sensor VOLKSWAGEN CORRADO 1990 Manual PDF

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 443 of 906

D - ADJUSTMENTS

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

NOTE: Before checking engine timing, raise engine speed above 2100

RPM at least 4 times. This must be done each time ignition

is turned off and restarted to clear ECU memory and by-pass

hot-start, fast-idle function.

3) Connect an inductive tachometer or Tester (VW 1367) to

alternator, Test Lead (VW 1473) to ignition coil, and timing light

lead to No. 1 spark plug wire. See Fig. 2. Start engine and ensure

engine speed and timing are correct. If not, adjust to specification.

4) Remove the Blue cap from the CO tap tube rising from the

exhaust manifold and connect exhaust gas analyzer. Disconnect the

coolant sensor harness connector. Raise the oil dipstick slightly to

vent crankcase. Disconnect and plug the crankcase ventilation hose.

Start engine and raise engine speed to 2100 RPM at least 4 times.

Check idle, adjust if incorrect. check CO is correct. See IDLE & CO

LEVEL table. If CO adjustment is needed, the idle mixture screw anti-

tamper plug must be remove from the top of the air flow sensor.

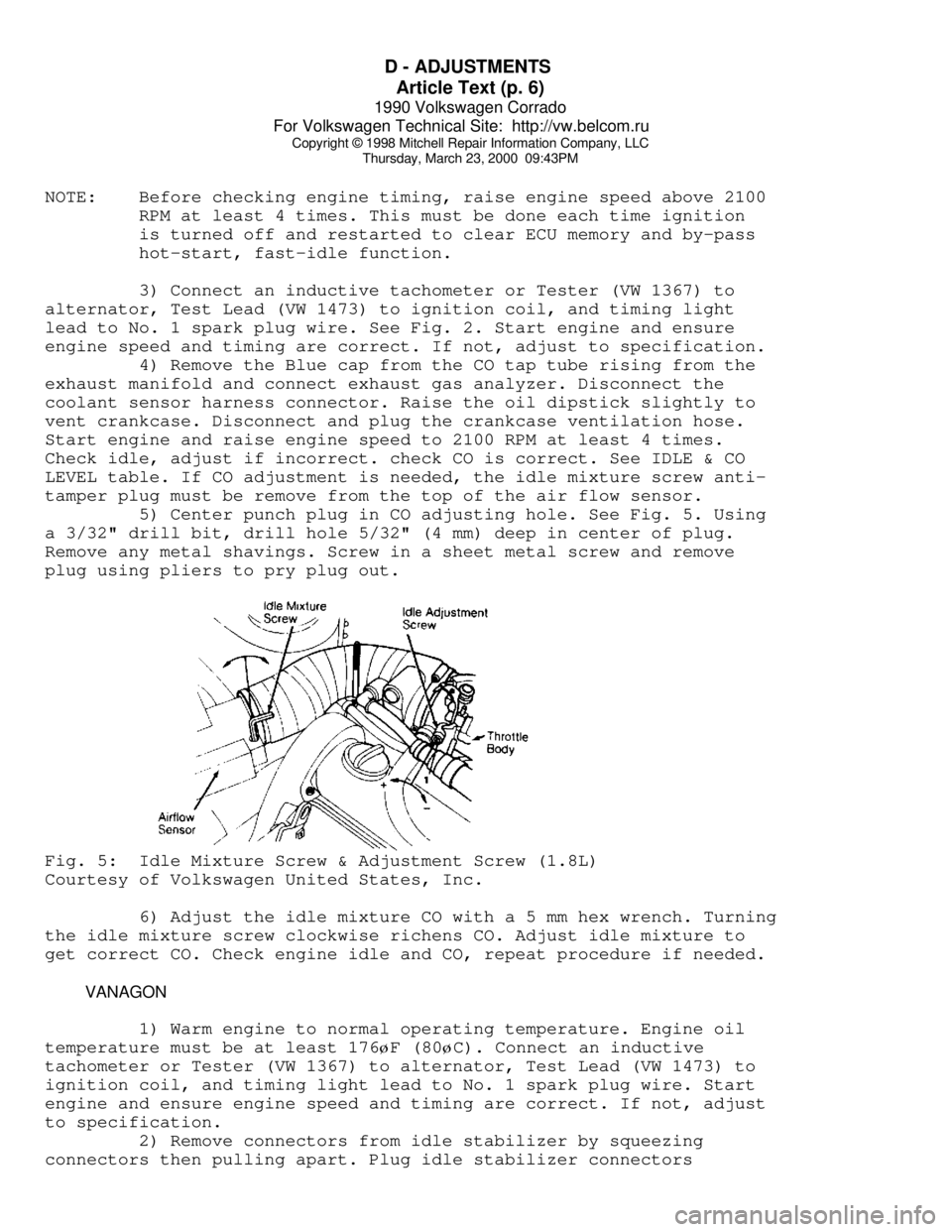

5) Center punch plug in CO adjusting hole. See Fig. 5. Using

a 3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.Fig. 5: Idle Mixture Screw & Adjustment Screw (1.8L)

Courtesy of Volkswagen United States, Inc.

6) Adjust the idle mixture CO with a 5 mm hex wrench. Turning

the idle mixture screw clockwise richens CO. Adjust idle mixture to

get correct CO. Check engine idle and CO, repeat procedure if needed.

VANAGON

1) Warm engine to normal operating temperature. Engine oil

temperature must be at least 176øF (80øC). Connect an inductive

tachometer or Tester (VW 1367) to alternator, Test Lead (VW 1473) to

ignition coil, and timing light lead to No. 1 spark plug wire. Start

engine and ensure engine speed and timing are correct. If not, adjust

to specification.

2) Remove connectors from idle stabilizer by squeezing

connectors then pulling apart. Plug idle stabilizer connectors

Page 444 of 906

D - ADJUSTMENTS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

together. Turn idle speed screw until idle speed is correct. To adjust

timing, see CHECKING & ADJUSTING under IGNITION TIMING in this

article.

3) Ensure all vehicle electrical equipment is off. Place

exhaust gas analyzer in exhaust pipe. See IDLE SPEED & CO LEVEL table.

If adjustment is needed, go to next step.

4) If adjustment is needed in step 2). Remove intake air

sensor from engine. Center punch plug in CO adjusting hole. Using a

3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.

5) Disconnect oxygen sensor connector on left side of engine

compartment (Green wire). Start engine. Set idle speed and CO reading

by alternately turning mixture and idle speed adjustment screws.

Reconnect oxygen sensor and idle stabilizer connectors. Let engine

idle for 2 minutes.

6) Check CO value. If incorrect, repeat adjusting procedure.

If correct turn ignition off. Drive in new adjusting hole plug flush

with air intake sensor. Remove all test equipment and reconnect all

hoses and wiring.

NOTE: Do not push down on adjustment screw and do not accelerate

engine with wrench in plate. Remove wrench after each

adjustment and accelerate engine briefly before measuring

current reading. Always adjust from a high to a low reading.

IDLE SPEED & CO LEVELÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level

Cabriolet .................. 850-1000 ................... 0.3-1.2%

Fox ........................ 800-1000 ................... 0.3-1.2%

Golf ....................... 800-1000 ................... 0.3-1.2%

Golf GT ..................... 800-900 ................... 0.3-1.2%

GTI ........................ 800-1000 ................... 0.3-1.2%

Jetta ...................... 800-1000 ................... 0.3-1.2%

Vanagon ..................... 830-930 ................... 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THROTTLE STOP SCREW

NOTE: Stop screw is set by manufacturer and should not be moved.

If basic factory setting has been changed, turn throttle stop

screw counterclockwise until there is a gap between stop and screw.

Turn screw in until it just touches stop. Turn screw 1/2 turn (180

degrees) further. Check and adjust idle speed and CO.

IDLE & FULL THROTTLE SWITCH ADJUSTMENTS

IDLE SWITCH ADJUSTMENT DIGIFANT II (EXCEPT VANAGON)

Page 445 of 906

D - ADJUSTMENTS

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

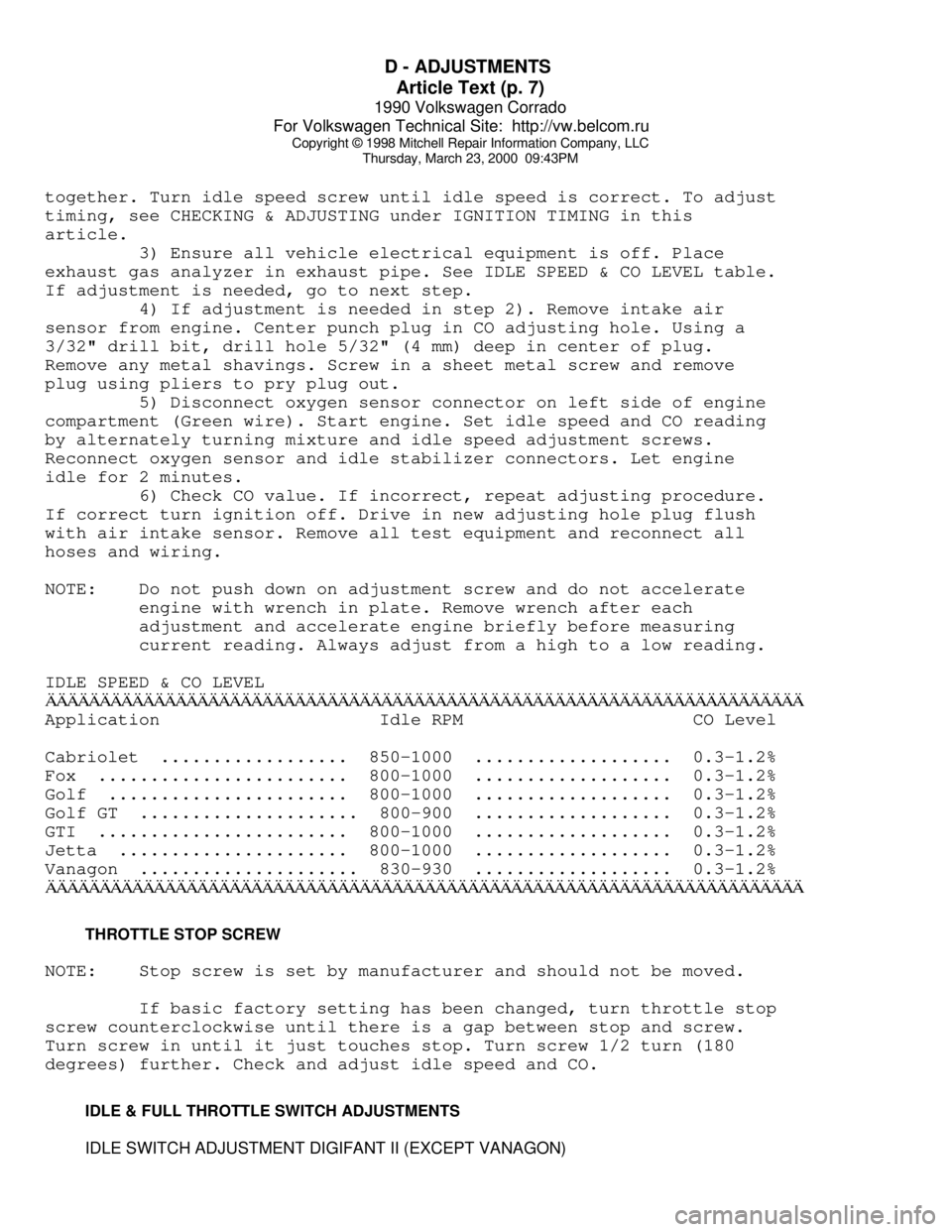

1) Check idle and adjust if needed. The idle air by-pass

screw is located in the throttle valve. Adjusting the screw changes

the amount of air by-passing the throttle plate raising or lowering

idle speed See Fig. 6.Fig. 6: Checking Idle Switch Adjustment

Courtesy of Volkswagen United States, Inc.

2) To adjust idle speed, disconnect the harness connector

from the coolant temperature sensor. Idle speed should be 925-1025

RPM. If not, turn idle air by-pass adjusting screw until 950-1000 RPM

is obtained. When the coolant temperature sensor harness is

reconnected, idle speed should drop to 750-850 RPM.

IDLE & FULL THROTTLE SWITCH DIGIFANT II (VANAGON)

1) The idle and full throttle switches are wired in parallel

on the throttle valve assembly. Disconnect throttle valve connector

from throttle valve switch. Connect voltmeter between terminal in

harness connector. Turn ignition on. If 5 volts is NOT present, check

for break in wiring and repair. If no break in wiring, replace

Digifant II control unit and recheck.

2) The circuit should be closed when throttle is at rest.

Check continuity between test harness terminal No. 1 and 2. If switch-

on point is incorrect, loosen and adjust idle switch position. Recheck

that clearance between the throttle valve lever and stop is .002-.006

(.15-.05 mm). The throttle switch is located on underside of throttle

valve housing, opposite idle stop.

NOTE: The airflow potentiometer is factory adjusted. No adjustment

should be needed, unless component is replaced.

AIRFLOW SENSOR POTENTIOMETER ADJUSTMENT (FOX)

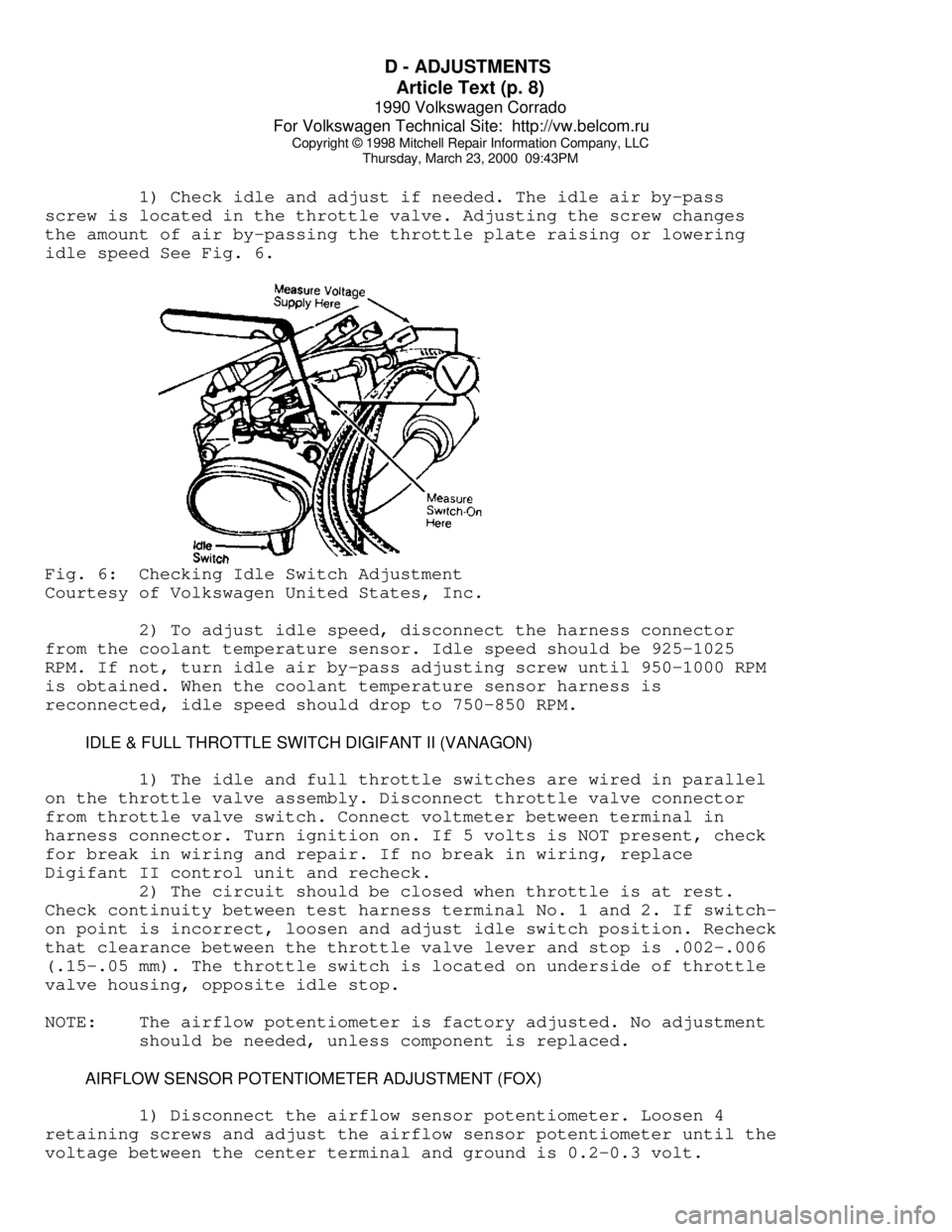

1) Disconnect the airflow sensor potentiometer. Loosen 4

retaining screws and adjust the airflow sensor potentiometer until the

voltage between the center terminal and ground is 0.2-0.3 volt.

Page 446 of 906

D - ADJUSTMENTS

Article Text (p. 9)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

2) Carefully tighten the mounting screws. Raise the sensor

plate, the voltage should increase to approximately 7.0 volts. If not,

readjust the airflow sensor potentiometer. See Fig. 7.Fig. 7: Airflow Sensor Potentiometer Adjustment (CIS-E)

90f04388 Courtesy of Volkswagen United States, Inc.

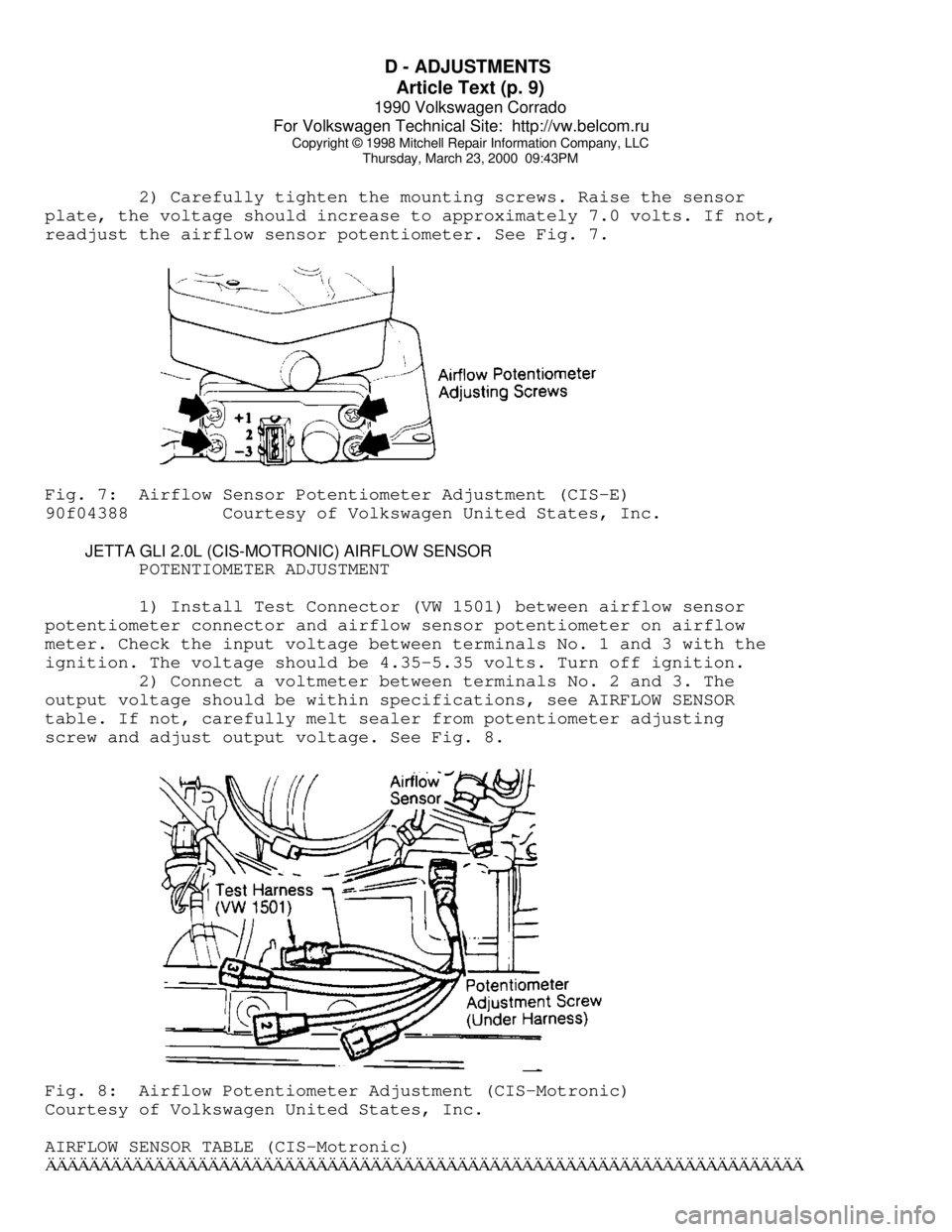

JETTA GLI 2.0L (CIS-MOTRONIC) AIRFLOW SENSOR

POTENTIOMETER ADJUSTMENT

1) Install Test Connector (VW 1501) between airflow sensor

potentiometer connector and airflow sensor potentiometer on airflow

meter. Check the input voltage between terminals No. 1 and 3 with the

ignition. The voltage should be 4.35-5.35 volts. Turn off ignition.

2) Connect a voltmeter between terminals No. 2 and 3. The

output voltage should be within specifications, see AIRFLOW SENSOR

table. If not, carefully melt sealer from potentiometer adjusting

screw and adjust output voltage. See Fig. 8.Fig. 8: Airflow Potentiometer Adjustment (CIS-Motronic)

Courtesy of Volkswagen United States, Inc.

AIRFLOW SENSOR TABLE (CIS-Motronic)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 452 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

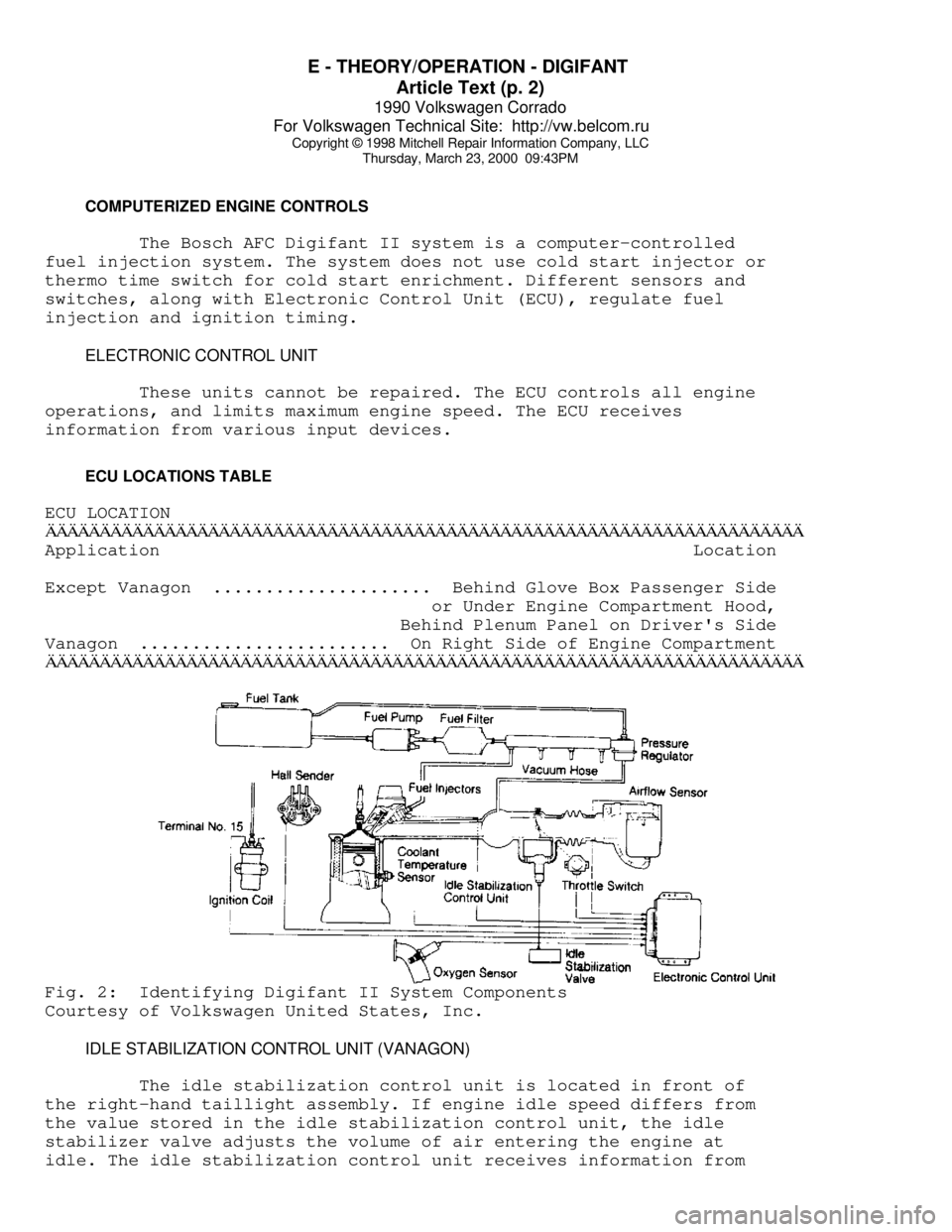

COMPUTERIZED ENGINE CONTROLS

The Bosch AFC Digifant II system is a computer-controlled

fuel injection system. The system does not use cold start injector or

thermo time switch for cold start enrichment. Different sensors and

switches, along with Electronic Control Unit (ECU), regulate fuel

injection and ignition timing.

ELECTRONIC CONTROL UNIT

These units cannot be repaired. The ECU controls all engine

operations, and limits maximum engine speed. The ECU receives

information from various input devices.

ECU LOCATIONS TABLE

ECU LOCATIONÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Location

Except Vanagon ..................... Behind Glove Box Passenger Side

or Under Engine Compartment Hood,

Behind Plenum Panel on Driver's Side

Vanagon ........................ On Right Side of Engine Compartment

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 2: Identifying Digifant II System Components

Courtesy of Volkswagen United States, Inc.

IDLE STABILIZATION CONTROL UNIT (VANAGON)

The idle stabilization control unit is located in front of

the right-hand taillight assembly. If engine idle speed differs from

the value stored in the idle stabilization control unit, the idle

stabilizer valve adjusts the volume of air entering the engine at

idle. The idle stabilization control unit receives information from

Page 453 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

the following:

* Coolant Temperature Sensor

* ECU Control Relay

* ECU

* Oxygen Sensor

* Power Steering Oil Pressure Switch

NOTE: Components are grouped into 2 categories. The first category

covers INPUT DEVICES, which control or produce voltage

signals monitored by the control unit. The second category

covers OUTPUT SIGNALS, which are components controlled by

the control unit.

INPUT DEVICES

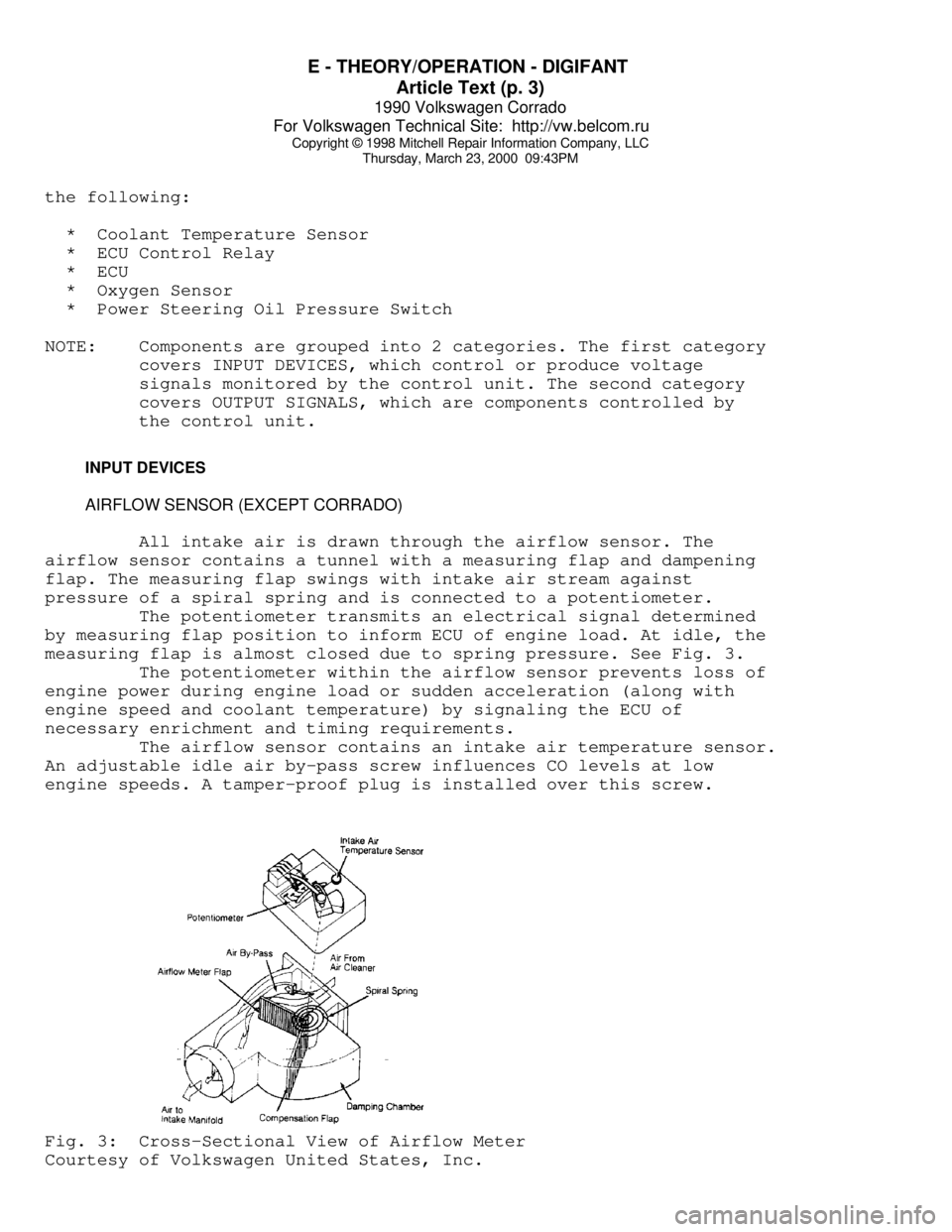

AIRFLOW SENSOR (EXCEPT CORRADO)

All intake air is drawn through the airflow sensor. The

airflow sensor contains a tunnel with a measuring flap and dampening

flap. The measuring flap swings with intake air stream against

pressure of a spiral spring and is connected to a potentiometer.

The potentiometer transmits an electrical signal determined

by measuring flap position to inform ECU of engine load. At idle, the

measuring flap is almost closed due to spring pressure. See Fig. 3.

The potentiometer within the airflow sensor prevents loss of

engine power during engine load or sudden acceleration (along with

engine speed and coolant temperature) by signaling the ECU of

necessary enrichment and timing requirements.

The airflow sensor contains an intake air temperature sensor.

An adjustable idle air by-pass screw influences CO levels at low

engine speeds. A tamper-proof plug is installed over this screw.Fig. 3: Cross-Sectional View of Airflow Meter

Courtesy of Volkswagen United States, Inc.

Page 454 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

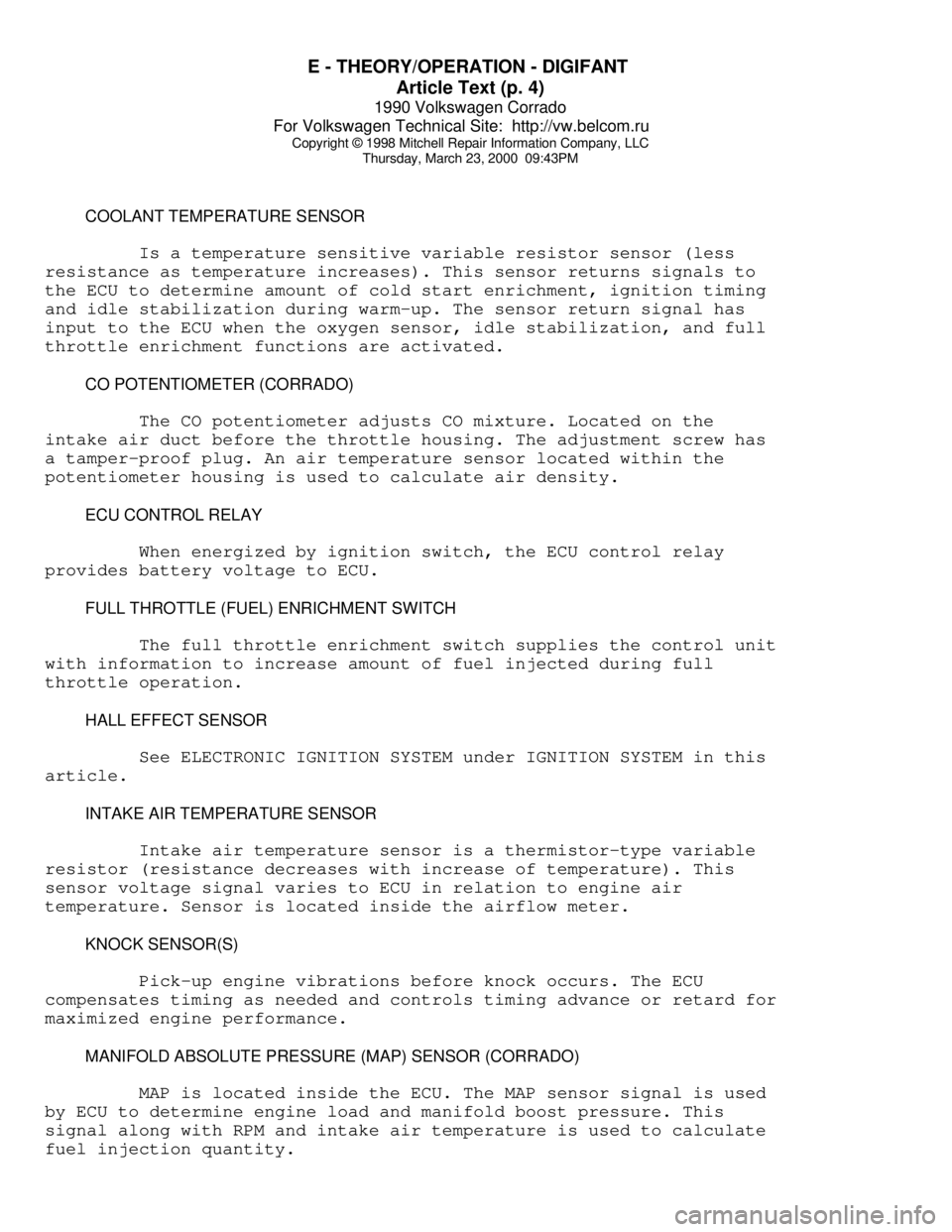

COOLANT TEMPERATURE SENSOR

Is a temperature sensitive variable resistor sensor (less

resistance as temperature increases). This sensor returns signals to

the ECU to determine amount of cold start enrichment, ignition timing

and idle stabilization during warm-up. The sensor return signal has

input to the ECU when the oxygen sensor, idle stabilization, and full

throttle enrichment functions are activated.

CO POTENTIOMETER (CORRADO)

The CO potentiometer adjusts CO mixture. Located on the

intake air duct before the throttle housing. The adjustment screw has

a tamper-proof plug. An air temperature sensor located within the

potentiometer housing is used to calculate air density.

ECU CONTROL RELAY

When energized by ignition switch, the ECU control relay

provides battery voltage to ECU.

FULL THROTTLE (FUEL) ENRICHMENT SWITCH

The full throttle enrichment switch supplies the control unit

with information to increase amount of fuel injected during full

throttle operation.

HALL EFFECT SENSOR

See ELECTRONIC IGNITION SYSTEM under IGNITION SYSTEM in this

article.

INTAKE AIR TEMPERATURE SENSOR

Intake air temperature sensor is a thermistor-type variable

resistor (resistance decreases with increase of temperature). This

sensor voltage signal varies to ECU in relation to engine air

temperature. Sensor is located inside the airflow meter.

KNOCK SENSOR(S)

Pick-up engine vibrations before knock occurs. The ECU

compensates timing as needed and controls timing advance or retard for

maximized engine performance.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR (CORRADO)

MAP is located inside the ECU. The MAP sensor signal is used

by ECU to determine engine load and manifold boost pressure. This

signal along with RPM and intake air temperature is used to calculate

fuel injection quantity.

Page 455 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

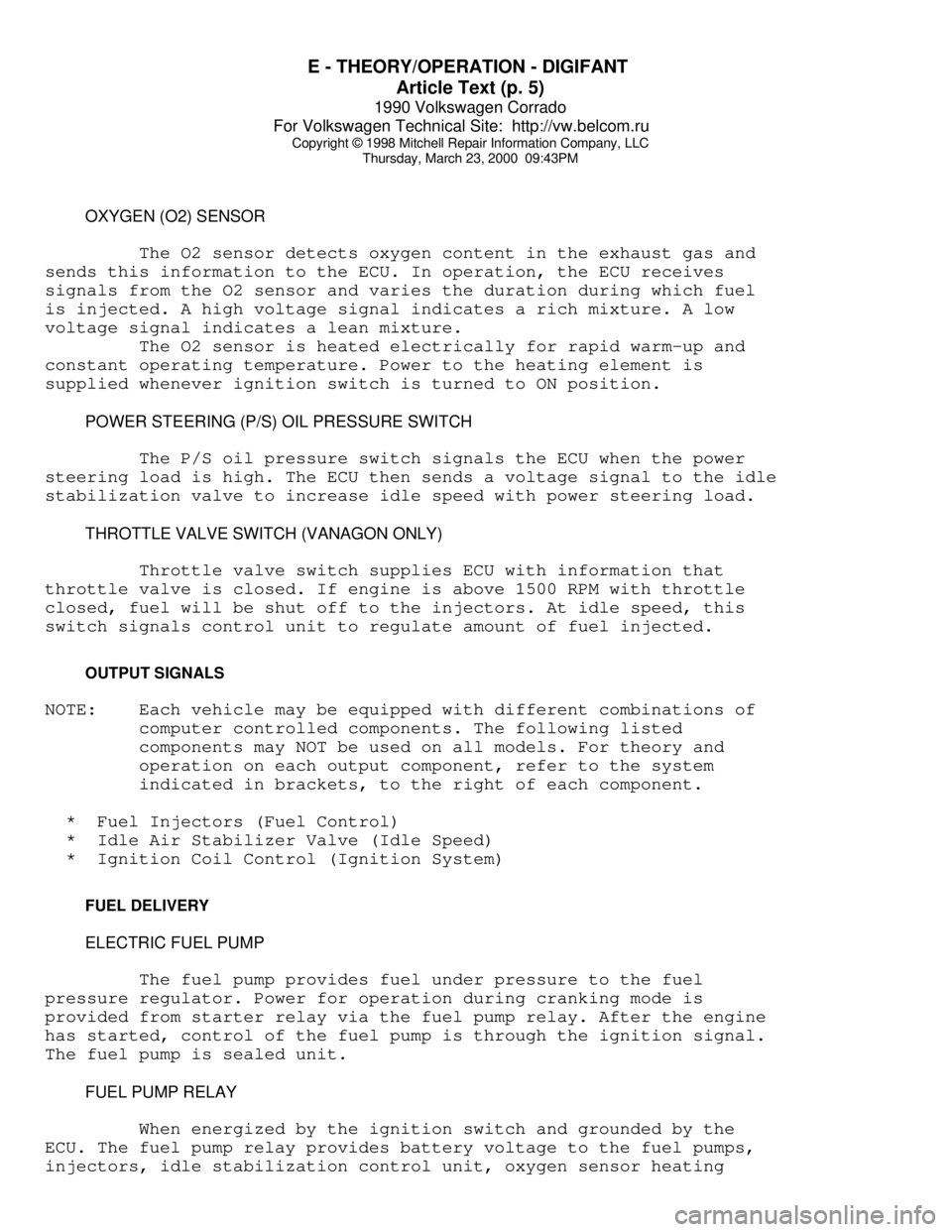

OXYGEN (O2) SENSOR

The O2 sensor detects oxygen content in the exhaust gas and

sends this information to the ECU. In operation, the ECU receives

signals from the O2 sensor and varies the duration during which fuel

is injected. A high voltage signal indicates a rich mixture. A low

voltage signal indicates a lean mixture.

The O2 sensor is heated electrically for rapid warm-up and

constant operating temperature. Power to the heating element is

supplied whenever ignition switch is turned to ON position.

POWER STEERING (P/S) OIL PRESSURE SWITCH

The P/S oil pressure switch signals the ECU when the power

steering load is high. The ECU then sends a voltage signal to the idle

stabilization valve to increase idle speed with power steering load.

THROTTLE VALVE SWITCH (VANAGON ONLY)

Throttle valve switch supplies ECU with information that

throttle valve is closed. If engine is above 1500 RPM with throttle

closed, fuel will be shut off to the injectors. At idle speed, this

switch signals control unit to regulate amount of fuel injected.

OUTPUT SIGNALS

NOTE: Each vehicle may be equipped with different combinations of

computer controlled components. The following listed

components may NOT be used on all models. For theory and

operation on each output component, refer to the system

indicated in brackets, to the right of each component.

* Fuel Injectors (Fuel Control)

* Idle Air Stabilizer Valve (Idle Speed)

* Ignition Coil Control (Ignition System)

FUEL DELIVERY

ELECTRIC FUEL PUMP

The fuel pump provides fuel under pressure to the fuel

pressure regulator. Power for operation during cranking mode is

provided from starter relay via the fuel pump relay. After the engine

has started, control of the fuel pump is through the ignition signal.

The fuel pump is sealed unit.

FUEL PUMP RELAY

When energized by the ignition switch and grounded by the

ECU. The fuel pump relay provides battery voltage to the fuel pumps,

injectors, idle stabilization control unit, oxygen sensor heating

Page 457 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

The idle air stabilizer valve is ECU controlled. On Vanagon

idle stabilizer valve is controlled by a separate idle stabilizer

controller. The idle air stabilizer operates to continuously maintains

engine idle at a computed engine idle speed.

IGNITION SYSTEM

The Hall Effect sending unit in the distributor, uses a

shutter window wheel mounted on the distributor shaft. The shutter

blades pass in and out of the air gap of the hall effect sender

resulting in signal pulses (engine speed signal). There is one shutter

window for each engine cylinder. Signals from distributor hall sender

are sent to the ECU.

ELECTRONIC IGNITION SYSTEM

IGNITION COIL CONTROL

Signals from distributor hall sender are sent to the ECU,

which produces a pulsating signal to the ignition coil. This computed

signal from ECU to ignition coil, control ignition timing according to

engine load (airflow sensor signal), engine speed (Hall Effect signal)

and engine coolant temperature.

IGNITION TIMING ADVANCE CONTROL SYSTEM

Timing is ECU controlled.

EMISSION SYSTEMS

EVAPORATIVE EMISSIONS SYSTEM

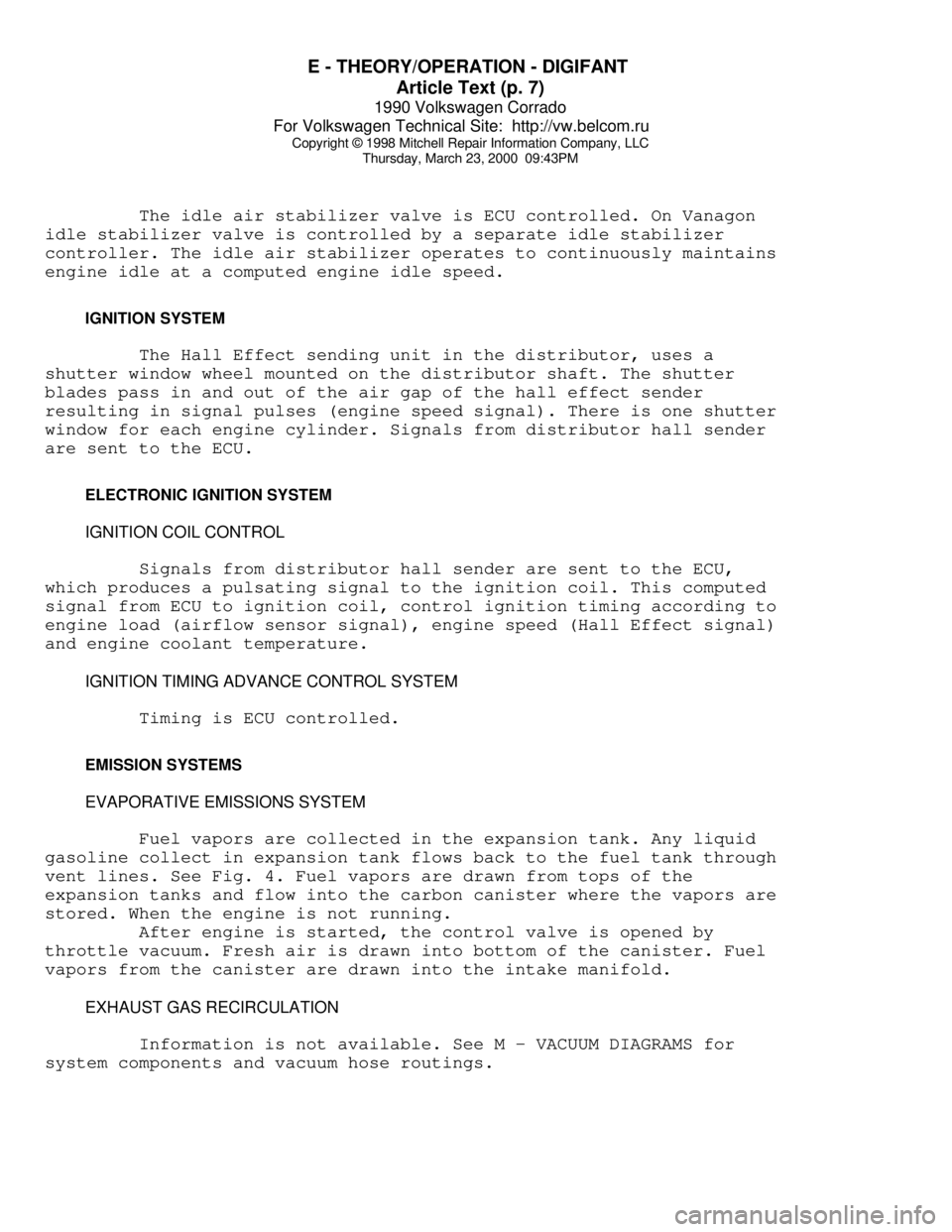

Fuel vapors are collected in the expansion tank. Any liquid

gasoline collect in expansion tank flows back to the fuel tank through

vent lines. See Fig. 4. Fuel vapors are drawn from tops of the

expansion tanks and flow into the carbon canister where the vapors are

stored. When the engine is not running.

After engine is started, the control valve is opened by

throttle vacuum. Fresh air is drawn into bottom of the canister. Fuel

vapors from the canister are drawn into the intake manifold.

EXHAUST GAS RECIRCULATION

Information is not available. See M - VACUUM DIAGRAMS for

system components and vacuum hose routings.

Page 458 of 906

E - THEORY/OPERATION - DIGIFANT

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PMFig. 4: Identifying Evaporative Emissions System Components

Courtesy of Volkswagen United States, Inc.

SELF-DIAGNOSTIC SYSTEM

O2 SENSOR WARNING LIGHT

All vehicles are equipped with an O2 sensor warning light

located on the instrument panel. The light will illuminate when a

mileage counter reaches 60,000 miles (on Vanagon 90,000 miles)

indicating recommended O2 sensor replacement and mileage counter

reset.

CHECK ENGINE LIGHT (CALIF MODELS)

Some California vehicles are equipped with a CHECK engine

light and rocker switch on the instrument panel. The light will

illuminate when the ignition switch is turned to the ON position (for

bulb check) and when engine management systems are malfunctioning

during normal operation with the engine running. For additional

information see appropriate SELF-DIAGNOSTICS article.

MISCELLANEOUS CONTROLS

NOTE: Although not considered true Engine Performance related

systems, some controlled devices may affect driveability if

they malfunction.