boot VOLKSWAGEN PASSAT 1996 B3, B4 / 3.G Service Owner's Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1996, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1996 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 91 of 369

Downloaded from www.Manualslib.com manuals search engine 40-77

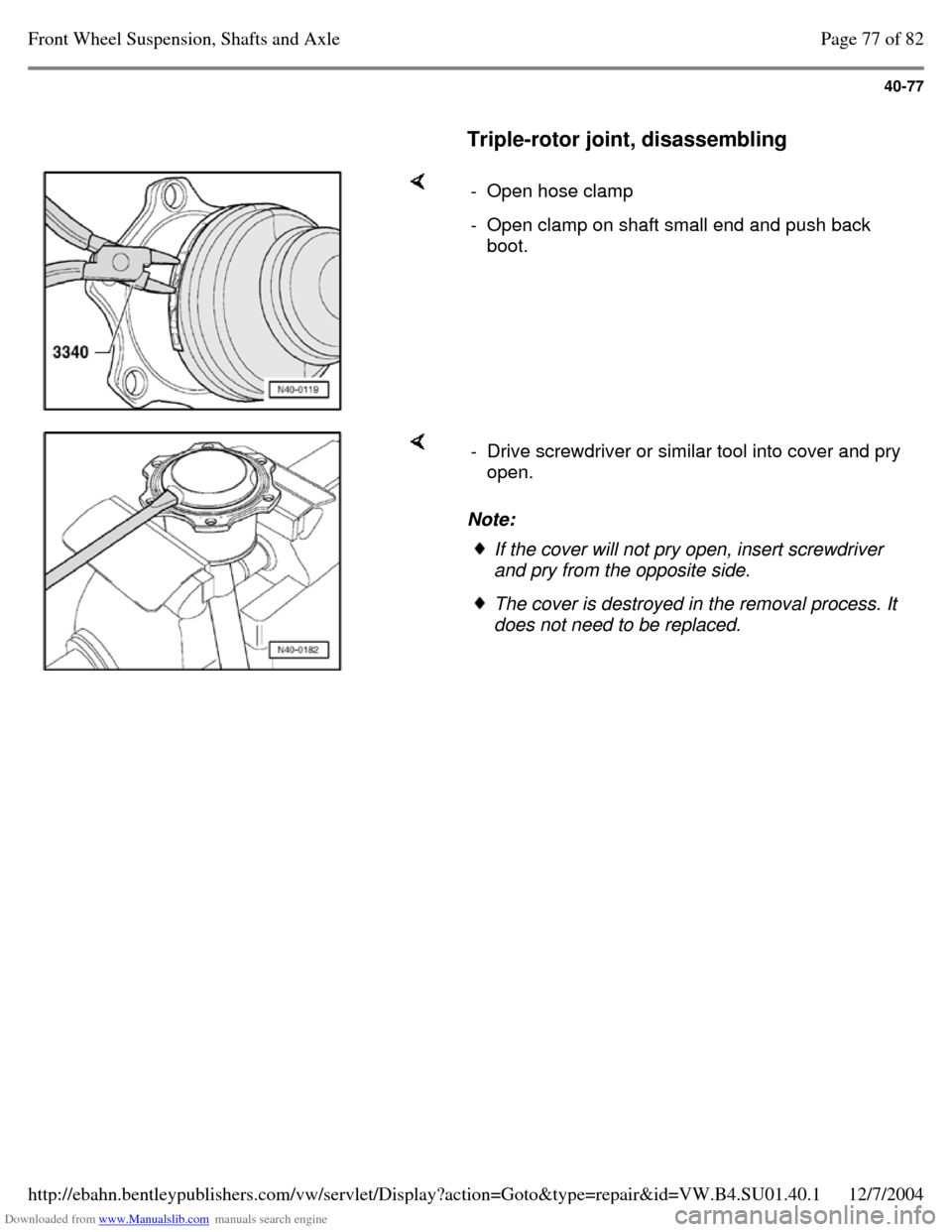

Triple-rotor joint, disassembling - Open hose clamp - Open clamp on shaft small end and push back

boot. Note: - Drive screwdriver or similar tool into cover and pry

open. If the cover will not pry open, insert screwdriver

and pry from the opposite side. The cover is destroyed in the removal process. It

does not need to be replaced. Page 77 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 94 of 369

Downloaded from www.Manualslib.com manuals search engine 40-80

Triple-rotor joint, assembling

- Slide small diameter boot clamp onto shaft.

- Slide triple-rotor joint boot onto shaft.

- Slide triple-rotor joint housing onto shaft.

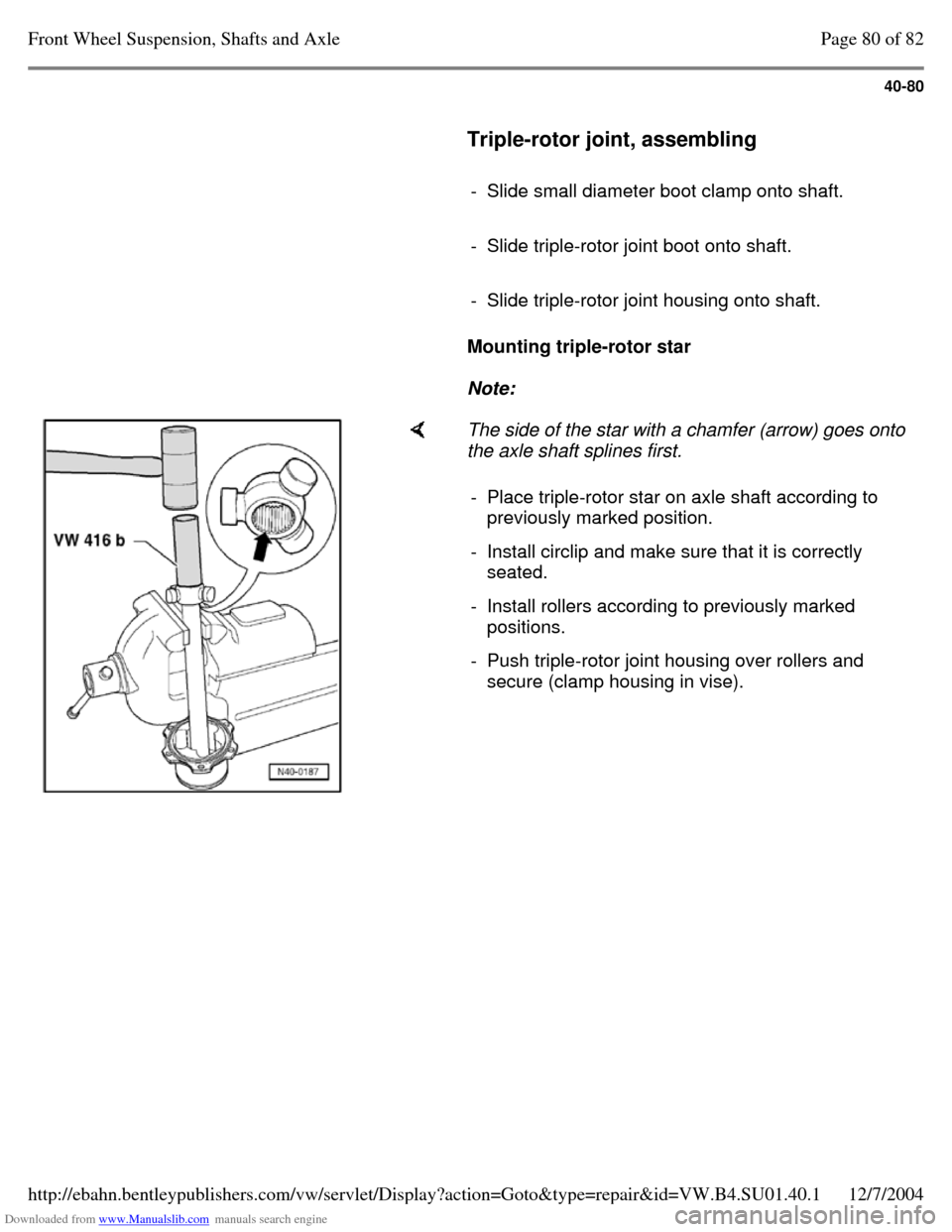

Mounting triple-rotor star

Note: The side of the star with a chamfer (arrow) goes onto

the axle shaft splines first.

- Place triple-rotor star on axle shaft according to

previously marked position.

- Install circlip and make sure that it is correctly

seated.

- Install rollers according to previously marked

positions.

- Push triple-rotor joint housing over rollers and

secure (clamp housing in vise). Page 80 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 95 of 369

Downloaded from www.Manualslib.com manuals search engine 40-81

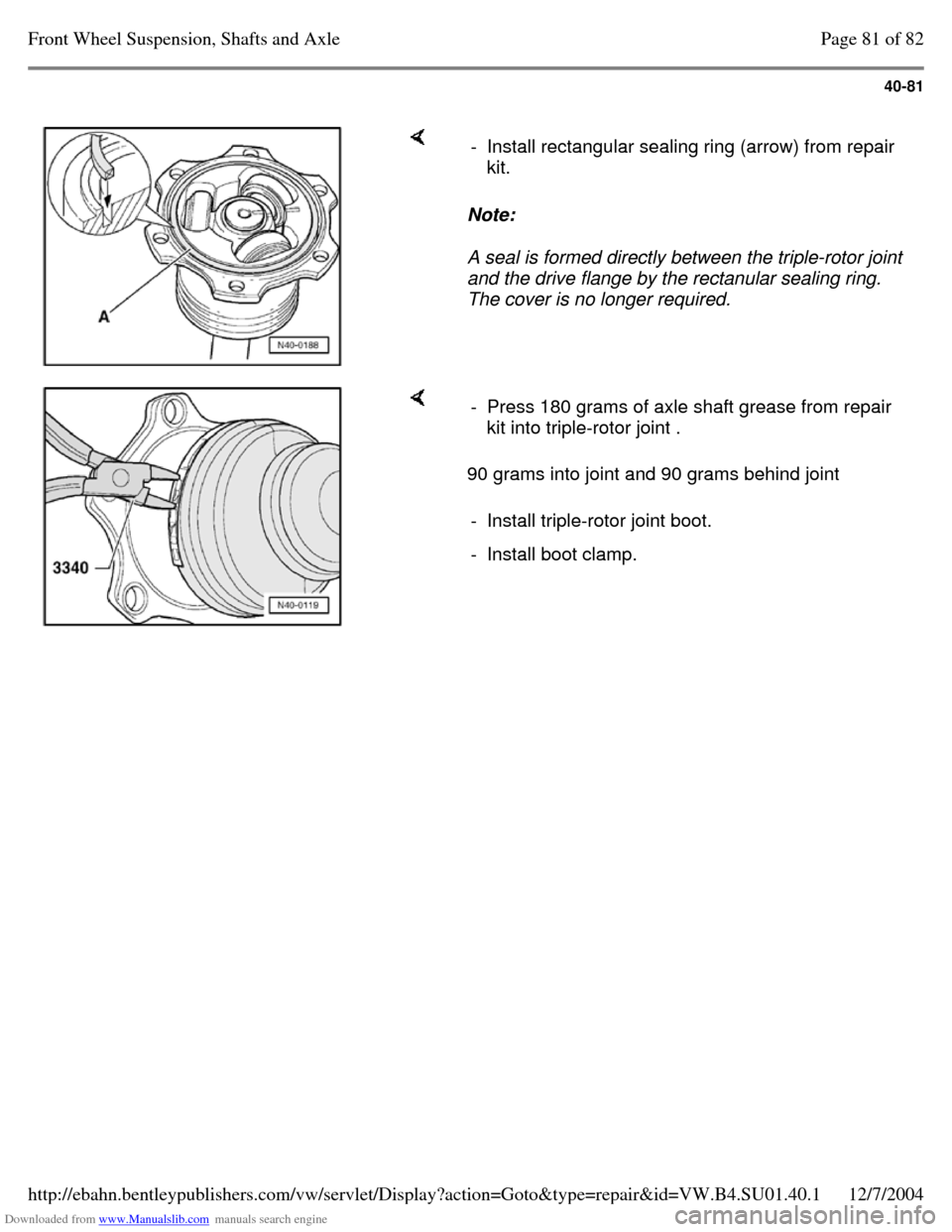

Note:

A seal is formed directly between the triple-rotor joint

and the drive flange by the rectanular sealing ring.

The cover is no longer required. - Install rectangular sealing ring (arrow) from repair

kit. 90 grams into joint and 90 grams behind joint - Press 180 grams of axle shaft grease from repair

kit into triple-rotor joint .

- Install triple-rotor joint boot. - Install boot clamp. Page 81 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 142 of 369

Downloaded from www.Manualslib.com manuals search engine 42-46

Rear drive shafts, servicing

Removing and installing drive shafts Page 42-37

Note:

Grease quantity:

- - outer constant velocity joint 80 g G-6.3

- - inner constant velocity joint 80 9 G-6.3 Greasing outer joint: press half of the grease

into the joint, and the other half evenly into the

boot.

Greasing inner joint: press half of the grease

into the inner joint from both sides, the other

half evenly into the boot.

When replacing the boot, regrease joint if

required. Page 1 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 144 of 369

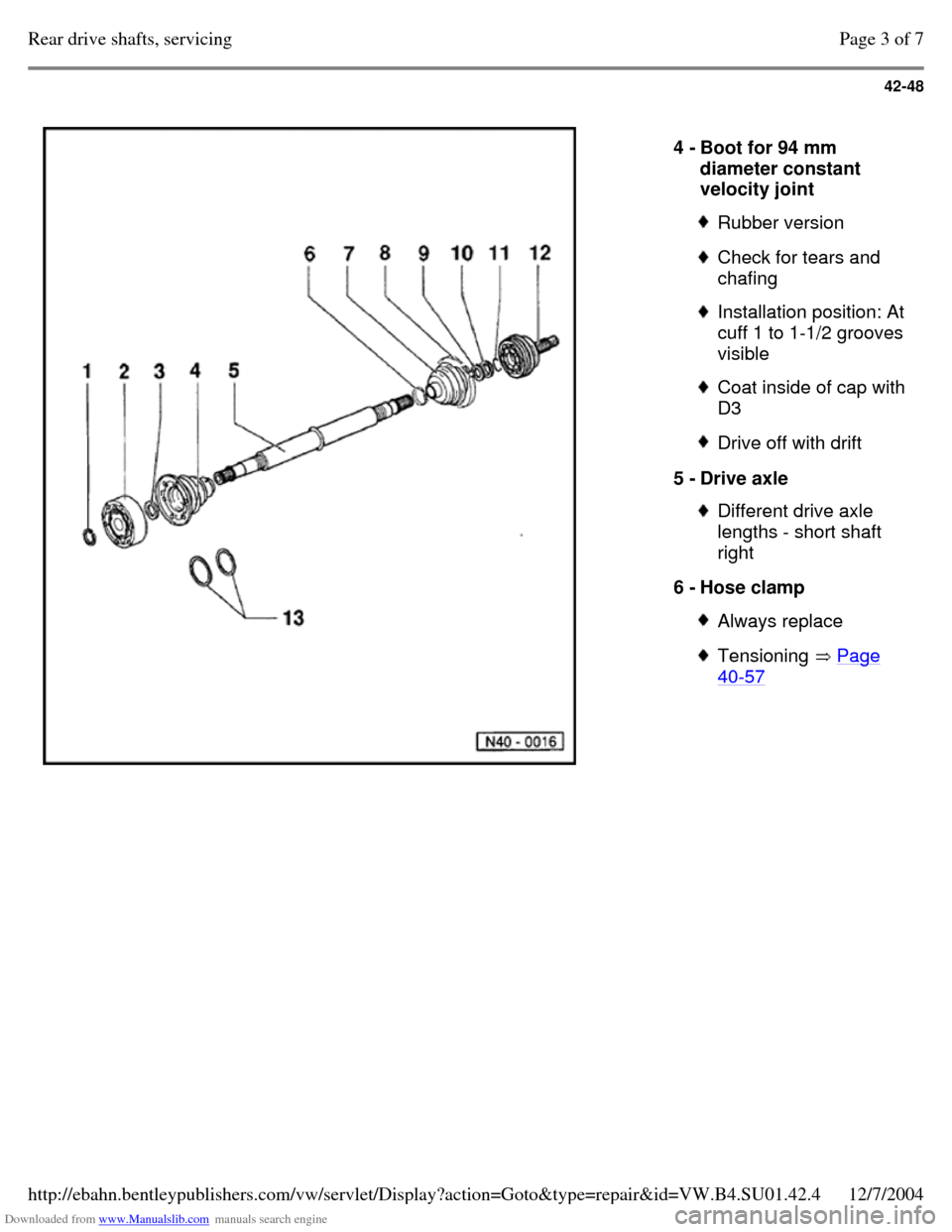

Downloaded from www.Manualslib.com manuals search engine 42-48

4 - Boot for 94 mm

diameter constant

velocity joint Rubber version Check for tears and

chafing Installation position: At

cuff 1 to 1-1/2 grooves

visible Coat inside of cap with D3 Drive off with drift 5 - Drive axle Different drive axle

lengths - short shaft

right

6 - Hose clamp Always replace Tensioning Page 40-57 Page 3 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 145 of 369

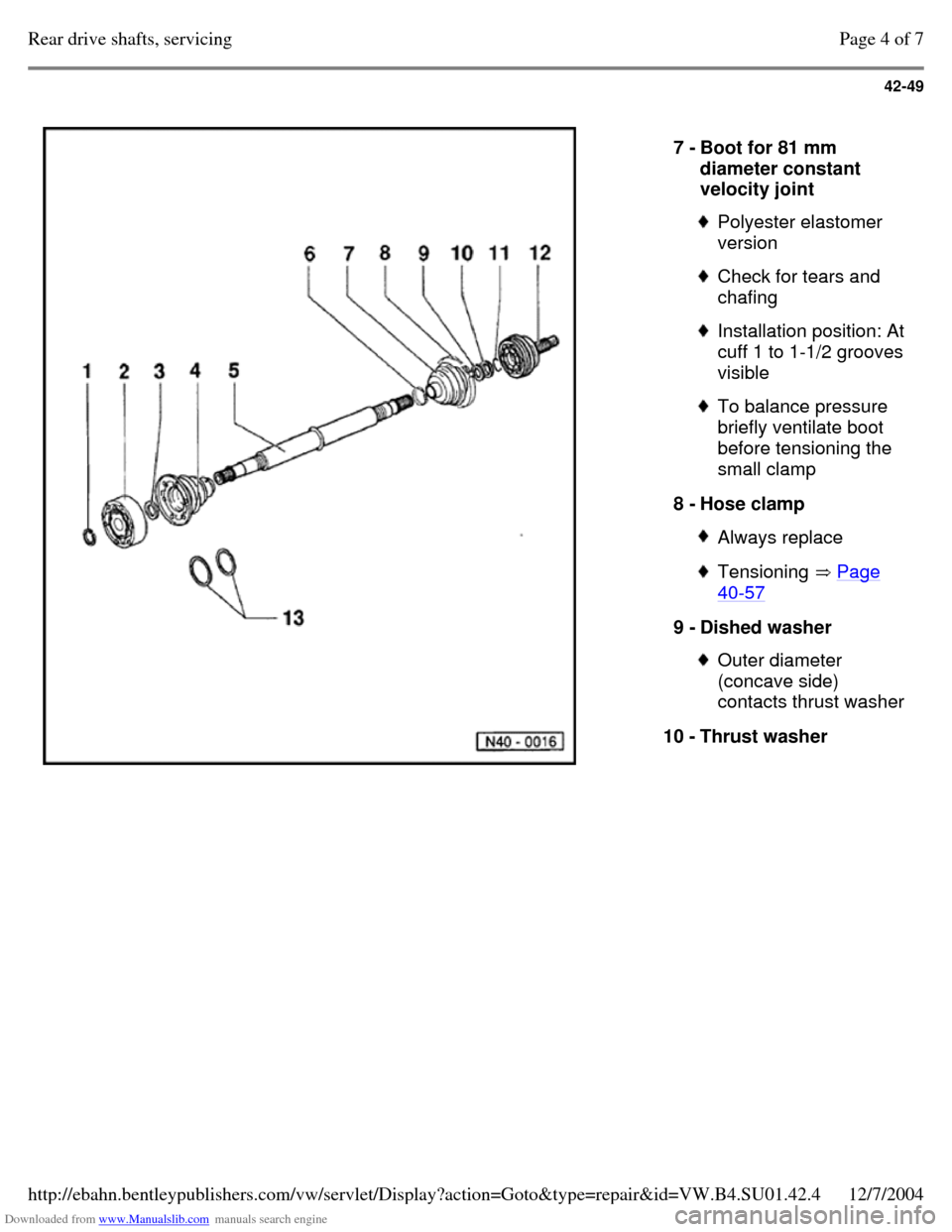

Downloaded from www.Manualslib.com manuals search engine 42-49

7 - Boot for 81 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing Installation position: At

cuff 1 to 1-1/2 grooves

visible To balance pressure

briefly ventilate boot

before tensioning the

small clamp

8 - Hose clamp Always replace Tensioning Page 40-57 9 - Dished washer Outer diameter

(concave side)

contacts thrust washer

10 - Thrust washer Page 4 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 146 of 369

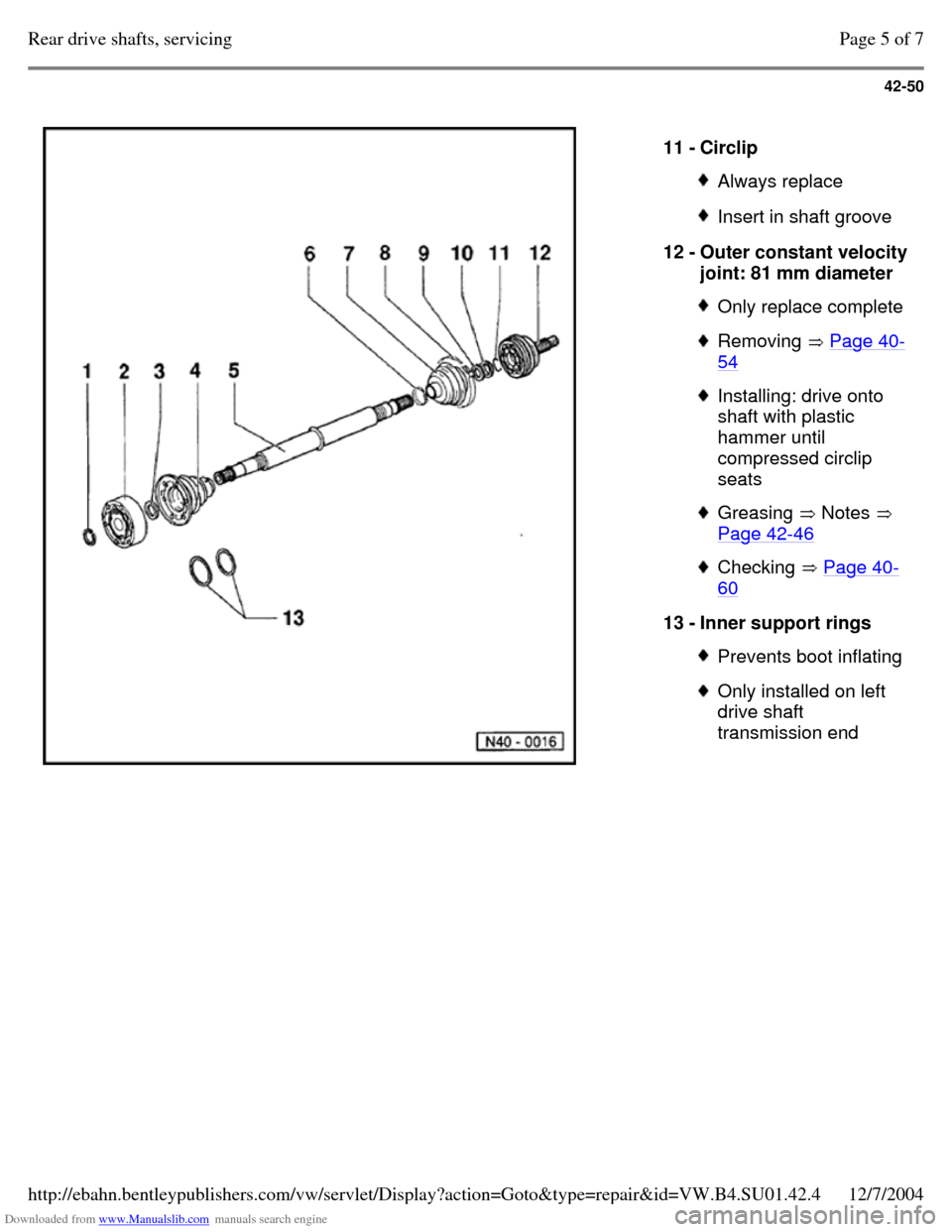

Downloaded from www.Manualslib.com manuals search engine 42-50

11 - Circlip Always replace Insert in shaft groove 12 - Outer constant velocity joint: 81 mm diameter Only replace complete Removing Page 40-54 Installing: drive onto

shaft with plastic

hammer until

compressed circlip

seats Greasing Notes

Page 42-46 Checking Page 40-60 13 - Inner support rings Prevents boot inflating Only installed on left

drive shaft

transmission end Page 5 of 7Rear drive shafts, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.4

Page 150 of 369

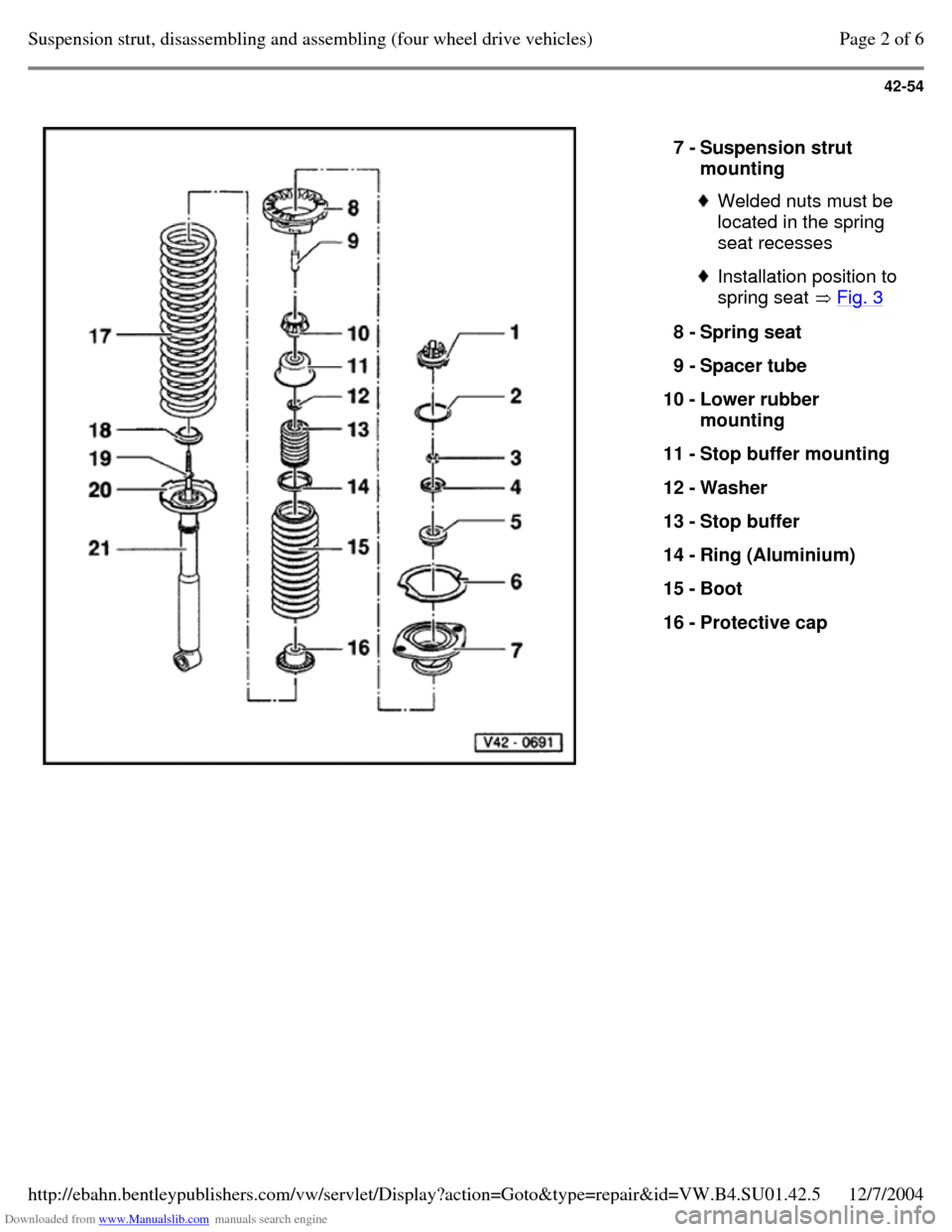

Downloaded from www.Manualslib.com manuals search engine 42-54

7 - Suspension strut

mounting Welded nuts must be

located in the spring

seat recesses Installation position to

spring seat Fig. 3 8 - Spring seat

9 - Spacer tube

10 - Lower rubber

mounting

11 - Stop buffer mounting

12 - Washer

13 - Stop buffer

14 - Ring (Aluminium)

15 - Boot

16 - Protective cap Page 2 of 6Suspension strut, disassembling and assembling (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.5

Page 218 of 369

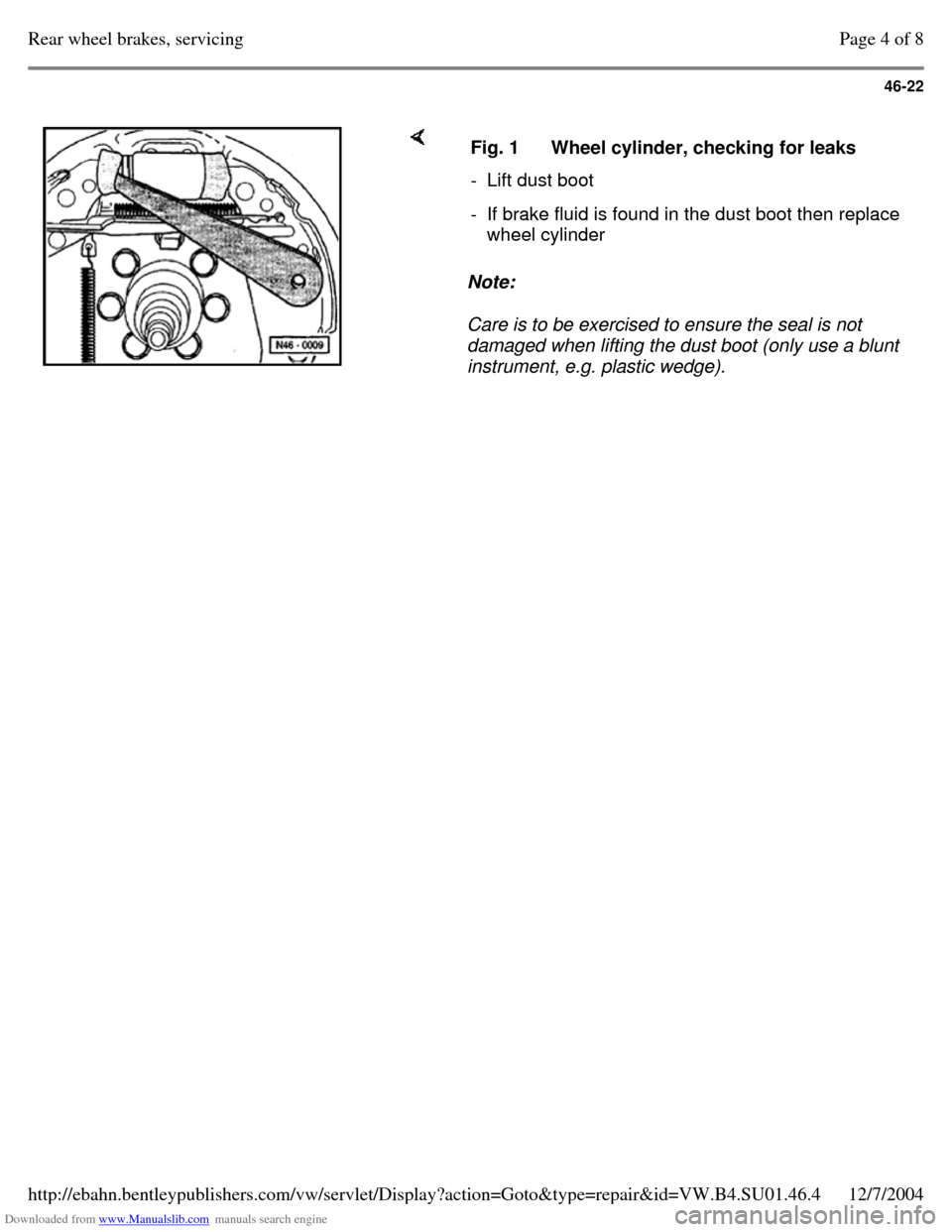

Downloaded from www.Manualslib.com manuals search engine 46-22

Note:

Care is to be exercised to ensure the seal is not

damaged when lifting the dust boot (only use a blunt

instrument, e.g. plastic wedge). Fig. 1 Wheel cylinder, checking for leaks - Lift dust boot - If brake fluid is found in the dust boot then replace

wheel cylinder Page 4 of 8Rear wheel brakes, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.46.4

Page 284 of 369

Downloaded from www.Manualslib.com manuals search engine 48-14

- With engine running at idling speed. Close cut-

off valve (not longer than 5 seconds) and read

off pressure.

Specification: 85 - 95 bar (1232 - 1377

psi)

Note:

If the reading is higher or lower than specified

replace pump.

Vehicles with up to 110 kW engine Page 48-90 . Vehicles with 128 kW engine Page 48-97 . If reservoir fluid level is low then check steering

system for leaks.

For leaks at the pinion first check the lines/line

connections for leaks and if necessary tighten

and wipe dry.

If the pinion seal or the rack seals in steering

box housing are leaking then replace steering

gear.

To check the rack seals loosen the clamp on

the boot and push to one side. Page 14 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1