boot VOLKSWAGEN PASSAT 1997 B3, B4 / 3.G Service User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1997, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1997 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 72 of 369

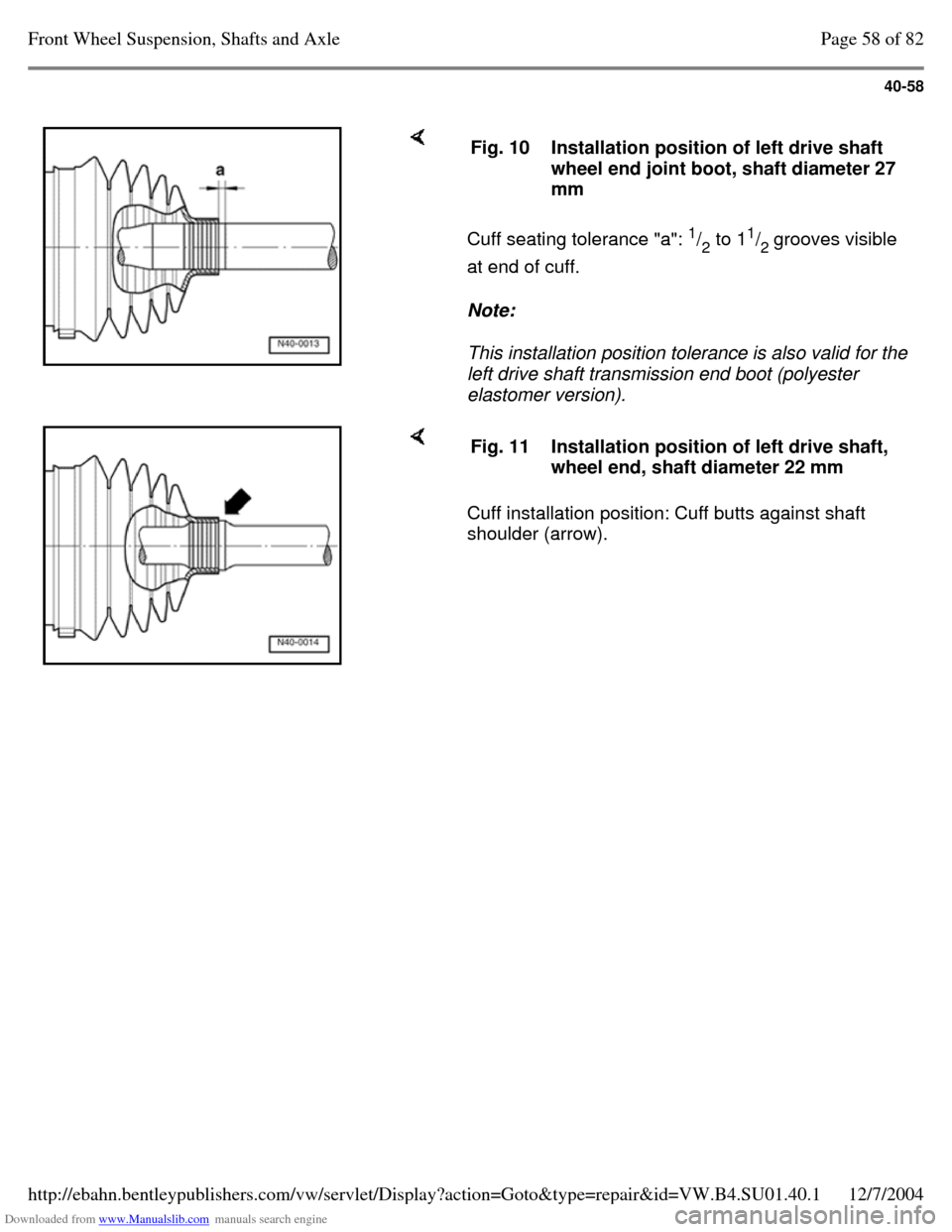

Downloaded from www.Manualslib.com manuals search engine 40-58

Cuff seating tolerance "a": 1

/

2 to 11

/

2 grooves visible

at end of cuff.

Note:

This installation position tolerance is also valid for the

left drive shaft transmission end boot (polyester

elastomer version). Fig. 10 Installation position of left drive shaft

wheel end joint boot, shaft diameter 27

mm Cuff installation position: Cuff butts against shaft

shoulder (arrow). Fig. 11 Installation position of left drive shaft,

wheel end, shaft diameter 22 mm Page 58 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 73 of 369

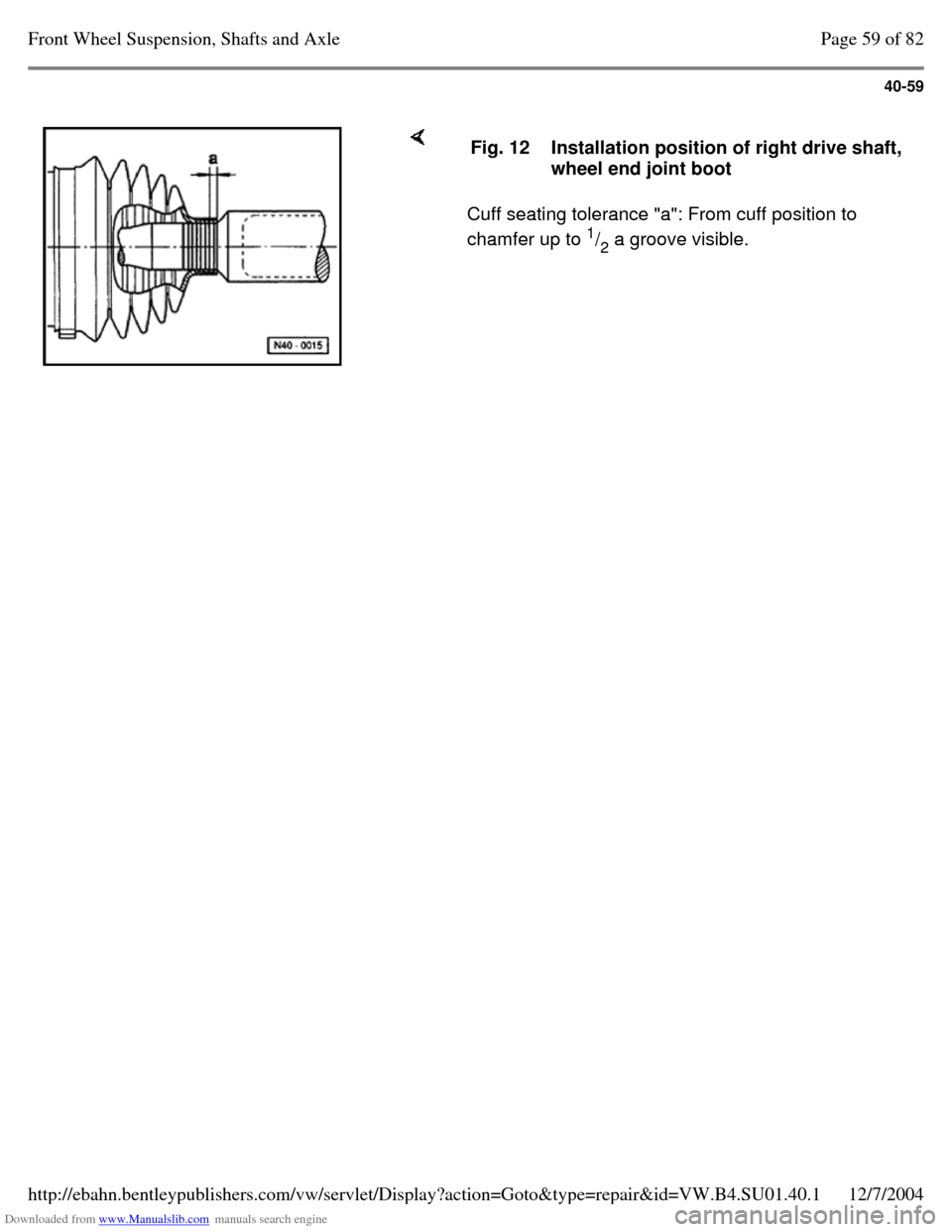

Downloaded from www.Manualslib.com manuals search engine 40-59

Cuff seating tolerance "a": From cuff position to

chamfer up to 1

/

2 a groove visible. Fig. 12 Installation position of right drive shaft,

wheel end joint boot Page 59 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 75 of 369

Downloaded from www.Manualslib.com manuals search engine 40-61

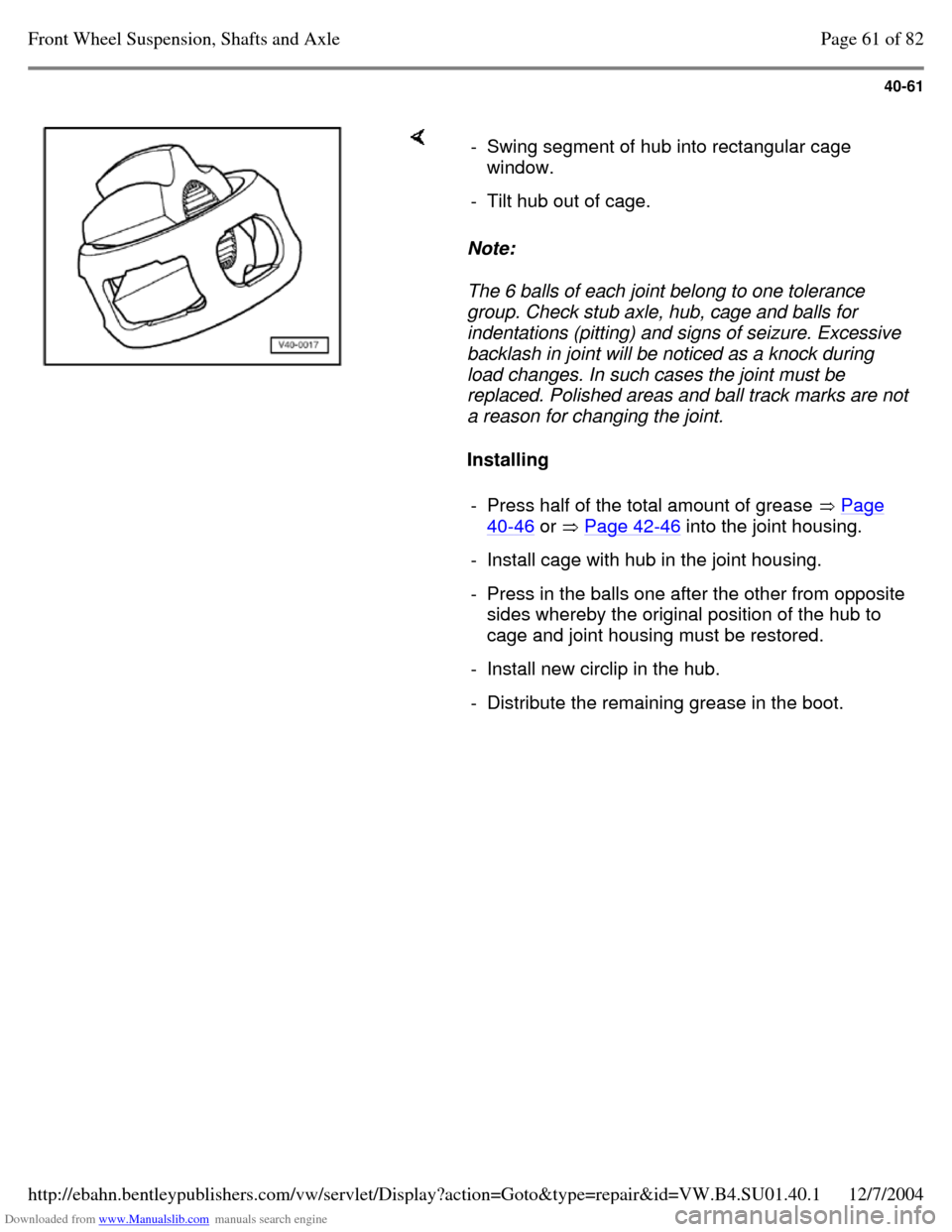

Note:

The 6 balls of each joint belong to one tolerance

group. Check stub axle, hub, cage and balls for

indentations (pitting) and signs of seizure. Excessive

backlash in joint will be noticed as a knock during

load changes. In such cases the joint must be

replaced. Polished areas and ball track marks are not

a reason for changing the joint.

Installing - Swing segment of hub into rectangular cage

window.

- Tilt hub out of cage. - Press half of the total amount of grease Page 40-46 or Page 42-46 into the joint housing. - Install cage with hub in the joint housing. - Press in the balls one after the other from opposite sides whereby the original position of the hub to

cage and joint housing must be restored.

- Install new circlip in the hub. - Distribute the remaining grease in the boot. Page 61 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 80 of 369

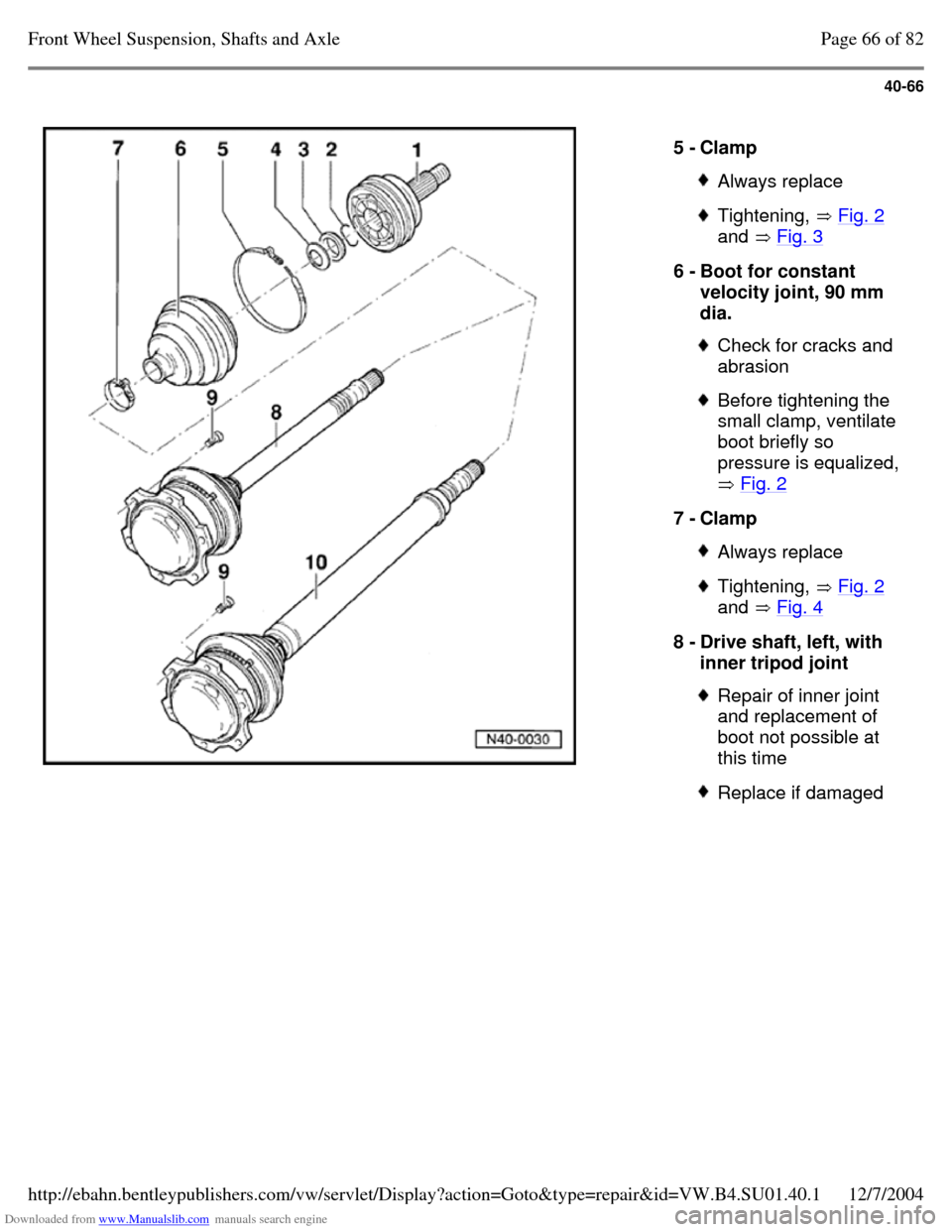

Downloaded from www.Manualslib.com manuals search engine 40-66

5 - Clamp Always replace Tightening, Fig. 2

and Fig. 3 6 - Boot for constant

velocity joint, 90 mm

dia. Check for cracks and

abrasion Before tightening the

small clamp, ventilate

boot briefly so

pressure is equalized,

Fig. 2 7 - Clamp Always replace Tightening, Fig. 2

and Fig. 4 8 - Drive shaft, left, with

inner tripod joint Repair of inner joint

and replacement of

boot not possible at

this time Replace if damaged Page 66 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 81 of 369

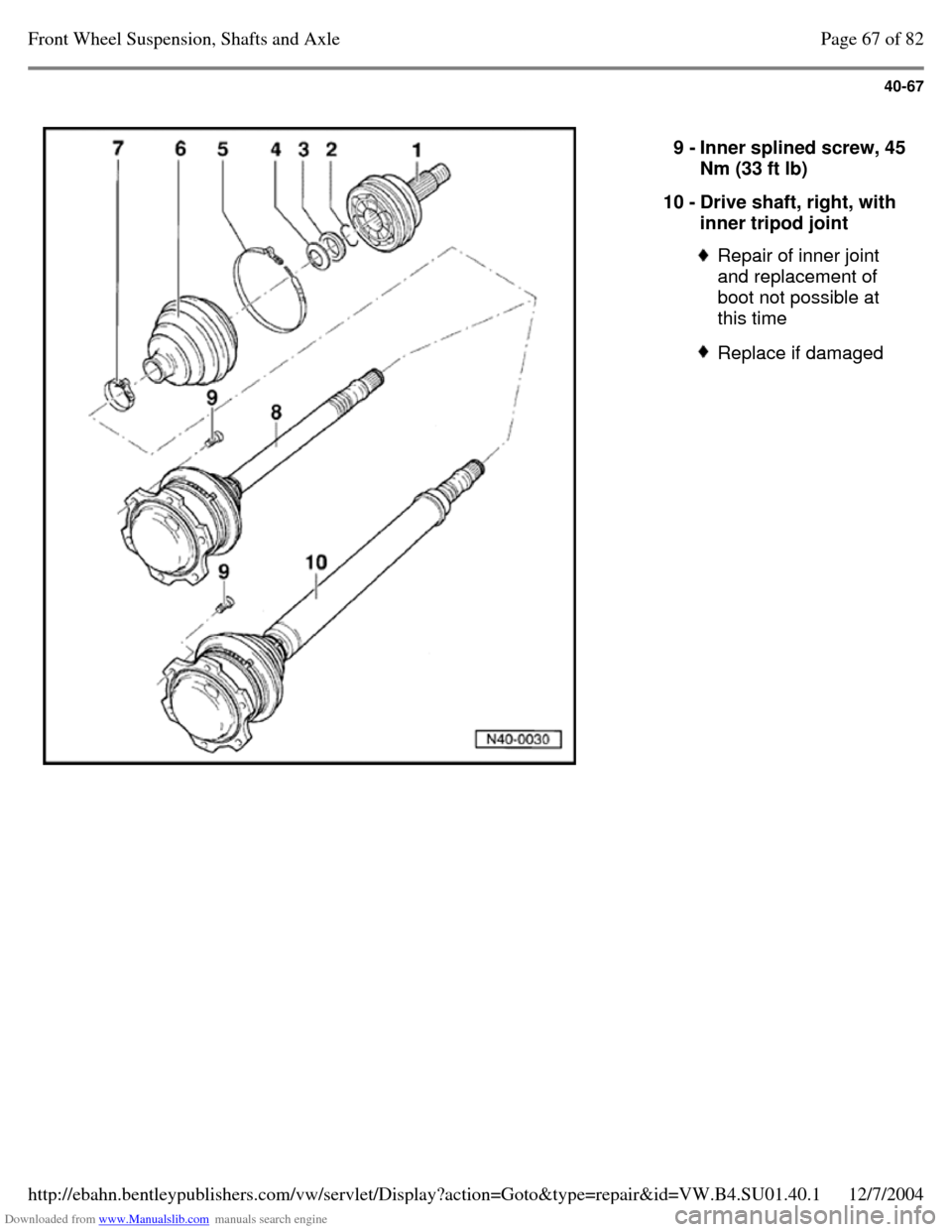

Downloaded from www.Manualslib.com manuals search engine 40-67

9 - Inner splined screw, 45 Nm (33 ft lb)

10 - Drive shaft, right, with

inner tripod joint Repair of inner joint

and replacement of

boot not possible at

this time Replace if damaged Page 67 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 82 of 369

Downloaded from www.Manualslib.com manuals search engine 40-68

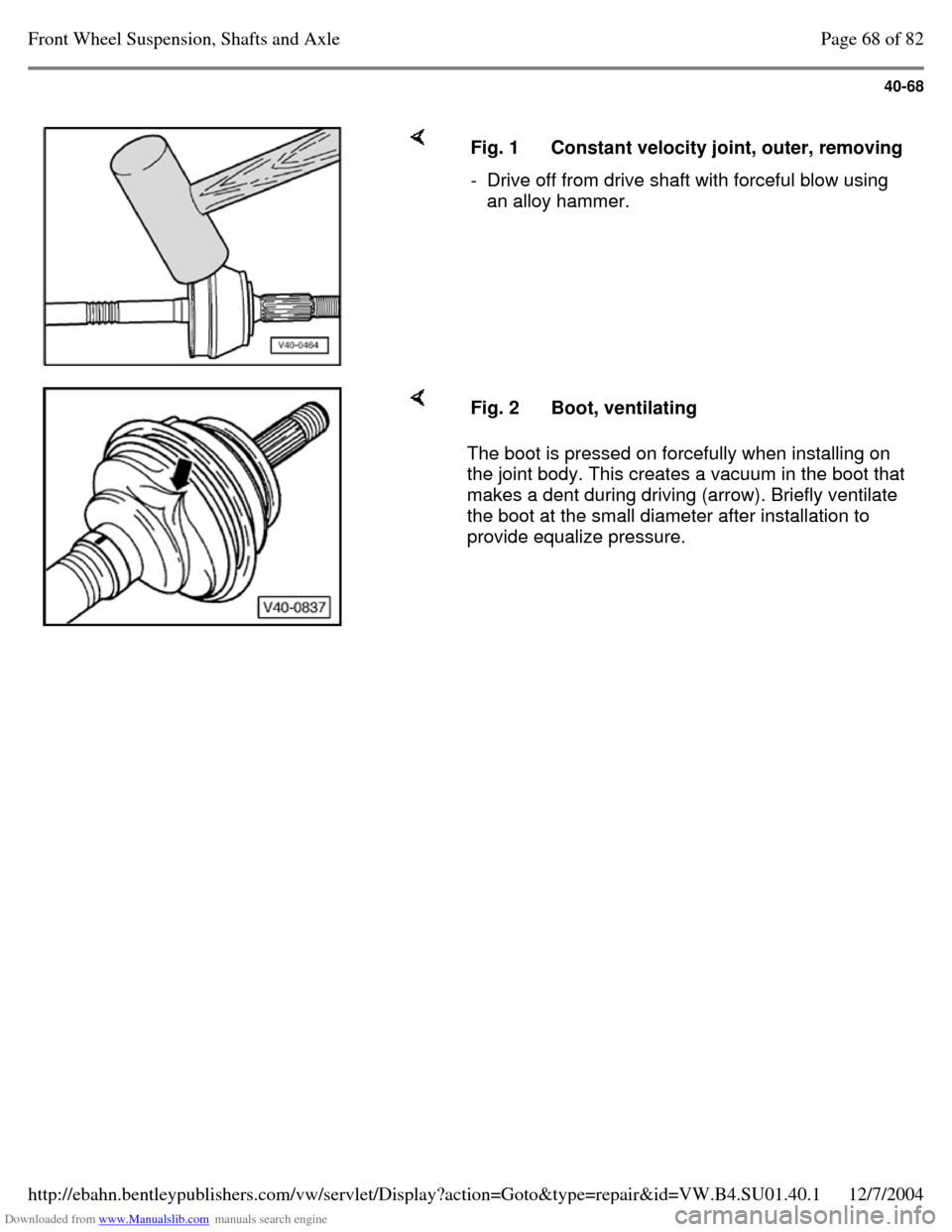

Fig. 1 Constant velocity joint, outer, removing - Drive off from drive shaft with forceful blow using

an alloy hammer. The boot is pressed on forcefully when installing on

the joint body. This creates a vacuum in the boot that

makes a dent during driving (arrow). Briefly ventilate

the boot at the small diameter after installation to

provide equalize pressure. Fig. 2 Boot, ventilating Page 68 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 83 of 369

Downloaded from www.Manualslib.com manuals search engine 40-69

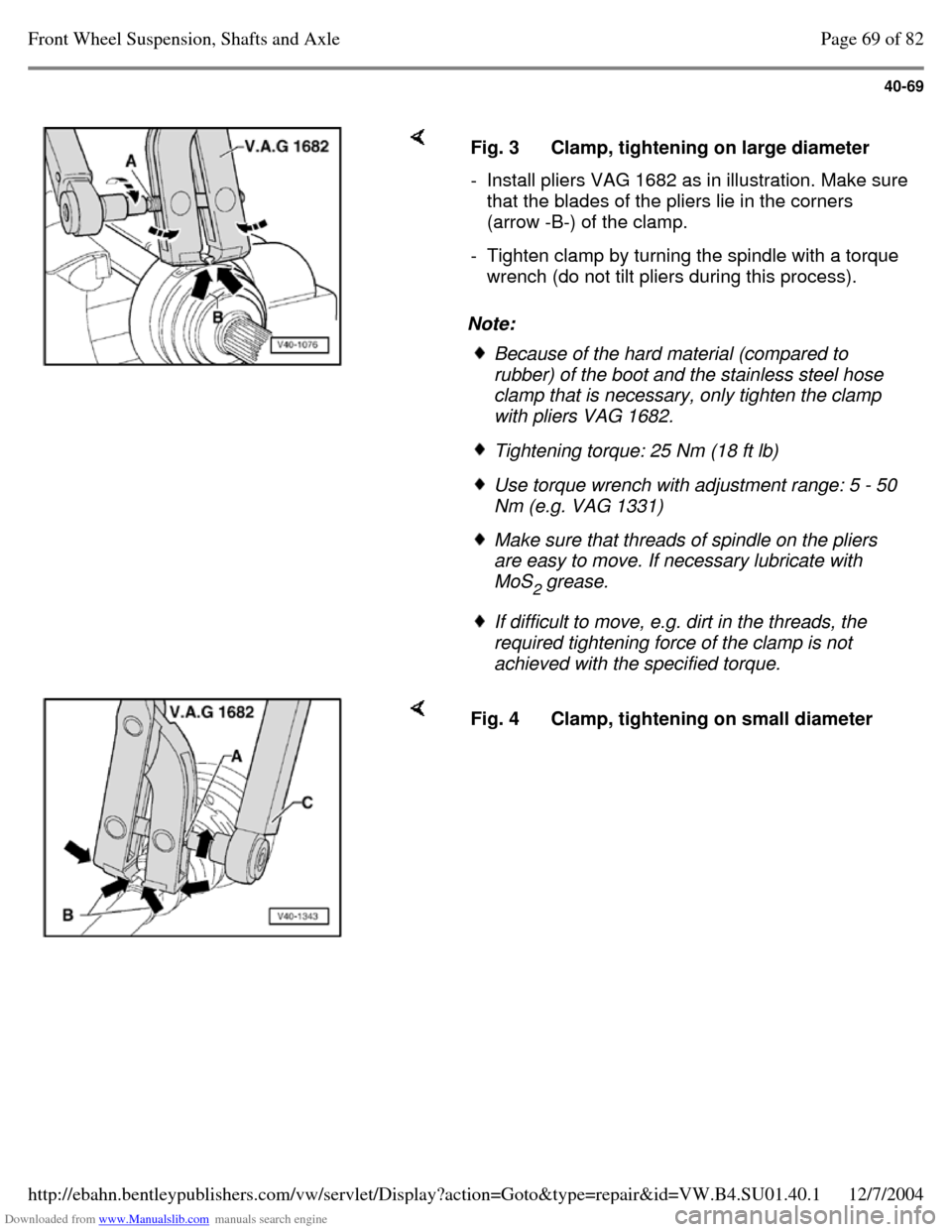

Note: Fig. 3 Clamp, tightening on large diameter - Install pliers VAG 1682 as in illustration. Make sure that the blades of the pliers lie in the corners

(arrow -B-) of the clamp.

- Tighten clamp by turning the spindle with a torque

wrench (do not tilt pliers during this process). Because of the hard material (compared to

rubber) of the boot and the stainless steel hose

clamp that is necessary, only tighten the clamp

with pliers VAG 1682. Tightening torque: 25 Nm (18 ft lb) Use torque wrench with adjustment range: 5 - 50

Nm (e.g. VAG 1331) Make sure that threads of spindle on the pliers

are easy to move. If necessary lubricate with

MoS

2 grease. If difficult to move, e.g. dirt in the threads, the

required tightening force of the clamp is not

achieved with the specified torque. Fig. 4 Clamp, tightening on small diameter Page 69 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 87 of 369

Downloaded from www.Manualslib.com manuals search engine 40-73

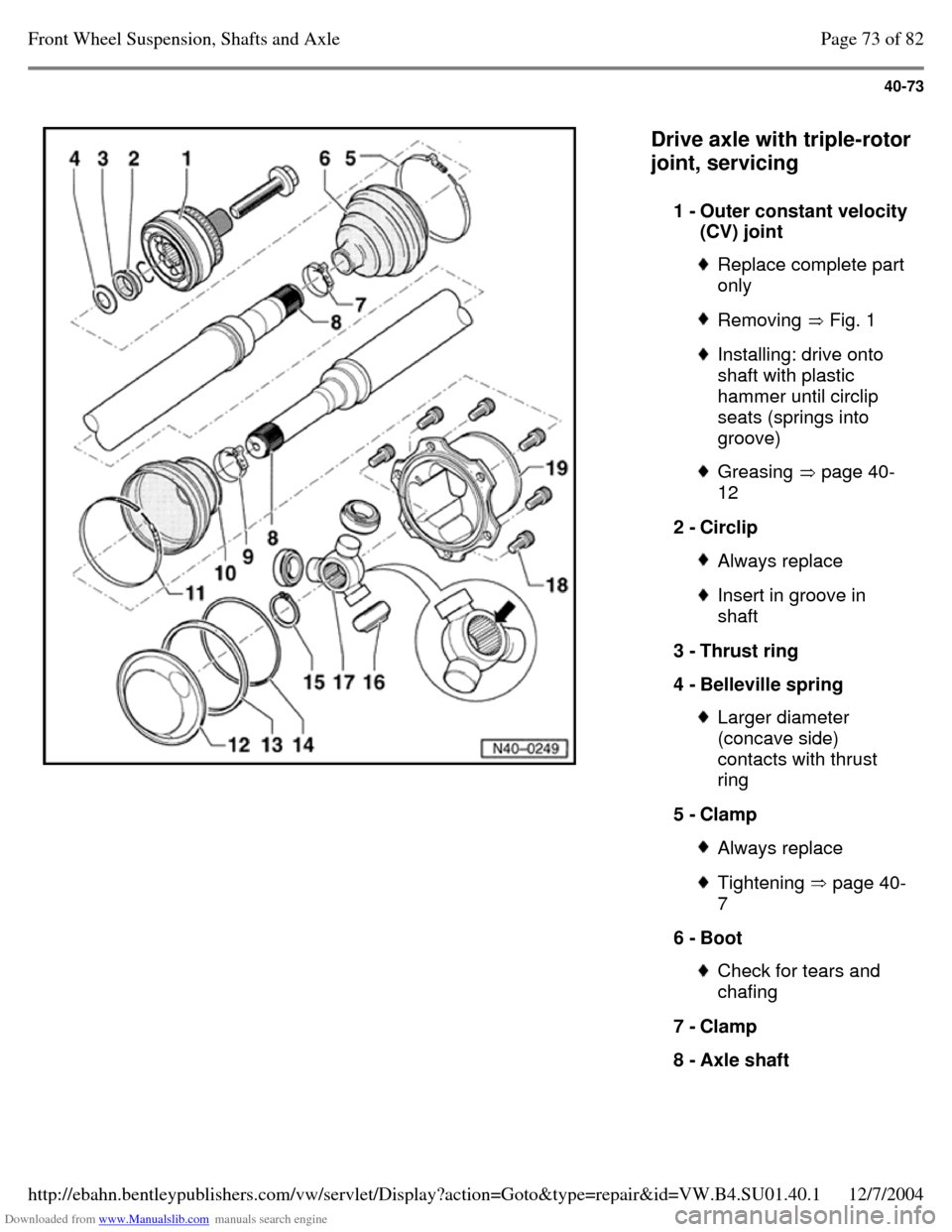

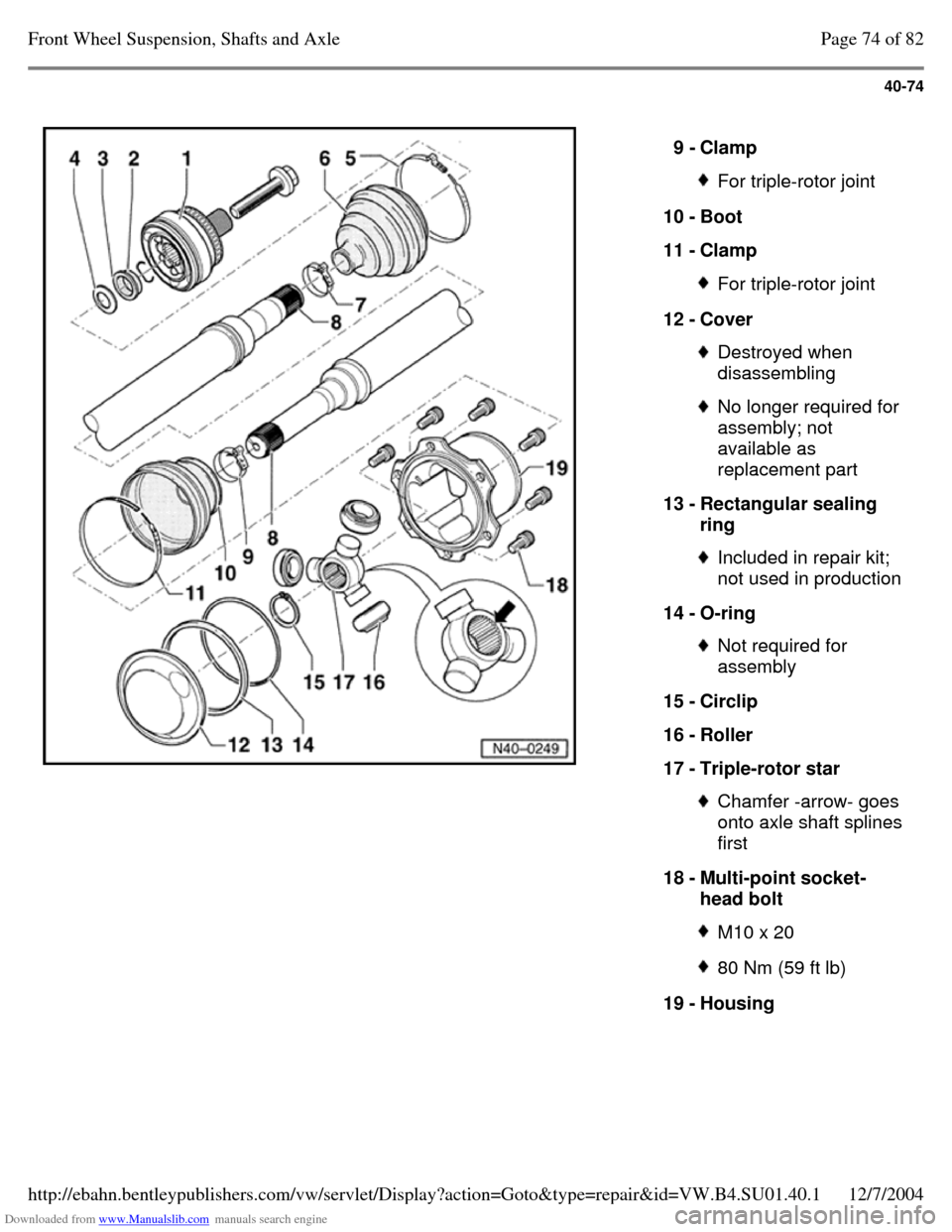

Drive axle with triple-rotor

joint, servicing

1 - Outer constant velocity (CV) joint Replace complete part

only Removing Fig. 1 Installing: drive onto

shaft with plastic

hammer until circlip

seats (springs into

groove) Greasing page 40-

12 2 - Circlip Always replace Insert in groove in

shaft

3 - Thrust ring

4 - Belleville spring Larger diameter

(concave side)

contacts with thrust

ring

5 - Clamp Always replace Tightening page 40-

7 6 - Boot Check for tears and

chafing

7 - Clamp

8 - Axle shaft Page 73 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 88 of 369

Downloaded from www.Manualslib.com manuals search engine 40-74

9 - Clamp For triple-rotor joint 10 - Boot

11 - Clamp For triple-rotor joint 12 - Cover Destroyed when

disassembling No longer required for

assembly; not

available as

replacement part

13 - Rectangular sealing

ring Included in repair kit;

not used in production

14 - O-ring Not required for

assembly

15 - Circlip

16 - Roller

17 - Triple-rotor star Chamfer -arrow- goes

onto axle shaft splines

first

18 - Multi-point socket-

head bolt M10 x 20 80 Nm (59 ft lb) 19 - Housing Page 74 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 90 of 369

Downloaded from www.Manualslib.com manuals search engine 40-76

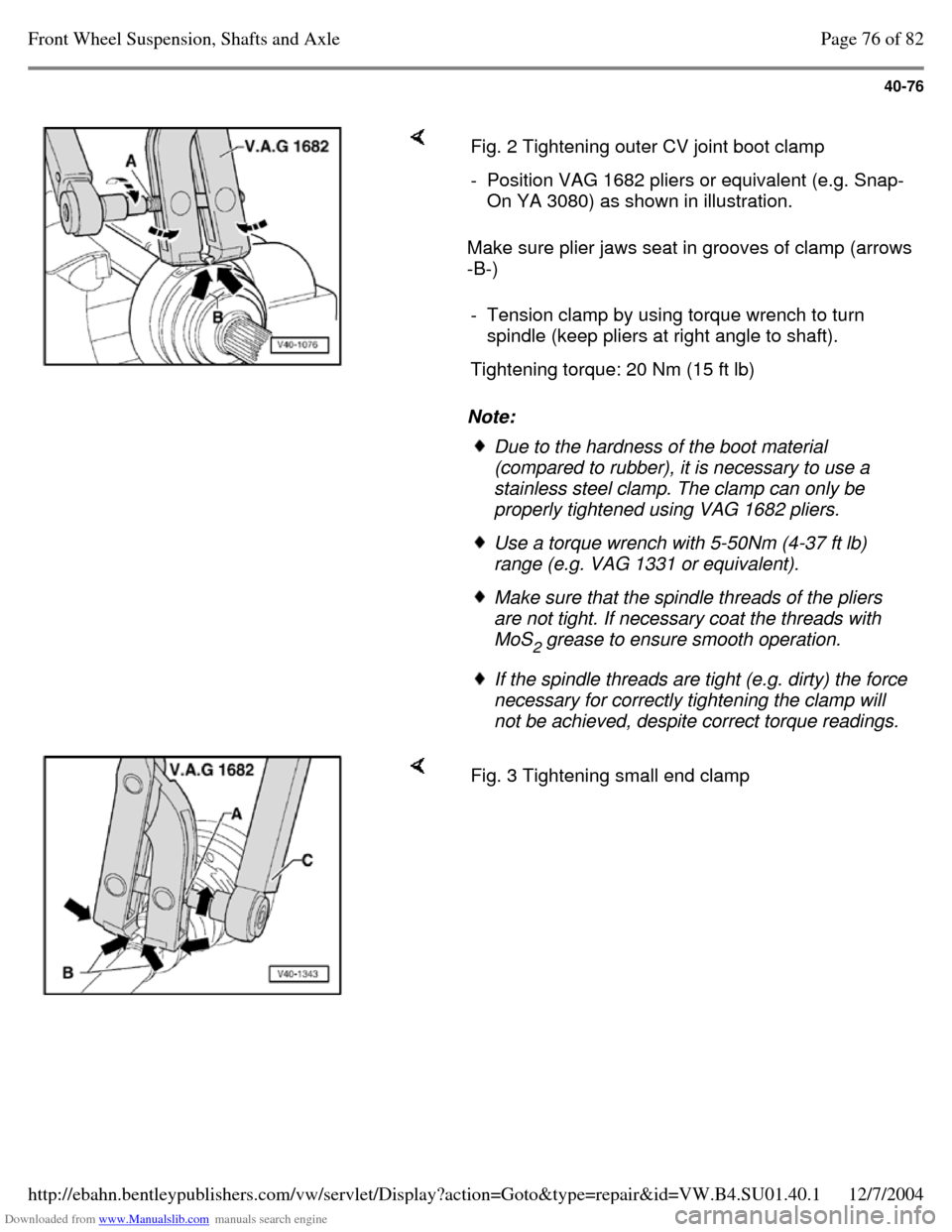

Make sure plier jaws seat in grooves of clamp (arrows

-B-)

Note: Fig. 2 Tightening outer CV joint boot clamp - Position VAG 1682 pliers or equivalent (e.g. Snap-

On YA 3080) as shown in illustration.

- Tension clamp by using torque wrench to turn

spindle (keep pliers at right angle to shaft).

Tightening torque: 20 Nm (15 ft lb) Due to the hardness of the boot material

(compared to rubber), it is necessary to use a

stainless steel clamp. The clamp can only be

properly tightened using VAG 1682 pliers. Use a torque wrench with 5-50Nm (4-37 ft lb)

range (e.g. VAG 1331 or equivalent). Make sure that the spindle threads of the pliers

are not tight. If necessary coat the threads with

MoS

2 grease to ensure smooth operation. If the spindle threads are tight (e.g. dirty) the force

necessary for correctly tightening the clamp will

not be achieved, despite correct torque readings. Fig. 3 Tightening small end clamp Page 76 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1