clock VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 87 of 920

* ELECTRICAL SYSTEM UNIFORM INSPECTION GUIDELINES *

Article Text (p. 22)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:34PMÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CLOCK

CLOCK

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing, damaged mounting hardware

³ Require repair or replacement

³ of mounting hardware.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged (e.g., melted, burned,

³ Suggest repair or replacement.

cracked, etc.)

³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CIGARETTE LIGHTER/SOCKET/ELEMENT

CIGARETTE LIGHTER/SOCKET/ELEMENT

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄInoperative, intermittent

³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCorroded, loose terminals

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing

³ Suggest replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing, damaged mounting hardware

³ Require repair or replacement

³ of mounting hardware.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDamaged

³ Suggest repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CRUISE CONTROL/LINKAGE/CABLES

CRUISE CONTROL/LINKAGE/CABLES

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure ³ Note

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄMissing

³ Require replacement. ³

Page 338 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

BOSCH 6-CYLINDER CLUTCH COIL R & I

Removal

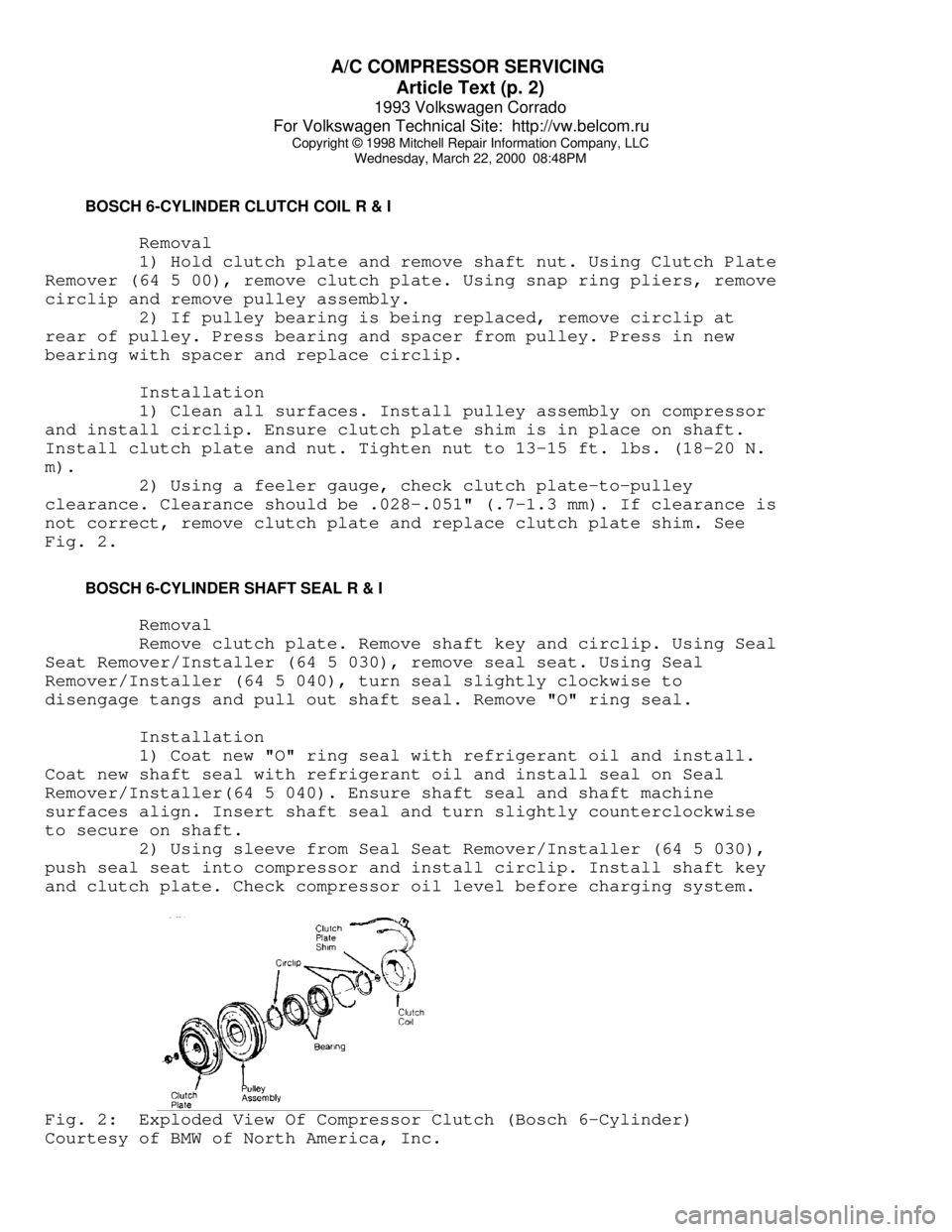

1) Hold clutch plate and remove shaft nut. Using Clutch Plate

Remover (64 5 00), remove clutch plate. Using snap ring pliers, remove

circlip and remove pulley assembly.

2) If pulley bearing is being replaced, remove circlip at

rear of pulley. Press bearing and spacer from pulley. Press in new

bearing with spacer and replace circlip.

Installation

1) Clean all surfaces. Install pulley assembly on compressor

and install circlip. Ensure clutch plate shim is in place on shaft.

Install clutch plate and nut. Tighten nut to 13-15 ft. lbs. (18-20 N.

m).

2) Using a feeler gauge, check clutch plate-to-pulley

clearance. Clearance should be .028-.051" (.7-1.3 mm). If clearance is

not correct, remove clutch plate and replace clutch plate shim. See

Fig. 2.

BOSCH 6-CYLINDER SHAFT SEAL R & I

Removal

Remove clutch plate. Remove shaft key and circlip. Using Seal

Seat Remover/Installer (64 5 030), remove seal seat. Using Seal

Remover/Installer (64 5 040), turn seal slightly clockwise to

disengage tangs and pull out shaft seal. Remove "O" ring seal.

Installation

1) Coat new "O" ring seal with refrigerant oil and install.

Coat new shaft seal with refrigerant oil and install seal on Seal

Remover/Installer(64 5 040). Ensure shaft seal and shaft machine

surfaces align. Insert shaft seal and turn slightly counterclockwise

to secure on shaft.

2) Using sleeve from Seal Seat Remover/Installer (64 5 030),

push seal seat into compressor and install circlip. Install shaft key

and clutch plate. Check compressor oil level before charging system.Fig. 2: Exploded View Of Compressor Clutch (Bosch 6-Cylinder)

Courtesy of BMW of North America, Inc.

Page 341 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

DIESEL KIKI 6-CYLINDER CLUTCH COIL R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal & Installation

1) Using Clutch Holder (J-33939) to prevent clutch disc from

rotating, remove shaft bolt. Using Clutch Disc Puller (J-33944-A) and

Forcing Bolt (J-33944-4), remove clutch disc. Remove shim(s) from

compressor drive shaft or clutch disc. See Fig. 5.

2) Remove snap ring, cover and pulley. With Puller Guide (J-

33943-A) in center of pulley, attach Crossbar (J-8433) to outside

diameter of pulley. Tighten crossbar bolt against puller guide to

remove pulley. Remove coil lead, screws, and coil.

3) To install, reverse removal procedure. Install cover snap

ring with beveled side facing out. Install clutch disc and tighten

center bolt to 133 INCH lbs. (15 N.m).

4) Using feeler gauge, ensure clearance between clutch disc

and pulley is .012-.024" (.30-.60 mm). If clearance is incorrect, add

or remove shim(s) as necessary.

DIESEL KIKI SHAFT SEAL R & I

Removal & Installation

1) Remove clutch coil. Remove and discard felt. Using Shaft

Seal Cover Remover/Installer (J-33942), push down and turn remover

clockwise to engage tangs to cover. Slowly remove seal cover from

bore.

2) Remove shaft seal snap ring. Use Shaft Seal Remover (J-

33942-B) to remove seal. Remove compressor through bolts, front head

and "O" ring. If necessary, replace front and rear valve plates, reed

valves, and "O" rings.

3) To install, reverse removal procedure. Coat "O" ring,

shaft seal and seal seat with refrigerant oil. Place Shaft Seal Guide

(J-34614) over end of compressor shaft. Ensure chamfered portion of

shaft seal retainer aligns with chamfered portion on compressor shaft.

4) Install front head and tighten compressor through bolts,

in a crisscross pattern, to 16 ft. lbs. (22 N.m). Install shaft seal

cover and felt. See Fig. 5. Rotate compressor drive shaft 2-3 times to

ensure compressor operates smoothly.

Page 343 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

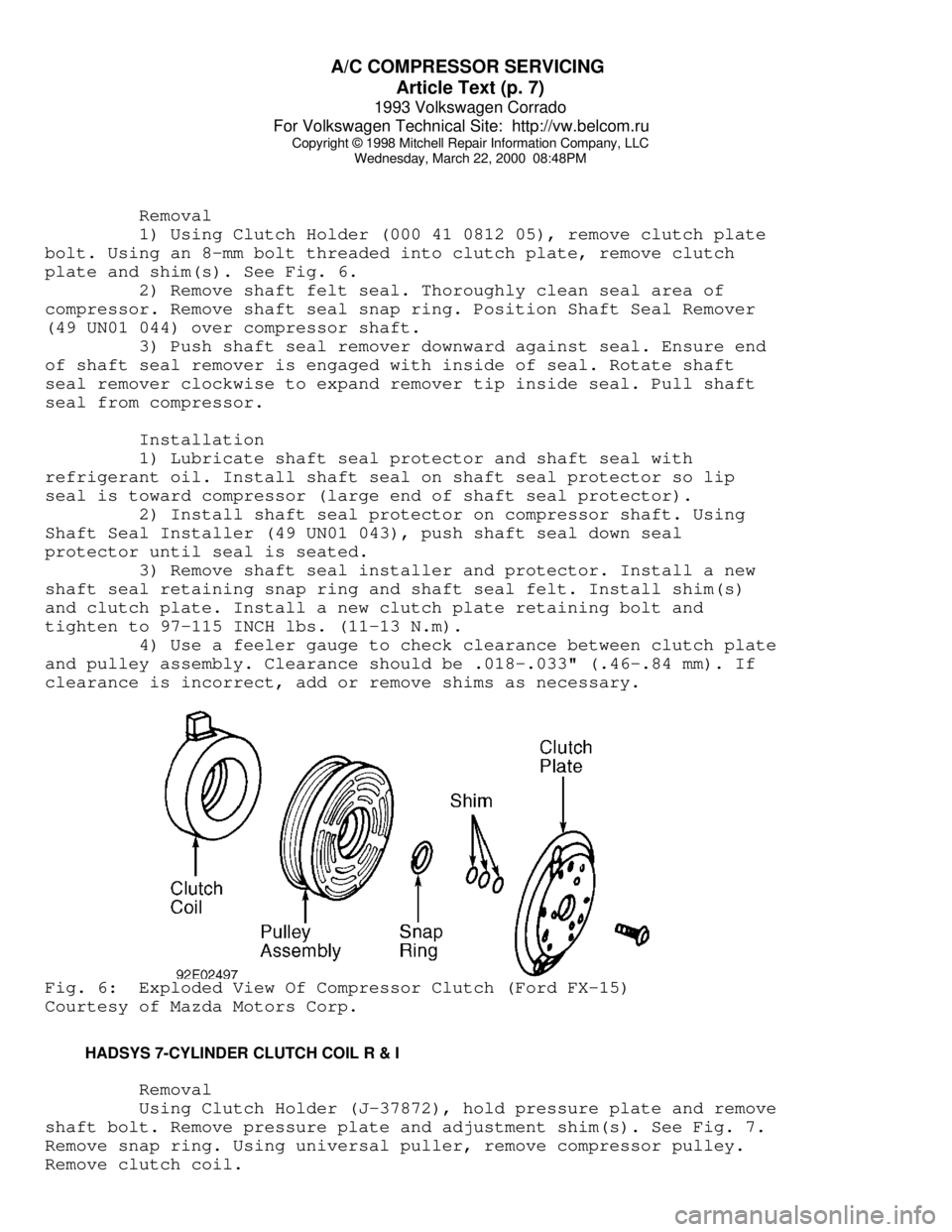

Removal

1) Using Clutch Holder (000 41 0812 05), remove clutch plate

bolt. Using an 8-mm bolt threaded into clutch plate, remove clutch

plate and shim(s). See Fig. 6.

2) Remove shaft felt seal. Thoroughly clean seal area of

compressor. Remove shaft seal snap ring. Position Shaft Seal Remover

(49 UN01 044) over compressor shaft.

3) Push shaft seal remover downward against seal. Ensure end

of shaft seal remover is engaged with inside of seal. Rotate shaft

seal remover clockwise to expand remover tip inside seal. Pull shaft

seal from compressor.

Installation

1) Lubricate shaft seal protector and shaft seal with

refrigerant oil. Install shaft seal on shaft seal protector so lip

seal is toward compressor (large end of shaft seal protector).

2) Install shaft seal protector on compressor shaft. Using

Shaft Seal Installer (49 UN01 043), push shaft seal down seal

protector until seal is seated.

3) Remove shaft seal installer and protector. Install a new

shaft seal retaining snap ring and shaft seal felt. Install shim(s)

and clutch plate. Install a new clutch plate retaining bolt and

tighten to 97-115 INCH lbs. (11-13 N.m).

4) Use a feeler gauge to check clearance between clutch plate

and pulley assembly. Clearance should be .018-.033" (.46-.84 mm). If

clearance is incorrect, add or remove shims as necessary.Fig. 6: Exploded View Of Compressor Clutch (Ford FX-15)

Courtesy of Mazda Motors Corp.

HADSYS 7-CYLINDER CLUTCH COIL R & I

Removal

Using Clutch Holder (J-37872), hold pressure plate and remove

shaft bolt. Remove pressure plate and adjustment shim(s). See Fig. 7.

Remove snap ring. Using universal puller, remove compressor pulley.

Remove clutch coil.

Page 357 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 21)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

cylinder head bolts, in a crisscross pattern, to 21-29 ft. lbs. (29-39

N.m).

SANDEN 5-CYLINDER SHAFT SEAL R & I

Removal

Remove shaft nut and clutch plate. Remove shaft key and

shim(s). Carefully remove felt ring. Remove shaft seal seat snap ring.

Using Seal Seat Remover/Installer (0000-41-0810-73), carefully remove

seal seat. Using Shaft Seal Remover/Installer (0000-41-0812-11),

carefully remove shaft seal.

Installation

1) Install Seal Protector (0000-41-0812-13) over shaft. Place

new seal on remover/installer. DO NOT touch carbon sealing surface

with fingers. Dip seal in refrigerant oil and install. Remove seal

installer by turning counterclockwise.

2) Coat seal seat with refrigerant oil. Install seal seat

using remover/installer. Install seal seat snap ring (with flat side

down). Install shim(s), felt ring and shaft key. Install shaft nut and

clutch plate. Ensure clearance between clutch plate and pulley is .

016-.032" (.40-.80 mm). If clearance is incorrect, add or remove

shim(s) as necessary.

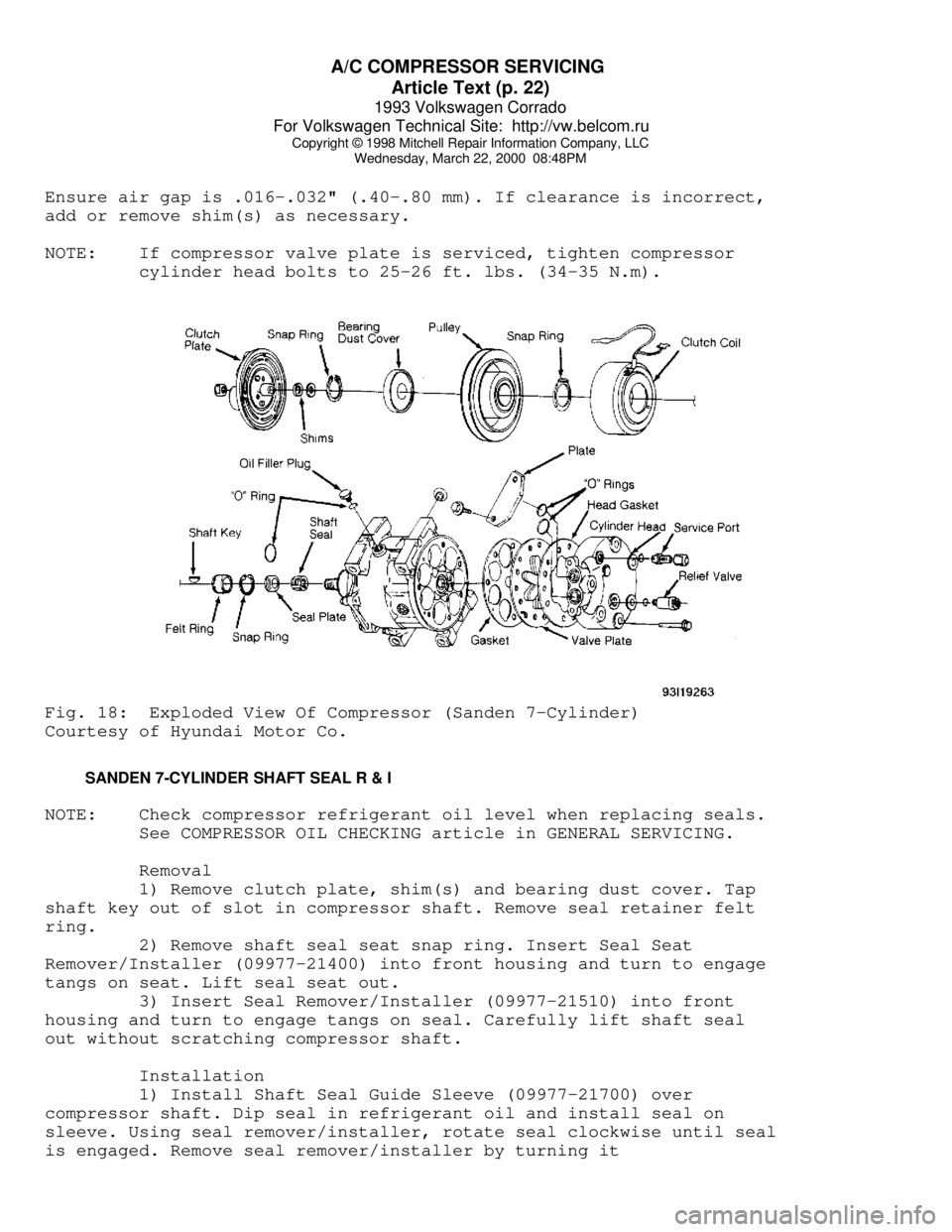

SANDEN 7-CYLINDER CLUTCH COIL AND BEARING R & I

NOTE: Due to variety of clutch and shaft seal configurations,

obtain appropriate A/C compressor service tools for

compressor being serviced.

Removal

1) Install two 6-mm bolts, 1" (25 mm) or longer, in clutch

plate holes. Using 2 box-end wrenches to hold bolts and to prevent

clutch plate from turning, remove shaft nut.

2) Remove clutch plate using Clutch Plate Puller (09977-

21100). Remove clutch shim(s) and bearing dust cover. Remove external

front housing snap ring. See Fig. 18.

3) Remove pulley using universal puller. Detach clutch coil

lead from compressor housing. Remove clutch coil snap ring and clutch

coil. If necessary, remove snap ring and bearing.

Installation

1) Align clutch coil lug with hole in compressor housing, and

install clutch coil. Install clutch coil snap ring. Install drive

pulley using Drive Pulley Installer (09977-21811).

2) Install external bearing snap ring. Using Seal Installer

(09977-21800), install bearing dust cover. After dust cover

installation, ensure there is no contact between cover and front

housing.

3) Install clutch shim(s) and clutch plate. Tighten shaft nut

to 13-14 ft. lbs. (17-19 N.m). Using a dial indicator, check air gap

between clutch plate and drive pulley. Apply voltage to clutch coil.

Page 358 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 22)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

Ensure air gap is .016-.032" (.40-.80 mm). If clearance is incorrect,

add or remove shim(s) as necessary.

NOTE: If compressor valve plate is serviced, tighten compressor

cylinder head bolts to 25-26 ft. lbs. (34-35 N.m).Fig. 18: Exploded View Of Compressor (Sanden 7-Cylinder)

Courtesy of Hyundai Motor Co.

SANDEN 7-CYLINDER SHAFT SEAL R & I

NOTE: Check compressor refrigerant oil level when replacing seals.

See COMPRESSOR OIL CHECKING article in GENERAL SERVICING.

Removal

1) Remove clutch plate, shim(s) and bearing dust cover. Tap

shaft key out of slot in compressor shaft. Remove seal retainer felt

ring.

2) Remove shaft seal seat snap ring. Insert Seal Seat

Remover/Installer (09977-21400) into front housing and turn to engage

tangs on seat. Lift seal seat out.

3) Insert Seal Remover/Installer (09977-21510) into front

housing and turn to engage tangs on seal. Carefully lift shaft seal

out without scratching compressor shaft.

Installation

1) Install Shaft Seal Guide Sleeve (09977-21700) over

compressor shaft. Dip seal in refrigerant oil and install seal on

sleeve. Using seal remover/installer, rotate seal clockwise until seal

is engaged. Remove seal remover/installer by turning it

Page 359 of 920

A/C COMPRESSOR SERVICING

Article Text (p. 23)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:48PM

counterclockwise.

2) Coat seal seat with refrigerant oil and install seal with

seal seat remover/installer. Remove shaft seal guide sleeve. Install

snap ring with beveled edge facing out. Install seal retainer felt

ring using seal seat remover/installer.

3) Install shaft key and clutch plate. Tighten shaft nut to

13-14 ft. lbs. (17-19 N.m). Using a dial indicator, check air gap

between clutch plate and drive pulley. Apply voltage to clutch coil.

Ensure air gap is .016-.032" (.40-.80 mm). If clearance is incorrect,

add or remove shim(s) as necessary.

SEIKO-SEIKI ROTARY VANE

NOTE: Volvo Seiko-Seiki compressor servicing procedure is not

available from manufacturer.

ZEXEL ROTARY VANE CLUTCH COIL AND BEARING R & I

Removal

1) Hold clutch disc using Clutch Disc Wrench (KV99231260) and

remove center bolt. Using Clutch Disc Puller (KV99232340), remove

drive plate and adjustment shim(s).

2) Remove snap ring. Remove pulley using Pilot (J-39023) and

universal puller. Remove clutch coil. If necessary, remove snap ring

and bearing. See Fig. 19.

Installation

1) Ensure coil lead is installed in original position.

Install and tighten coil screws. Press pulley onto compressor using

Pulley Installer (J-33940). Install snap ring and adjustment shim(s).

2) Install clutch disc and tighten center bolt to 11-13 ft.

lbs. (15-18 N.m). Using feeler gauge, ensure clearance between clutch

disc and pulley is .012-.024" (.30-.60 mm). If clearance is incorrect,

add or remove shim(s) as necessary. Break-in clutch by engaging and

disengaging clutch 30 times.

NOTE: Shaft seal assembly servicing procedure is not available

from manufacturer. Use exploded view as a guide. See

Fig. 19. Tighten thermal protector, if removed, to

11-13 ft.lbs. (15-18 N.m).

Page 377 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

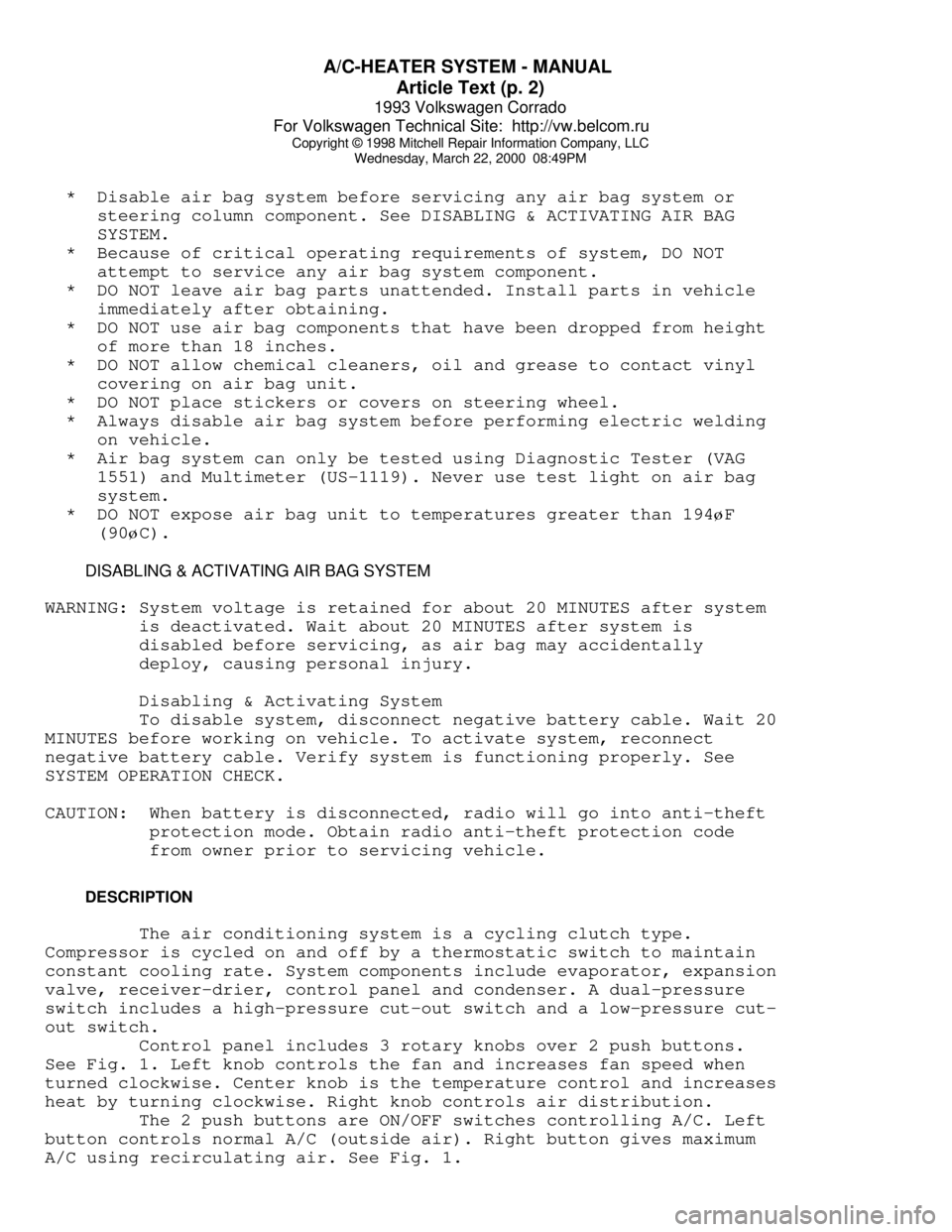

* Disable air bag system before servicing any air bag system or

steering column component. See DISABLING & ACTIVATING AIR BAG

SYSTEM.

* Because of critical operating requirements of system, DO NOT

attempt to service any air bag system component.

* DO NOT leave air bag parts unattended. Install parts in vehicle

immediately after obtaining.

* DO NOT use air bag components that have been dropped from height

of more than 18 inches.

* DO NOT allow chemical cleaners, oil and grease to contact vinyl

covering on air bag unit.

* DO NOT place stickers or covers on steering wheel.

* Always disable air bag system before performing electric welding

on vehicle.

* Air bag system can only be tested using Diagnostic Tester (VAG

1551) and Multimeter (US-1119). Never use test light on air bag

system.

* DO NOT expose air bag unit to temperatures greater than 194øF

(90

øC).

DISABLING & ACTIVATING AIR BAG SYSTEM

WARNING: System voltage is retained for about 20 MINUTES after system

is deactivated. Wait about 20 MINUTES after system is

disabled before servicing, as air bag may accidentally

deploy, causing personal injury.

Disabling & Activating System

To disable system, disconnect negative battery cable. Wait 20

MINUTES before working on vehicle. To activate system, reconnect

negative battery cable. Verify system is functioning properly. See

SYSTEM OPERATION CHECK.

CAUTION: When battery is disconnected, radio will go into anti-theft

protection mode. Obtain radio anti-theft protection code

from owner prior to servicing vehicle.

DESCRIPTION

The air conditioning system is a cycling clutch type.

Compressor is cycled on and off by a thermostatic switch to maintain

constant cooling rate. System components include evaporator, expansion

valve, receiver-drier, control panel and condenser. A dual-pressure

switch includes a high-pressure cut-out switch and a low-pressure cut-

out switch.

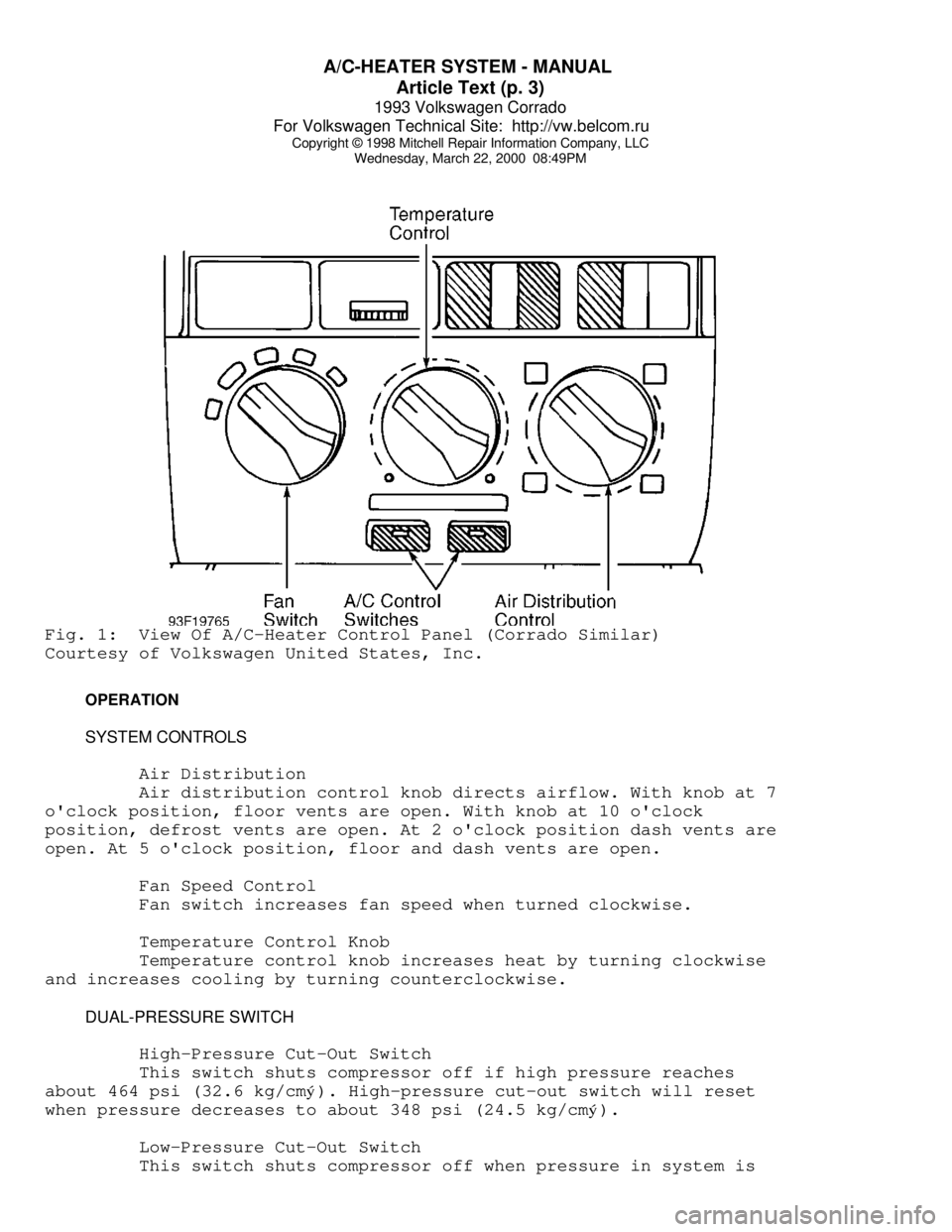

Control panel includes 3 rotary knobs over 2 push buttons.

See Fig. 1. Left knob controls the fan and increases fan speed when

turned clockwise. Center knob is the temperature control and increases

heat by turning clockwise. Right knob controls air distribution.

The 2 push buttons are ON/OFF switches controlling A/C. Left

button controls normal A/C (outside air). Right button gives maximum

A/C using recirculating air. See Fig. 1.

Page 378 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PMFig. 1: View Of A/C-Heater Control Panel (Corrado Similar)

Courtesy of Volkswagen United States, Inc.

OPERATION

SYSTEM CONTROLS

Air Distribution

Air distribution control knob directs airflow. With knob at 7

o'clock position, floor vents are open. With knob at 10 o'clock

position, defrost vents are open. At 2 o'clock position dash vents are

open. At 5 o'clock position, floor and dash vents are open.

Fan Speed Control

Fan switch increases fan speed when turned clockwise.

Temperature Control Knob

Temperature control knob increases heat by turning clockwise

and increases cooling by turning counterclockwise.

DUAL-PRESSURE SWITCH

High-Pressure Cut-Out Switch

This switch shuts compressor off if high pressure reaches

about 464 psi (32.6 kg/cmý). High-pressure cut-out switch will reset

when pressure decreases to about 348 psi (24.5 kg/cm

ý).

Low-Pressure Cut-Out Switch

This switch shuts compressor off when pressure in system is

Page 384 of 920

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 08:49PM

BLOWER MOTOR

Removal & Installation

Disconnect blower motor harness connector. Depress blower

motor retainer clip and rotate blower motor clockwise to disengage lug

on blower motor from clip. To install, reverse removal procedure.

COMPRESSOR

Removal & Installation

Remove ribbed belt. Discharge A/C system using approved

refrigerant recovery/recycling equipment. Remove hoses and plug.

Remove compressor. To install, reverse removal procedure.

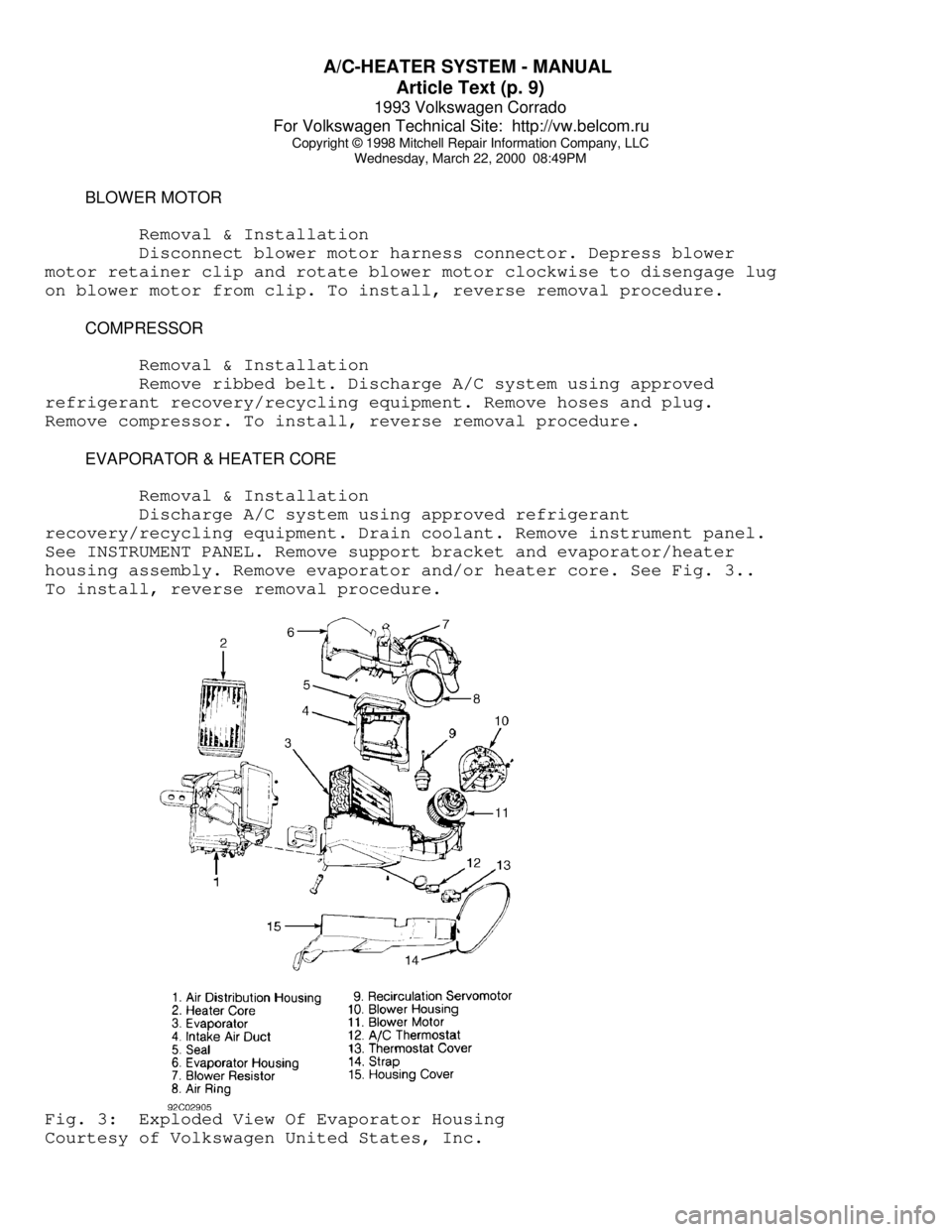

EVAPORATOR & HEATER CORE

Removal & Installation

Discharge A/C system using approved refrigerant

recovery/recycling equipment. Drain coolant. Remove instrument panel.

See INSTRUMENT PANEL. Remove support bracket and evaporator/heater

housing assembly. Remove evaporator and/or heater core. See Fig. 3..

To install, reverse removal procedure.Fig. 3: Exploded View Of Evaporator Housing

Courtesy of Volkswagen United States, Inc.