel at the base of the windshield. The VIN

chart explains the code characters.

VIN CODE ID EXPLANATION

Numbers preceding the explanations in the legend below refer

to the sequence of characters as listed on VIN identification label.

See VIN example below.ÚÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

³ (VIN) W V W A B 0 5 3 2 M H 0 9 9 7 1 7

³

³ 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

³

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ1 - Manufacturing Country

W * Germany

1 * United States

3 * Mexico

9 * Brazil

2-3 - Manufacturer

VW * Volkswagen

4 - Series

D * 2-Door G60 (1990-92)

E * 2-Door SLC (1992-94 USA)

E * 2-Door VR6 (1992-94 Canada)

Page 645 of 906

MAINTENANCE INFORMATION

Article Text (p. 10)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:48PM

SERVICE LABOR TIMES

SERVICE LABOR TIMES TABLE (HOURS)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ (1)(2) 15,000 (1)(2) 30,000 (60,000)

Application Mile Service Mile Service

Automatic Transmission ..... 1.6 .................. 3.3 (4.2)

Manual Transmission ........ 1.8 .................. 2.7 (3.6)

(1) - Add .2 hr. if equipped with A/C. Add .1 hr. if equipped

with cruise control.

(2) - Add 1.8 hrs. to replace camshaft timing belt (if equipped).

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ LUBRICATION SPECIFICATIONS

LUBRICATION SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Fluid Specifications

Engine Oil (1)

Ambient Temperatures

Greater Than 50

øF (10øC) .............. SAE 20W-50 API SF/CD

14

øF To 50øF (-10øC To +10øC) ......... SAE 10W-40 API SF/CD

Less Than 14

øF (-10ø C) ................ SAE 5W-30 API SF/CD

Brake Fluid ........................ SAE J1703 (DOT 3 Or DOT 4)

Power Steering Fluid ......................... VW Hydraulic Oil

(G 002000) Or Equivalent

Automatic Transmission ........... Dexron-IIE ATF Or Equivalent

Manual Transaxle .......................... SAE 80W API GL-4 Or

SAE 75W-90 (G50 Synthetic Gear Oil)

Final Drive (A/T & M/T)

(Differential) .......... SAE 75W-90 (G50 Synthetic Gear Oil)

Wheel Bearings .................... NLGI Grade 2 Category GC-LB

Drive Shaft U-Joints .............. NLGI Grade 2 Category GC-LB

Steering Linkage (2)(3) ........... NLGI Grade 2 Category GC-LB

Ball Joints (2)(4) ................ NLGI Grade 2 Category GC-LB

Weatherstrip ....................... Dielectric Silicone Grease

(1) - SAE 15W-40 or 20W-40 engine oil is recommended for extreme

conditions or extended highway operation.

(2) - Use low pressure grease gun to prevent seal damage.

(3) - Fill until lubricant squeezes out from the base of seals.

(4) - Fill ball joint until seal starts to swell.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ FLUID CAPACITIES

FLUID CAPACITIES TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 646 of 906

MAINTENANCE INFORMATION

Article Text (p. 11)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:48PM

Application Quantity (1)

A/C System R-12 Refrigerant

1990-92 (up to 7/92) ............................. 37-40 Ozs.

A/C System R-134a Refrigerant (2)

1993-94 (from 7/92) ........................... 28.2-31.8 Ozs.

Cooling System

4-Cyl. ...................................... 6.8 Qts. (6.5L)

V6 .......................................... 9.1 Qts. (8.6L)

Engine Oil (3)

4-Cyl. ...................................... 4.3 Qts. (4.0L)

V6 .......................................... 6.3 Qts. (6.0L)

Fuel Tank

4-Cyl. ..................................... 14.5 Gals. (55L)

V6 ......................................... 18.5 Gals. (55L)

Automatic Transmission

Fluid Change ................................ 3.2 Qts. (3.0L)

Overhaul .................................... 5.9 Qts. (5.6L)

Manual Transmission ........................... 2.1 Qts. (2.0L)

Final Drive

Differential (A/T) (4) ....................... 0.8 Qt. (.75L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Use of R-12 in a R134a system will result in SEVERE DAMAGE.

(3) - Includes oil filter change.

(4) - Lifetime fill.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WHEEL & TIRE SPECIFICATIONS

Wheel and tire sizes vary according to vehicle and equipment

and can be found on tire information label on each vehicle. Wheel and

tire specifications and tire inflation pressures are listed on a label

found inside fuel tank flap.

NOTE: Snow chains must be used on drive wheels, in pairs only.

WHEEL TIGHTENING

Tighten all wheel lugs to 80 ft. lbs. (110 N.m).

BATTERY SPECIFICATIONS

CAUTION: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in the GENERAL INFORMATION

section.

All models use BCI group 41 batteries with cold crank rating

Page 674 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Removal, Overhaul & Installation

Volkswagen; Cabriolet, Corrado, Fox, Golf GL/GTI,

Jetta, Vanagon

INTRODUCTION

Removal, overhaul and installation procedures are covered in

this article. If component removal and installation is primarily an

unbolt and bolt-on procedure, only a torque specification may be

furnished. See TORQUE SPECIFICATIONS at the end of this article.

REMOVAL & INSTALLATION

DISTRIBUTOR (DIGIFANT)

Removal (AFC-Digifant II)

Turn engine crankshaft to TDC. Remove distributor cap. Rotor

should point to No. 1 cylinder mark on edge of distributor housing.

Index mark the distributor housing to the crankcase relation. Remove

distributor hold-down clamp and bolt. Remove distributor assembly.

Installation

Align rotor with No. 1 cylinder mark on edge of distributor

housing. Install distributor and align housing to index mark made on

crankcase. Install distributor hold-down clamp and bolt. Install

distributor cap. Check timing. Tighten hold-down bolt to

specification. See TORQUE SPECIFICATIONS.

DISTRIBUTOR (CIS SYSTEMS)

Removal (CIS-E & CIS-E Motronic)

1) Turn engine crankshaft to TDC. Marking on vibration

dampener pulley must align with drive belt guard pointer. Marking on

cam shaft gear sprocket must align with cylinder head cover.

2) Remove distributor cap and mark position of rotor. Rotor

should be pointing to No. 1 cylinder in distributor firing sequence.

Mark position of distributor housing for installation reference.

Remove distributor hold-down clamp and bolt. Remove distributor

assembly, noting position of rotor when distributor shaft gear is

disengaged from driving gear.

Installation

1) Align oil pump drive pinion lug parallel to crankshaft.

Set rotor pointing toward mark made when distributor was disengaged

from drive gear.

2) Install distributor. Rotor should now point to mark made

for No. 1 cylinder in distributor firing sequence. Align mark for

Page 675 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

distributor housing and install distributor hold-down clamp and bolt.

Install distributor cap. Check timing. Tighten hold-down bolt to

specification. See TORQUE SPECIFICATIONS.

AIRFLOW SENSOR PLATE

Removal & Installation

1) Remove air filter and unscrew stop bracket. Using heat

gun, heat locking compound on fastening bolt. Remove bolt slowly. DO

NOT damage threads. Clean locking compound from bolt hole threads.

2) Install airflow sensor plate. Ensure 5 dimple marks are

up. Lightly tighten self-locking screw. Ensure sensor plate is

centered and rest position is correct. To complete installation,

reverse removal procedure. See TORQUE SPECIFICATIONS.

AIRFLOW SENSOR POTENTIOMETER

Removal & Installation

Remove differential pressure regulator. Remove insulating

compound covering mounting screws. Remove potentiometer. DO NOT touch

or damage slide contact and conductor. To install, reverse removal

procedure. See TORQUE SPECIFICATIONS. Adjust potentiometer. See D -

ADJUSTMENTS article.

FUEL DISTRIBUTOR (1.8L ONLY)

CAUTION: Fuel system pressure must be relieved before removing or

disconnecting any fuel lines. Wipe up all spilled fuel

BEFORE continuing service.

Removal

1) Disconnect battery and remove air cleaner. Disconnect all

fuel and injector lines from fuel distributor. Plug fuel supply and

return lines. Catch any spilled fuel.

2) Disconnect wiring from differential pressure regulator.

Remove screws holding fuel distributor to airflow sensor housing.

Remove fuel distributor by turning back and forth while lifting up.

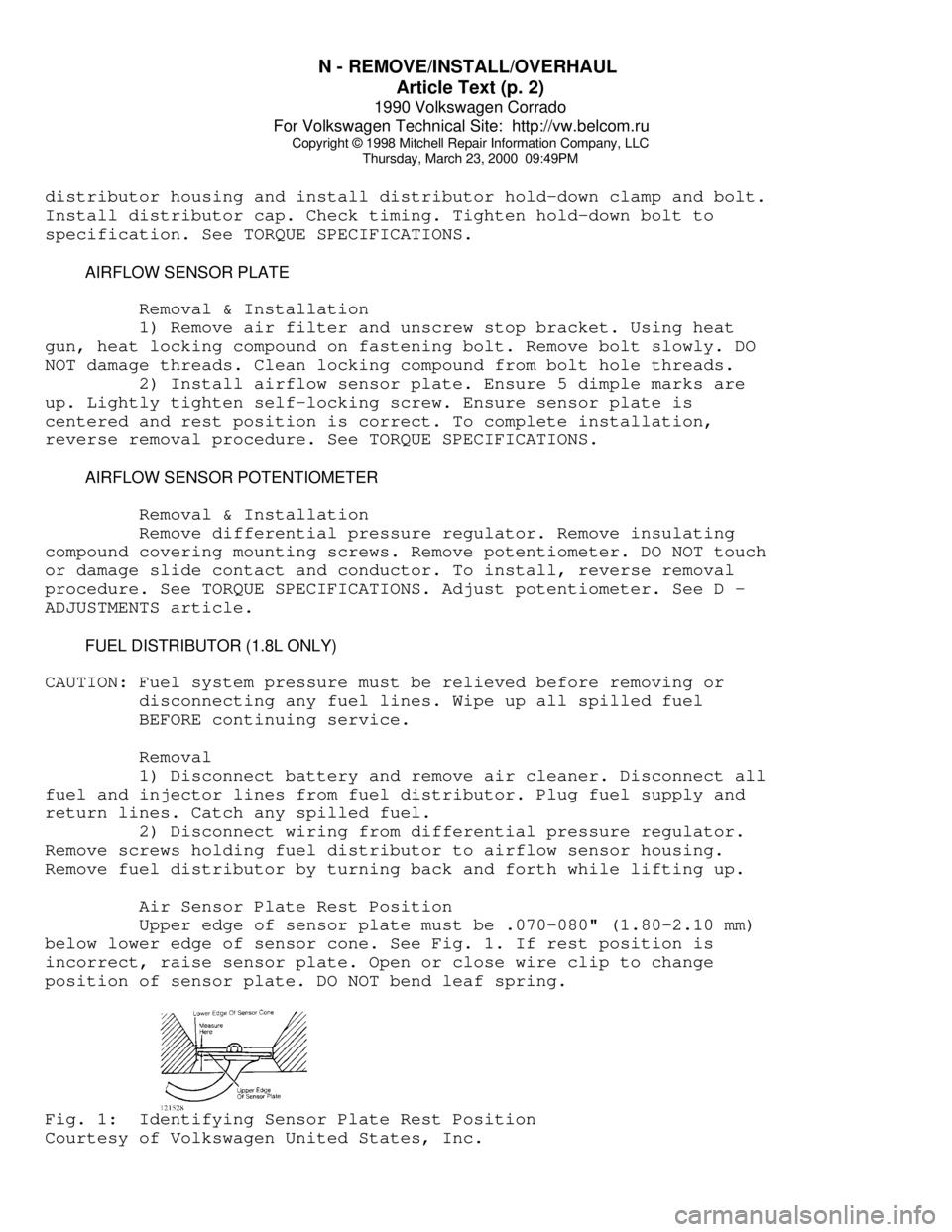

Air Sensor Plate Rest Position

Upper edge of sensor plate must be .070-080" (1.80-2.10 mm)

below lower edge of sensor cone. See Fig. 1. If rest position is

incorrect, raise sensor plate. Open or close wire clip to change

position of sensor plate. DO NOT bend leaf spring.Fig. 1: Identifying Sensor Plate Rest Position

Courtesy of Volkswagen United States, Inc.

Page 678 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

distributor. Install fuel distributor. See TORQUE SPECIFICATIONS for

tightening specifications. Connect all fuel lines except those to fuel

injectors. Check sensor plate adjusting lever and fuel distributor

control piston for smooth operation.

2) Remove fuel pump relay and bridge fuel pump circuit. Use

Jumper Switch (US 4480/3) in place of fuel pump relay. When pressure

has built up, turn off fuel pump. Move sensor plate from rest position

to end of travel.

3) Uniform resistance should be felt during entire movement.

No resistance should be felt during entire movement. No resistance

should be felt on quick return to rest position. Connect injector

lines. Install fuel pump relay. Start engine and check for leaks.

INJECTORS (DIGIFANT)

CAUTION: Fuel system pressure must be relieved before removing

injectors. Wipe up all spilled fuel BEFORE continuing

service.

Removal (AFC-Digifant II)

Disconnect negative battery cable. Disconnect main electrical

connector from fuel rail. Remove idle stabilizer valve. Loosen and

remove both hoses on each end of fuel rail. Remove fuel pressure

regulator and mounting bracket. Remove fuel rail mounting bolts. Pry

off injector mounting clips. Disconnect injector electrical

connectors. Remove fuel rail. Remove each injector from its insert.

Installation

To install injectors, reverse removal procedures. Use new "O"

rings when installing injectors. Replace hose clamps if necessary. See

TORQUE SPECIFICATIONS table at end of this article. Check for fuel

leaks.

INJECTORS (CIS SYSTEMS)

Removal (CIS-E & CIS-E Motronic)

Remove injectors from inserts in cylinder head with fuel

lines attached. Using 12-mm or 13-mm hex wrench, remove inserts from

head. Use 2 wrenches to remove injectors from fuel lines.

Installation

To install, reverse removal procedures. Use 2 wrenches when

tightening injector lines to injectors. Use new "O" rings lightly

lubricated. On models with 2-piece inserts, replace insert sealing

washer (against head) and use sealing compound on upper insert

threaded portion. See TORQUE SPECIFICATIONS.

OXYGEN (O2) SENSOR

Removal & Installation

Oxygen (O2) sensor is mounted in the exhaust pipe in front of

catalytic converter. Disconnect permanent pigtail from sensor. Ensure

Page 679 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

sensor is free of contaminants, avoid using any cleaning solvents.

Sensor may be difficult to remove when engine temperature is less than

118øF (48øC). Always use anti-seize compound on threads before

installation. Tighten sensor to specification. See

TORQUE SPECIFICATIONS.

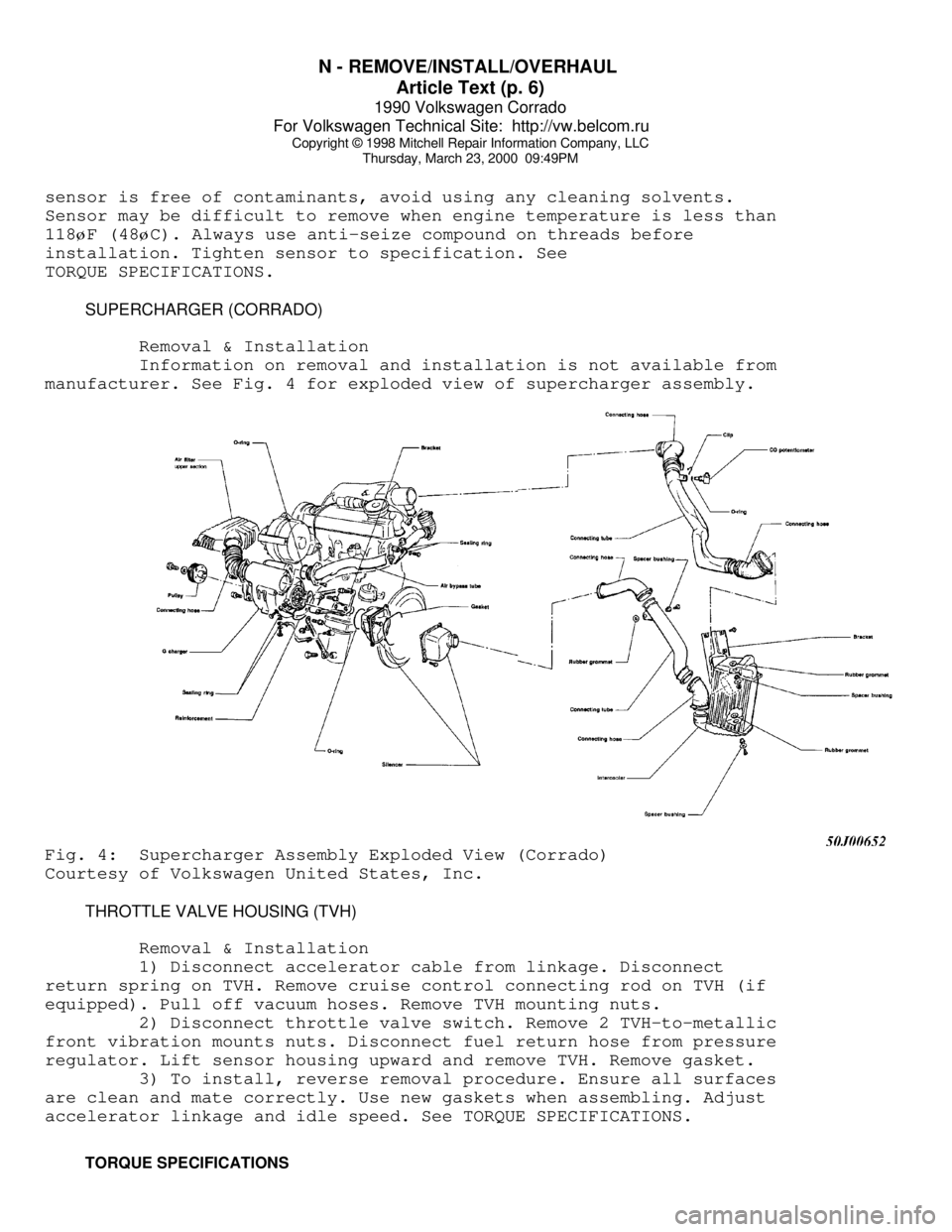

SUPERCHARGER (CORRADO)

Removal & Installation

Information on removal and installation is not available from

manufacturer. See Fig. 4 for exploded view of supercharger assembly.Fig. 4: Supercharger Assembly Exploded View (Corrado)

Courtesy of Volkswagen United States, Inc.

THROTTLE VALVE HOUSING (TVH)

Removal & Installation

1) Disconnect accelerator cable from linkage. Disconnect

return spring on TVH. Remove cruise control connecting rod on TVH (if

equipped). Pull off vacuum hoses. Remove TVH mounting nuts.

2) Disconnect throttle valve switch. Remove 2 TVH-to-metallic

front vibration mounts nuts. Disconnect fuel return hose from pressure

regulator. Lift sensor housing upward and remove TVH. Remove gasket.

3) To install, reverse removal procedure. Ensure all surfaces

are clean and mate correctly. Use new gaskets when assembling. Adjust

accelerator linkage and idle speed. See TORQUE SPECIFICATIONS.

TORQUE SPECIFICATIONS

Page 680 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

TORQUE SPECIFICATIONSÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ft. Lbs. (N.m)

AFC-Digifant II

Fuel Injector Inserts .................................... 15 (20)

Fuel Pressure Regulator Mounting Bolt .................... 11 (15)

Intercooler Bracket Mounting Bolts (Corrado) ............. 15 (20)

Knock Sensor ............................................. 15 (20)

Oxygen Sensor ............................................ 37 (50)

Supercharger Mounting Bolts (Corrado) .................... 18 (24)

Supercharger Pulley Bolt (Corrado) ....................... 33 (45)

Supercharger To Silencer Assembly Bolts (Corrado) ........ 18 (24)

Throttle Valve Body Mounting Bolts ....................... 15 (20)

CIS-E & CIS-E Motronic

Distributor Hold-Down Bolt (Fox) ......................... 18 (24)

Fuel Injection Valve Fuel Line Nut ....................... 18 (24)

Fuel Return Line Fitting ................................. 15 (20)

Fuel Supply Line Union Bolts ............................. 15 (20)

Intake Manifold Temperature Sensor (Jetta GLi 2.0L) ...... 15 (20)

Oxygen Sensor ............................................ 37 (50)

Thermo Time Switch (CIS-E) ............................... 22 (30)

Throttle Valve Housing Mounting Bolts .................... 15 (20)

INCH Lbs. (N.m)

AFC-Digifant II

Fuel Rail Mounting Bolts ................................. 87 (10)

Idle Stabilizer Valve Mounting Nuts ...................... 87 (10)

Intercooler Mounting Bolts (Corrado) ..................... 87 (10)

Supercharger Air Hose Mounting Bolts (Corrado) ........... 87 (10)

CIS-E & CIS-E Motronic

Auxiliary Air Regulator Mounting Bolts ................... 87 (10)

Cold Start Valve Mounting Bolts .......................... 87 (10)

Coolant Temperature Sensor ............................... 87 (10)

Distributor Hold-Down Bolt (Jetta GLi) ................... 87 (10)

EGR Valve Mounting Bolts ................................. 87 (10)

Fuel Distributor Mounting Bolts ......................... 30 (3.4)

Fuel Line Fittings ....................................... 87 (10)

Test Port Plug ........................................... 87 (10)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 683 of 906

PRE-ALIGNMENT CHECKS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

Wheel Alignment

PRE-ALIGNMENT INSPECTION PROCEDURES

PRE-ALIGNMENT CHECKS

Before making wheel alignment adjustment, perform the

following checks:

1) Tires should be equal in size and runout must not be

excessive. Tires and wheels should be in balance, and inflated to

manufacturer's specifications.

2) Wheel bearings must be properly adjusted. Steering linkage

and suspension must not have excessive looseness. Check for wear in

tie rod ends and ball joints.

3) Steering gear box must not have excessive play. Check and

adjust to manufacturer's specifications.

4) Vehicle must be at curb height with full fuel load and

spare tire in vehicle. No extra load should be on vehicle.

5) Vehicle must be level with floor and with suspension

settled. Jounce front and rear of vehicle several times and allow it

to settle to normal curb height.

6) If steering wheel is not centered with front wheels in

straight-ahead position, correct by shortening one tie rod adjusting

sleeve and lengthening opposite sleeve equal amounts.

7) Ensure wheel lug nuts are tightened to torque

specifications.

END OF ARTICLE

Page 684 of 906

SCHEDULED SERVICES

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

1990-94 MAINTENANCE

Volkswagen Maintenance & Service Intervals

Corrado G60 (1990-92)

SLC (1992-94 USA)

VR6 (1992-94 Canada)

* PLEASE READ THIS FIRST *

NOTE: All SERVICE SCHEDULES are listed for normal service

vehicles. If vehicle is operated under severe service

conditions, see SEVERE SERVICE REQUIREMENTS (PERFORM

W/SERVICE SCHEDULES) for items requiring additional

maintenance.

NOTE: This article contains scheduled maintenance service

information. Fluid types and capacities listed with each

service in this article are only those necessary to perform

that scheduled service. For specifications pertaining to

fluid capacities for the entire vehicle, fuse and circuit

breaker identification, wheel and tire size, battery type,

warranty information, or model identification refer to the

MAINTENANCE INFORMATION article in this section.

CAUTIONS & WARNINGS

SUPPLEMENTAL RESTRAINT SYSTEM (AIR BAG) - 1995 MODELS

NOTE: See the AIR BAGS article in the ACCESSORIES/SAFETY EQUIPMENT

Section.

Modifications or improper maintenance, including incorrect

removal and installation of the Supplemental Restraint System (SRS),

can adversely affect system performance. DO NOT cover, obstruct or

change the steering wheel horn pad in any way, as such action could

cause improper function of the system. Use only plain water when

cleaning the horn pad. Solvents or cleaners could adversely affect the

air bag cover and cause improper deployment of the system.

WARNING: To avoid injury from accidental air bag deployment, read and

carefully follow all warnings and service precautions. See

appropriate AIR BAGS article in ACCESSORIES/SAFETY EQUIPMENT.

CAUTION: Disconnect negative battery cable before servicing any air

bag system, steering column or passenger side dash

component. After any repair, turn ignition key to the ON

position from passenger's side of vehicle in case of

accidental air bag inflation