sensor VOLKSWAGEN CORRADO 1990 Manual Online

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 558 of 906

F - BASIC TESTING

Article Text (p. 13)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

DISTRIBUTOR

HALL EFFECT SENDER

1) Remove coil secondary and attach to ground. Disconnect

Hall Effect sender wire at the distributor. Using a LED Test Light (US

1115), check for voltage between outer terminals of connector. See

Fig. 5 or 8. With ignition on, light should be on. If not, check

wiring for short or open circuit. If wiring is okay, replace Digifant

control unit.

2) If light came on in step 1), reconnect Hall Effect sender

harness connector. Pull back Hall Effect sender boot to expose contact

terminals. Apply LED Test Light (US 1115) probe to center contact and

battery positive terminal. See Fig. 5. Observe test light while

cranking engine. If test light blinks, Hall Effect sender is okay. If

not, replace Hall Effect-sender.

IDLE SPEED, CO LEVEL & IGNITION TIMING

Ensure idle speed, CO level and base ignition timing are set

to specification. If necessary, see ON-VEHICLE ADJUSTMENTS article.

IDLE SPEED & CO LEVEL TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level %

All Models ............ 800-1000 .............. 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄIGNITION TIMING TABLE (Degrees BTDC @ RPM)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Checking Adjusting

1.8L ............... 4-8 @ 2250-2350 . 5-7 @ 2250-2350

2.0L ................ 4-8 @ 770-830 ...... 5-7 @ 770-830

2.1L (1) ........... 4-8 @ 2250-2350 . 5-7 @ 2250-2350

(1) - With coolant temperature sensor disconnected.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ SUMMARY

If no faults were found while performing F - BASIC TESTING,

proceed to H - TESTS W/CODES article for diagnosis by symptom (i.e.,

ROUGH IDLE, NO START, etc.) or intermittent diagnostic procedures.

END OF ARTICLE

Page 564 of 906

FUSES & CIRCUIT BREAKERS

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

Right Tail & Side Lights

8 - 10 Amp

Left Tail & Side Lights

9 - 20 Amp

Rear Window & Mirror Heating

10 - 15 Amp

Foglights

11 - 10 Amp

Left High Beam, High Beam Indicator

12 - 10 Amp

Right High Beam

13 - 10 Amp

Horn, Radiator Fan

14 - 15 Amp

Back-Up Lights, Electric Mirrors, Heated Windshield Washer

Jets

15 - 10 Amp

Engine Electronic

16 - 15 Amp

Warning/Indicator Lights, Multi-Function Indicator, Glove Box

Light, Cassette Storage Light, Rear Spoiler

17 - 10 Amp

Turn Signals

18 - 20 Amp

Fuel Pump, Oxygen Sensor

19 - 30 Amp

Radiator Fan, Air Conditioner

20 - 10 Amp

Brakelights, Cruise Control

21 - 15 Amp

Dome & Luggage Compartment Lights, Cigarette Lighter, Central

Locking System, Multi-Function Indicator

22 - 10 Amp

Radio

CAUTIONS & WARNINGS

ELECTRICAL SHOCK

WARNING: Contact with live components of ignition system while

engine is running could lead to a fatal electric shock.

RADIATOR FAN

Keep hands away from radiator fan. Fan is controlled by a

thermostatic switch which may come on or run for up to 15 minutes even

after engine is turned off.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

radiator fan. The fan is temperature controlled and could

Page 575 of 906

H - TESTS W/O CODES

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

WILL NOT START OR STARTS HARD COLD (CRANKS OKAY)

* Check ignition fuse (if equipped).

* Check fuel pump fuse and fuel pump relay.

* Verify air intake system is unrestricted.

* Ensure fuel system pressure and volume are correct.

* Check cold start valve and thermo time switch operation.

* Ensure airflow sensor plate is in rest position. Adjust as

necessary.

* Test coolant temperature sensor and wiring. Repair or replace

as required.

* Check for poor ignition ground (1.8L & 2.0L 16-valve engines).

* Check for poor quality or contaminated fuel.

* Check condensation (water) in fuel tank causing fuel pump to

freeze (cold climate).

* Check exhaust system for restriction.

* Test airflow meter. Replace if faulty.

* Ensure sufficient secondary spark is available.

* Check air induction system for cracks or restriction.

* Ensure vacuum hoses are not disconnected or damaged.

* Ensure fuel system residual pressure is correct.

* Ensure fuel injector operation is correct.

* Ensure EGR valve operation is correct and valve closes

completely (if equipped).

* Check for cracks or poor connections at throttle body.

* Ensure ignition and valve timing are correct.

* Check ignition coil primary connections and wiring harness.

* Ensure ignition coil resistance is within specification.

* Check air temperature sensor operation (if equipped).

* Ensure electrical harness and connectors are not broken or loose.

* Ensure ECU or ignition control unit has correct voltage supply

and is properly grounded.

* Ensure engine has sufficient compression.

* Inspect intake air components for leaking hoses, connections or

cracks. Repair as required.

WILL NOT START OR STARTS HARD HOT (CRANKS OKAY)

* Check ignition fuse (if equipped).

* Check fuel system fuse and fuel pump relay.

* Check for poor quality or contaminated fuel.

* Check condensation (water) in fuel tank causing fuel pump to

freeze (cold climate).

* Check exhaust system for restriction.

* Check cold start valve and thermo time switch operation.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Check residual fuel pressure. Replace fuel pump check valve or

fuel accumulator as necessary.

* Check oxygen sensor system operation.

* Ensure airflow sensor plate is in rest position. Adjust as

Page 576 of 906

H - TESTS W/O CODES

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

necessary.

* Ensure injector spray patterns and volume are correct. Replace

faulty injectors.

* Inspect fuel lines and connections for leaks.

* Check carbon canister solenoid valves (CIS-E Motronic).

* Test airflow meter. Replace if faulty.

* Ensure sufficient secondary spark is available.

* Check air induction system for cracks or restriction.

* Check airflow sensor plate rest position.

* Ensure vacuum hoses are not disconnected or damaged.

* Ensure EGR valve operation is correct and valve closes

completely (if equipped).

* Check for cracks or poor connections at throttle body.

* Ensure ignition and valve timing are correct.

* Check ignition coil primary connections and wiring harness.

* Ensure ignition coil resistance is within specification.

* Check air temperature sensor operation.

* Check coolant temperature sensor operation.

* Ensure electrical harness and connectors are not broken or loose.

* Ensure ECU or ignition control unit has correct voltage supply

and is properly grounded.

* Ensure engine has sufficient compression.

ENGINE STALLS OR IDLES ROUGH

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Check cold start valve for leaking (engine warm).

* Ensure injector spray patterns and volume are correct. Replace

faulty injectors.

* Test coolant temperature sensor and wiring. Repair or replace

as required.

* Inspect intake air components for leaking hoses, connections or

cracks. Repair as required.

* Ensure airflow sensor plate movement and rest position. Adjust

as necessary.

* Test idle switch and idle air stabilizer valve.

* Perform system electrical checks.

* Check airflow meter. Replace if faulty.

* Ensure idle RPM is correct.

* Check auxiliary air by-pass regulator.

* Check fuel injector electrical connections.

* Use stethoscope to verify fuel injectors are operating.

* Ensure sufficient secondary spark is available in all cylinders.

* Verify vacuum hose routing is correct and there are no

vacuum leaks.

* Check idle stabilizer operation.

* Check for EGR system malfunction (if equipped).

* Check O2 sensor operation.

* Check for distortion or cracks in fuel injector(s) plastic

connecting flange(s).

* Check for use of poor quality fuel containing insufficient

Page 577 of 906

H - TESTS W/O CODES

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

cleaning additives. Prolonged use of poor quality fuel can

cause injector clogging and carbon build-up on intake system.

ENGINE MISFIRES OR HESITATES

CIS-E & CIS-E MOTRONIC

* Ensure injector spray patterns and volume are correct. Replace

faulty injectors.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Check Oxygen (O2) sensor system operation.

* Check fuel lines and connections for leaks.

* Test coolant temperature sensor and wiring. Repair or replace

as required.

* Check airflow meter and throttle switch. Replace if faulty.

* Ensure vacuum hoses are not disconnected or damaged.

* Ensure electrical harness connectors and wires are not

broken or loose.

* Check cold start valve for leaking (engine warm).

DIGIFANT II

* Check airflow sensor flap and sensor resistance. Replace

if faulty.

* Inspect intake air components for leaking hoses, connections

or cracks. Repair as required.

* Test intake air preheating system. Replace faulty components

as required.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Ensure vacuum hoses are not disconnected or damaged.

* Ensure electrical harness connectors and wires are not

broken or loose.

* Check cold start valve for leaking (engine warm).

* Check coolant temperature sensor operation.

* Check Oxygen (O2) sensor voltage output.

EXCESSIVE FAST IDLE

* Inspect accelerator pedal and cable for worn parts or binding.

* Test idle switch (if equipped).

* Test auxiliary air regulator and replace if necessary

(if equipped).

* Inspect throttle valve and adjust or replace as required.

* Check carbon canister solenoid valves (CIS-E Motronic).

* Test idle boost valve system operation (1.8L 8-valve engine

only). Replace faulty parts as necessary.

* Test coolant temperature sensor and wiring (Digifant II). Repair

or replace as required.

* Check throttle cable adjustment.

* Verify vacuum hose routing is correct.

Page 578 of 906

H - TESTS W/O CODES

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

* Ensure there are no vacuum leaks.

* Check idle stabilizer operation (if equipped).

* Ensure fuel system pressure and volume are correct.

* Check auxiliary air by-pass regulator.

* Check cold start valve for leaking (engine warm).

ENGINE HESITATES ON ACCELERATION

* Inspect intake air components for leaking hoses

* Check injector spray pattern. Check for faulty injectors.

* Check cold start valve for leaking (engine warm).

* Check airflow sensor plate movement. Replace fuel distributor

as necessary.

* Check airflow sensor plate position. Adjust as necessary.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Test airflow sensor plate potentiometer. Adjust or replace

as necessary.

* Perform system electrical checks.

* Check idle mixture CO adjustment. Adjust as necessary.

ENGINE LACKS POWER

* Test coolant temperature sensor and wiring. Repair or

replace as required.

* Check fuel system and control system pressure. Replace pressure

regulator if necessary.

* Check throttle cable adjustment.

* Check throttle switch. Adjust or replace as necessary.

* Check airflow sensor screen for damage or incorrect installation

(if equipped).

* Check ignition timing and knock sensor control (if equipped).

Adjust as necessary.

* Check EGR system for correct operation (if equipped).

* Ensure base timing is correct and timing advance system

is functional.

* Check transmission for correct downshift (auto. trans.)

* Check fuel tank filler tube for tampering of restrictor. If

tampering has occurred, check catalytic converter for lead

contamination and exhaust system restriction.

* Check for use of poor quality fuel containing insufficient

cleaning additives. Prolonged use of poor quality fuel can

cause injector clogging and carbon build-up on intake system.

* Inspect intake air element, housing, and preheating system.

* Check airflow sensor plate movement. Replace if necessary.

POOR FUEL MILEAGE

* Ensure idle speed, base timing and timing advance are

set to specifications.

* Check cold start valve for leaking (engine warm).

Page 579 of 906

H - TESTS W/O CODES

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:45PM

* Check fuel system and control system pressure. Replace

pressure regulator if necessary.

* Check thermo time switch operation.

* Check airflow sensor voltage output.

* Check air induction system for leaks.

* Check fuel injector operation.

* Check coolant temperature sensor operation.

* Check Oxygen (O2) sensor operation.

ENGINE DIESELING

CIS-E & CIS-E MOTRONIC

* Ensure ignition timing and timing advance are set to

specifications.

* Check for engine overheating.

* Check cold start valve for leaking (engine warm).

* Check for leaking injectors.

* Check airflow sensor plate/control plunger rest position.

Adjust as necessary.

* Check carbon canister solenoid valve.

* Verify no leaks in exhaust system.

FAILED EMISSIONS TEST

* Test lambda control system. Replace if faulty.

* Check air/fuel mixture. Adjust if necessary.

* Ensure air intake system is not restricted.

* Ensure engine is at normal operating temperature.

* Ensure fuel system pressure is correct.

* Check cold start valve for leaking (engine warm).

* Check thermo time switch operation.

* Verify base timing is correct.

* Check for correct PCV valve operation.

* Check crankcase for gasoline contamination.

* Check idle stabilizer operation.

* Check EGR system for correct operation (if equipped).

* Check vapor recovery system operation.

* Check operation of coolant temperature sensor.

* Check fuel tank filler tube for tampering of restrictor.

If tampering has occurred, check catalytic converter for

lead contamination and exhaust system restriction.

* Check for use of poor quality fuel containing insufficient

cleaning additives. Prolonged use of poor quality fuel can

cause injector clogging and carbon build-up on intake system.

INTERMITTENT PROBLEM DIAGNOSIS

Intermittent fault testing requires duplicating circuit or

component failure to identify the problem. If necessary, monitor

voltage or resistance values using a DVOM while attempting to

Page 588 of 906

I - SYSTEM/COMPONENT TESTS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Systems & Component Testing

Volkswagen; Cabriolet, Corrado, Fox, Golf GL/GTI,

Jetta, Vanagon

INTRODUCTION

Before testing separate components or systems, perform

procedures in F - BASIC TESTING and H - TESTS W/O CODES articles.

NOTE: Testing individual components does not isolate shorts or

opens. Perform all voltage tests with a Digital

Volt-Ohmmeter (DVOM) with a minimum 10-megohm input

impedance, unless stated otherwise in test procedure. Use

ohmmeter to isolate wiring harness shorts or opens.

AIR INDUCTION SYSTEMS (SUPERCHARGER)

BOOST PRESSURE

1) Before checking supercharger boost pressure, ensure engine

idle speed is correct. See D - ADJUSTMENTS article. Ensure engine oil

temperature is 176øF (80øC). Check knock sensor operation. See KNOCK

SENSOR under IDLE CONTROL SYSTEM in this article.

2) Connect Pressure Gauge (VW1397) or equivalent to the

pressure regulator hose using adapter "T". Open pressure gauge check

valve to position "A" and start engine.

3) Remove harness connector from CO potentiometer and Blue

connector from temperature sensor (in front flange on cylinder head).

Accelerate to full throttle. Engine speed must increase periodically

then drop (surge). Watch pressure gauge, boost pressure must reach 8.7

psi (0.6 kg/cm

ý). If boost does not reach specification, check for

leaks in air system and correct by-pass valve setting. Check

supercharger.

COMPUTERIZED ENGINE CONTROLS

NOTE: For fuel system used on model being tested, see FUEL SYSTEM

APPLICATION table.

FUEL SYSTEM APPLICATION

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Fuel System

Cabriolet, Corrado, Golf GL/GTI,

Jetta & Vanagon .................................. AFC-Digifant II

Fox .......................................................... CIS-E

Jetta GLi ............................................. CIS-Motronic

Page 590 of 906

I - SYSTEM/COMPONENT TESTS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

circuits to ECU. The ECU engine ground is near ignition distributor.

Remove ECU connector. Check resistance to ground on terminal No. 35.

Resistance should be zero ohms. If resistance is not zero ohms, repair

open or short in wiring.

POWER CIRCUITS

Turn ignition off. Disconnect ECU connector. Using a

voltmeter, check terminals No. 12, 14, 19 and 34 for battery voltage.

If battery voltage is not present. Check fuses No. 15, 18 and 24. If

fuses are okay, check for open in wiring between ECU and fuse box. See

L - WIRING DIAGRAMS for terminal identification and wire colors.

ENGINE SENSORS & SWITCHES

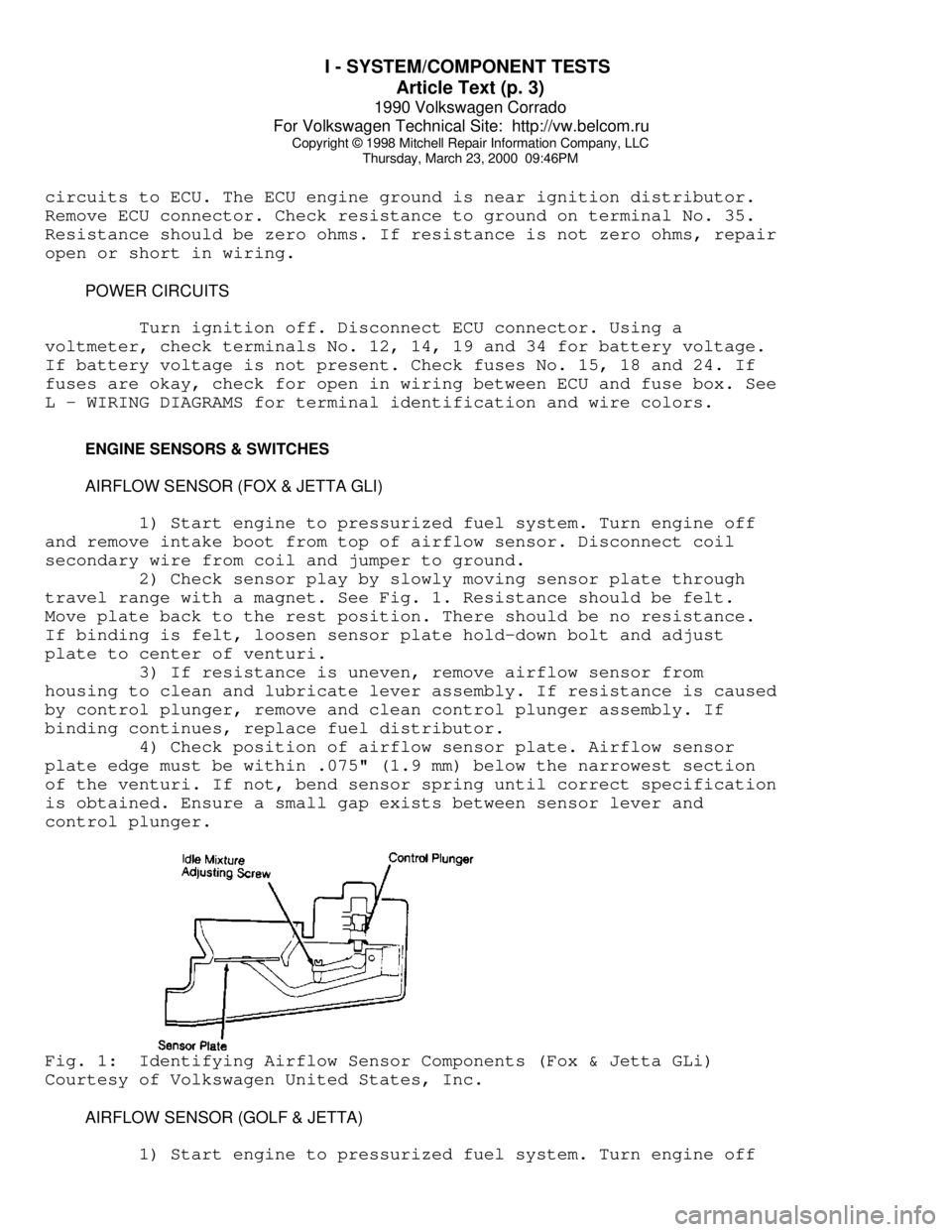

AIRFLOW SENSOR (FOX & JETTA GLI)

1) Start engine to pressurized fuel system. Turn engine off

and remove intake boot from top of airflow sensor. Disconnect coil

secondary wire from coil and jumper to ground.

2) Check sensor play by slowly moving sensor plate through

travel range with a magnet. See Fig. 1. Resistance should be felt.

Move plate back to the rest position. There should be no resistance.

If binding is felt, loosen sensor plate hold-down bolt and adjust

plate to center of venturi.

3) If resistance is uneven, remove airflow sensor from

housing to clean and lubricate lever assembly. If resistance is caused

by control plunger, remove and clean control plunger assembly. If

binding continues, replace fuel distributor.

4) Check position of airflow sensor plate. Airflow sensor

plate edge must be within .075" (1.9 mm) below the narrowest section

of the venturi. If not, bend sensor spring until correct specification

is obtained. Ensure a small gap exists between sensor lever and

control plunger.Fig. 1: Identifying Airflow Sensor Components (Fox & Jetta GLi)

Courtesy of Volkswagen United States, Inc.

AIRFLOW SENSOR (GOLF & JETTA)

1) Start engine to pressurized fuel system. Turn engine off

Page 591 of 906

I - SYSTEM/COMPONENT TESTS

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

and remove intake boot from top of airflow sensor. Check sensor plate

by lifting plate through travel cycle with magnet or pliers.

2) Continuous resistance should be felt. Move plate back to

rest position. There should be no resistance. If resistance is felt,

replace airflow sensor. If sensor plate lever is difficult to move

upward but moves freely downward, check sensor plate for correct

centering.

3) Sensor plate should be evenly centered in the housing with

plate edge at the narrowest section of the venturi while at rest

position. If sensor plate adjustment is correct, check control plunger

for sticking. If control plunger is sticking, replace fuel distributor

assembly.

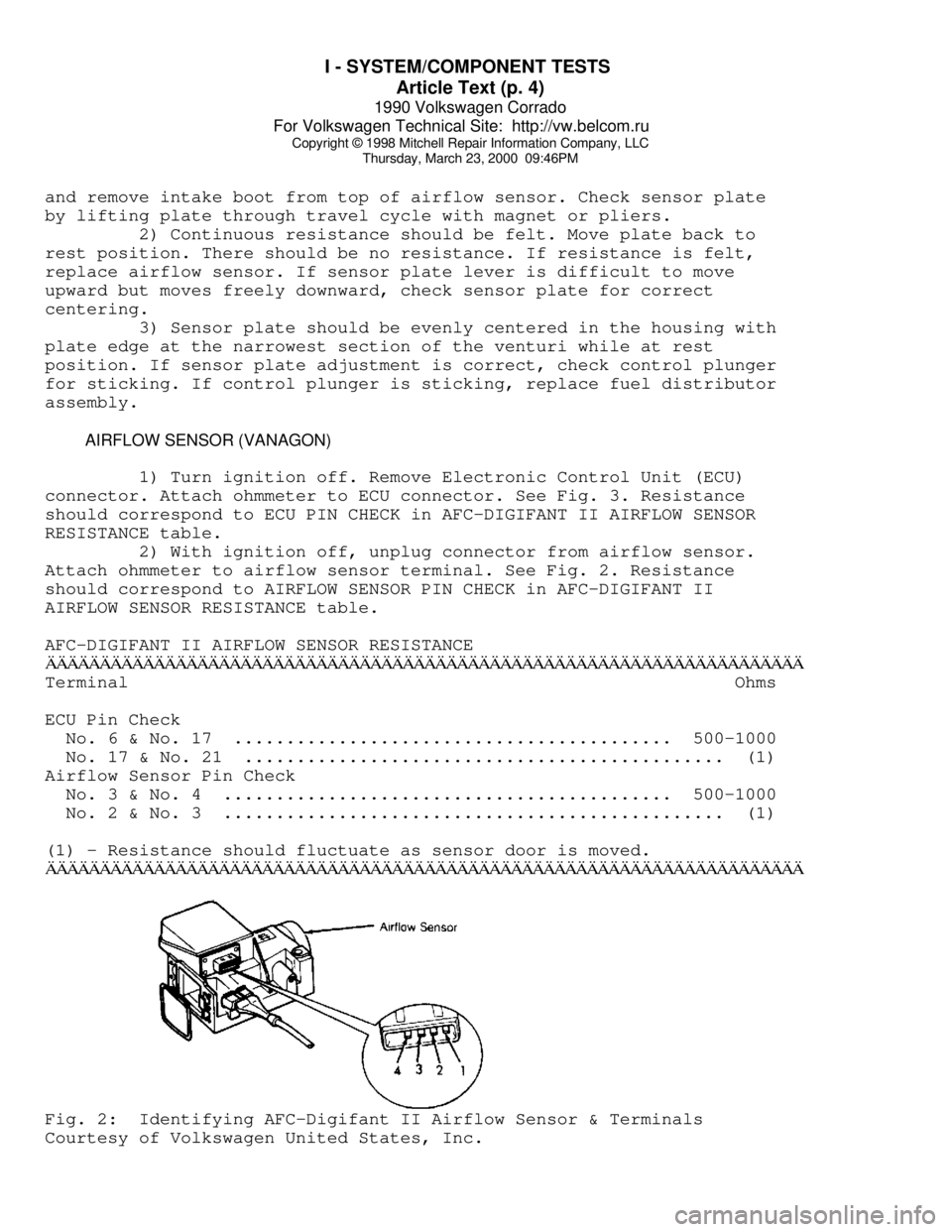

AIRFLOW SENSOR (VANAGON)

1) Turn ignition off. Remove Electronic Control Unit (ECU)

connector. Attach ohmmeter to ECU connector. See Fig. 3. Resistance

should correspond to ECU PIN CHECK in AFC-DIGIFANT II AIRFLOW SENSOR

RESISTANCE table.

2) With ignition off, unplug connector from airflow sensor.

Attach ohmmeter to airflow sensor terminal. See Fig. 2. Resistance

should correspond to AIRFLOW SENSOR PIN CHECK in AFC-DIGIFANT II

AIRFLOW SENSOR RESISTANCE table.

AFC-DIGIFANT II AIRFLOW SENSOR RESISTANCEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTerminal Ohms

ECU Pin Check

No. 6 & No. 17 .......................................... 500-1000

No. 17 & No. 21 .............................................. (1)

Airflow Sensor Pin Check

No. 3 & No. 4 ........................................... 500-1000

No. 2 & No. 3 ................................................ (1)

(1) - Resistance should fluctuate as sensor door is moved.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 2: Identifying AFC-Digifant II Airflow Sensor & Terminals

Courtesy of Volkswagen United States, Inc.