technical data VOLKSWAGEN CORRADO 1993 Owner's Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 656 of 920

MAINTENANCE INFORMATION

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

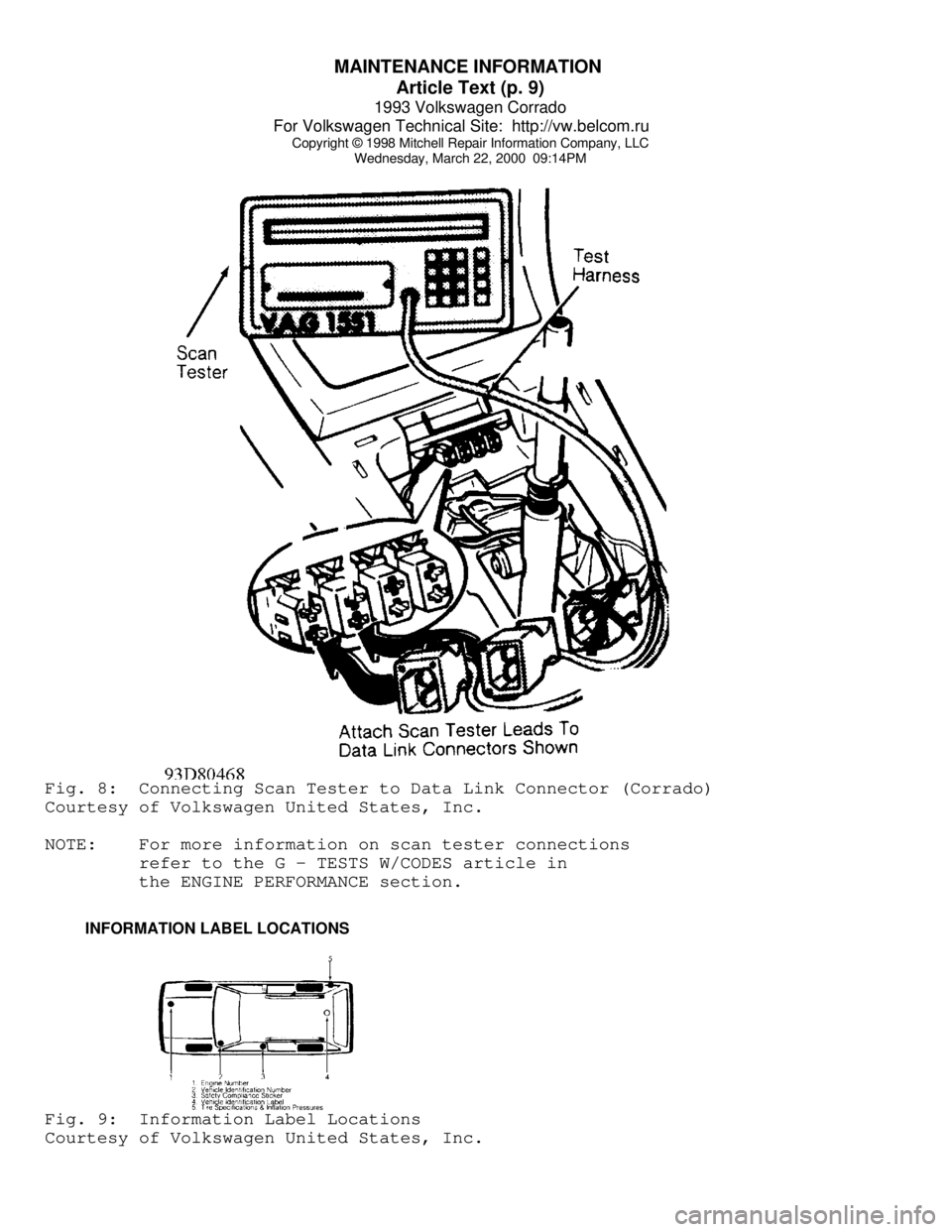

Wednesday, March 22, 2000 09:14PMFig. 8: Connecting Scan Tester to Data Link Connector (Corrado)

Courtesy of Volkswagen United States, Inc.

NOTE: For more information on scan tester connections

refer to the G - TESTS W/CODES article in

the ENGINE PERFORMANCE section.

INFORMATION LABEL LOCATIONSFig. 9: Information Label Locations

Courtesy of Volkswagen United States, Inc.

Page 658 of 920

MAINTENANCE INFORMATION

Article Text (p. 11)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:14PM

Application Quantity (1)

A/C System R-12 Refrigerant

1990-92 (up to 7/92) ............................. 37-40 Ozs.

A/C System R-134a Refrigerant (2)

1993-94 (from 7/92) ........................... 28.2-31.8 Ozs.

Cooling System

4-Cyl. ...................................... 6.8 Qts. (6.5L)

V6 .......................................... 9.1 Qts. (8.6L)

Engine Oil (3)

4-Cyl. ...................................... 4.3 Qts. (4.0L)

V6 .......................................... 6.3 Qts. (6.0L)

Fuel Tank

4-Cyl. ..................................... 14.5 Gals. (55L)

V6 ......................................... 18.5 Gals. (55L)

Automatic Transmission

Fluid Change ................................ 3.2 Qts. (3.0L)

Overhaul .................................... 5.9 Qts. (5.6L)

Manual Transmission ........................... 2.1 Qts. (2.0L)

Final Drive

Differential (A/T) (4) ....................... 0.8 Qt. (.75L)

(1) - Capacities are recommended or calculated levels. Always use

dipstick (if available) to measure level.

(2) - Use of R-12 in a R134a system will result in SEVERE DAMAGE.

(3) - Includes oil filter change.

(4) - Lifetime fill.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WHEEL & TIRE SPECIFICATIONS

Wheel and tire sizes vary according to vehicle and equipment

and can be found on tire information label on each vehicle. Wheel and

tire specifications and tire inflation pressures are listed on a label

found inside fuel tank flap.

NOTE: Snow chains must be used on drive wheels, in pairs only.

WHEEL TIGHTENING

Tighten all wheel lugs to 80 ft. lbs. (110 N.m).

BATTERY SPECIFICATIONS

CAUTION: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in the GENERAL INFORMATION

section.

All models use BCI group 41 batteries with cold crank rating

Page 678 of 920

N - REMOVE/INSTALL/OVERHAUL

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:21PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Removal, Overhaul & Installation

Corrado SLC

CAUTION: When battery is disconnected, vehicle computer and memory

systems may lose memory data. Driveability problems may

exist until computer systems have completed a relearn

cycle. See the COMPUTER RELEARN PROCEDURES article in

GENERAL INFORMATION before disconnecting battery.

INTRODUCTION

Removal, overhaul and installation procedures are covered in

this article. If component removal and installation is primarily an

unbolt and bolt-on procedure, only a torque specification may be

furnished.

CAUTION: When disconnecting battery, obtain and record radio

anti-theft code. If wrong code is entered into radio after

power is restored, radio will become inoperable.

IGNITION SYSTEM

NOTE: Corrado SLC ignition system removal and installation

information not available from manufacturer. These vehicles

are equipped with a distributorless ignition system.

DISTRIBUTOR

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

To relieve fuel system pressure, remove fuel pump fuse (No.

5, 13 or 18) or fuel pump relay to deactivate fuel pump. Place a clean

shop rag around fuel line fitting and slowly loosen fitting.

WARNING: Fuel system pressure release procedure is not available

from manufacturer. Fuel will discharge when disconnecting

fuel system components. Disconnect ignition coil output

stage wiring harness to deactivate ignition. DO NOT smoke

or work near heaters or other fire hazards. Keep a fire

extinguisher handy.

FUEL PUMP

Removal & Installation (Corrado SLC)

1) Obtain and record radio anti-theft code. Disconnect

Page 684 of 920

SCHEDULED SERVICES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:22PM

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR BAR WARNING

NOTE: For information on air bag DIAGNOSIS & TESTING or DISPOSAL

PROCEDURES, see AIR BAGS article in the ACCESSORIES/SAFETY

EQUIPMENT Section.

System circuit is grounded by 2 screws beneath the driver's

seat. DO NOT use these screws to ground any other accessory. DO NOT

ground any other components near this system.

AIR CONDITIONING SERVICING (1993 & LATER)

CAUTION: Avoid breathing R-134a refrigerant and PAG lubricant vapors,

exposure may irritate eyes, nose and throat. To remove

R-134a from system use R-134a recycling equipment that meets

SAE J2210 specifications. If accidental system discharge

occurs, ventilate work area before resuming service.

WARNING: R-134a service equipment or vehicle A/C systems SHOULD NOT

be pressure tested or leak tested with compressed air. Some

mixtures of air/R134a have shown to be combustible at

elevated pressures. These mixtures are dangerous and may

cause fire and/or explosions. See AIR CONDITIONING SERVICE

article in GENERAL INFORMATION section.

ANTI-LOCK BRAKE SYSTEM

The anti-lock brake system contains electronic equipment that

can be susceptible to interference caused by improperly installed or

high output radio transmitting equipment. Since this interference

could cause the possible loss of the anti-lock braking capability,

such equipment should be installed by qualified professionals.

On models equipped with anti-lock brake systems, ALWAYS

observe the following cautions:

* DO NOT attempt to bleed hydraulic system without first

referring to the appropriate ANTI-LOCK BRAKE SYSTEM article

in the BRAKES Section.

* DO NOT mix tire sizes. As long as tires remain close to the

original diameter, increasing the width is acceptable.

Rolling diameter must be identical for all 4 tires. Some

manufacturers recommend tires of the same brand, style and

type. Failure to follow this precaution may cause inaccurate

wheel speed readings.

* Use ONLY recommended brake fluids. DO NOT use silicone brake

fluids in an ABS-equipped vehicle.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

Page 690 of 920

SCHEDULED SERVICES

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

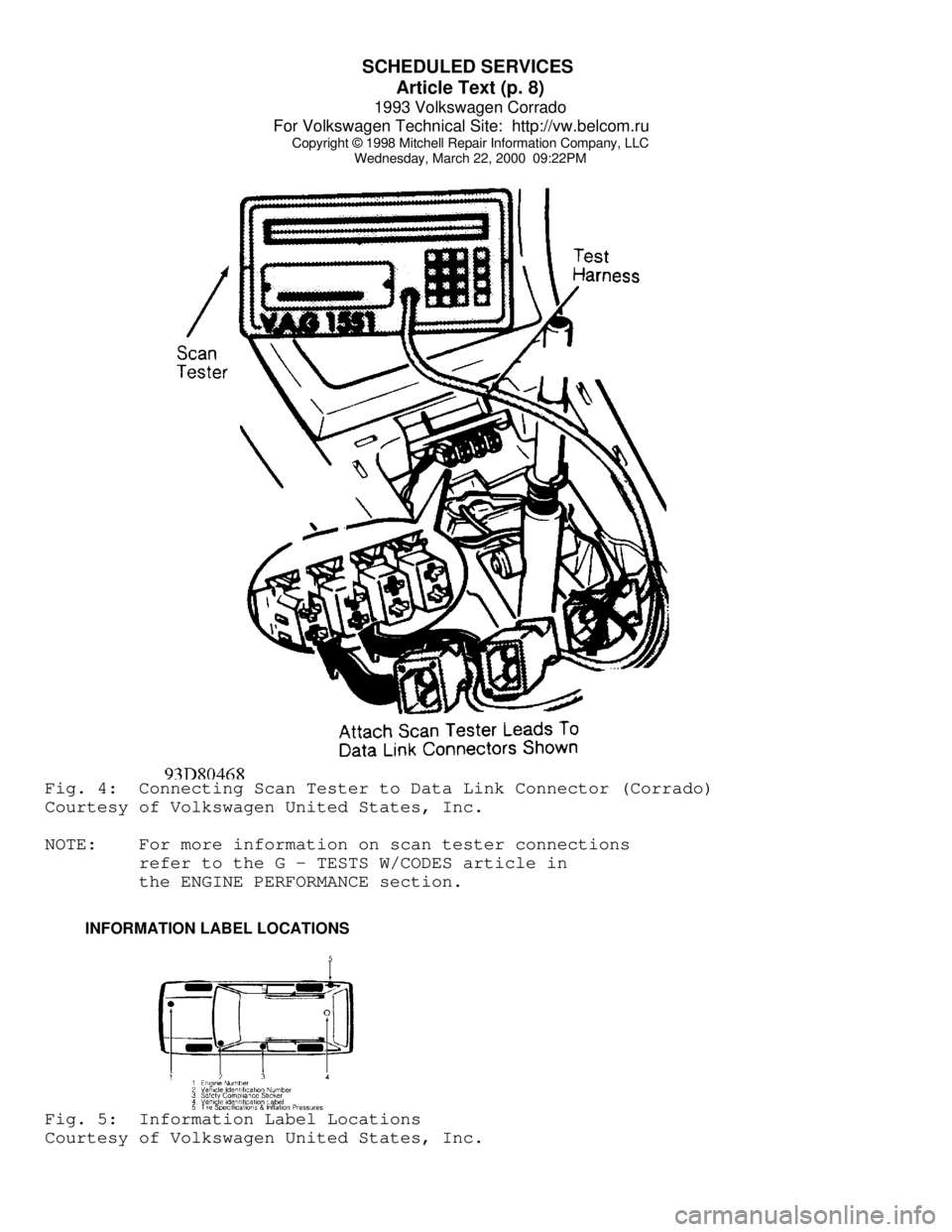

Wednesday, March 22, 2000 09:22PMFig. 4: Connecting Scan Tester to Data Link Connector (Corrado)

Courtesy of Volkswagen United States, Inc.

NOTE: For more information on scan tester connections

refer to the G - TESTS W/CODES article in

the ENGINE PERFORMANCE section.

INFORMATION LABEL LOCATIONSFig. 5: Information Label Locations

Courtesy of Volkswagen United States, Inc.

Page 725 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

fan is not coming on at proper temperature and engine is

overheating.

Corrado SLC, Passat GLX

The cooling fan is either a 1 or 2-speed motor. If vehicle is

equipped with single-speed motor, the fan comes on at 198-207øF (92-

97

øC) and turns off at 183-196øF (84-91øC). If equipped with a 2-speed

motor, low speed of cooling fan should come on at 198-208

øF (92-98øC)

on vehicles without A/C, or 183-207

øF (84-97øC) on vehicles with A/C.

Low speed will shut off at 183-196

øF (84-91øC) on all vehicles. High

speed comes on at 210-226

øF (99-108øC) on vehicles without A/C, or

201-226

øF (94-108øC) on vehicles with A/C. High speed will shut off at

196-220

øF (91-104øC) on all vehicles.

After-Run Thermoswitch

An after-run switch is used to help prevent fuel

vaporization. The thermoswitch turns cooling fan on when temperatures

in engine compartment exceeds 230

øF (110øC), and turns it off at 217øF

(103

øC).

Passat GL

The cooling fan is a 2-speed motor. Low speed of cooling fan

should come on at 198-207

øF (92-97øC) and will shut off at 183-196øF

(84-91

øC). High speed comes on at 210-221øF (99-105øC) and will shut

off at 196-208

øF (91-98øC).

TROUBLE SHOOTING

NOTE: Trouble shooting information not available from manufacturer.

TESTING

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Corrado SLC & Passat GLX (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 01 and read coolant

temperature value in field No. 2 of scan tester. Temperature value

must increase uniformly without interruption. If value increases as

specified, select END OUTPUT function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ECT SENSOR

LOCATION table. Replace ECT sensor if resistance is not within

specification. See ECT SENSOR RESISTANCE table.

Passat GL

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console. Start engine and

Page 761 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Osnabrueck, Germany

5. Evaluation of Emissions and Driveability of the Defect:

Not Applicable.

6. Available Emissions Data:

Not Applicable.

7. Anticipated Follow-Up Action:

VWoA will recall all affected vehicles and instruct dealers to

affix a new label in addition to performing safety recall work.

The details of the safety recall have been reported to the

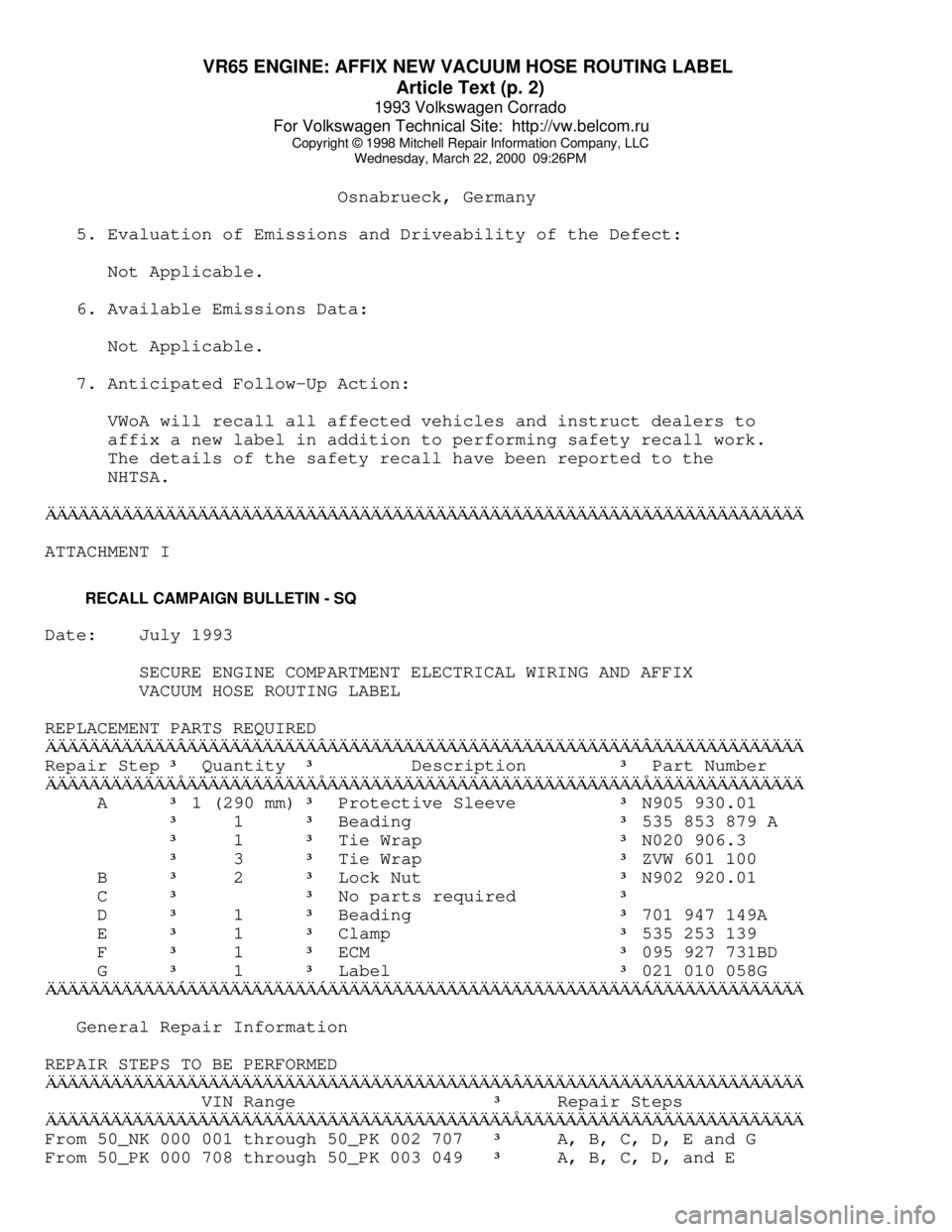

NHTSA.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄATTACHMENT I

RECALL CAMPAIGN BULLETIN - SQ

Date: July 1993

SECURE ENGINE COMPARTMENT ELECTRICAL WIRING AND AFFIX

VACUUM HOSE ROUTING LABEL

REPLACEMENT PARTS REQUIRED

ÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄRepair Step

³ Quantity ³ Description ³ Part Number

ÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄ A

³ 1 (290 mm) ³ Protective Sleeve ³ N905 930.01

³ 1 ³ Beading ³ 535 853 879 A

³ 1 ³ Tie Wrap ³ N020 906.3

³ 3 ³ Tie Wrap ³ ZVW 601 100

B

³ 2 ³ Lock Nut ³ N902 920.01

C

³ ³ No parts required ³ D

³ 1 ³ Beading ³ 701 947 149A

E

³ 1 ³ Clamp ³ 535 253 139

F

³ 1 ³ ECM ³ 095 927 731BD

G

³ 1 ³ Label ³ 021 010 058G

ÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄ General Repair Information

REPAIR STEPS TO BE PERFORMED

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VIN Range

³ Repair Steps

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFrom 50_NK 000 001 through 50_PK 002 707

³ A, B, C, D, E and G

From 50_PK 000 708 through 50_PK 003 049

³ A, B, C, D, and E

Page 770 of 920

VR65 ENGINE: AFFIX NEW VACUUM HOSE ROUTING LABEL

Article Text (p. 11)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

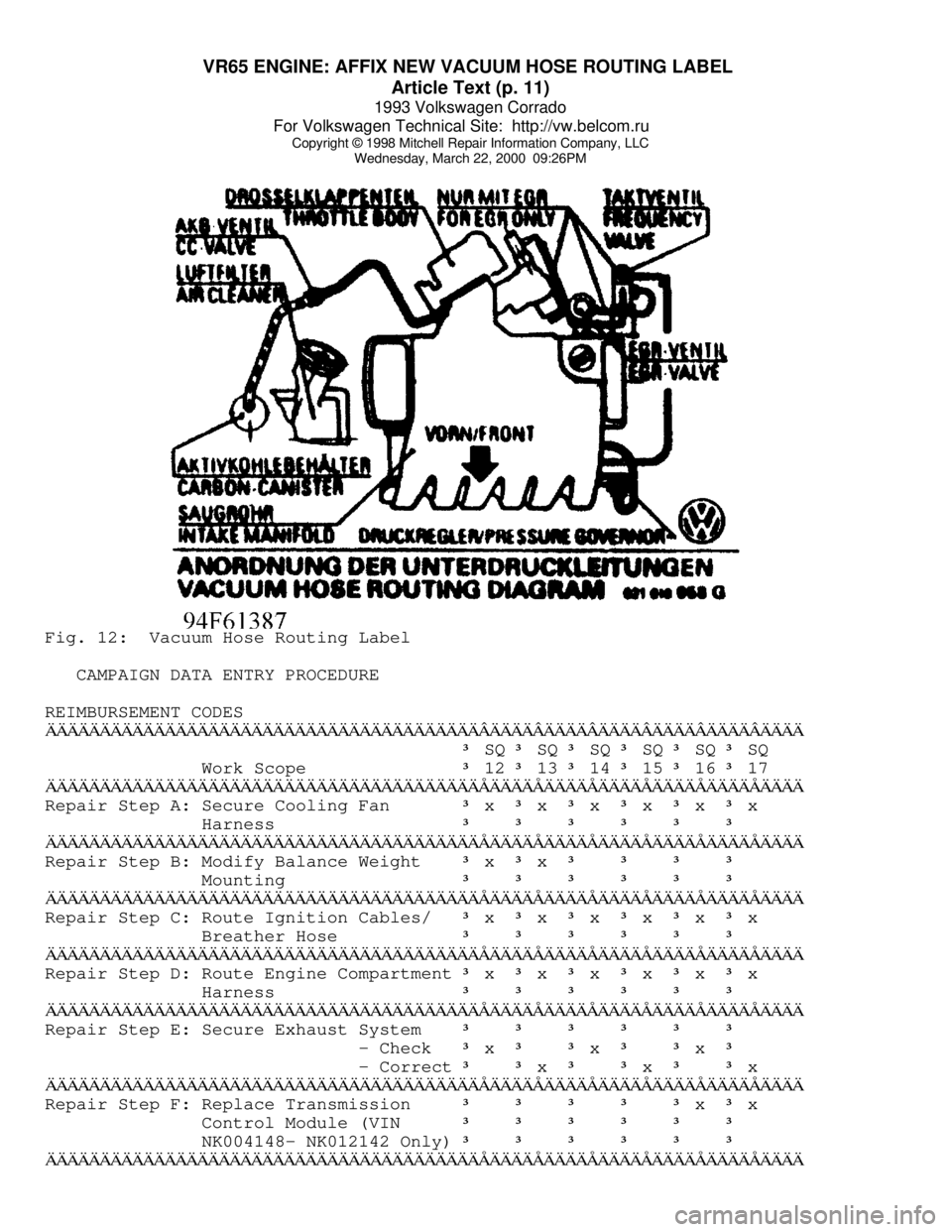

Wednesday, March 22, 2000 09:26PMFig. 12: Vacuum Hose Routing Label

CAMPAIGN DATA ENTRY PROCEDURE

REIMBURSEMENT CODESÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÂÄÄÄÄÂÄÄÄÄÂÄÄÄÄÂÄÄÄÄÂÄÄÄÄ

³ SQ ³ SQ ³ SQ ³ SQ ³ SQ ³ SQ

Work Scope

³ 12 ³ 13 ³ 14 ³ 15 ³ 16 ³ 17

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step A: Secure Cooling Fan

³ x ³ x ³ x ³ x ³ x ³ x

Harness

³ ³ ³ ³ ³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step B: Modify Balance Weight

³ x ³ x ³ ³ ³ ³ Mounting

³ ³ ³ ³ ³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step C: Route Ignition Cables/

³ x ³ x ³ x ³ x ³ x ³ x

Breather Hose

³ ³ ³ ³ ³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step D: Route Engine Compartment

³ x ³ x ³ x ³ x ³ x ³ x

Harness

³ ³ ³ ³ ³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step E: Secure Exhaust System

³ ³ ³ ³ ³ ³ - Check

³ x ³ ³ x ³ ³ x ³ - Correct

³ ³ x ³ ³ x ³ ³ x

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄRepair Step F: Replace Transmission

³ ³ ³ ³ ³ x ³ x

Control Module (VIN

³ ³ ³ ³ ³ ³ NK004148- NK012142 Only)

³ ³ ³ ³ ³ ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄÅÄÄÄÄ

Page 866 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

everything together it does not miss anything (though this is also a

severe weakness that we will look at later). If an injector has a

fault where it occasionally skips a pulse, the meter registers it and

the reading changes accordingly.

Let's go back to figuring out dwell/duty readings by using

injector on-time specification. This is not generally practical, but

we will cover it for completeness. You NEED to know three things:

* Injector mS on-time specification.

* Engine RPM when specification is valid.

* How many times the injectors fire per crankshaft revolution.

The first two are self-explanatory. The last one may require

some research into whether it is a bank-fire type that injects every

360ø of crankshaft rotation, a bank-fire that injects every 720ø, or

an SFI that injects every 720

ø. Many manufacturers do not release this

data so you may have to figure it out yourself with a frequency meter.

Here are the four complete steps to convert millisecond on-

time:

1) Determine the injector pulse width and RPM it was obtained

at. Let's say the specification is for one millisecond of on-time at a

hot idle of 600 RPM.

2) Determine injector firing method for the complete 4 stroke

cycle. Let's say this is a 360

ø bank-fired, meaning an injector fires

each and every crankshaft revolution.

3) Determine how many times the injector will fire at the

specified engine speed (600 RPM) in a fixed time period. We will use

100 milliseconds because it is easy to use.

Six hundred crankshaft Revolutions Per Minute (RPM) divided

by 60 seconds equals 10 revolutions per second.

Multiplying 10 times .100 yields one; the crankshaft turns

one time in 100 milliseconds. With exactly one crankshaft rotation in

100 milliseconds, we know that the injector fires exactly one time.

4) Determine the ratio of injector on-time vs. off-time in

the fixed time period, then figure duty cycle and/or dwell. The

injector fires one time for a total of one millisecond in any given

100 millisecond period.

One hundred minus one equals 99. We have a 99% duty cycle. If

we wanted to know the dwell (on 6 cylinder scale), multiple 99% times

.6; this equals 59.4

ø dwell.

Weaknesses of Dwell/Duty Meter

The weaknesses are significant. First, there is no one-to-one

correspondence to actual mS on-time. No manufacturer releases

dwell/duty data, and it is time-consuming to convert the mS on-time

readings. Besides, there can be a large degree of error because the

conversion forces you to assume that the injector(s) are always firing

at the same rate for the same period of time. This can be a dangerous

assumption.

Second, all level of detail is lost in the averaging process.

This is the primary weakness. You cannot see the details you need to

make a confident diagnosis.