wiring VOLKSWAGEN CORRADO 1990 Service Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 423 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 15)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

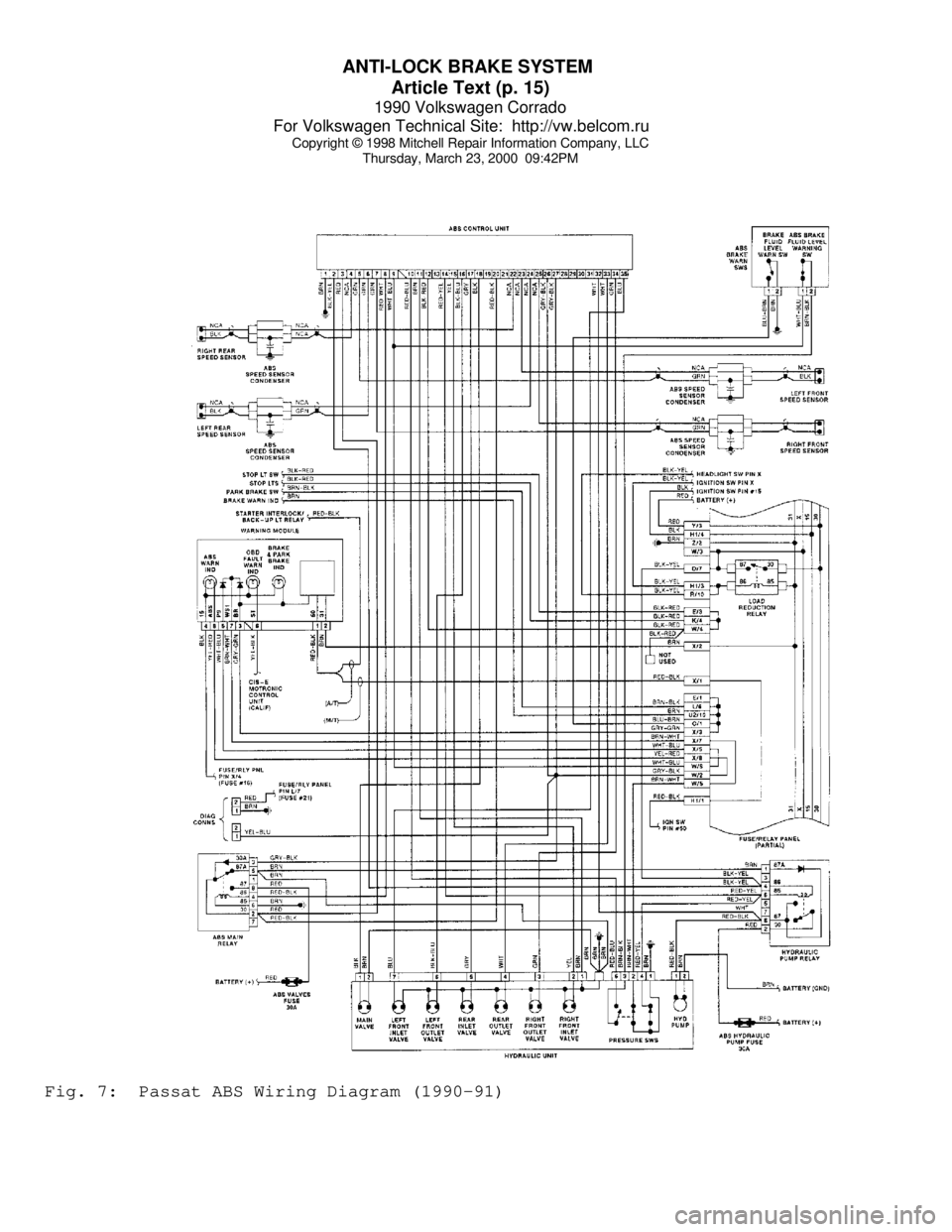

Thursday, March 23, 2000 09:42PMFig. 7: Passat ABS Wiring Diagram (1990-91)

Page 424 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 16)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

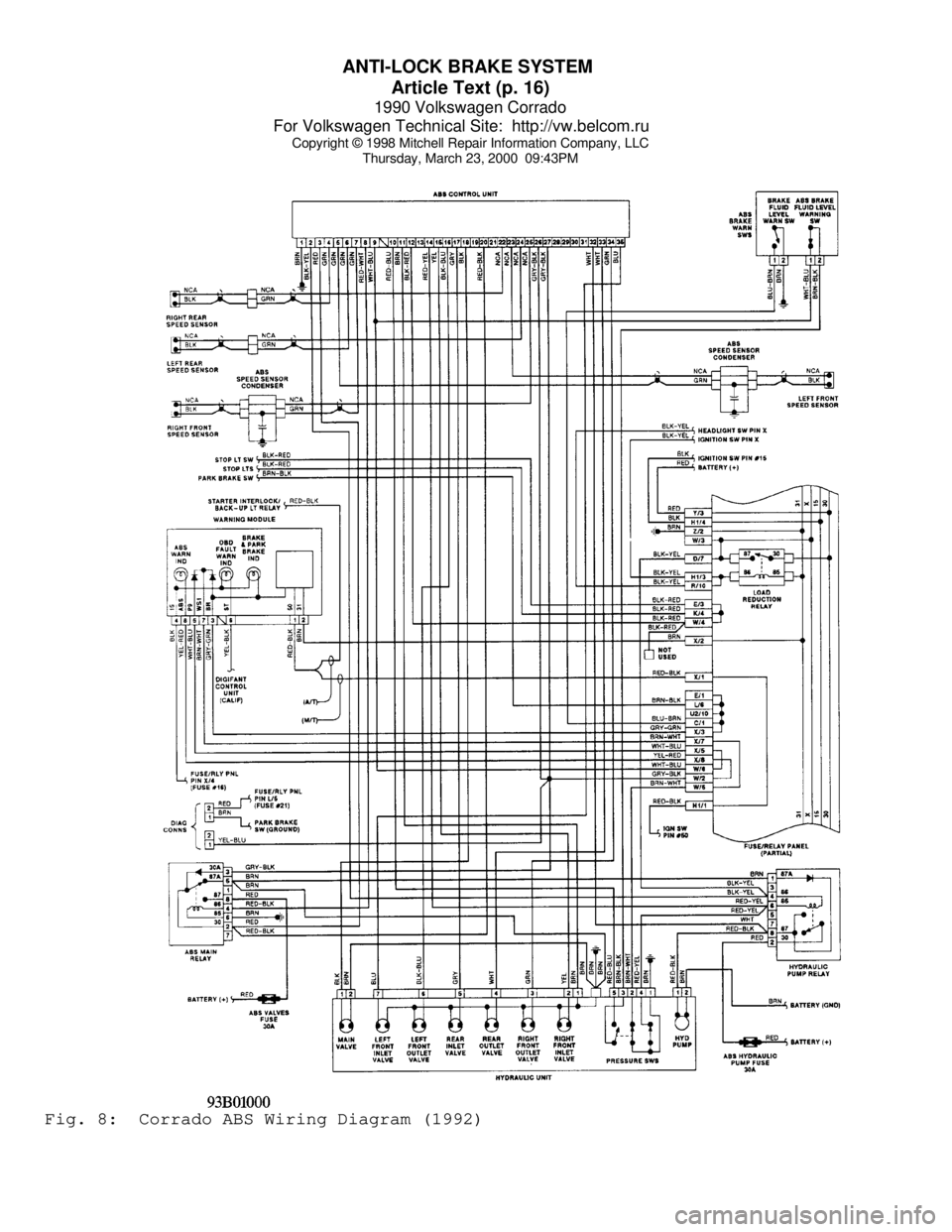

Thursday, March 23, 2000 09:43PMFig. 8: Corrado ABS Wiring Diagram (1992)

Page 425 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 17)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

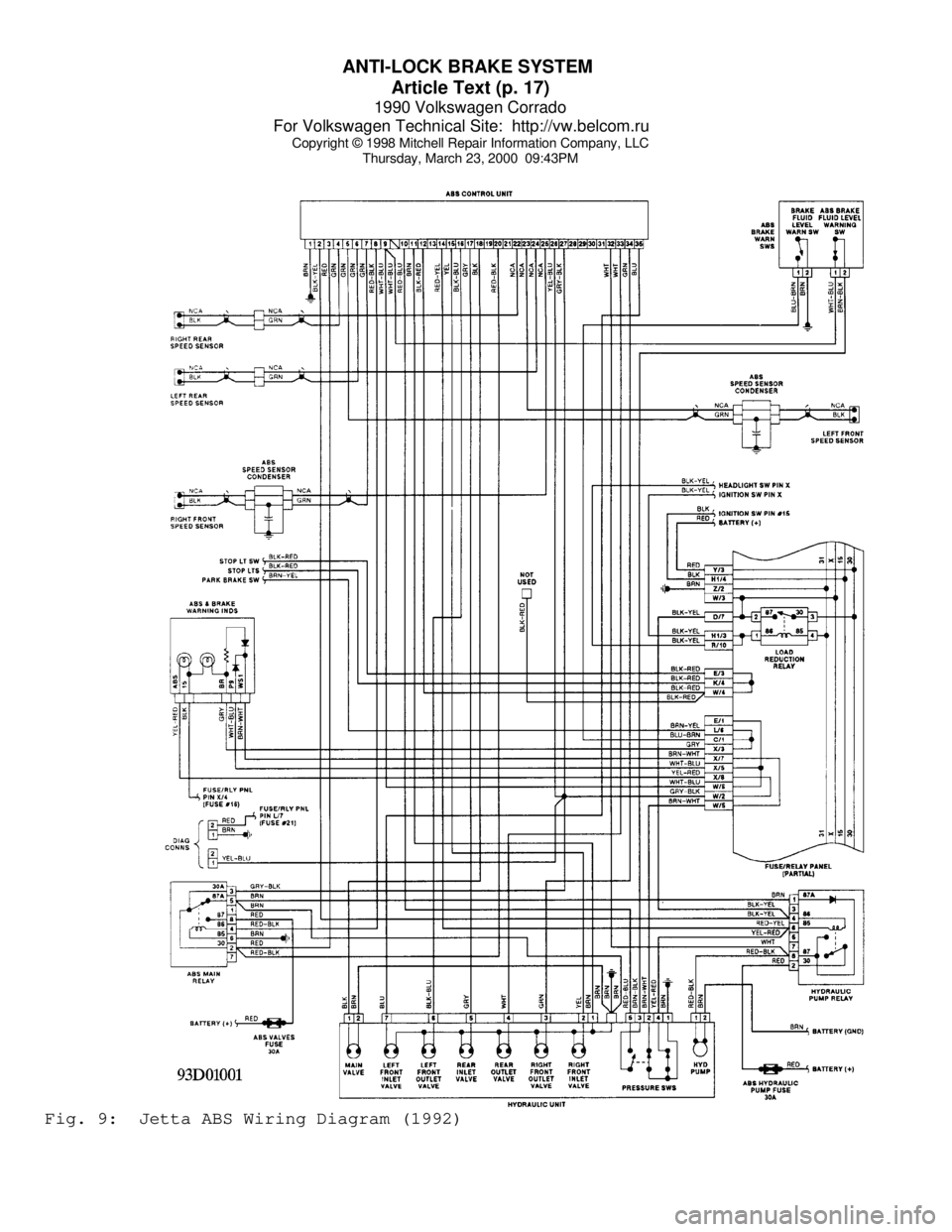

Thursday, March 23, 2000 09:43PMFig. 9: Jetta ABS Wiring Diagram (1992)

Page 426 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 18)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

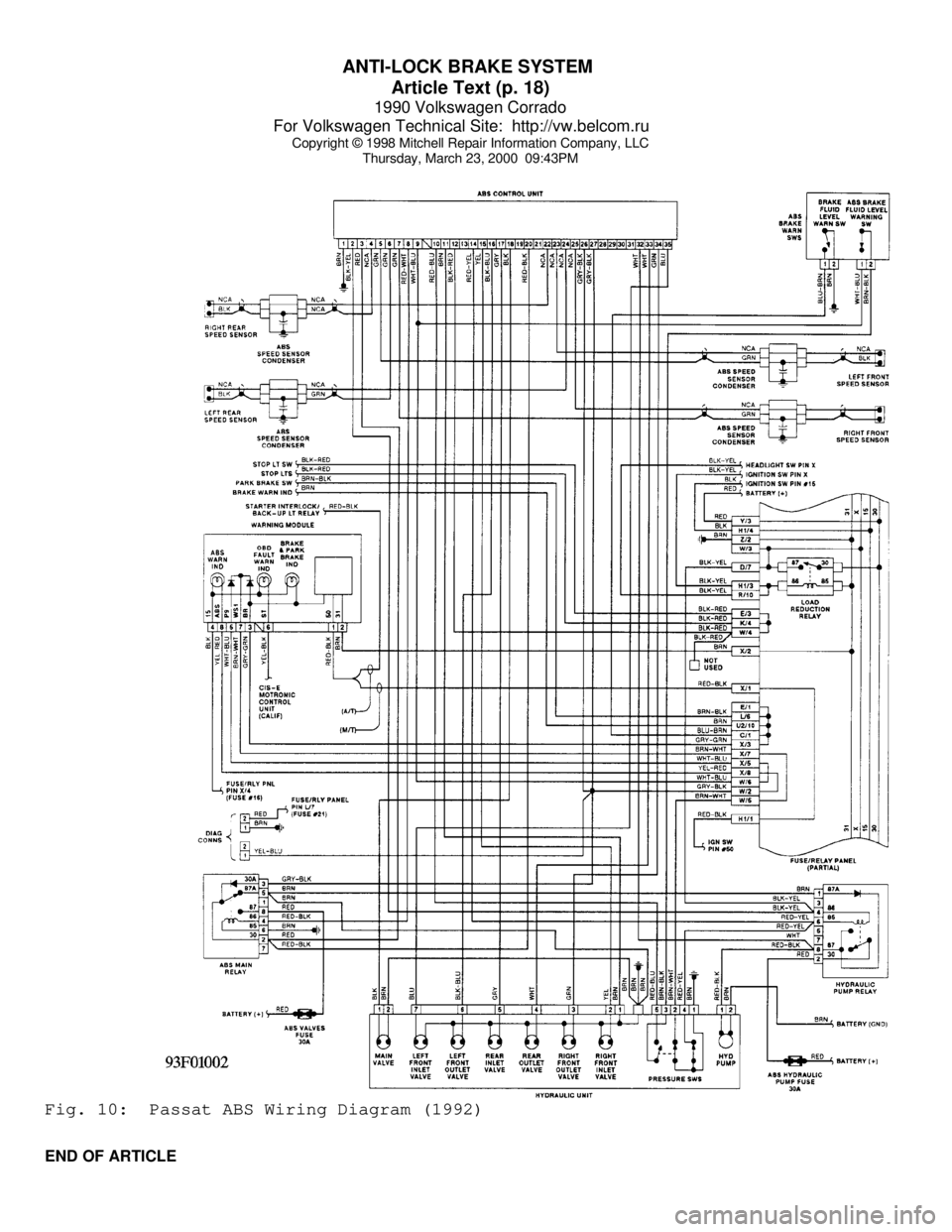

Thursday, March 23, 2000 09:43PMFig. 10: Passat ABS Wiring Diagram (1992)

END OF ARTICLE

Page 442 of 906

D - ADJUSTMENTS

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

8) Connect adapter between connector and regulator. Connect

multimeter to adapter and turn switch to DCA 200 milliamp-range. Read

and compare current (4-16 milliamps) and CO values to specifications.

Turn engine off.

9) If CO reading is more than 1.2% at current reading of 4-16

milliamps, check for exhaust system leaks, ignition timing, injector

inserts for leaks, and fuel distributor for uneven fuel distribution.

If required, seal injector inserts with sealing compound and tighten

to 15 ft. lbs. (20 N.m).

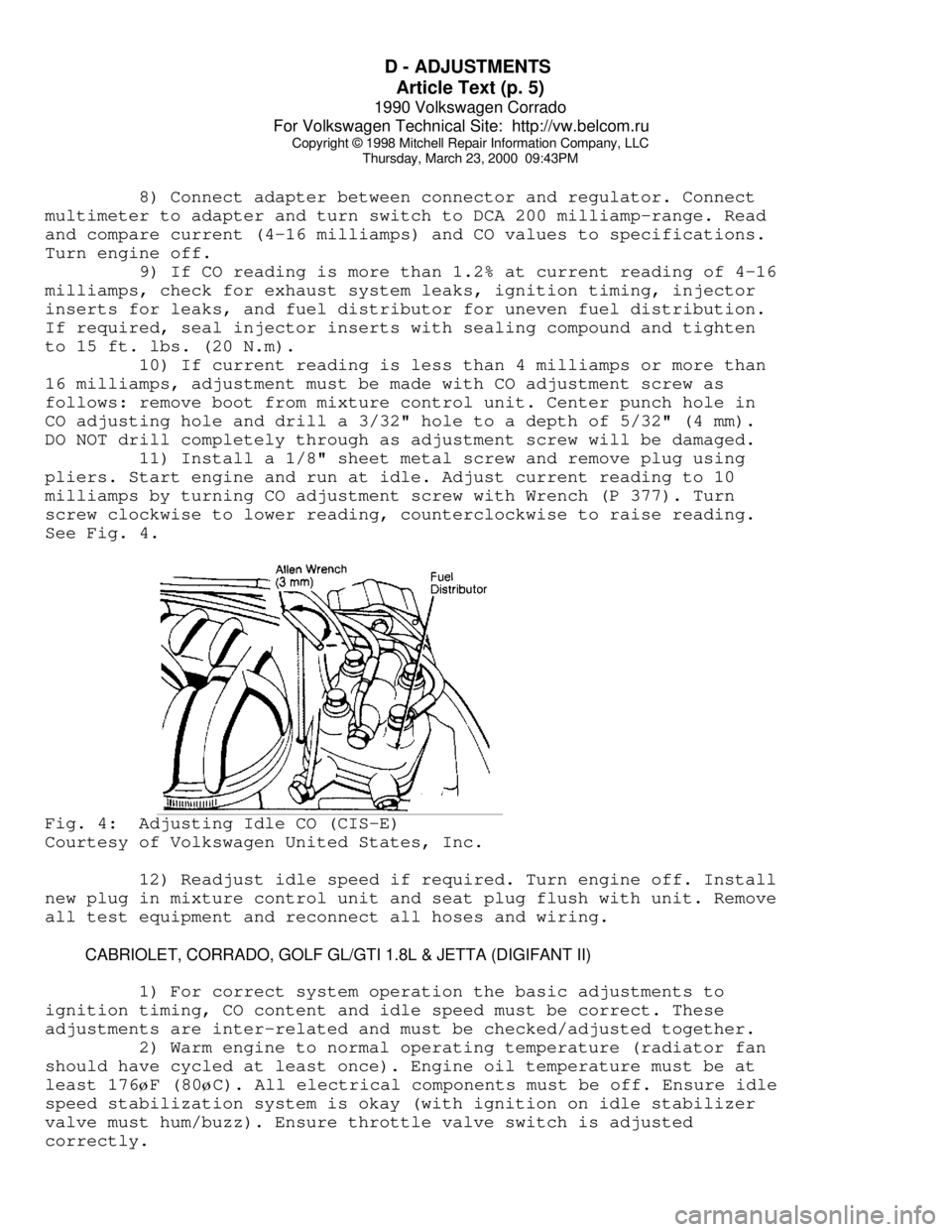

10) If current reading is less than 4 milliamps or more than

16 milliamps, adjustment must be made with CO adjustment screw as

follows: remove boot from mixture control unit. Center punch hole in

CO adjusting hole and drill a 3/32" hole to a depth of 5/32" (4 mm).

DO NOT drill completely through as adjustment screw will be damaged.

11) Install a 1/8" sheet metal screw and remove plug using

pliers. Start engine and run at idle. Adjust current reading to 10

milliamps by turning CO adjustment screw with Wrench (P 377). Turn

screw clockwise to lower reading, counterclockwise to raise reading.

See Fig. 4.Fig. 4: Adjusting Idle CO (CIS-E)

Courtesy of Volkswagen United States, Inc.

12) Readjust idle speed if required. Turn engine off. Install

new plug in mixture control unit and seat plug flush with unit. Remove

all test equipment and reconnect all hoses and wiring.

CABRIOLET, CORRADO, GOLF GL/GTI 1.8L & JETTA (DIGIFANT II)

1) For correct system operation the basic adjustments to

ignition timing, CO content and idle speed must be correct. These

adjustments are inter-related and must be checked/adjusted together.

2) Warm engine to normal operating temperature (radiator fan

should have cycled at least once). Engine oil temperature must be at

least 176øF (80øC). All electrical components must be off. Ensure idle

speed stabilization system is okay (with ignition on idle stabilizer

valve must hum/buzz). Ensure throttle valve switch is adjusted

correctly.

Page 444 of 906

D - ADJUSTMENTS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

together. Turn idle speed screw until idle speed is correct. To adjust

timing, see CHECKING & ADJUSTING under IGNITION TIMING in this

article.

3) Ensure all vehicle electrical equipment is off. Place

exhaust gas analyzer in exhaust pipe. See IDLE SPEED & CO LEVEL table.

If adjustment is needed, go to next step.

4) If adjustment is needed in step 2). Remove intake air

sensor from engine. Center punch plug in CO adjusting hole. Using a

3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.

5) Disconnect oxygen sensor connector on left side of engine

compartment (Green wire). Start engine. Set idle speed and CO reading

by alternately turning mixture and idle speed adjustment screws.

Reconnect oxygen sensor and idle stabilizer connectors. Let engine

idle for 2 minutes.

6) Check CO value. If incorrect, repeat adjusting procedure.

If correct turn ignition off. Drive in new adjusting hole plug flush

with air intake sensor. Remove all test equipment and reconnect all

hoses and wiring.

NOTE: Do not push down on adjustment screw and do not accelerate

engine with wrench in plate. Remove wrench after each

adjustment and accelerate engine briefly before measuring

current reading. Always adjust from a high to a low reading.

IDLE SPEED & CO LEVELÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level

Cabriolet .................. 850-1000 ................... 0.3-1.2%

Fox ........................ 800-1000 ................... 0.3-1.2%

Golf ....................... 800-1000 ................... 0.3-1.2%

Golf GT ..................... 800-900 ................... 0.3-1.2%

GTI ........................ 800-1000 ................... 0.3-1.2%

Jetta ...................... 800-1000 ................... 0.3-1.2%

Vanagon ..................... 830-930 ................... 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THROTTLE STOP SCREW

NOTE: Stop screw is set by manufacturer and should not be moved.

If basic factory setting has been changed, turn throttle stop

screw counterclockwise until there is a gap between stop and screw.

Turn screw in until it just touches stop. Turn screw 1/2 turn (180

degrees) further. Check and adjust idle speed and CO.

IDLE & FULL THROTTLE SWITCH ADJUSTMENTS

IDLE SWITCH ADJUSTMENT DIGIFANT II (EXCEPT VANAGON)

Page 445 of 906

D - ADJUSTMENTS

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

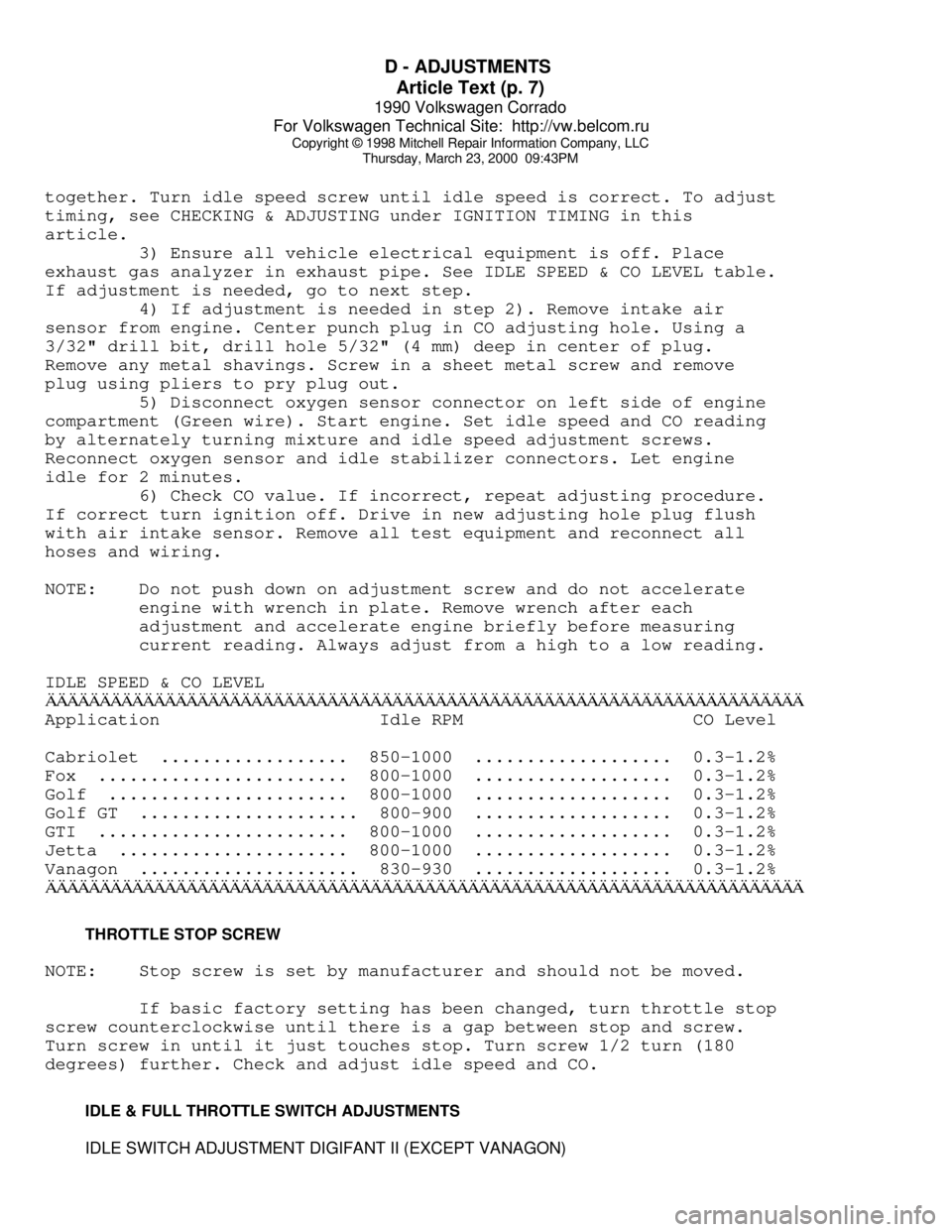

1) Check idle and adjust if needed. The idle air by-pass

screw is located in the throttle valve. Adjusting the screw changes

the amount of air by-passing the throttle plate raising or lowering

idle speed See Fig. 6.Fig. 6: Checking Idle Switch Adjustment

Courtesy of Volkswagen United States, Inc.

2) To adjust idle speed, disconnect the harness connector

from the coolant temperature sensor. Idle speed should be 925-1025

RPM. If not, turn idle air by-pass adjusting screw until 950-1000 RPM

is obtained. When the coolant temperature sensor harness is

reconnected, idle speed should drop to 750-850 RPM.

IDLE & FULL THROTTLE SWITCH DIGIFANT II (VANAGON)

1) The idle and full throttle switches are wired in parallel

on the throttle valve assembly. Disconnect throttle valve connector

from throttle valve switch. Connect voltmeter between terminal in

harness connector. Turn ignition on. If 5 volts is NOT present, check

for break in wiring and repair. If no break in wiring, replace

Digifant II control unit and recheck.

2) The circuit should be closed when throttle is at rest.

Check continuity between test harness terminal No. 1 and 2. If switch-

on point is incorrect, loosen and adjust idle switch position. Recheck

that clearance between the throttle valve lever and stop is .002-.006

(.15-.05 mm). The throttle switch is located on underside of throttle

valve housing, opposite idle stop.

NOTE: The airflow potentiometer is factory adjusted. No adjustment

should be needed, unless component is replaced.

AIRFLOW SENSOR POTENTIOMETER ADJUSTMENT (FOX)

1) Disconnect the airflow sensor potentiometer. Loosen 4

retaining screws and adjust the airflow sensor potentiometer until the

voltage between the center terminal and ground is 0.2-0.3 volt.

Page 459 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 9)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

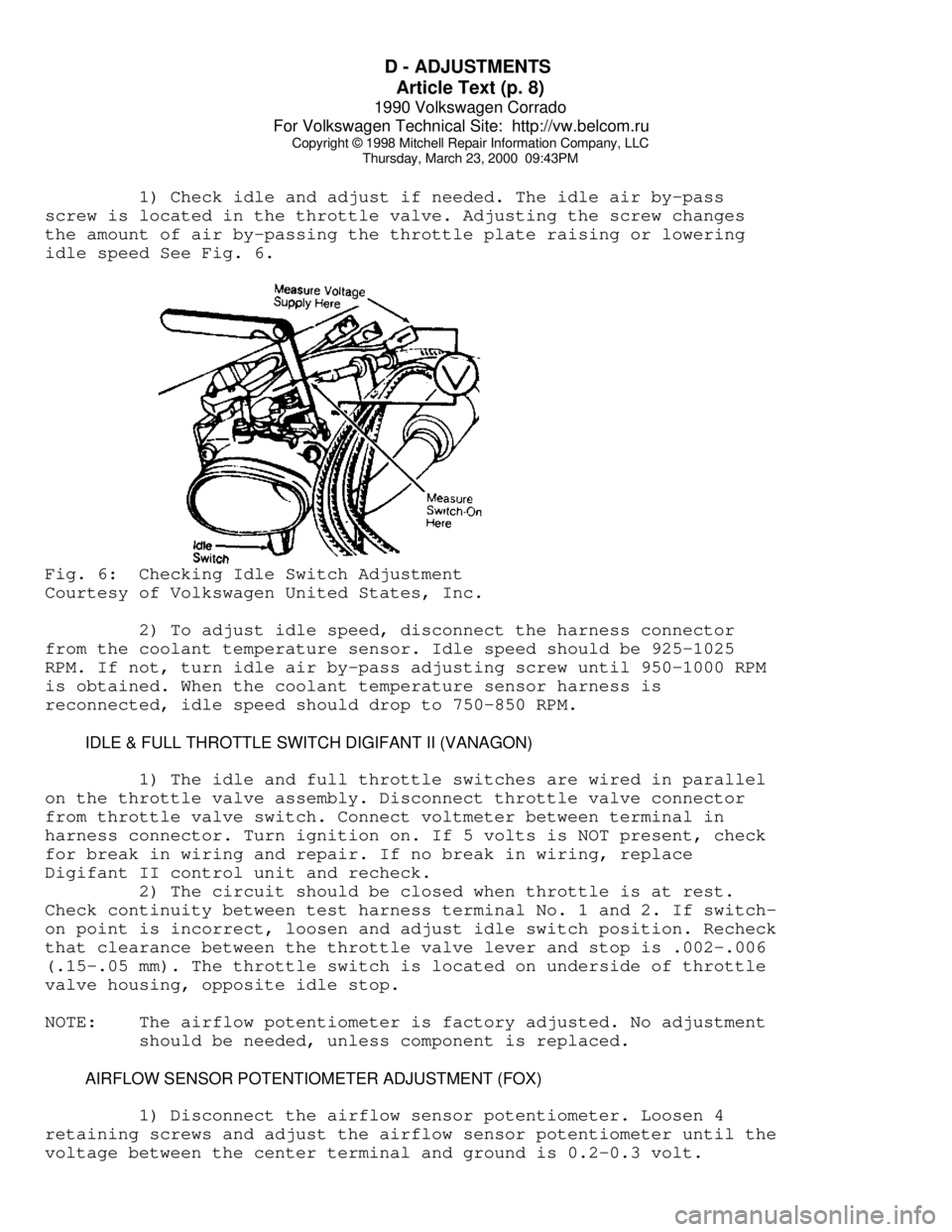

CRANKCASE VENT LINE HEATING ELEMENT

A heating element is used in the crankcase vent line to

prevent icing during cold engine operation, this element has a 5.5-mm

hole in the restrictor plate. The circuitry to operate the heating

element is protected by an in-line 5 amp fuse located in the wiring

connector box located in the engine compartment.Fig. 5: Locating Crankcase Vent Line Heating Element

Courtesy of Volkswagen United States, Inc.

COOLING FAN MOTOR

The cooling fan is either a one or two speed motor. If

vehicle is equipped with single speed motor the fan comes on at 198-

207øF (92-97øC) and off at 183-196øF (84-91øC). If equipped with a two

speed motor. The first speed of cooling fan should come on at 197

øF

(91

øC) and go off at 98øF (18øC). Second speed comes on at 203-121øF

(95-100

øC) and off at 188øF (87øC).

AFTER-RUN THERMOSWITCH (CORRADO)

An after-run switch is used to help prevent fuel

vaporization. The thermoswitch turns the cooling fan on when

temperatures in the engine compartment exceed 230

øF (110øC) and off at

217

øF (103øC).

END OF ARTICLE

Page 546 of 906

F - BASIC TESTING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Volkswagen Basic Diagnostic Procedures

Cabriolet, Corrado, Fox, Golf GL/GTI, Jetta, Vanagon

INTRODUCTION

The following diagnostic steps will help prevent overlooking

a simple problem. This is also where to begin diagnosis for a no start

condition.

The first step in diagnosing any driveability problem is

verifying the customer's complaint with a test drive under the

conditions the problem reportedly occurred.

Perform a careful and complete visual inspection. Most engine

control problems result from mechanical breakdowns, poor electrical

connections or damaged/misrouted vacuum hoses. Before condemning the

computerized system, perform each test listed in this article.

NOTE: Perform all voltage tests with a Digital Volt-Ohmmeter

(DVOM) with a minimum 10-megohm input impedance, unless

stated otherwise in test procedure.

VISUAL INSPECTION

Visually inspect all electrical wiring, looking for chafed,

stretched, cut or pinched wiring. Ensure electrical connectors fit

tightly and are not corroded. Ensure vacuum hoses are properly routed

and are not pinched or cut. See M - VACUUM DIAGRAMS article to verify

routing and connections (if necessary). Inspect air induction system

for possible vacuum leaks.

MECHANICAL INSPECTION

COMPRESSION

Check engine mechanical condition with a compression gauge,

vacuum gauge, or an engine analyzer. See engine analyzer manual for

specific instructions.

DO NOT use ignition switch during compression tests on fuel

injected vehicles. Use a remote starter to crank engine. Fuel

injectors on many models are triggered by ignition switch during

cranking mode, which can create a fire hazard or contaminate the

engine's oiling system.

EXHAUST SYSTEM BACKPRESSURE

The exhaust system can be checked with a vacuum or pressure

gauge. Remove O2 sensor or air injection check valve (if equipped).

Connect a 1-10 psi pressure gauge and run engine at 2500 RPM. If

Page 550 of 906

F - BASIC TESTING

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

to OFF position.

(2) - With pressure regulator vacuum hose disconnected, pressure

should be 36 psi (2.5 kg/cmý).

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ TRANSFER PUMP CHECK

TRANSFER PUMP FUEL VOLUME CHECK

1) Turn ignition off. To check transfer pump (in tank),

remove rear seat. Remove fuel sending unit access cover. Disconnect

ignition coil secondary wire and jumper to ground. With transmission

in neutral, crank engine for a 3-4 seconds. While the starter is

turning and for a few seconds afterwards, an audible sound should be

heard at the pump. If not, proceed to step 2).

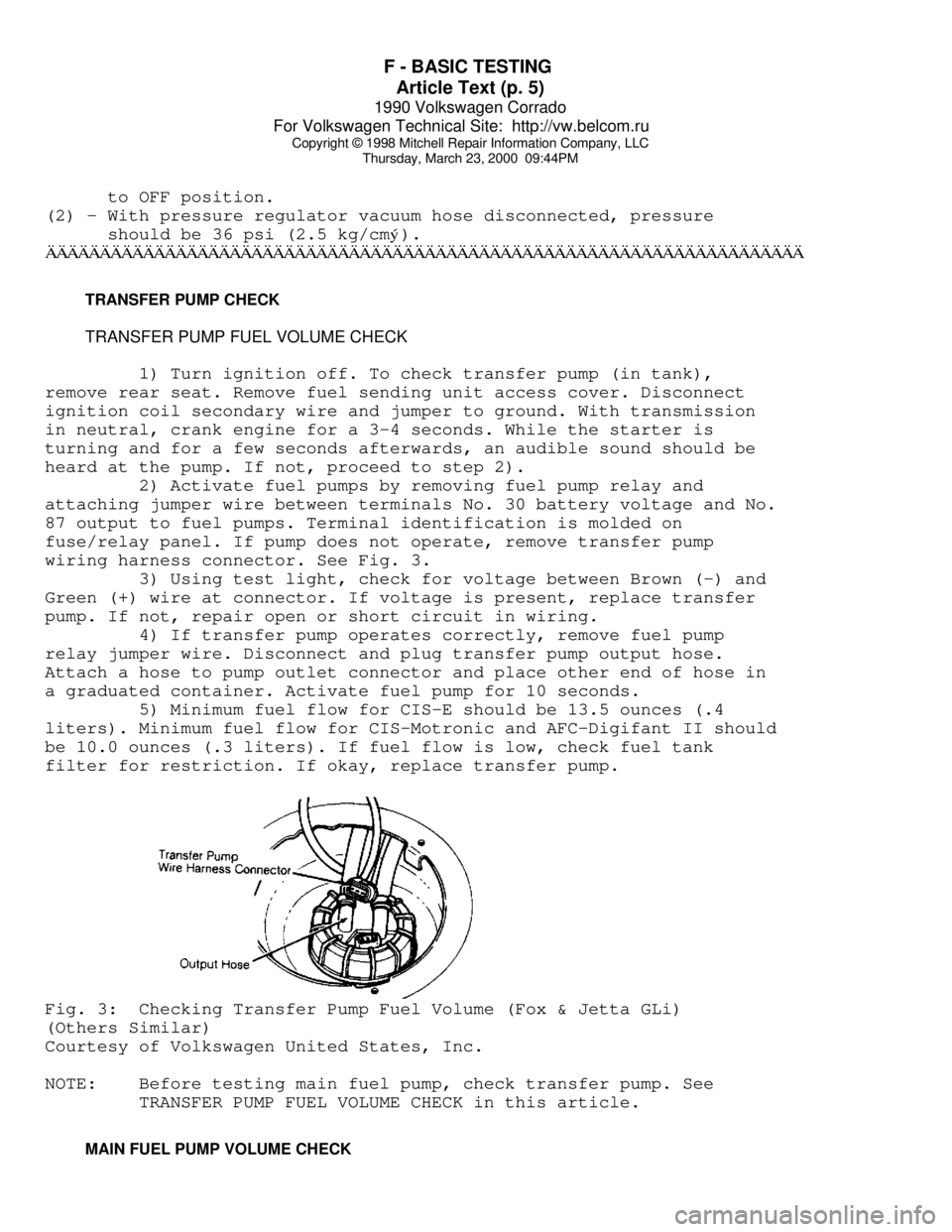

2) Activate fuel pumps by removing fuel pump relay and

attaching jumper wire between terminals No. 30 battery voltage and No.

87 output to fuel pumps. Terminal identification is molded on

fuse/relay panel. If pump does not operate, remove transfer pump

wiring harness connector. See Fig. 3.

3) Using test light, check for voltage between Brown (-) and

Green (+) wire at connector. If voltage is present, replace transfer

pump. If not, repair open or short circuit in wiring.

4) If transfer pump operates correctly, remove fuel pump

relay jumper wire. Disconnect and plug transfer pump output hose.

Attach a hose to pump outlet connector and place other end of hose in

a graduated container. Activate fuel pump for 10 seconds.

5) Minimum fuel flow for CIS-E should be 13.5 ounces (.4

liters). Minimum fuel flow for CIS-Motronic and AFC-Digifant II should

be 10.0 ounces (.3 liters). If fuel flow is low, check fuel tank

filter for restriction. If okay, replace transfer pump.Fig. 3: Checking Transfer Pump Fuel Volume (Fox & Jetta GLi)

(Others Similar)

Courtesy of Volkswagen United States, Inc.

NOTE: Before testing main fuel pump, check transfer pump. See

TRANSFER PUMP FUEL VOLUME CHECK in this article.

MAIN FUEL PUMP VOLUME CHECK