VOLKSWAGEN ID.3 2020 Owner´s Manual

Manufacturer: VOLKSWAGEN, Model Year: 2020, Model line: ID.3, Model: VOLKSWAGEN ID.3 2020Pages: 708, PDF Size: 46.5 MB

Page 511 of 708

Corre ct h an dlin g o f t h e h ig h-v o lt a g e b atte ry m ake s a s ig nif ic a n t c o n trib utio n m ain ta in in g it s

g ood a n d r e lia b le c o n dit io n in t h e l o n g t e rm . T h e s a m e a ls o a p plie s t o c h arg in g a n d s ta n din g

tim es o f t h e v e h ic le .

V olk sw ag en r e co m men ds o b se rv in g t h e f o llo w in g c a re in stru ctio n s:

—A vo id c o m ple te d is c h arg e o f t h e h ig h-v o lt a g e b atte ry if p ossib le , e .g . d ue t o e xte n ded

sta n din g t im es w it h a l o w c h arg e l e ve l → . T h e c h arg e l e ve l s h ould n ot f a ll b elo w 2 0% f o r

exte n ded p erio d s.

—D o n ot c h arg e t h e h ig h-v o lt a g e b atte ry t o a l e ve l o f 1 00% in e ve ry d ay o p era tio n . F o r d ail y

c h arg in g, s e t a n u p per b atte ry c h arg e l im it in t h e I n fo ta in m en t s y ste m w hic h c o rre sp on ds t o

re q uir e m en ts , e .g . 8 0% (→ Tim er- c o n tro lle d c h arg in g).

—A vo id r e g ula r f a st c h arg in g w it h d ir e ct c u rre n t (D C) d ue t o t h e h ig h c h arg in g c u rre n ts .

T e m pera tur e b eh av io ur

Th e h ig h-v o lt a g e b atte ry p ro vid es l e ss p ow er a t v e ry l o w t e m pera tu re s. I f t h e c h arg e l e ve l is a ls o

lo w , p ow er m ay b e s ig nif ic a n tly r e stric te d o n ly a s h ort t im e a ft e r d riv in g o ff.

—In f ro st c o n dit io n s, d o n ot p ark t h e v e h ic le f o r s e ve ra l h ours w it h a c h arg e l e ve l b elo w 4 0% (→

A lt e rn atin g c u rre n t ( A C)).

—U se t h e s ta tio n ary a ir c o n dit io n in g in g ood t im e t o im pro ve c o m fo rt a n d p erfo rm an ce ,

p art ic u la rly a t t e m pera tu re s b elo w - 1 5 °C (→ Sta tio n ary a ir c o n dit io n in g).

N OTIC E

If t h e v e h ic le is p ark e d f o r a n e xte n ded p erio d w it h d is c h arg ed h ig h-v o lt a g e b atte ry , it is

p ossib le t h at t h e h ig h-v o lt a g e b atte ry w il l n o l o n ger b e c h arg ed o r t h e v e h ic le w il l n o l o n ger

sta rt . I n t h e l o n g t e rm , ir re ve rs ib le d am ag e c a n b e c a u se d t o t h e h ig h-v o lt a g e b atte ry .

●C harg e t h e h ig h-v o lt a g e b atte ry a t r e g ula r in te rv a ls .

C are i ns tru ctio ns f o r t he hi gh- vo lt a g e b atte ry

Page 512 of 708

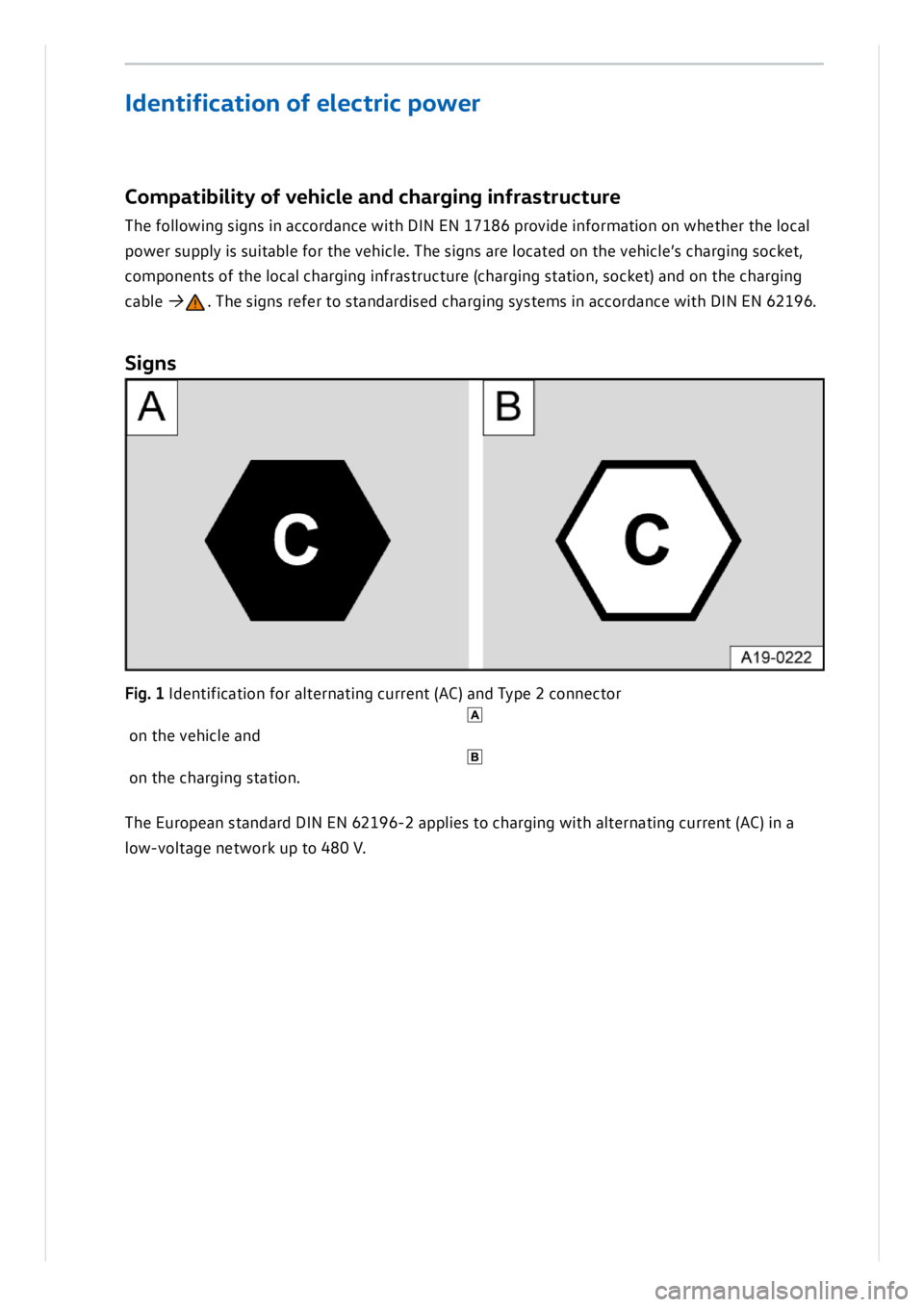

Com patib il it y o f v e h ic le a n d c h arg in g i n fra struc tur e

Th e f o llo w in g s ig ns in a cco rd an ce w it h D IN E N 1 7186 p ro vid e in fo rm atio n o n w heth er t h e l o ca l

p ow er s u p ply is s u it a b le f o r t h e v e h ic le . T h e s ig ns a re l o ca te d o n t h e v e h ic le ’s c h arg in g s o cke t,

c o m pon en ts o f t h e l o ca l c h arg in g in fra stru ctu re (c h arg in g s ta tio n , s o cke t) a n d o n t h e c h arg in g

ca b le → . T h e s ig ns r e fe r t o s ta n dard is e d c h arg in g s y ste m s in a cco rd an ce w it h D IN E N 6 2196.

S ig ns

Fig . 1 I d en tif ic a tio n f o r a lt e rn atin g c u rre n t (A C) a n d T y p e 2 c o n necto r

o n t h e v e h ic le a n d

o n t h e c h arg in g s ta tio n .

Th e E uro p ean s ta n dard D IN E N 6 2196 -2 a p plie s t o c h arg in g w it h a lt e rn atin g c u rre n t (A C) in a

l o w -v o lt a g e n etw ork u p t o 4 80 V .

Id ent if ic a tio n of e le ctric p ow er

Page 513 of 708

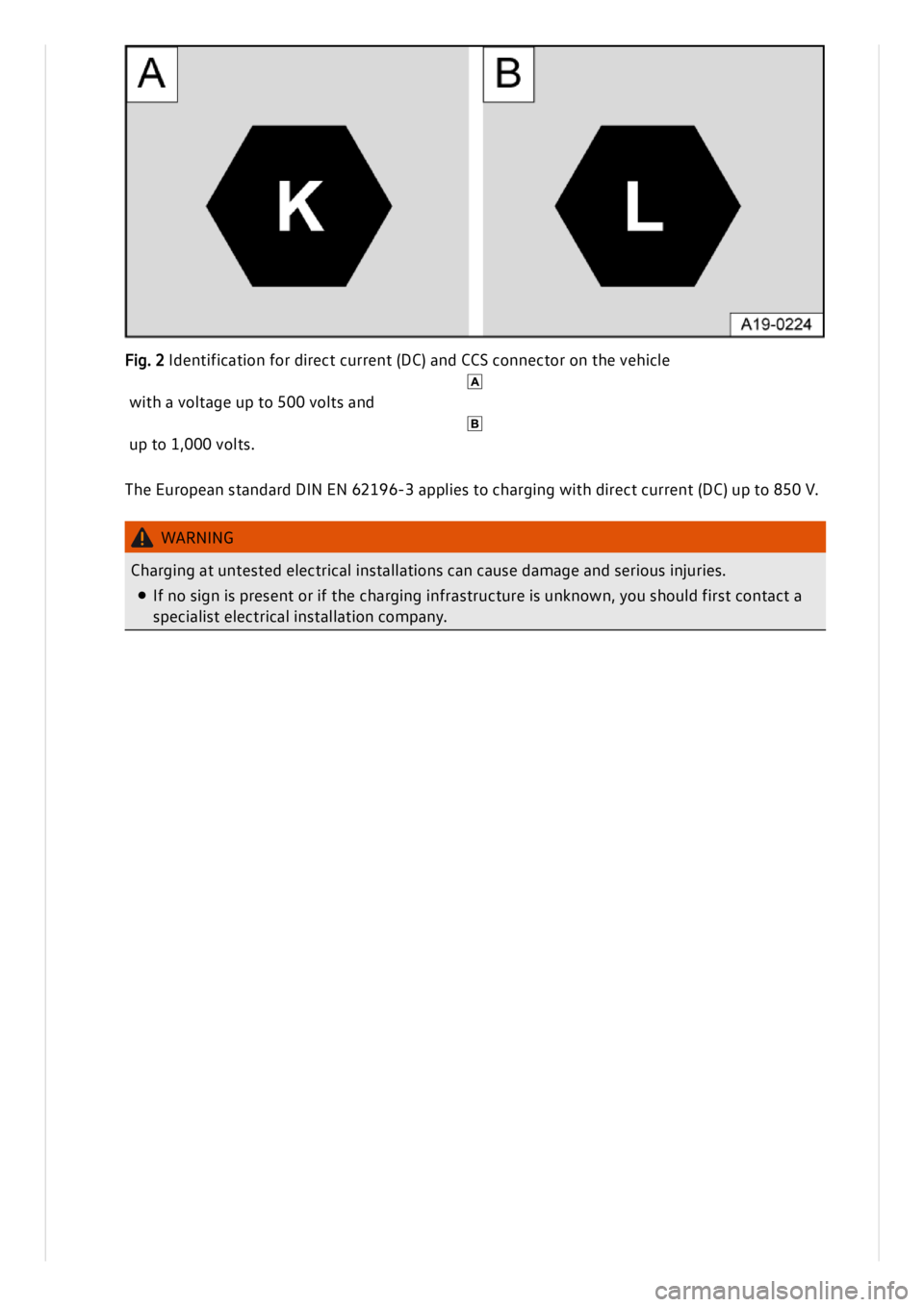

Fig . 2 I d en tif ic a tio n f o r d ir e ct c u rre n t (D C) a n d C C S c o n necto r o n t h e v e h ic le

w it h a v o lt a g e u p t o 5 00 v o lt s a n d

u p t o 1 ,0 00 v o lt s .

T h e E uro p ean s ta n dard D IN E N 6 2196 -3 a p plie s t o c h arg in g w it h d ir e ct c u rre n t (D C) u p t o 8 50 V .

W AR N IN G

Charg in g a t u n te ste d e le ctric a l in sta lla tio n s c a n c a u se d am ag e a n d s e rio us in ju rie s.

●If n o s ig n is p re se n t o r if t h e c h arg in g in fra stru ctu re is u n kn ow n, y o u s h ould f ir s t c o n ta ct a

s p ecia lis t e le ctric a l in sta lla tio n c o m pan y.

Page 514 of 708

Th e c h arg in g c a b le s u p plie d w it h t h e v e h ic le d ep en ds o n t h e s c o p e o f d eliv e ry a n d t h e c o un try -

sp ecif ic t e ch nic a l r e q uir e m en ts , e .g . c h arg in g c o n necto r c o n nectio n s f o r m ain s s o cke ts .

V olk sw ag en r e co m men ds u sin g on ly t h e s u p plie d c h arg in g c a b le → .

Han dlin g t h e c h arg in g c a b le

—H an dle w it h c a re .

—D o n ot f o ld o r b en d o ve r s h arp e d ges.

—P ull o n ly a t t h e c o n necto rs .

H an dlin g t h e s a fe ty d evic e a n d t h e c h arg in g c o n necto rs

—F it t h e p ro te ctiv e c a p s a ft e r u se .

—P ro te ct a g ain st in te n se s u n lig ht (a m bie n t t e m pera tu re n ot h ig her t h an 5 0°C o r 1 22°F ).

—D o n ot d ro p .

—D o n ot im mers e in l iq uid .

W AR N IN G

Neve r u se d am ag ed c h arg in g c o n necto rs a n d c h arg in g c a b le s.

●A lw ays c h eck c h arg in g c o n necto rs a n d c a b le s f o r d am ag e b efo re u se .

●H ave t h e c h arg in g c a b le c h ecke d b y a V olk sw ag en d eale rs h ip if t h ere is a m alf u n ctio n .

W AR N IN G

Alw ays c o n nect t h e c h arg in g c a b le f o r m ain s s o cke ts d ir e ctly t o a m ain s s o cke t. N eve r u se t h e

ch arg in g c a b le t o g eth er w it h a n e xte n sio n c a b le , a c a b le r e el, a m ult ip le s o cke t o utle t o r a n

ad ap te r s u ch a s a r e g io n al a d ap te r o r t im er. I n ju rie s d ue t o f ir e c o uld b e in cu rre d o r t h e

ch arg in g c a b le o r t h e h ouse 's e le ctric a l s y ste m c o uld b eco m e d am ag ed .

W AR N IN G

If y o u a re n ot f a m il ia r w it h t h e e le ctric a l in sta lla tio n o r it h as n ot b een c h ecke d b y q ualif ie d

exp ert p ers o n nel, n eve r u se it f o r c h arg in g. I f t h e e le ctric a l in sta lla tio n is in p oor c o n dit io n , t h is

c a n c a u se s e rio us d am ag e, p art ic u la rly f ir e s.

●If a f a u lt o cc u rs o n t h e m ain s s o cke t o r e le ctric a l s y ste m , s e ek a ssis ta n ce f ro m a n e xp ert in

e le ctric a l s y ste m s.

N OTIC E

Th e c h arg in g c a b le m ay b e s u b je ct t o a r e g ula r t e stin g r e q uir e m en ts a s m ob il e e le ctric a l

e q uip m en t. A t e st a d ap te r is r e q uir e d .

C om ply w it h t h e m axim um l o ad f o r t h e s a fe ty c ir c u it u se d . I f t h e c h arg in g c a b le is

c o n necte d t o a m ain s s o cke t w it h o th er e le ctric a l c o n su m ers in t h e s a m e e le ctric a l

cir c u it , t h e f u se in t h e e le ctric a l c ir c u it c a n b e t rip ped .

C ha rg ing c a b le

I nt ro d uctio n to t he t o p ic

Page 515 of 708

Charg in g c a b le s m ust b e d is p ose d o f in a n e n vir o n m en ta lly f rie n dly w ay a n d m ust n ot b e

dis p ose d o f a s h ouse h old w aste .

Page 516 of 708

Th e m axim um c h arg in g c u rre n t is 1 6 A o r 3 2 A a n d d ep en ds o n t h e v e h ic le e q uip m en t a n d t h e

su p plie d c h arg in g c a b le → Charg in g c a b le f o r c h arg in g s ta tio n s w it h a lt e rn atin g c u rre n t ( A C).

C harg in g i n N orw ay

In N orw ay, t h ere a re m an y e le ctric a l in sta lla tio n s t h at a re c o n stru cte d a cco rd in g t o d if fe re n t

te ch nic a l r u le s t h an t h ose in p la ce in E uro p e.

O nly u se a c h arg in g c a b le w it h a c ro ss-s e ctio n o f 5 x 6 m m2 → . P le ase n ote t h e in fo rm atio n

on t h e c h arg in g c a b le .

B efo re t ra ve llin g t o N orw ay, c h eck w heth er t h e c a rrie d c h arg in g c a b le f o r c h arg in g s ta tio n s

m eets t h e r e q uir e m en ts l is te d a b ove .

W AR N IN G

Charg in g t h e h ig h-v o lt a g e b atte ry w it h a n u n su it a b le c h arg in g c a b le m ay l e ad t o s h ort c ir c u it s ,

se ve re in ju ry a n d f a ta l e le ctric s h ock s.

●D o n ot u se a c h arg in g c a b le if t h e c ro ss-s e ctio n is t o o s m all.

N OTIC E

Fo llo w t h e m an ufa ctu re r's in fo rm atio n a n d in stru ctio n s o n u sin g t h e c h arg in g s ta tio n .

C ha rg ing c a b le f o r c ha rg ing s ta tio ns w it h alt e rna tin g

cu rre nt ( A C)

Fig . 1 C harg in g c a b le f o r c h arg in g s ta tio n s w it h a lt e rn atin g c u rre n t (A C).

Page 517 of 708

Charg in g w it h a c h arg in g c a b le w it h a r a tin g o f 1 6 A is n ot p ossib le a t s o m e c h arg in g

sta tio n s t h at s u p port 3 2 A .

Page 518 of 708

Cha rg ing c a b le f o r m ains s o ck e ts

Fig . 1 C harg in g c a b le f o r m ain s s o cke ts (il lu stra tio n )

Page 519 of 708

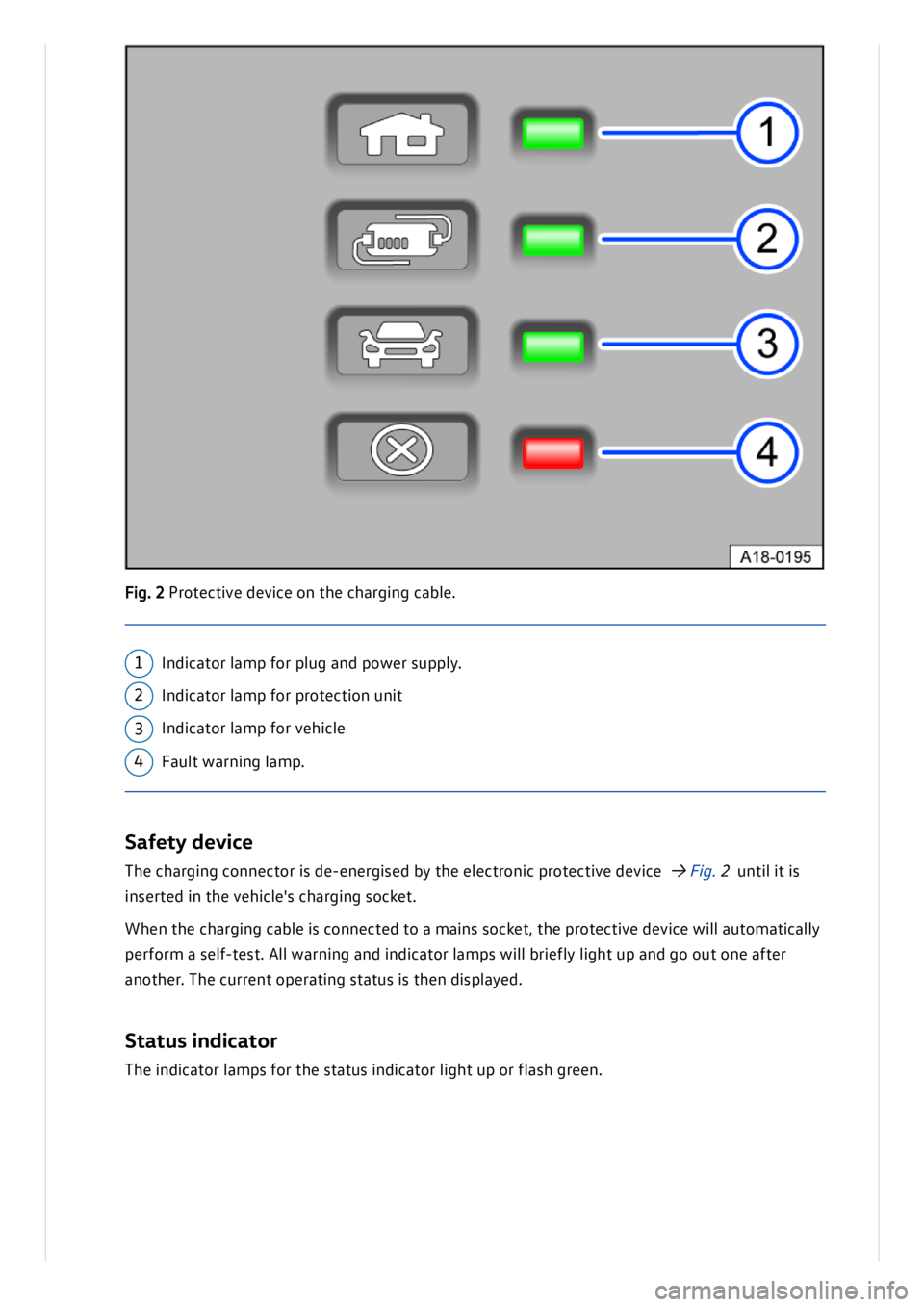

Safe ty d ev ic e

Th e c h arg in g c o n necto r is d e-e n erg is e d b y t h e e le ctro n ic p ro te ctiv e d evic e → Fig . 2 u n til it is

in se rt e d in t h e v e h ic le 's c h arg in g s o cke t.

W hen t h e c h arg in g c a b le is c o n necte d t o a m ain s s o cke t, t h e p ro te ctiv e d evic e w il l a u to m atic a lly

p erfo rm a s e lf - te st. A ll w arn in g a n d in dic a to r l a m ps w il l b rie fly l ig ht u p a n d g o o ut o n e a ft e r

an oth er. T h e c u rre n t o p era tin g s ta tu s is t h en d is p la ye d .

S ta tus i n d ic a to r

Th e in dic a to r l a m ps f o r t h e s ta tu s in dic a to r l ig ht u p o r f la sh g re en .

Fig . 2 P ro te ctiv e d evic e o n t h e c h arg in g c a b le .

1In dic a to r l a m p f o r p lu g a n d p ow er s u p ply .

2In dic a to r l a m p f o r p ro te ctio n u n it

3I n dic a to r l a m p f o r v e h ic le

4F au lt w arn in g l a m p.

Page 520 of 708

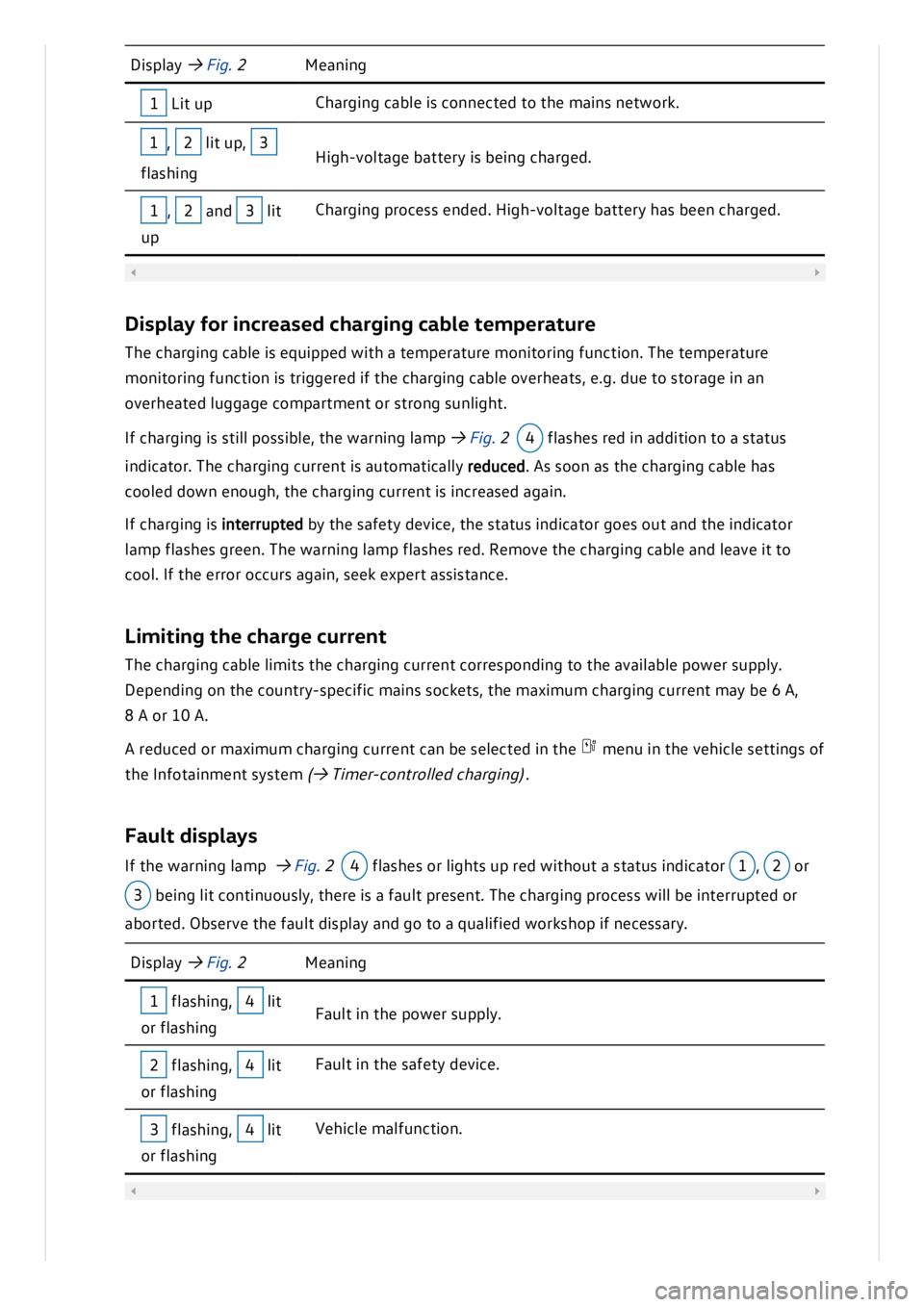

Dis p la y → Fig . 2M ean in g

1 Li t u pC harg in g c a b le is c o n necte d t o t h e m ain s n etw ork .

1, 2 l it u p , 3

f la sh in g

H ig h-v o lt a g e b atte ry is b ein g c h arg ed .

1, 2 a n d 3 l it

u p

C harg in g p ro ce ss e n ded . H ig h-v o lt a g e b atte ry h as b een c h arg ed .

D is p la y f o r i n cre a se d c h arg in g c a b le t e m pera tur e

Th e c h arg in g c a b le is e q uip ped w it h a t e m pera tu re m on it o rin g f u n ctio n . T h e t e m pera tu re

m on it o rin g f u n ctio n is t rig gere d if t h e c h arg in g c a b le o ve rh eats , e .g . d ue t o s to ra g e in a n

o ve rh eate d l u g gag e c o m part m en t o r s tro n g s u n lig ht.

If c h arg in g is s til l p ossib le , t h e w arn in g l a m p → Fig . 2 4 f la sh es r e d in a d dit io n t o a s ta tu s

in dic a to r. T h e c h arg in g c u rre n t is a u to m atic a lly re d uce d. A s s o on a s t h e c h arg in g c a b le h as

co ole d d ow n e n oug h, t h e c h arg in g c u rre n t is in cre ase d a g ain .

If c h arg in g is in te rru p te d b y t h e s a fe ty d evic e , t h e s ta tu s in dic a to r g oes o ut a n d t h e in dic a to r

la m p f la sh es g re en . T h e w arn in g l a m p f la sh es r e d . R em ove t h e c h arg in g c a b le a n d l e ave it t o

c o ol. I f t h e e rro r o cc u rs a g ain , s e ek e xp ert a ssis ta n ce .

L im it in g t h e c h arg e c ur re n t

Th e c h arg in g c a b le l im it s t h e c h arg in g c u rre n t c o rre sp on din g t o t h e a va il a b le p ow er s u p ply .

D ep en din g o n t h e c o un try -s p ecif ic m ain s s o cke ts , t h e m axim um c h arg in g c u rre n t m ay b e 6 A ,

8 A o r 1 0 A .

A r e d uce d o r m axim um c h arg in g c u rre n t c a n b e s e le cte d in t h e m en u in t h e v e h ic le s e ttin gs o f

th e I n fo ta in m en t s y ste m (→ Tim er- c o n tro lle d c h arg in g).

F aul t d is p la y s

If t h e w arn in g l a m p → Fig . 2 4 f la sh es o r l ig hts u p r e d w it h out a s ta tu s in dic a to r 1, 2 o r

3 b ein g l it c o n tin uo usly , t h ere is a f a u lt p re se n t. T h e c h arg in g p ro ce ss w il l b e in te rru p te d o r

ab ort e d . O bse rv e t h e f a u lt d is p la y a n d g o t o a q ualif ie d w ork sh op if n ece ssa ry .

D is p la y → Fig . 2M ean in g

1 f la sh in g, 4 l it

o r f la sh in g

Fau lt in t h e p ow er s u p ply .

2 f la sh in g, 4 l it

o r f la sh in g

Fau lt in t h e s a fe ty d evic e .

3 f la sh in g, 4 l it

o r f la sh in g

V eh ic le m alf u n ctio n .