display VOLKSWAGEN CORRADO 1993 User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 589 of 920

G - TESTS W/CODES

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

arrow button twice to select END OUTPUT function on scan tester. Press

"Q" to enter input. Turn ignition off. Disconnect scan tester.

READ MEASUREMENT & READ MEASURING (TEST) VALUE BLOCK

NOTE: See ENTERING SELF-DIAGNOSTICS for additional scan tester

operating instructions.

Corrado SLC (2.8L)

1) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. With scan

tester in READ MEASURING VALUE BLOCK function, press "01" to "06"

buttons to select desired display group. See appropriate DISPLAY GROUP

table.

2) When display group is selected, only the second number is

shown on display (the zero does not appear on display). With READ

MEASUREMENT BLOCK function completed, select END OUTPUT function on

scan tester. Turn ignition off. Disconnect scan tester.

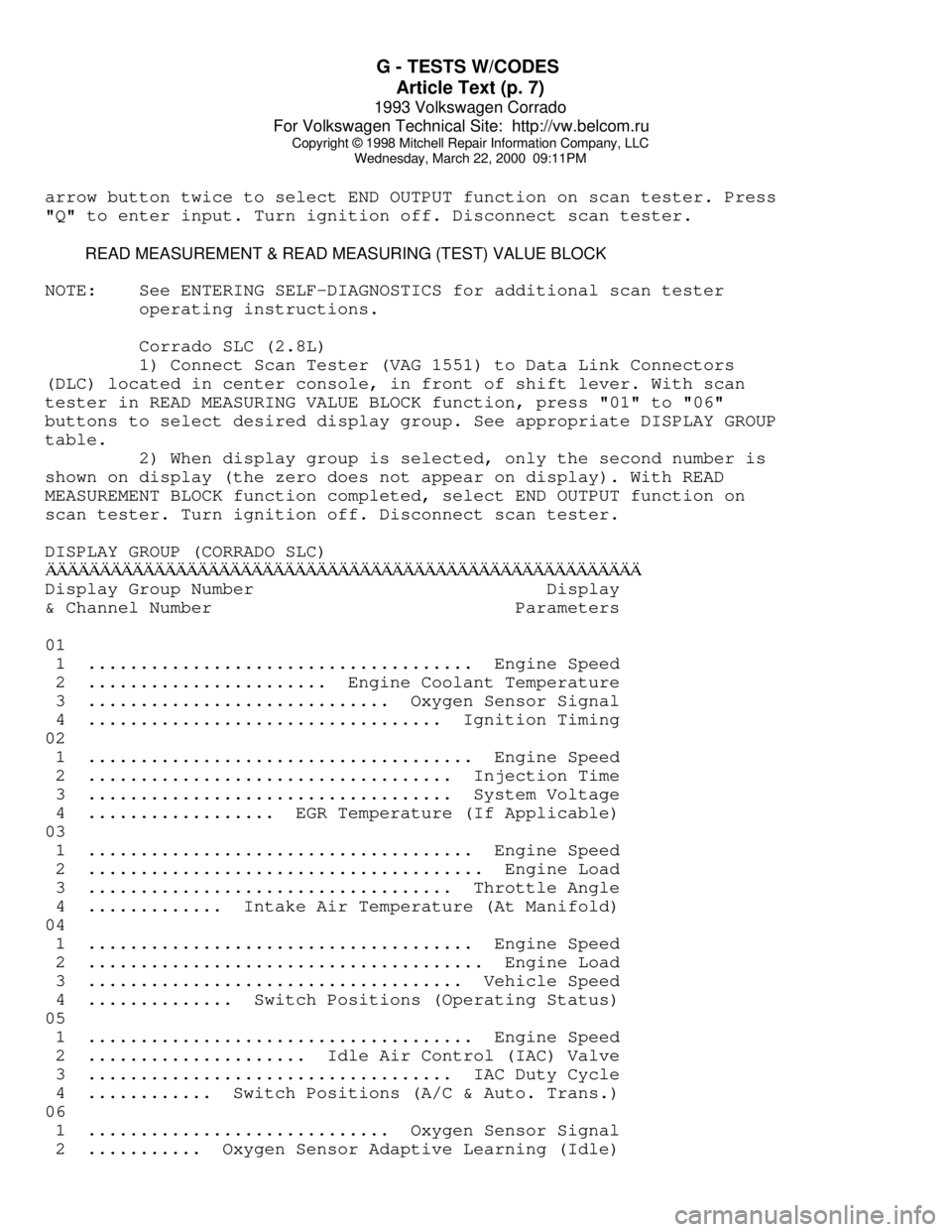

DISPLAY GROUP (CORRADO SLC)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDisplay Group Number Display

& Channel Number Parameters

01

1 ..................................... Engine Speed

2 ....................... Engine Coolant Temperature

3 ............................. Oxygen Sensor Signal

4 .................................. Ignition Timing

02

1 ..................................... Engine Speed

2 ................................... Injection Time

3 ................................... System Voltage

4 .................. EGR Temperature (If Applicable)

03

1 ..................................... Engine Speed

2 ...................................... Engine Load

3 ................................... Throttle Angle

4 ............. Intake Air Temperature (At Manifold)

04

1 ..................................... Engine Speed

2 ...................................... Engine Load

3 .................................... Vehicle Speed

4 .............. Switch Positions (Operating Status)

05

1 ..................................... Engine Speed

2 ..................... Idle Air Control (IAC) Valve

3 ................................... IAC Duty Cycle

4 ............ Switch Positions (A/C & Auto. Trans.)

06

1 ............................. Oxygen Sensor Signal

2 ........... Oxygen Sensor Adaptive Learning (Idle)

Page 614 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

COMPUTERIZED ENGINE CONTROLS

ELECTRONIC CONTROL MODULE (ECM)

Ground & Power Circuits

Check ECM ground and power circuits using the values in the

appropriate J - PIN VOLTAGE CHARTS article.

ENGINE SENSORS & SWITCHES

ENGINE COOLANT TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever. Start engine and allow it to idle.

2) With scan tester in READ TEST VALUE BLOCK function, select

group No. 01 and read coolant temperature value in field No. 2 of scan

tester. Temperature value must increase uniformly without

interruption. If value increases as specified, select END OUTPUT

function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ENGINE

COOLANT TEMPERATURE SENSOR RESISTANCE table.

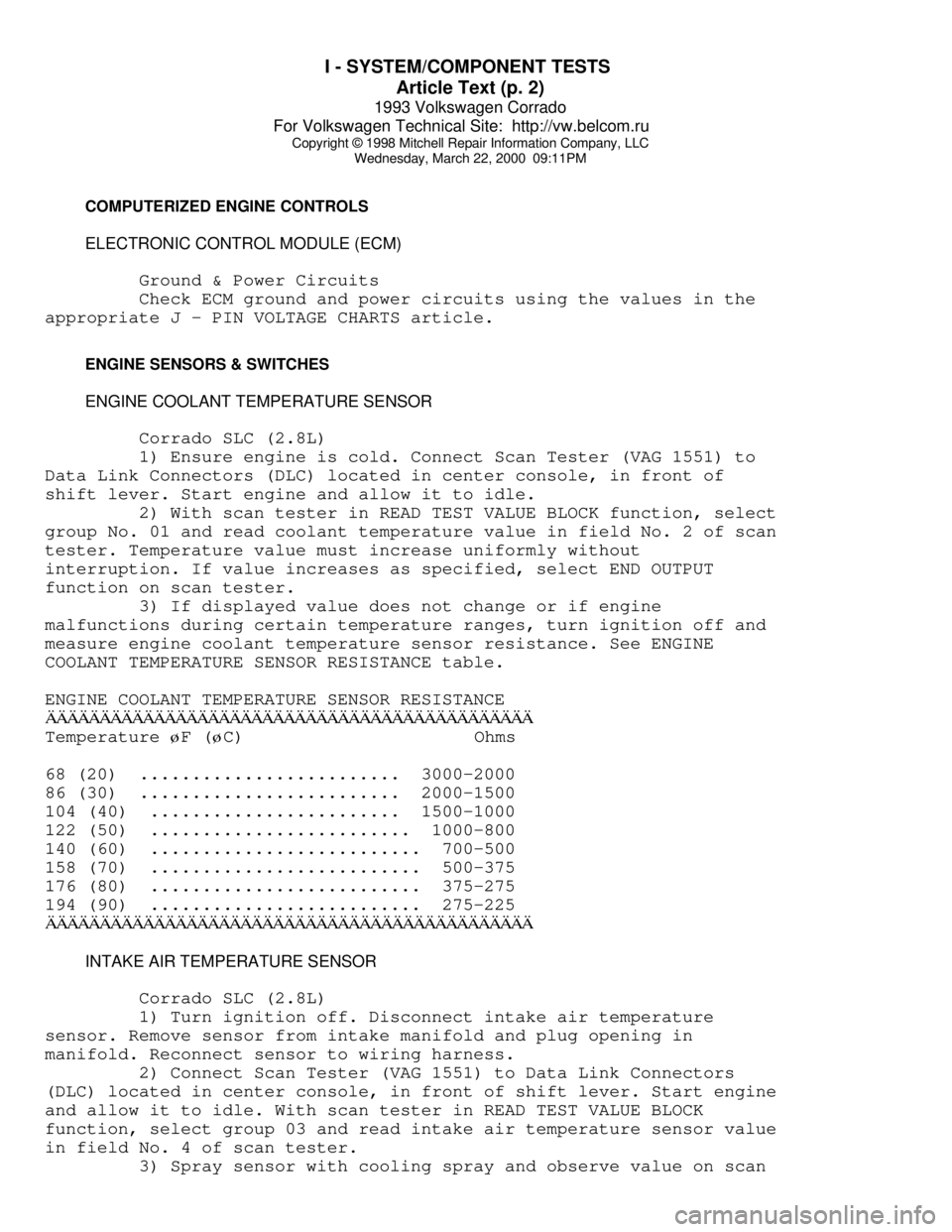

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature

øF (øC) Ohms

68 (20) ......................... 3000-2000

86 (30) ......................... 2000-1500

104 (40) ........................ 1500-1000

122 (50) ......................... 1000-800

140 (60) .......................... 700-500

158 (70) .......................... 500-375

176 (80) .......................... 375-275

194 (90) .......................... 275-225

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ INTAKE AIR TEMPERATURE SENSOR

Corrado SLC (2.8L)

1) Turn ignition off. Disconnect intake air temperature

sensor. Remove sensor from intake manifold and plug opening in

manifold. Reconnect sensor to wiring harness.

2) Connect Scan Tester (VAG 1551) to Data Link Connectors

(DLC) located in center console, in front of shift lever. Start engine

and allow it to idle. With scan tester in READ TEST VALUE BLOCK

function, select group 03 and read intake air temperature sensor value

in field No. 4 of scan tester.

3) Spray sensor with cooling spray and observe value on scan

Page 615 of 920

I - SYSTEM/COMPONENT TESTS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

tester. Scan tester value must decrease. If temperature value does not

change, repair intake air temperature sensor circuit or replace sensor

as necessary. After repairs, erase Diagnostic Trouble Code (DTC)

memory (if applicable) and select END OUTPUT function.

HALL EFFECT SENSOR

Corrado SLC (2.8L)

Testing information is not available from manufacturer. These

vehicles are equipped with a distributorless ignition system.

FUEL SYSTEM

ACCELERATION/FULL THROTTLE ENRICHMENT & DECELERATION FUEL

CUT-OFF

Corrado SLC (2.8L)

1) Ensure engine coolant temperature is at least 176øF

(80

øC). Connect Scan Tester (VAG 1551) to Data Link Connectors (DLC)

located in center console, in front of shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 04 and read value in

field No. 4 of scan tester. Display value must be 00010 at idle.

3) Using accelerator pedal, increase engine speed to 3000 RPM

and observe scan tester. Display value in field No. 4 of scan tester

must briefly be 10100. Release accelerator pedal and observe scan

tester.

4) Display value in field No. 4 of scan tester must briefly

be 00011, then return to 00010 at idle. If values are not as

specified, see THROTTLE POSITION (TP) SENSOR ADJUSTMENT procedures in

the D - ADJUSTMENTS article. If values are as specified, select END

OUTPUT function on scan tester.

FUEL INJECTORS & CIRCUIT

Corrado SLC (2.8L)

1) To access fuel injectors, remove ignition wires. Remove

hose from mass airflow sensor. Disconnect hose to fuel evaporative

(frequency) solenoid valve at throttle body.

2) Disconnect throttle position sensor and idle air control

valve. Disconnect accelerator cable from throttle body. Disconnect and

plug coolant hoses at throttle body.

3) Disconnect hose from air intake heated tube. Detach fuel

lines at cylinder head cover and remove from fuel rail. Disconnect

vacuum hose from fuel pressure regulator. Remove intake manifold upper

section. See Fig. 2.

4) With intake manifold upper section removed, disconnect

wiring harness from fuel injectors. Using a Digital Volt-Ohmmeter

(DVOM) and test leads from Adapter Kit (VW 1594), check fuel injector

resistance. See Fig. 3.

5) Fuel injector resistance should be 15.0-21.5 ohms. If

resistance is zero ohms, check for a short circuit in wiring harness.

Page 669 of 920

MAINTENANCE REMINDER LIGHT RESET PROCEDURES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:20PM

ARTICLE BEGINNING

1983-96 MAINTENANCE

Volkswagen Maintenance Reminder Light Reset Procedures

EGR MAINTENANCE LIGHT (IF EQUIPPED)

EGR light comes on at 15,000 mile intervals to indicate EGR

servicing is required. After checking EGR system, reset mileage

counter. See RESETTING MILEAGE COUNTER.

OXYGEN SENSOR WARNING LIGHT (IF EQUIPPED)

Oxygen sensor (OXS) light comes on at 30,000 mile intervals

to indicate oxygen sensor replacement. After installing new sensor,

reset mileage counter. See RESETTING MILEAGE COUNTER.

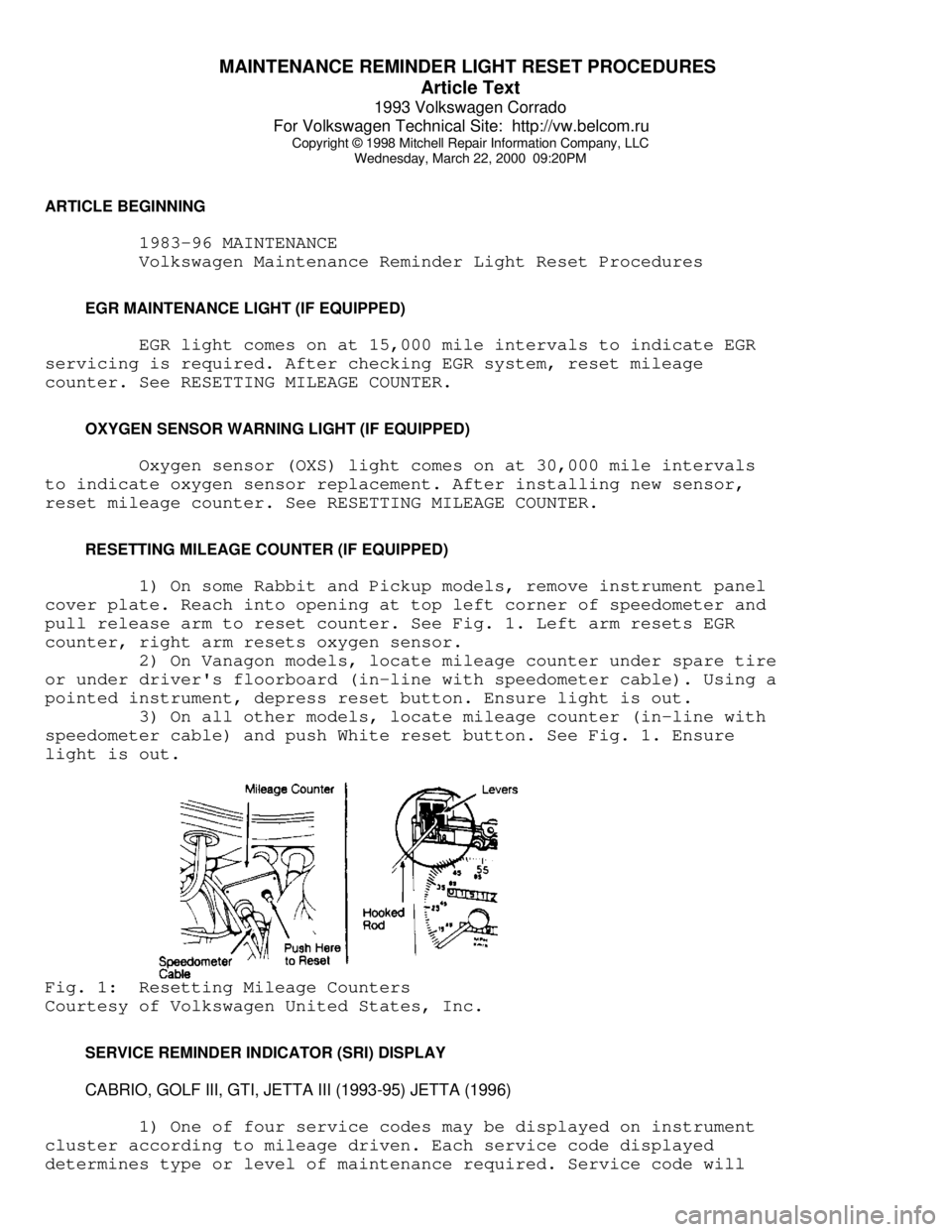

RESETTING MILEAGE COUNTER (IF EQUIPPED)

1) On some Rabbit and Pickup models, remove instrument panel

cover plate. Reach into opening at top left corner of speedometer and

pull release arm to reset counter. See Fig. 1. Left arm resets EGR

counter, right arm resets oxygen sensor.

2) On Vanagon models, locate mileage counter under spare tire

or under driver's floorboard (in-line with speedometer cable). Using a

pointed instrument, depress reset button. Ensure light is out.

3) On all other models, locate mileage counter (in-line with

speedometer cable) and push White reset button. See Fig. 1. Ensure

light is out.Fig. 1: Resetting Mileage Counters

Courtesy of Volkswagen United States, Inc.

SERVICE REMINDER INDICATOR (SRI) DISPLAY

CABRIO, GOLF III, GTI, JETTA III (1993-95) JETTA (1996)

1) One of four service codes may be displayed on instrument

cluster according to mileage driven. Each service code displayed

determines type or level of maintenance required. Service code will

Page 670 of 920

MAINTENANCE REMINDER LIGHT RESET PROCEDURES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:20PM

flash for approximately 3 seconds in odometer display window as

ignition is turned on. When servicing becomes due (every 7500 miles),

appropriate service code will flash for approximately 60 seconds. The

four service codes available for display are as follows:

* IN 00 (No Service Necessary)

* OEL (Oil Change Service) Every 7500 Miles

* IN 01 (Inspection Service) Every 15,000 Miles

* IN 02 (Additional Servicing Work) Every 30,000 Miles

2) After performing required maintenance, each effected

service code displayed must be reset individually. For example, at 15,

000 miles service codes OEL and IN 01 will both need to be reset.

3) To reset service codes, turn ignition on. Press and hold

odometer reset button located below speedometer. While holding button,

press clock reset button (lower button for digital clock) located to

left of fuel gauge. Release buttons. Programming mode is now

activated. Service code OEL1.S (distance counter) should be displayed.

4) Press clock reset button once more. 7500 miles should now

be indicated on display. Desired mileage for reset may be attained by

pressing clock reset button. Mileage displayed will decrease in

increments of 500 miles each time button is pressed. This feature

should only be used to calibrate mileage when instrument cluster is

replaced. When desired mileage is displayed, press odometer reset

button.

5) Service code OEL2.S (time counter) should be displayed.

Press clock reset button. 6 (months) will be indicated on display.

Time counter for next oil change may be set by pressing clock reset

button if instrument cluster was replaced. When desired time is

displayed, press odometer reset button.

6) Service code IN 01.S (time counter) should be displayed.

Press clock reset button. 12 (months) will be indicated on display.

Time counter for next maintenance interval may be set by pressing

clock reset button if instrument cluster was replaced. When desired

time is displayed, press odometer reset button.

7) Service code IN 02.S (distance counter) should be

displayed. Press clock reset button. 30,000 (miles) will be indicated

on display. Desired mileage for reset may be attained by pressing

clock reset button. Mileage displayed will decrease in increments of

500 miles each time button is pressed. This feature should only be

used to calibrate mileage when instrument cluster is replaced. When

desired mileage is displayed, turn ignition off. Programming is now

stored in memory.

END OF ARTICLE

Page 686 of 920

SCHEDULED SERVICES

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:22PM

To avoid possible damage to vehicle use only ethylene-glycol

based coolants with a mixture ratio from 44-68% anti-freeze.

DO NOT use 100% anti-freeze as it will cause the formation

of cooling system deposits. This results in coolant

temperatures of over 300ø F (149øC) which can melt plastics.

100% anti-freeze has a freeze point of only -8

ø F (-22øC).

CAUTION: Propylene-Glycol Mixtures has a smaller temperature range

than Ethylene-Glycol. The temperature range (freeze-boil)

of a 50/50 Anti-Freeze/Water Mix is as follows:

Propylene-Glycol -26

ø F (-32øC) - 257ø F (125øC)

Ethylene-Glycol -35

ø F (-37øC) - 263ø F (128øC)

CAUTION: Propylene-Glycol/Ethylene-Glycol Mixtures can cause the

destabilization of various corrosion inhibitors. Also

Propylene-Glycol/Ethylene-Glycol has a different specific

gravity than Ethylene-Glycol coolant, which will result in

inaccurate freeze point calculations.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

WARNING: Many solid state electrical components can be damaged by

static electricity (ESD). Some will display a warning label,

but many will not. Discharge personal static electricity by

touching a metal ground point on the vehicle prior to

servicing any ESD sensitive component.

ELECTRIC SHOCK HAZARD

WARNING: Contact with live components of ignition system while

engine is running could lead to a fatal electric shock.

ENGINE OIL

CAUTION: Never use non-detergent or straight mineral oil.

FUEL SYSTEM SERVICE

WARNING: Relieve fuel system pressure prior to servicing any fuel

system component (fuel injection models).

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if

overheated. DO NOT touch glass portion of bulb with bare hands. Eye

protection should be worn when handling or working around halogen

bulbs.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

Page 725 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

fan is not coming on at proper temperature and engine is

overheating.

Corrado SLC, Passat GLX

The cooling fan is either a 1 or 2-speed motor. If vehicle is

equipped with single-speed motor, the fan comes on at 198-207øF (92-

97

øC) and turns off at 183-196øF (84-91øC). If equipped with a 2-speed

motor, low speed of cooling fan should come on at 198-208

øF (92-98øC)

on vehicles without A/C, or 183-207

øF (84-97øC) on vehicles with A/C.

Low speed will shut off at 183-196

øF (84-91øC) on all vehicles. High

speed comes on at 210-226

øF (99-108øC) on vehicles without A/C, or

201-226

øF (94-108øC) on vehicles with A/C. High speed will shut off at

196-220

øF (91-104øC) on all vehicles.

After-Run Thermoswitch

An after-run switch is used to help prevent fuel

vaporization. The thermoswitch turns cooling fan on when temperatures

in engine compartment exceeds 230

øF (110øC), and turns it off at 217øF

(103

øC).

Passat GL

The cooling fan is a 2-speed motor. Low speed of cooling fan

should come on at 198-207

øF (92-97øC) and will shut off at 183-196øF

(84-91

øC). High speed comes on at 210-221øF (99-105øC) and will shut

off at 196-208

øF (91-98øC).

TROUBLE SHOOTING

NOTE: Trouble shooting information not available from manufacturer.

TESTING

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Corrado SLC & Passat GLX (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 01 and read coolant

temperature value in field No. 2 of scan tester. Temperature value

must increase uniformly without interruption. If value increases as

specified, select END OUTPUT function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ECT SENSOR

LOCATION table. Replace ECT sensor if resistance is not within

specification. See ECT SENSOR RESISTANCE table.

Passat GL

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console. Start engine and

Page 726 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

allow it to idle. With scan tester in READ MEASUREMENT BLOCK function,

read coolant temperature value in channel No. 1 of scan tester.

2) If temperature value increases uniformly without

interruption, sensor and its circuit are okay. Select END OUTPUT

function on scan tester. If display value is incorrect, test wiring

harness for open or short circuit. See Corrado SLC WIRING DIAGRAMS,

or Passat WIRING DIAGRAMS articles.

3) If necessary, use test leads from Adapter Kit (VAG 1594)

to measure ECT sensor resistance. See ECT SENSOR LOCATION table.

Replace engine coolant temperature sensor if not within specification.

See ECT SENSOR RESISTANCE table.

ECT SENSOR RESISTANCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature

øF (øC) Ohms

68 (20) ........................................ 3000-2000

86 (30) ........................................ 2000-1500

104 (40) ....................................... 1500-1000

122 (50) ........................................ 1000-800

140 (60) ......................................... 700-500

158 (70) ......................................... 500-375

176 (80) ......................................... 375-275

194 (90) ......................................... 275-225

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄECT SENSOR LOCATION TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄModel Location

Corrado SLC & Passat GLX

Blue, Brown & Yellow Sensor . On Radiator Near Upper Hose

Passat GL .............................. Below Distributor

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 813 of 920

TROUBLE SHOOTING - BASIC PROCEDURES

Article Text (p. 22)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

as heard. Extra differential thrust washers installed during axle

repair can cause a condition of partial lock-up that creates this

chatter.

AXLE SHAFT NOISE

Axle shaft noise is similar to gear noise and pinion bearing

whine. Axle shaft bearing noise will normally distinguish itself from

gear noise by occurring in all driving modes (Drive, cruise, coast and

float), and will persist with transmission in Neutral while vehicle is

moving at problem speed.

If vehicle displays this noise condition, remove suspect

axle shafts, replace wheel seals and install a new set of bearings.

Re-evaluate vehicle for noise before removing any internal components.

VIBRATION

Vibration is a high-frequency trembling, shaking or grinding

condition (felt or heard) that may be constant or variable in level

and can occur during the total operating speed range of the vehicle.

The types of vibrations that can be felt in the vehicle can

be divided into 3 main groups:

* Vibrations of various unbalanced rotating parts of the

vehicle.

* Resonance vibrations of the body and frame structures caused

by rotating of unbalanced parts.

* Tip-in moans of resonance vibrations from stressed engine or

exhaust system mounts or driveline flexing modes.

DRIVE AXLE - RWD TROUBLE SHOOTING

WARNING: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle

configuration. The purpose of this Trouble Shooting

information is to provide a list of common causes to

problem symptoms. For model-specific Trouble Shooting,

refer to SUBJECT, DIAGNOSTIC, or TESTING articles available

in the section(s) you are accessing. For definitions

of listed noises or sounds, see DRIVE AXLE - NOISE DIAGNOSIS.

DRIVE AXLE (RWD) TROUBLE SHOOTINGÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCONDITION POSSIBLE CAUSE CORRECTION

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄKnocking or Clunking

Differential Side Gear

Clearance Check Clearance

Worn Pinion Shaft Replace Pinion Shaft

Axle Shaft End Play Check End Play

Page 863 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

In any cases of doubt regarding the use of a noid light, a

lab scope will overcome all inherent weaknesses.

OVERVIEW OF DVOM

A DVOM is typically used to check injector resistance and

available voltage at the injector. Some techs also use it check

injector on-time either with a built-in feature or by using the

dwell/duty function.

There are situations where the DVOM performs these checks

dependably, and other situations where it can deceive you. It is

important to be aware of these strengths and weaknesses. We will cover

the topics above in the following text.

Checking Injector Resistance

If a short in an injector coil winding is constant, an

ohmmeter will accurately identify the lower resistance. The same is

true with an open winding. Unfortunately, an intermittent short is an

exception. A faulty injector with an intermittent short will show

"good" if the ohmmeter cannot force the short to occur during testing.

Alcohol in fuel typically causes an intermittent short,

happening only when the injector coil is hot and loaded by a current

high enough to jump the air gap between two bare windings or to break

down any oxides that may have formed between them.

When you measure resistance with an ohmmeter, you are only

applying a small current of a few milliamps. This is nowhere near

enough to load the coil sufficiently to detect most problems. As a

result, most resistance checks identify intermittently shorted

injectors as being normal.

There are two methods to get around this limitation. The

first is to purchase an tool that checks injector coil windings under

full load. The Kent-Moore J-39021 is such a tool, though there are

others. The Kent-Moore costs around $240 at the time of this writing

and works on many different manufacturer's systems.

The second method is to use a lab scope. Remember, a lab

scope allows you to see the regular operation of a circuit in real

time. If an injector is having an short or intermittent short, the lab

scope will show it.

Checking Available Voltage At the Injector

Verifying a fuel injector has the proper voltage to operate

correctly is good diagnostic technique. Finding an open circuit on the

feed circuit like a broken wire or connector is an accurate check with

a DVOM. Unfortunately, finding an intermittent or excessive resistance

problem with a DVOM is unreliable.

Let's explore this drawback. Remember that a voltage drop due

to excessive resistance will only occur when a circuit is operating?

Since the injector circuit is only operating for a few milliseconds at

a time, a DVOM will only see a potential fault for a few milliseconds.

The remaining 90+% of the time the unloaded injector circuit will show

normal battery voltage.

Since DVOMs update their display roughly two to five times a