engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 594 of 920

GENERAL COOLING SYSTEM SERVICING

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

GENERAL INFORMATION

General Cooling System Servicing

* PLEASE READ THIS FIRST *

The following article is for general information only.

Information may not apply to all years, makes and models. See specific

article in the ENGINE COOLING section.

DESCRIPTION

The basic liquid cooling system consists of a radiator, water

pump, thermostat, electric or belt-driven cooling fan, pressure cap,

heater, and various connecting hoses and cooling passages in the block

and cylinder head.

MAINTENANCE

DRAINING

Remove radiator cap and open heater control valve to maximum

heat position. Open drain cocks or remove plugs in bottom of radiator

and engine block. In-line engines usually have one plug or drain cock,

while "V" type engines will have 2, one in each bank of cylinders.

CLEANING

A good cleaning compound removes most rust and scale. Follow

manufacturer's instructions in the use of cleaner. If considerable

rust and scale has to be removed, cooling system should be flushed.

Clean radiator air passages with compressed air.

FLUSHING

CAUTION: Some manufacturers use an aluminum and plastic radiator.

Flushing solution must be compatible with aluminum.

Back Flushing

Back flushing is an effective means of removing cooling

system rust and scale. The radiator, engine and heater core should be

flushed separately.

Radiator

To flush radiator, connect flushing gun to water outlet of

radiator and disconnect water inlet hose. To prevent flooding engine,

use a hose connected to radiator inlet. Use air in short bursts to

prevent damage to radiator. Continue flushing until water runs clear.

Engine

Page 595 of 920

GENERAL COOLING SYSTEM SERVICING

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

To flush engine, remove thermostat and replace housing.

Connect flushing gun to water outlet of engine. Flush using short air

bursts until water runs clean.

Heater Core

Flush heater core as described for radiator. Ensure heater

control valve is set to maximum heat position before flushing heater.

REFILLING

To prevent air from being trapped in engine block, engine

should be running when refilling cooling system. After system is full,

continue running engine until thermostat is open, then recheck fill

level. Do not overfill system.

TESTING

THERMOSTAT

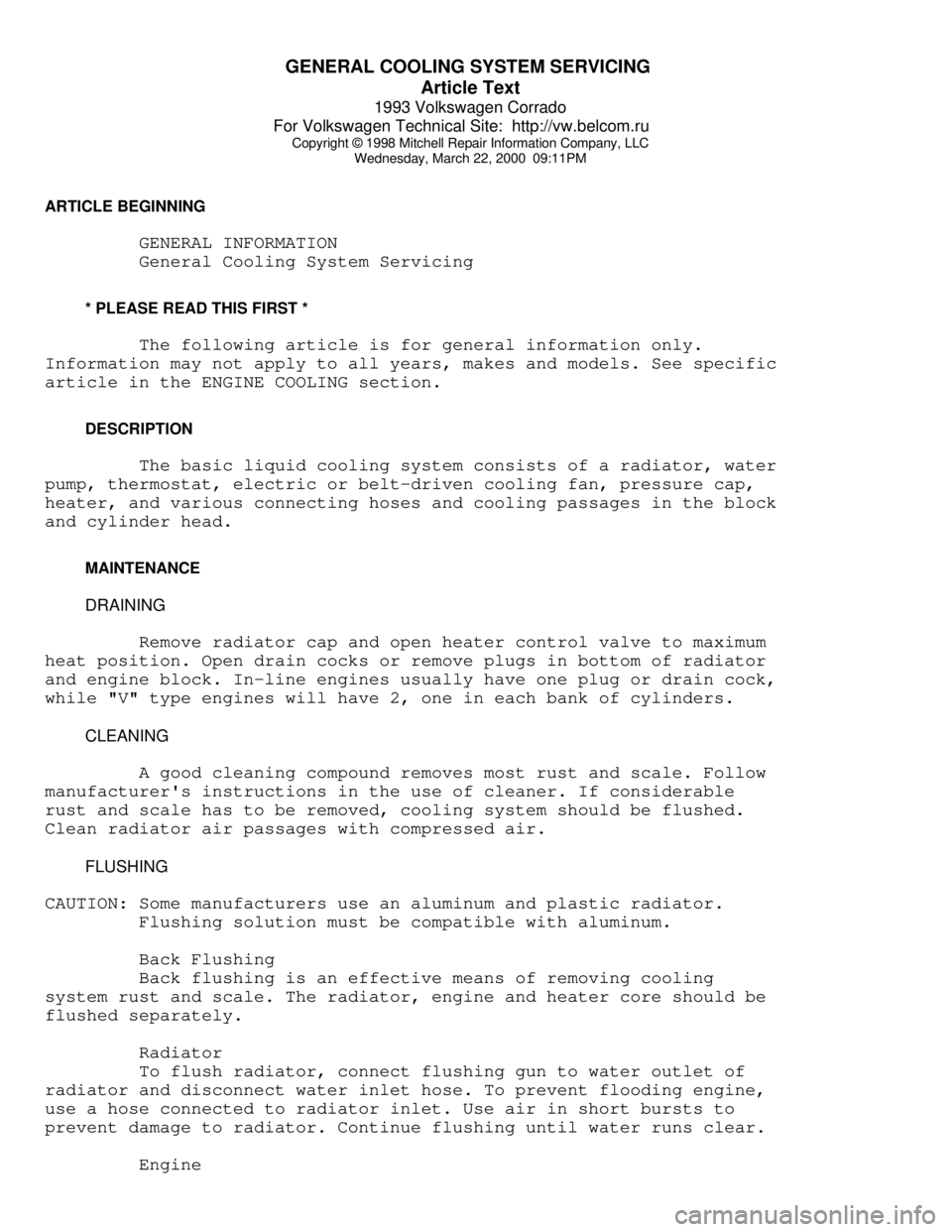

1) Visually inspect thermostat for corrosion and proper

sealing of valve and seat. If okay, suspend thermostat and thermometer

in a 50/50 mixture of coolant and water. See Fig. 1. Do not allow

thermostat or thermometer to touch bottom of container. Heat water

until thermostat just begins to open.

2) Read temperature on thermometer. This is the initial

opening temperature and should be within specification. Continue

heating water until thermostat is fully open and note temperature.

This is the fully opened temperature. If either reading is not to

specification, replace thermostat.Fig. 1: Testing Thermostat in Anti-Freeze/Water Solution

PRESSURE TESTING

A pressure tester is used to check both radiator cap and

complete cooling system. Test components as follows, following tool

Page 596 of 920

GENERAL COOLING SYSTEM SERVICING

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

manufacturer's instructions.

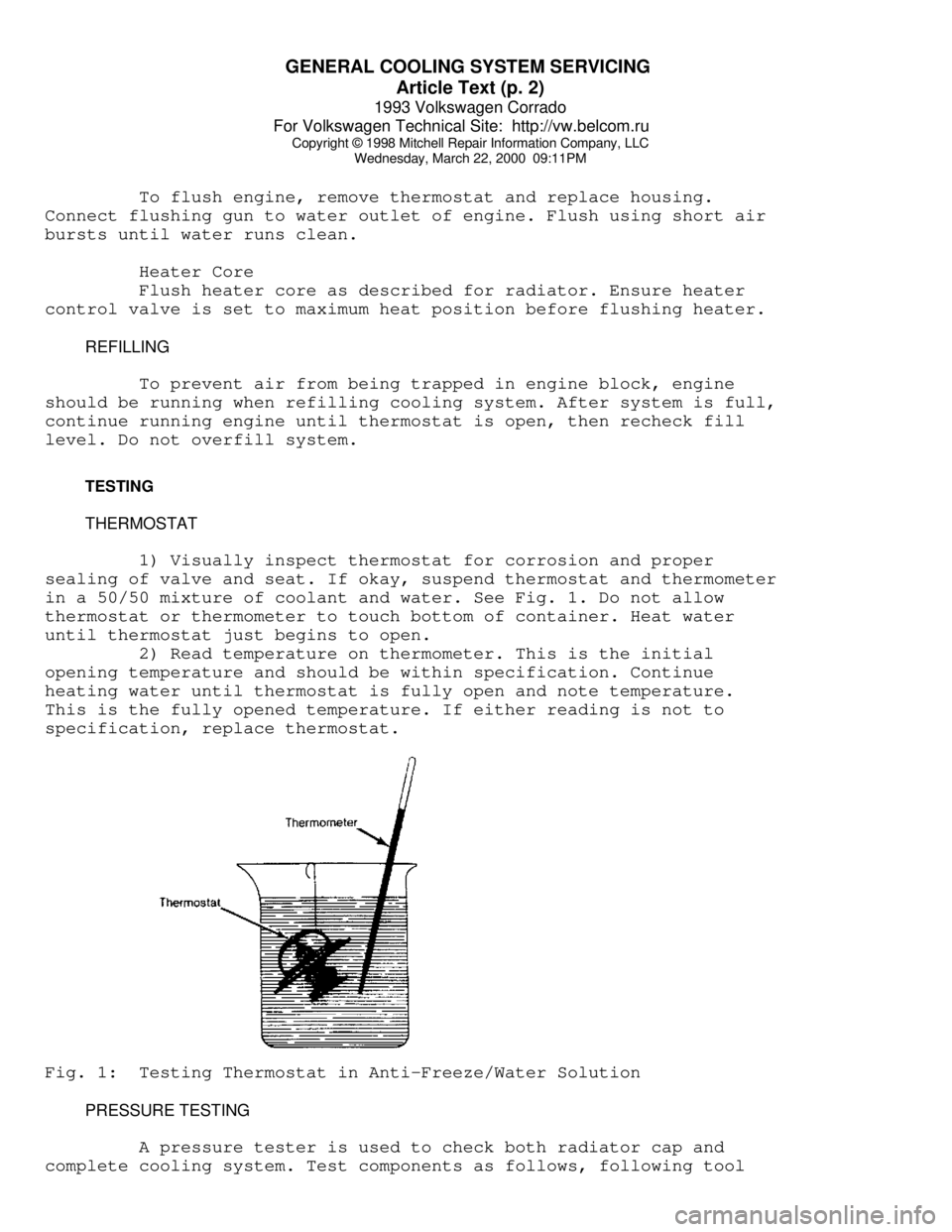

Radiator Cap

Visually inspect radiator cap, then dip cap into water and

connect to tester. Pump tester to bring pressure to upper limit of cap

specification. If cap fails to hold pressure, replace cap.Fig. 2: Testing Radiator Pressure Cap

Cooling System

1) With engine off, wipe radiator filler neck seat clean.

Fill radiator to correct level. Attach tester to radiator and pump

until pressure is at upper level of radiator rating.

2) If pressure drops, inspect for external leaks. If no leaks

are apparent, detach tester and run engine until normal operating

temperature is reached. Reattach tester and observe. If pressure

builds up immediately, a possible leak exists from a faulty head

gasket or crack in head or block.

NOTE: Pressure may build up quickly. Release any excess pressure

or cooling system damage may result.

3) If there is no immediate pressure build up, pump tester to

within system pressure range (on radiator cap). Vibration of gauge

pointer indicates compression or combustion leak into cooling system.

Isolate leak by shorting each spark plug wire to cylinder block. Gauge

pointer should stop or decrease vibration when leaking cylinder is

shorted.

END OF ARTICLE

Page 597 of 920

H - TESTS W/O CODES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Trouble Shooting - No Codes

Cabriolet, Corrado SLC, EuroVan, Fox

Golf, GTI, Jetta, Passat GL, Passat GLX

INTRODUCTION

PRELIMINARY INFORMATION

Before diagnosing symptoms or intermittent faults, perform

steps in the F - BASIC TESTING article in this section. Use this

article to diagnose driveability problems existing when a hard fault

code is not present or vehicle is not equipped with a self-diagnostic

system.

NOTE: Some driveability problems may have been corrected by

manufacturer with a revised computer calibration chip or

computer control unit. Check with manufacturer for latest

chip or computer application.

Symptom checks can direct the technician to malfunctioning

component(s) for further diagnosis. A symptom should lead to a

specific component, system test or an adjustment.

Use intermittent test procedures to locate driveability

problems that DO NOT occur when the vehicle is being tested. These

test procedures should also be used if a soft (intermittent) trouble

code was present, but no problem was found during self-diagnostic

testing.

NOTE: For specific test procedures, see the I - SYS/COMP TESTS

article in this section. For adjustment procedures, see the

appropriate D - ADJUSTMENTS article. For Engine Performance

related specifications, see appropriate C - SPECIFICATIONS

article in this section. See the following menus:

C - SPECIFICATIONS ARTICLES MENU

NOTE: For the appropriate C - SPECIFICATIONS article, go to:

* For Cabriolet, see: C - SPECIFICATIONS

* For Corrado SLC, see: C - SPECIFICATIONS

* For EuroVan, see: C - SPECIFICATIONS

* For Fox, see: C - SPECIFICATIONS

* For Golf, GTI, Jetta, see: C - SPECIFICATIONS

* For Passat, see: C - SPECIFICATIONS

D - ADJUSTMENTS ARTICLES MENU

NOTE: For the appropriate D - ADJUSTMENTS article, go to:

Page 598 of 920

H - TESTS W/O CODES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

* For Cabriolet, see: D - ADJUSTMENTS

* For Corrado SLC, see: D - ADJUSTMENTS

* For EuroVan, see: D - ADJUSTMENTS

* For Fox, see: D - ADJUSTMENTS

* For Golf, GTI, Jetta, see: D - ADJUSTMENTS

* For Passat GL 2.0L 4-Cylinder, see: D - ADJUSTMENTS - 4-CYL

* For Passat GLX 2.8L VR6, see: D - ADJUSTMENTS - VR6

I - SYS/COMP TESTS ARTICLES MENU

NOTE: For the appropriate I - SYS/COMP TESTS article, go to:

* For Cabriolet, see: I - SYSTEM/COMPONENT TESTS

* For Corrado SLC, see: I - SYSTEM/COMPONENT TESTS

* For EuroVan, see: I - SYSTEM/COMPONENT TESTS

* For Fox, see: I - SYSTEM/COMPONENT TESTS

* For Golf, GTI, Jetta, see: I - SYSTEM/COMPONENT TESTS

* For Passat GL 2.0L 4-Cylinder, see:

I - SYSTEM/COMPONENT TESTS - 4-CYL

* For Passat GLX 2.8L VR6, see:

I - SYSTEM/COMPONENT TESTS - VR6

SYMPTOMS

SYMPTOM DIAGNOSIS

Symptom checks cannot be used properly unless the problem is

actually happening while the vehicle is being tested. To reduce

diagnostic time, ensure battery voltage is okay and starter motor

turns engine over before attempting to diagnose a symptom.

Check engine mechanical condition (compression pressure,

valve timing, etc.), wiring harness and connections (terminals not

corroded or pushed back), and vacuum hose (not disconnected or

leaking).

Also check for correct tire sizes, as recommended by

manufacturer. Ensure wheels rotate freely (brake drag or bad wheel

bearings). Ensure no speed reducing accessories are installed.

Symptoms available for diagnosis include the following.

* Engine Does Not Start Or Is Difficult To Start When Cold

* Engine Does Not Start Or Is Difficult To Start When Warm

* Uneven Idle Or No Idle With Cold Engine Or During Warm-Up

* Engine Starts But Stalls

* Idle Speed Exceeds Specification

* Poor Acceleration With Cold Engine Or During Warm-Up

* Engine Stalls While Driving

* Poor Performance

* Engine Run-On (Dieseling)

* High Fuel Consumption

* Engine Knock

* Engine Runs Unevenly Over Entire Speed Range

Page 599 of 920

H - TESTS W/O CODES

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

NOTE: Symptoms listed are for CIS-E Motronic system. When working

on Digifant and Motronic systems, use symptoms listed only

as a diagnostic guide. A list of specific symptoms for

Digifant and Motronic systems is not available from

manufacturer.

ENGINE DOES NOT START OR IS DIFFICULT TO START WHEN COLD

* Check for insufficient fuel in tank.

* Check fuel pump relay and fuel pump.

* Check fuel system for leaks.

* Check auxiliary air intake system.

* Check fuel system after-start, acceleration enrichment and

warm-up circuits.

* Check cold-start valve.

* Check airflow sensor lever adjustment and control plunger.

* Check sensor plate rest position and idle circuit.

* Check fuel system differential and residual pressures.

* Check fuel injection volume.

* Check engine coolant temperature sensor.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

* Check Hall Effect sensor.

* Check ignition coil power output stage.

ENGINE DOES NOT START OR IS DIFFICULT TO START WHEN WARM

* Check radiator cooling fan after-run circuit.

* Check fuel pump check valve.

* Check fuel evaporative frequency solenoid(s).

* Check fuel system for leaks.

* Check auxiliary air intake system.

* Check idle speed.

* Check fuel system after-start, acceleration enrichment and

warm-up circuits.

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check sensor plate rest position and idle circuit.

* Check sealing ring under control plunger.

* Check fuel system differential and residual pressures.

* Check engine coolant temperature sensor.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

UNEVEN IDLE OR NO IDLE WITH COLD ENGINE OR DURING WARM-UP

* Check fuel evaporative frequency solenoid(s).

* Check fuel system for leaks.

* Check auxiliary air intake system.

* Check idle speed.

* Check oxygen sensor control circuit.

Page 600 of 920

H - TESTS W/O CODES

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check throttle potentiometer.

* Check fuel system differential and residual pressures.

* Check idle switch.

* Check engine coolant temperature sensor.

* Check exhaust system.

* Check ignition timing and spark plugs.

ENGINE STARTS BUT STALLS

* Check fuel pump relay and fuel pump.

* Check auxiliary air intake system.

* Check idle speed.

* Check fuel system after-start, acceleration enrichment and

warm-up circuits.

* Check airflow sensor lever adjustment and control plunger.

* Check sensor plate rest position and idle circuit.

* Check fuel system differential and residual pressures.

* Check idle switch.

* Check engine coolant temperature sensor.

IDLE SPEED EXCEEDS SPECIFICATION

* Check throttle cable adjustment.

* Check fuel evaporative frequency solenoid(s).

* Check auxiliary air intake system.

* Check idle speed.

* Check throttle potentiometer.

* Check idle switch.

* Check engine coolant temperature sensor.

* Check throttle body basic adjustment.

* Check ignition timing.

POOR ACCELERATION WITH COLD ENGINE OR DURING WARM-UP

* Check fuel pump.

* Check auxiliary air intake system.

* Check oxygen sensor control circuit.

* Check fuel system after-start, acceleration enrichment and

warm-up circuits.

* Check airflow sensor lever adjustment and control plunger.

* Check throttle potentiometer.

* Check fuel system differential and residual pressures.

* Check injector fuel pressure and volume.

* Check idle switch.

* Check engine coolant temperature sensor.

* Check throttle body basic adjustment.

* Check exhaust system.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

Page 601 of 920

H - TESTS W/O CODES

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ENGINE STALLS WHILE DRIVING

* Check fuel pump.

* Check auxiliary air intake system.

* Check injector fuel pressure and volume.

* Check idle and full throttle switches.

* Check intake air preheating system.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

POOR PERFORMANCE

* Check fuel pump.

* Check throttle cable adjustment.

* Check auxiliary air intake system.

* Check airflow sensor lever adjustment and control plunger.

* Check throttle potentiometer.

* Check fuel system differential and residual pressures.

* Check injector fuel pressure and volume.

* Check full throttle switch.

* Check mass airflow sensor (if equipped).

* Check intake air preheating system.

* Check catalytic converter.

* Check ignition timing.

ENGINE RUN-ON (DIESELING)

* Check fuel evaporative frequency solenoid(s).

* Check fuel system for leaks.

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check airflow sensor lever adjustment and control plunger.

HIGH FUEL CONSUMPTION

* Check fuel system for leaks.

* Check oxygen sensor control circuit.

* Check cold-start valve.

* Check injector fuel pressure and volume.

* Check airflow sensor lever adjustment and control plunger.

* Check throttle potentiometer.

* Check injector fuel pressure and volume.

* Check full throttle switch.

* Check mass airflow sensor (if equipped).

* Check intake air preheating system.

* Check exhaust system for leaks (between cylinder and

oxygen (O2) sensor).

* Check ignition timing.

ENGINE KNOCK

* Check knock sensors (if equipped).

Page 602 of 920

H - TESTS W/O CODES

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

* Check full throttle switch.

* Check ignition timing.

ENGINE RUNS UNEVENLY OVER ENTIRE SPEED RANGE

* Check auxiliary air intake system.

* Check injector fuel pressure and volume.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

INTERMITTENTS

INTERMITTENT PROBLEM DIAGNOSIS

Intermittent fault testing requires duplicating circuit or

component failure to identify the problem. These procedures may lead

to the computer setting a fault code (on some systems) which may help

in diagnosis.

If problem vehicle does not produce fault codes, monitor

voltage or resistance values using a DVOM while attempting to

reproduce conditions causing intermittent fault. A status change on

DVOM indicates a fault has been located.

Use a DVOM to pinpoint faults. When monitoring voltage,

ensure ignition switch is in ON position or engine is running. Ensure

ignition switch is in OFF position or negative battery cable is

disconnected when monitoring circuit resistance. Status changes on

DVOM during test procedures indicate area of fault.

TEST PROCEDURES

Intermittent Simulation

To reproduce the conditions creating an intermittent fault,

use the following methods:

* Lightly vibrate component.

* Heat component.

* Wiggle or bend wiring harness.

* Spray component with water.

* Remove/apply vacuum source.

Monitor circuit/component voltage or resistance while

simulating intermittent. If engine is running, monitor for self-

diagnostic codes. Use the test results to identify a faulty component

or circuit. For system or component testing refer to the appropriate

I - SYS/COMP TESTS article in this section. See the menu below:

* For Cabriolet, see: I - SYSTEM/COMPONENT TESTS

* For Corrado SLC, see: I - SYSTEM/COMPONENT TESTS

* For EuroVan, see: I - SYSTEM/COMPONENT TESTS

* For Fox, see: I - SYSTEM/COMPONENT TESTS

* For Golf, GTI, Jetta, see: I - SYSTEM/COMPONENT TESTS

* For Passat GL 2.0L 4-Cylinder, see:

Page 607 of 920

HOW TO USE SYSTEM WIRING DIAGRAMS

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

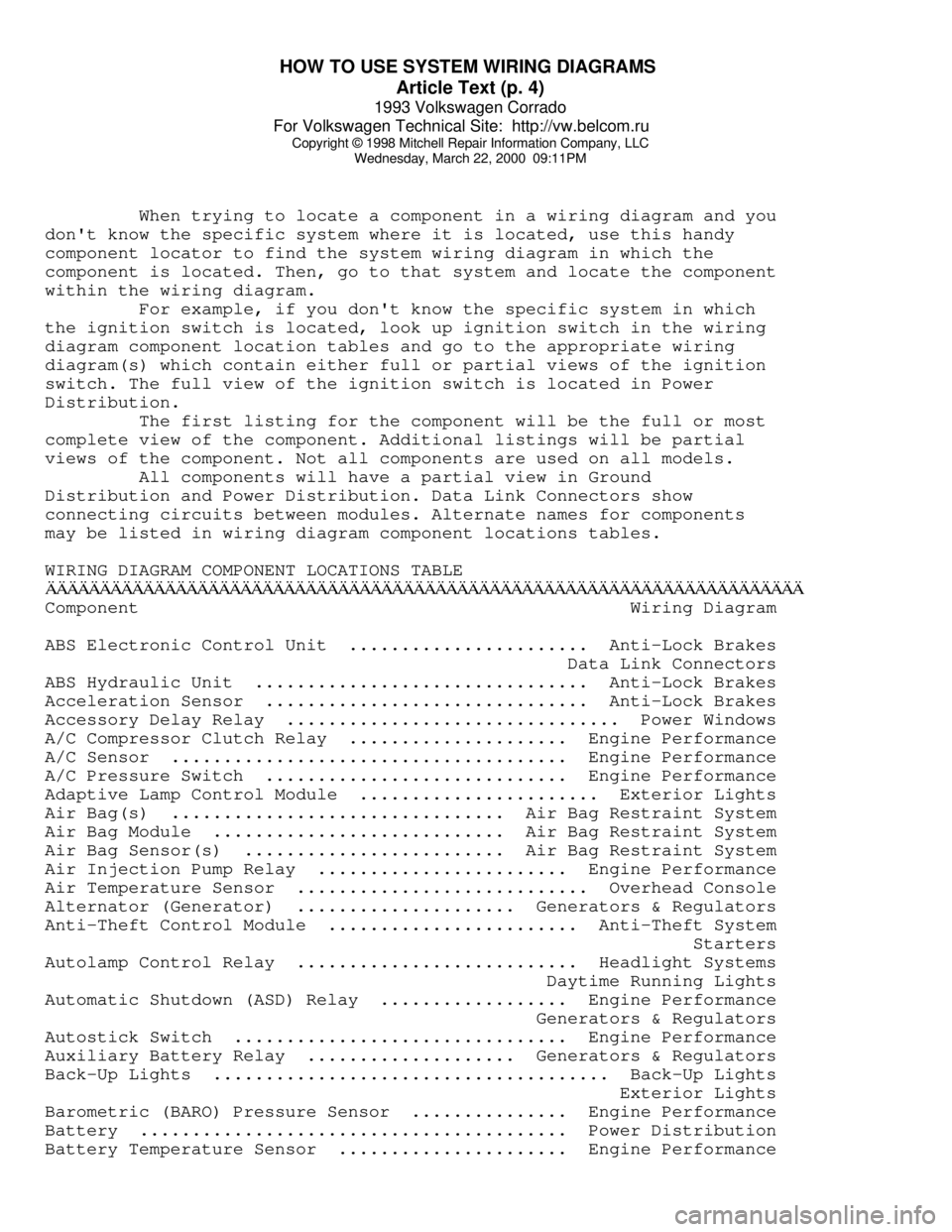

When trying to locate a component in a wiring diagram and you

don't know the specific system where it is located, use this handy

component locator to find the system wiring diagram in which the

component is located. Then, go to that system and locate the component

within the wiring diagram.

For example, if you don't know the specific system in which

the ignition switch is located, look up ignition switch in the wiring

diagram component location tables and go to the appropriate wiring

diagram(s) which contain either full or partial views of the ignition

switch. The full view of the ignition switch is located in Power

Distribution.

The first listing for the component will be the full or most

complete view of the component. Additional listings will be partial

views of the component. Not all components are used on all models.

All components will have a partial view in Ground

Distribution and Power Distribution. Data Link Connectors show

connecting circuits between modules. Alternate names for components

may be listed in wiring diagram component locations tables.

WIRING DIAGRAM COMPONENT LOCATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Wiring Diagram

ABS Electronic Control Unit ....................... Anti-Lock Brakes

Data Link Connectors

ABS Hydraulic Unit ................................ Anti-Lock Brakes

Acceleration Sensor ............................... Anti-Lock Brakes

Accessory Delay Relay ................................ Power Windows

A/C Compressor Clutch Relay ..................... Engine Performance

A/C Sensor ...................................... Engine Performance

A/C Pressure Switch ............................. Engine Performance

Adaptive Lamp Control Module ....................... Exterior Lights

Air Bag(s) ................................ Air Bag Restraint System

Air Bag Module ............................ Air Bag Restraint System

Air Bag Sensor(s) ......................... Air Bag Restraint System

Air Injection Pump Relay ........................ Engine Performance

Air Temperature Sensor ............................ Overhead Console

Alternator (Generator) ..................... Generators & Regulators

Anti-Theft Control Module ........................ Anti-Theft System

Starters

Autolamp Control Relay ........................... Headlight Systems

Daytime Running Lights

Automatic Shutdown (ASD) Relay .................. Engine Performance

Generators & Regulators

Autostick Switch ................................ Engine Performance

Auxiliary Battery Relay .................... Generators & Regulators

Back-Up Lights ...................................... Back-Up Lights

Exterior Lights

Barometric (BARO) Pressure Sensor ............... Engine Performance

Battery ......................................... Power Distribution

Battery Temperature Sensor ...................... Engine Performance