engine VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 674 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Removal, Overhaul & Installation

Volkswagen; Cabriolet, Corrado, Fox, Golf GL/GTI,

Jetta, Vanagon

INTRODUCTION

Removal, overhaul and installation procedures are covered in

this article. If component removal and installation is primarily an

unbolt and bolt-on procedure, only a torque specification may be

furnished. See TORQUE SPECIFICATIONS at the end of this article.

REMOVAL & INSTALLATION

DISTRIBUTOR (DIGIFANT)

Removal (AFC-Digifant II)

Turn engine crankshaft to TDC. Remove distributor cap. Rotor

should point to No. 1 cylinder mark on edge of distributor housing.

Index mark the distributor housing to the crankcase relation. Remove

distributor hold-down clamp and bolt. Remove distributor assembly.

Installation

Align rotor with No. 1 cylinder mark on edge of distributor

housing. Install distributor and align housing to index mark made on

crankcase. Install distributor hold-down clamp and bolt. Install

distributor cap. Check timing. Tighten hold-down bolt to

specification. See TORQUE SPECIFICATIONS.

DISTRIBUTOR (CIS SYSTEMS)

Removal (CIS-E & CIS-E Motronic)

1) Turn engine crankshaft to TDC. Marking on vibration

dampener pulley must align with drive belt guard pointer. Marking on

cam shaft gear sprocket must align with cylinder head cover.

2) Remove distributor cap and mark position of rotor. Rotor

should be pointing to No. 1 cylinder in distributor firing sequence.

Mark position of distributor housing for installation reference.

Remove distributor hold-down clamp and bolt. Remove distributor

assembly, noting position of rotor when distributor shaft gear is

disengaged from driving gear.

Installation

1) Align oil pump drive pinion lug parallel to crankshaft.

Set rotor pointing toward mark made when distributor was disengaged

from drive gear.

2) Install distributor. Rotor should now point to mark made

for No. 1 cylinder in distributor firing sequence. Align mark for

Page 678 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

distributor. Install fuel distributor. See TORQUE SPECIFICATIONS for

tightening specifications. Connect all fuel lines except those to fuel

injectors. Check sensor plate adjusting lever and fuel distributor

control piston for smooth operation.

2) Remove fuel pump relay and bridge fuel pump circuit. Use

Jumper Switch (US 4480/3) in place of fuel pump relay. When pressure

has built up, turn off fuel pump. Move sensor plate from rest position

to end of travel.

3) Uniform resistance should be felt during entire movement.

No resistance should be felt during entire movement. No resistance

should be felt on quick return to rest position. Connect injector

lines. Install fuel pump relay. Start engine and check for leaks.

INJECTORS (DIGIFANT)

CAUTION: Fuel system pressure must be relieved before removing

injectors. Wipe up all spilled fuel BEFORE continuing

service.

Removal (AFC-Digifant II)

Disconnect negative battery cable. Disconnect main electrical

connector from fuel rail. Remove idle stabilizer valve. Loosen and

remove both hoses on each end of fuel rail. Remove fuel pressure

regulator and mounting bracket. Remove fuel rail mounting bolts. Pry

off injector mounting clips. Disconnect injector electrical

connectors. Remove fuel rail. Remove each injector from its insert.

Installation

To install injectors, reverse removal procedures. Use new "O"

rings when installing injectors. Replace hose clamps if necessary. See

TORQUE SPECIFICATIONS table at end of this article. Check for fuel

leaks.

INJECTORS (CIS SYSTEMS)

Removal (CIS-E & CIS-E Motronic)

Remove injectors from inserts in cylinder head with fuel

lines attached. Using 12-mm or 13-mm hex wrench, remove inserts from

head. Use 2 wrenches to remove injectors from fuel lines.

Installation

To install, reverse removal procedures. Use 2 wrenches when

tightening injector lines to injectors. Use new "O" rings lightly

lubricated. On models with 2-piece inserts, replace insert sealing

washer (against head) and use sealing compound on upper insert

threaded portion. See TORQUE SPECIFICATIONS.

OXYGEN (O2) SENSOR

Removal & Installation

Oxygen (O2) sensor is mounted in the exhaust pipe in front of

catalytic converter. Disconnect permanent pigtail from sensor. Ensure

Page 679 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

sensor is free of contaminants, avoid using any cleaning solvents.

Sensor may be difficult to remove when engine temperature is less than

118øF (48øC). Always use anti-seize compound on threads before

installation. Tighten sensor to specification. See

TORQUE SPECIFICATIONS.

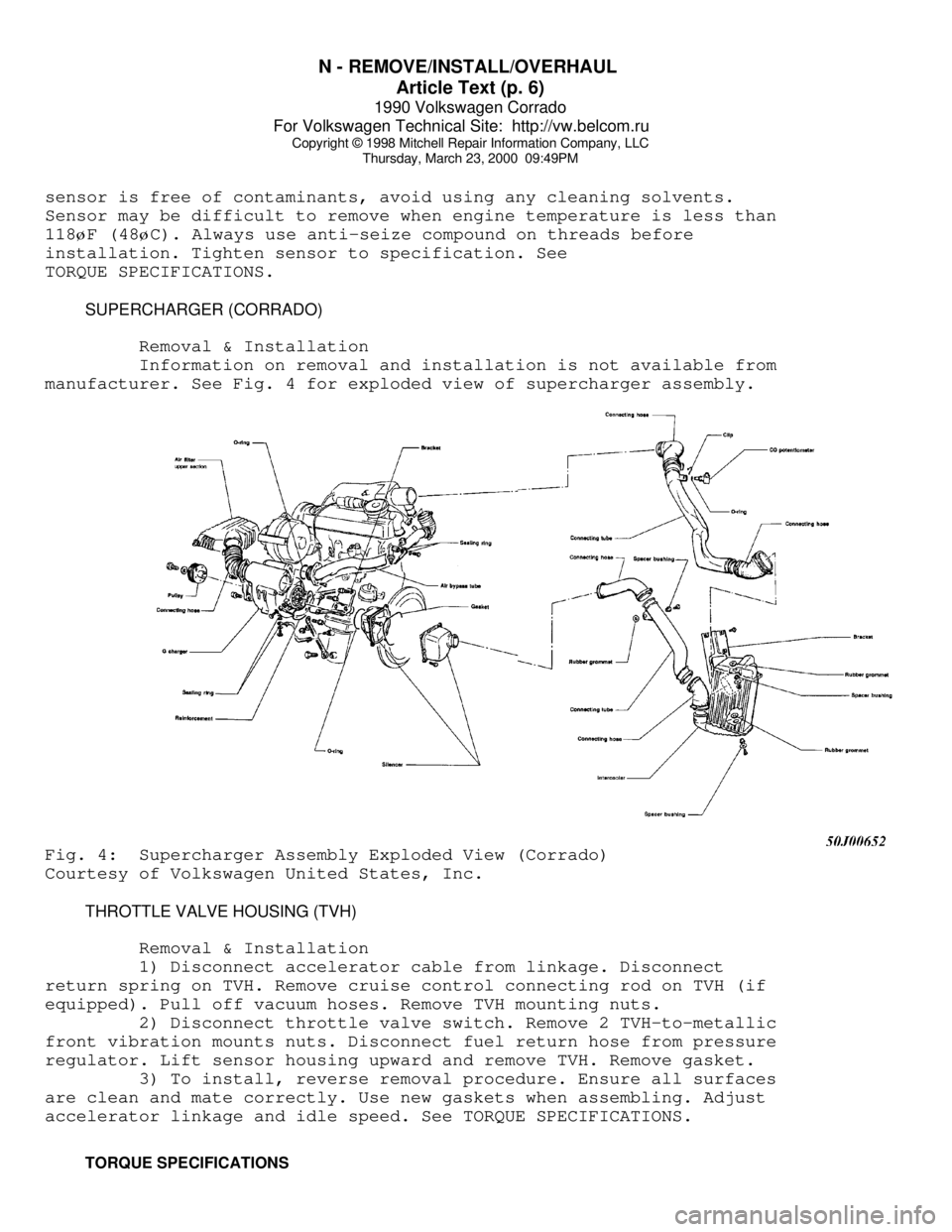

SUPERCHARGER (CORRADO)

Removal & Installation

Information on removal and installation is not available from

manufacturer. See Fig. 4 for exploded view of supercharger assembly.Fig. 4: Supercharger Assembly Exploded View (Corrado)

Courtesy of Volkswagen United States, Inc.

THROTTLE VALVE HOUSING (TVH)

Removal & Installation

1) Disconnect accelerator cable from linkage. Disconnect

return spring on TVH. Remove cruise control connecting rod on TVH (if

equipped). Pull off vacuum hoses. Remove TVH mounting nuts.

2) Disconnect throttle valve switch. Remove 2 TVH-to-metallic

front vibration mounts nuts. Disconnect fuel return hose from pressure

regulator. Lift sensor housing upward and remove TVH. Remove gasket.

3) To install, reverse removal procedure. Ensure all surfaces

are clean and mate correctly. Use new gaskets when assembling. Adjust

accelerator linkage and idle speed. See TORQUE SPECIFICATIONS.

TORQUE SPECIFICATIONS

Page 681 of 906

P - EGR FUNCTION TESTING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

1989-95 ENGINE PERFORMANCE

Volkswagen EGR Function Testing

All Models

EGR VALVE (EXCEPT DIESEL)

1) Run engine at idle speed. Using a hand-held vacuum pump,

apply 12 in. Hg to EGR valve. Engine should run rough or stall. If

not, check EGR valve pintle for movement. If EGR pintle is moving, EGR

port is plugged. If EGR valve does not function, replace EGR valve.

2) To check EGR port vacuum supply, connect vacuum gauge to

EGR vacuum line using a "T" fitting. Start engine and increase engine

speed to about 3000 RPM. Vacuum gauge should indicate vacuum. If

vacuum is not present, vacuum source is plugged. Repair as necessary

and repeat test.

END OF ARTICLE

Page 682 of 906

POSSIBLE ENGINE STALL DUE TO FUEL RESTRICTION

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

ARTICLE BEGINNING

NHTSA RECALL BULLETIN

Model(s): 1990 Volkswagen Corrado

1991 Volkswagen Corrado

Campaign No: 91V068000

Number of Affected Vehicles: 8500

Beginning Date of Manufacture: 1989 OCTOBER

Ending Date of Manufacture: 1991 OCTOBER

VEHICLE DESCRIPTION:

Passenger cars.

DESCRIPTION OF DEFECT:

The fuel filter housing, which serves as the base for the fuel pump

(located in the fuel tank) could deform, resulting in the fuel pump

becoming loose.

FAULT:

Poor fit/loose

SYSTEM:

Fuel pump filter.

CONSEQUENCE OF DEFECT:

A loose and improperly seated fuel pump can cause reduced fuel flow to

the engine resulting in possible driveability problems and stalling of

the vehicle.

CORRECTIVE ACTION:

Replace fuel filter.

ADDITIONAL INFORMATION:

The National Highway Traffic Safety Administration operates Monday

through Friday from 8:00 AM to 4:00 PM, Eastern Time. For more

information call (800) 424-9393 or (202) 366-0123. For the hearing

impaired, call (800) 424-9153.

END OF ARTICLE

Page 686 of 906

SCHEDULED SERVICES

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in GENERAL INFORMATION section.

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous

electrical system overload.

BRAKE PAD REPLACEMENT

WARNING: Use caution when checking and/or changing brake pads, some

pads may contain asbestos which can irritate eyes and may

cause other health hazards. A water based solution should be

used to clean brake dust from wheel and brake components.

DO NOT use compressed air to blow off brake dust.

BRAKE SYSTEM

CAUTION: If brake warning light comes on while driving it indicates

a low fluid level or failure in one of the braking

circuits. If the brake pedal can be depressed further than

normal it is an indication that one of the brake circuits

is not functioning. Stop vehicle and check brake reservoir

fluid level. If level is below MIN mark, DO NOT drive

vehicle. Have it towed to a repair shop. If level is

between the MIN and MAX marks, proceed cautiously to a

repair shop.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning

that brake pads need replacement.

BRAKE PEDAL PRESSURE WITH ENGINE NOT RUNNING

CAUTION: Brake pedal requires extreme pressure to stop the vehicle

when the engine is not running.

CATALYTIC CONVERTER

Continued operation of vehicle with a severe malfunction

could cause converter to overheat, resulting in possible damage to

converter and vehicle.

Any modification to the exhaust system on turbo models, which

reduces exhaust backpressure, will lead to lean fuel mixtures and

excessive spark advance. This could cause serious engine damage.

COOLANT (PROPYLENE-GLYCOL FORMULATIONS)

Page 687 of 906

SCHEDULED SERVICES

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

To avoid possible damage to vehicle use only ethylene-glycol

based coolants with a mixture ratio from 44-68% anti-freeze.

DO NOT use 100% anti-freeze as it will cause the formation

of cooling system deposits. This results in coolant

temperatures of over 300ø F (149øC) which can melt plastics.

100% anti-freeze has a freeze point of only -8

ø F (-22øC).

CAUTION: Propylene-Glycol Mixtures has a smaller temperature range

than Ethylene-Glycol. The temperature range (freeze-boil)

of a 50/50 Anti-Freeze/Water Mix is as follows:

Propylene-Glycol -26

ø F (-32øC) - 257ø F (125øC)

Ethylene-Glycol -35

ø F (-37øC) - 263ø F (128øC)

CAUTION: Propylene-Glycol/Ethylene-Glycol Mixtures can cause the

destabilization of various corrosion inhibitors. Also

Propylene-Glycol/Ethylene-Glycol has a different specific

gravity than Ethylene-Glycol coolant, which will result in

inaccurate freeze point calculations.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

WARNING: Many solid state electrical components can be damaged by

static electricity (ESD). Some will display a warning label,

but many will not. Discharge personal static electricity by

touching a metal ground point on the vehicle prior to

servicing any ESD sensitive component.

ELECTRIC SHOCK HAZARD

WARNING: Contact with live components of ignition system while

engine is running could lead to a fatal electric shock.

ENGINE OIL

CAUTION: Never use non-detergent or straight mineral oil.

FUEL SYSTEM SERVICE

WARNING: Relieve fuel system pressure prior to servicing any fuel

system component (fuel injection models).

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if

overheated. DO NOT touch glass portion of bulb with bare hands. Eye

protection should be worn when handling or working around halogen

bulbs.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

Page 688 of 906

SCHEDULED SERVICES

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

radiator fan. The fan is temperature controlled and could

start at any time even when the ignition key is in the OFF

position. DO NOT loosen or remove radiator cap when cooling

system is hot.

RADIATOR FAN

WARNING: Keep hands away from radiator fan. Fan is controlled by a

thermostatic switch which may come on or run for up to

15 minutes even after engine is turned off.

WHEELS & TIRES

Only wheels tested and approved by the manufacturer should be

used on models equipped with Air Dam aerodynamic components.

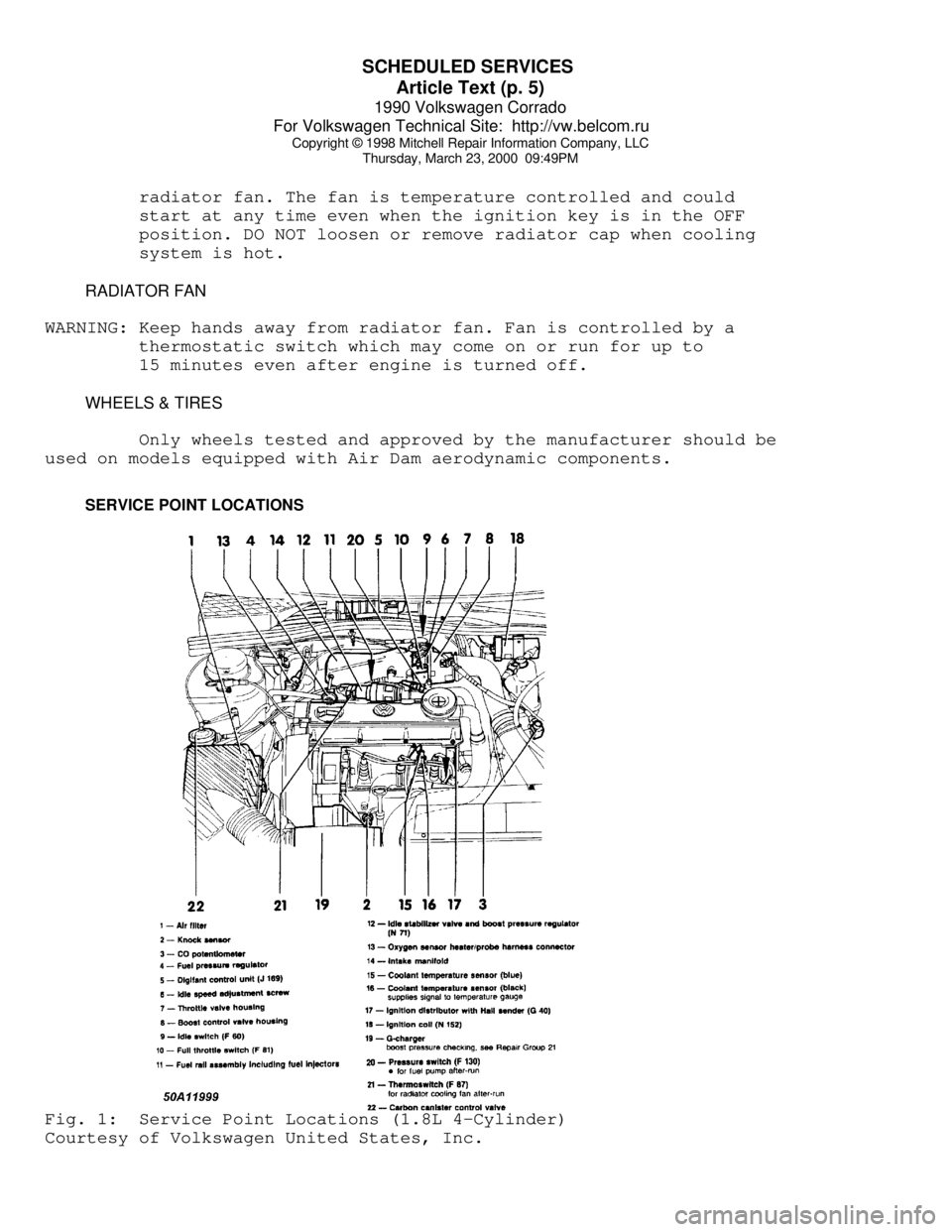

SERVICE POINT LOCATIONSFig. 1: Service Point Locations (1.8L 4-Cylinder)

Courtesy of Volkswagen United States, Inc.

Page 690 of 906

SCHEDULED SERVICES

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

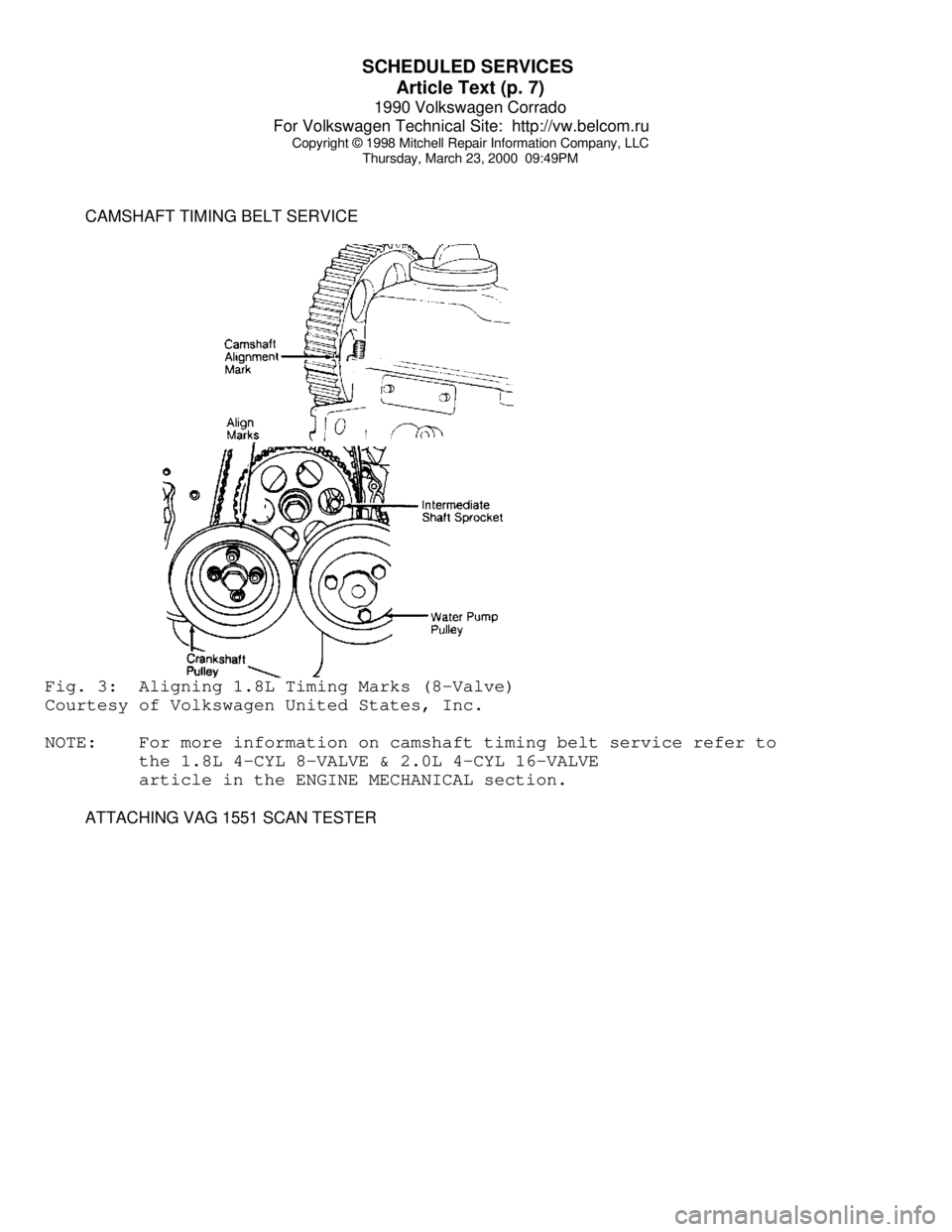

CAMSHAFT TIMING BELT SERVICEFig. 3: Aligning 1.8L Timing Marks (8-Valve)

Courtesy of Volkswagen United States, Inc.

NOTE: For more information on camshaft timing belt service refer to

the 1.8L 4-CYL 8-VALVE & 2.0L 4-CYL 16-VALVE

article in the ENGINE MECHANICAL section.

ATTACHING VAG 1551 SCAN TESTER

Page 691 of 906

SCHEDULED SERVICES

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

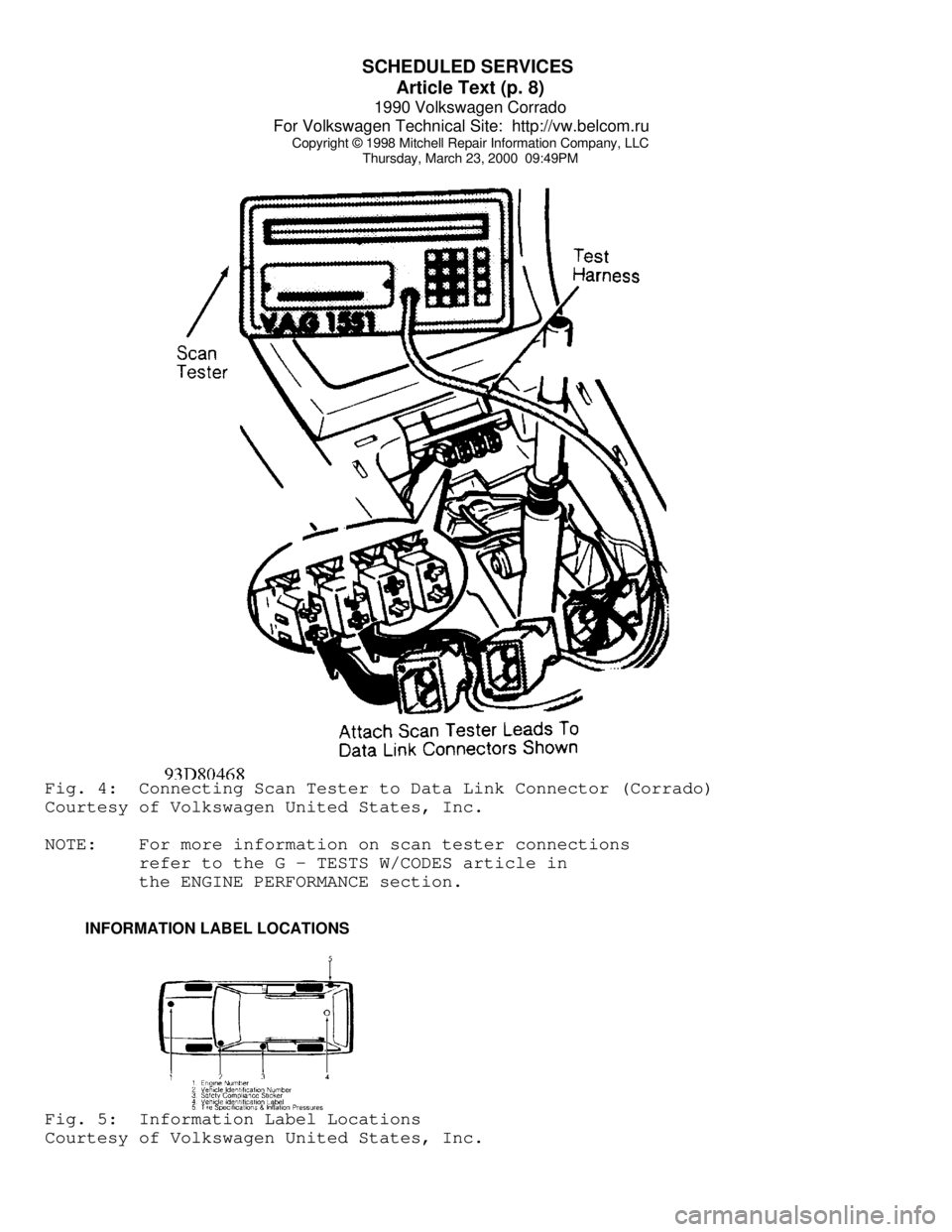

Thursday, March 23, 2000 09:49PMFig. 4: Connecting Scan Tester to Data Link Connector (Corrado)

Courtesy of Volkswagen United States, Inc.

NOTE: For more information on scan tester connections

refer to the G - TESTS W/CODES article in

the ENGINE PERFORMANCE section.

INFORMATION LABEL LOCATIONSFig. 5: Information Label Locations

Courtesy of Volkswagen United States, Inc.